Low-temperature cooling system of superconduction high-intensity magnetic field magnetron sputtering cathode

A technology of magnetron sputtering and cooling system, which is applied to discharge tubes, electrical components, circuits, etc., can solve the problems of reducing the service life of refrigerators, increasing operating costs, difficult to meet the rapidity of cooling and temperature recovery, and achieving rapid cooling and the effect of rewarming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

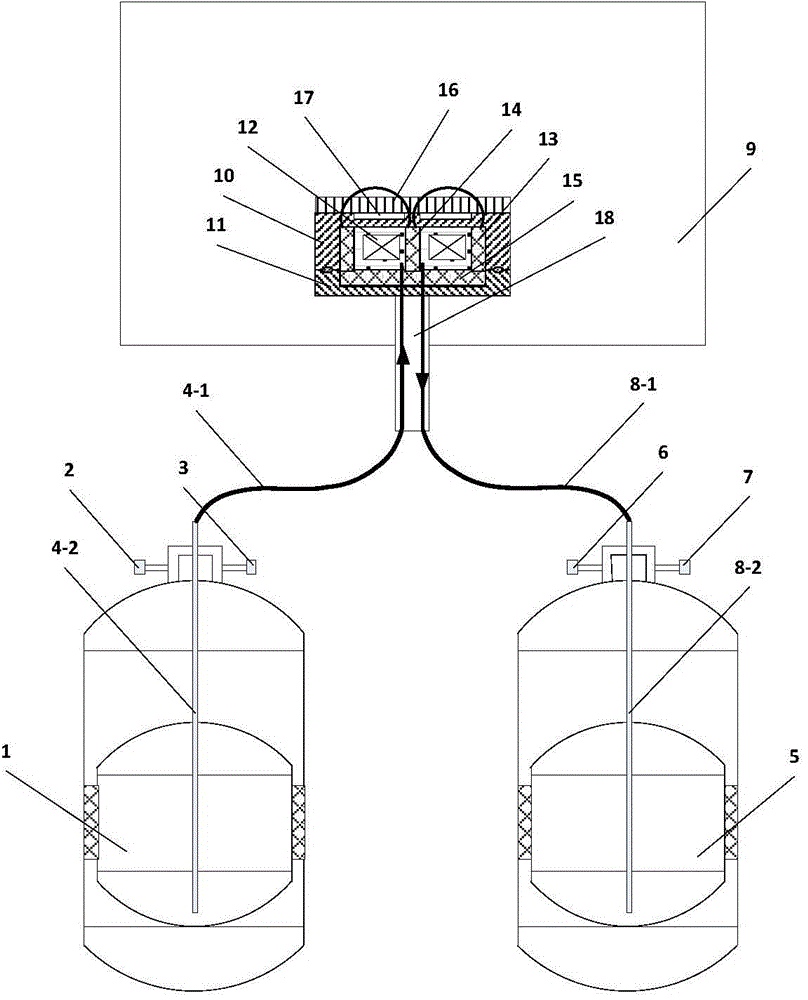

[0017] figure 2 Shown is the specific embodiment 1 of the low temperature cooling system for the superconducting strong magnetic field magnetron sputtering cathode of the present invention. Such as figure 2 As shown, the cryogenic cooling system of the present invention consists of a first liquid nitrogen storage Dewar 1, a first booster valve 2, a first deflation valve 3, a first infusion pipeline 4-1, a first infusion rod 4-2, a second Liquid nitrogen storage Dewar 5, second booster valve 6, second deflation valve 7, second infusion pipeline 8-1, second infusion rod 8-2, vacuum cavity 9, magnet Dewar upper cover 10, and The magnet Dewar base 11 is composed. The first booster valve 2 and the first purge valve 3 are installed on the first liquid nitrogen storage Dewar 1 for controlling the nitrogen pressure inside the first liquid nitrogen storage Dewar 1, and the first infusion pipeline 4-1 passes through the first liquid nitrogen storage Dewar 1 An infusion rod 4-2 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com