Flat-mold biomass granulating apparatus with raw material pre-optimization function

A biomass and flat die technology, applied in chemical/physical processes, feeding devices, mold extrusion granulation, etc., can solve the problem of large deviation between the amount of feed and the required value, poor quality of formed products, and granulation and forming effects To improve the molding speed and molding quality, reduce equipment failure, improve independence and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to more fully explain the implementation of the present invention, the implementation examples of the present invention are provided, and these implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

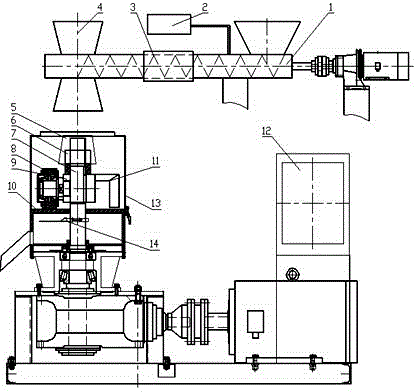

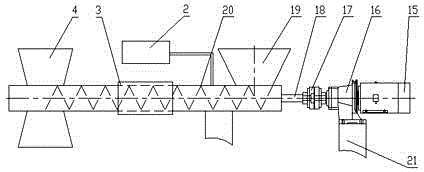

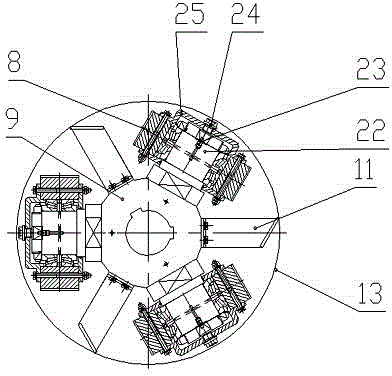

[0010] The flat-die biomass granulation equipment with raw material pre-optimization includes a granulator and a controller. There is a material paddle conveyor in front of the granulator. The paddle conveyor adopts a frequency conversion motor and is controlled by the controller. The temperature sensor and heating device are set on the conveyor, the temperature sensor is connected to the controller, the controller controls the heating device, the humidity sensor and the humidification sprayer are set on the paddle conveyor, the humidity sensor is connected to the controller, and the controller controls the humidification sprayer and The heating device controls the moisture content of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com