Patents

Literature

73results about How to "Easy to splash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

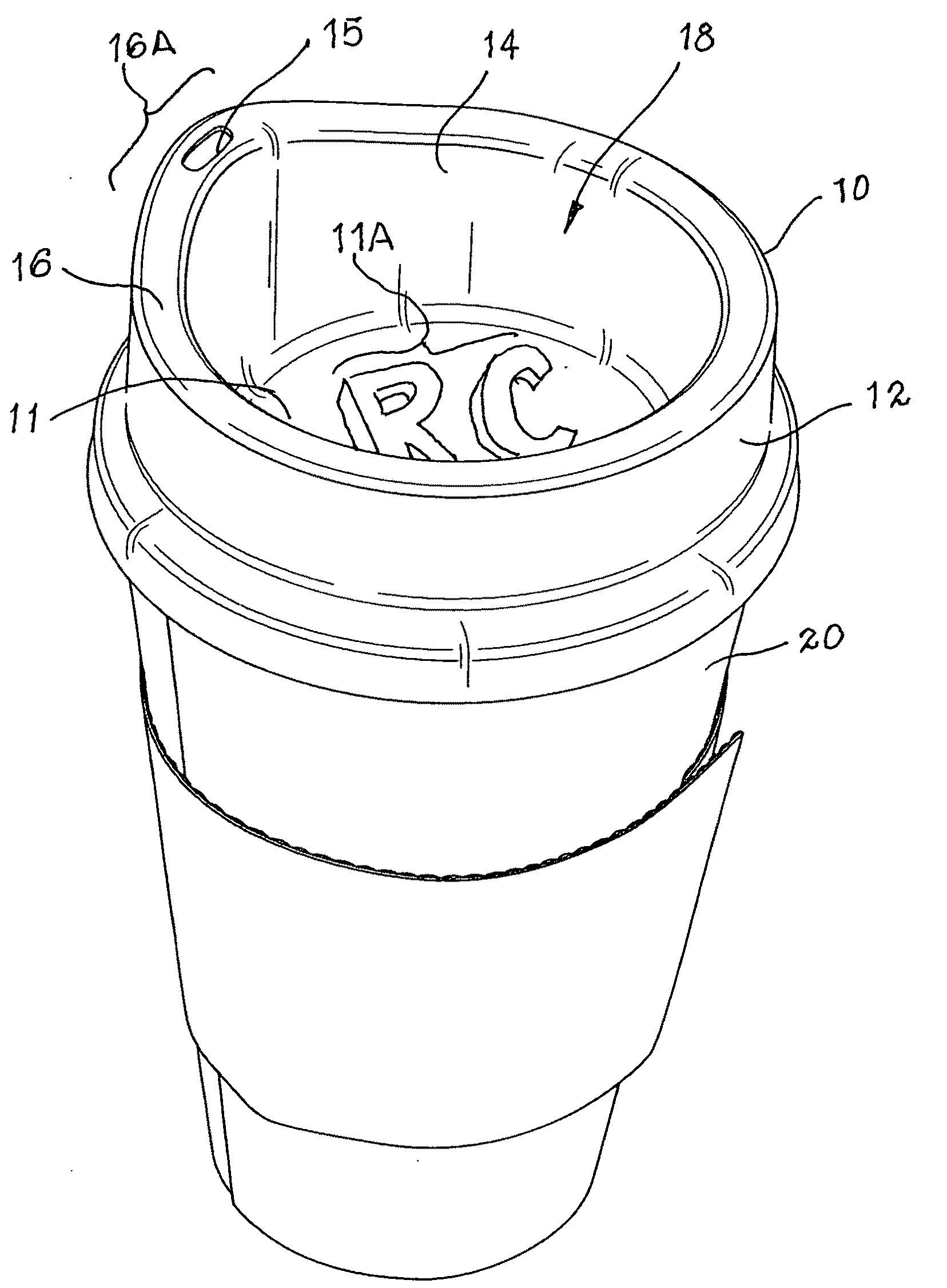

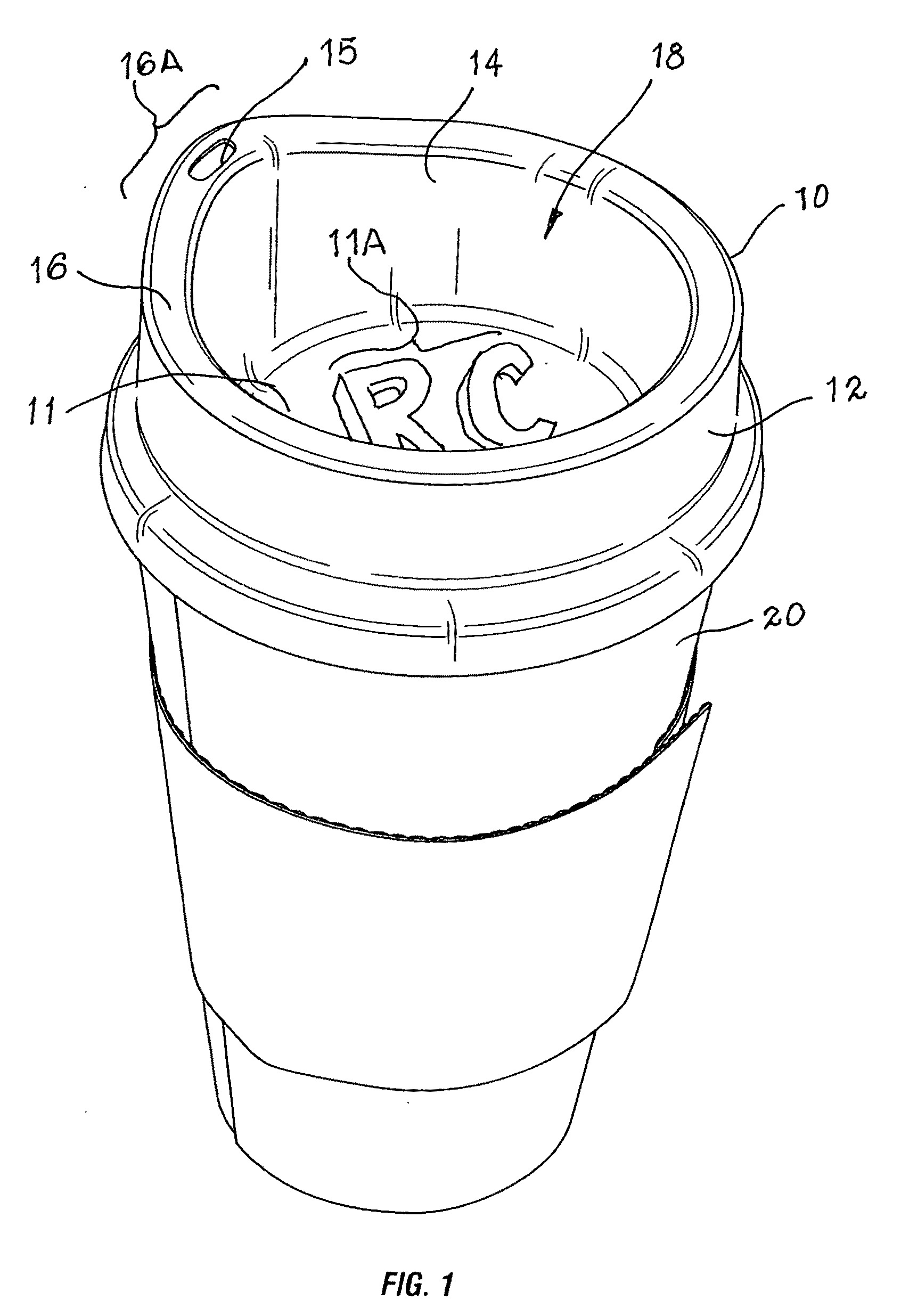

Cup lid with an anti-splash ergonomic shape

A cup lid for covering a disposable beverage cup has an outer peripheral wall and concentric therewith, an inner peripheral wall. The outer and inner peripheral walls are spaced apart and are mutually joined by a top rim having an aperture through which liquids in the beverage cup may be disbursed when the top rim is held between the lips. A well is defined by the inner peripheral wall and a panel where the panel is contiguous with the inner peripheral wall. The top rim and horizontal panel are spaced apart by approximately one inch thereby establishing an adequate space for a person's nose within the well when the beverage cup is raised for draining liquid therein.

Owner:ICON DEV GROUP

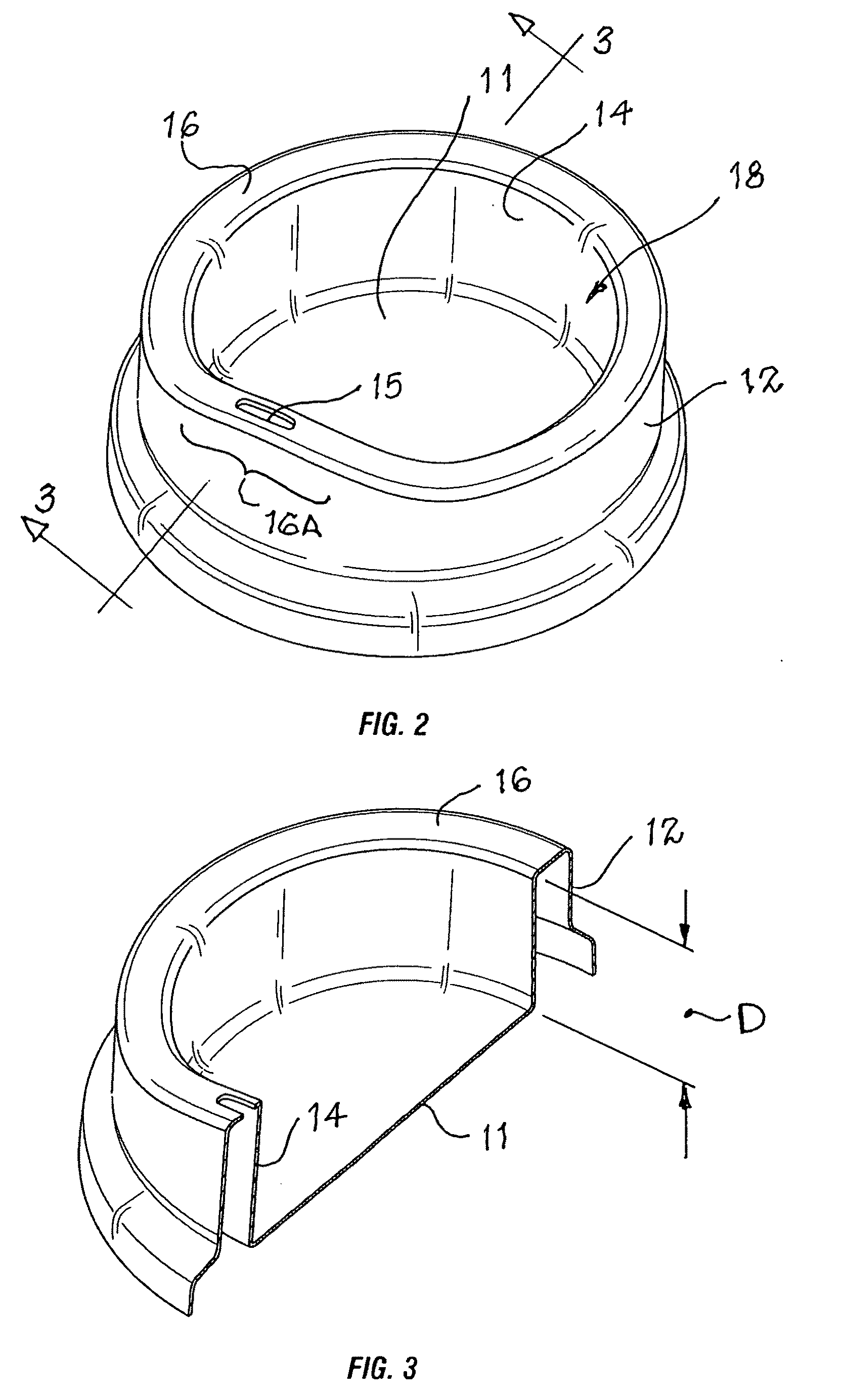

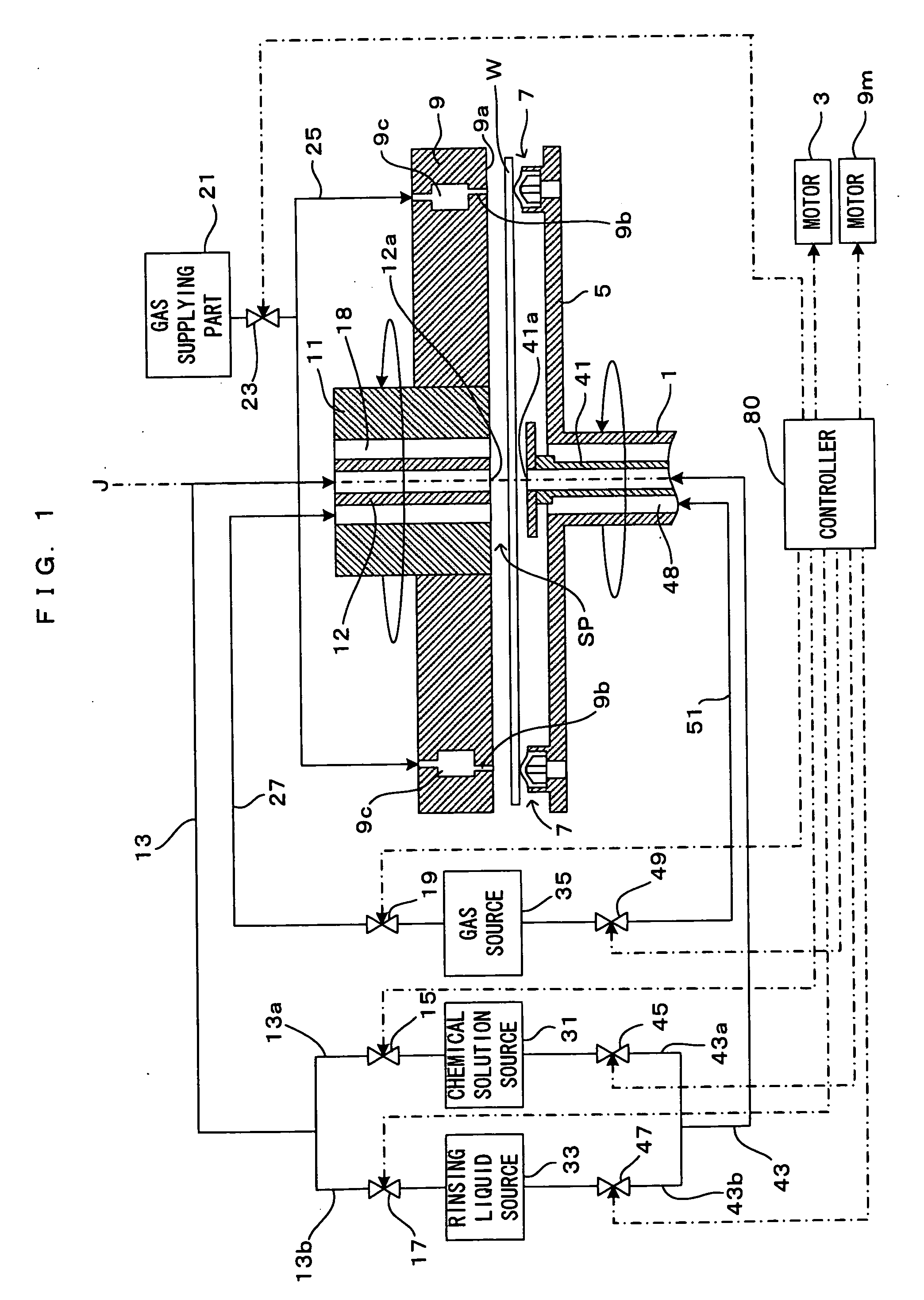

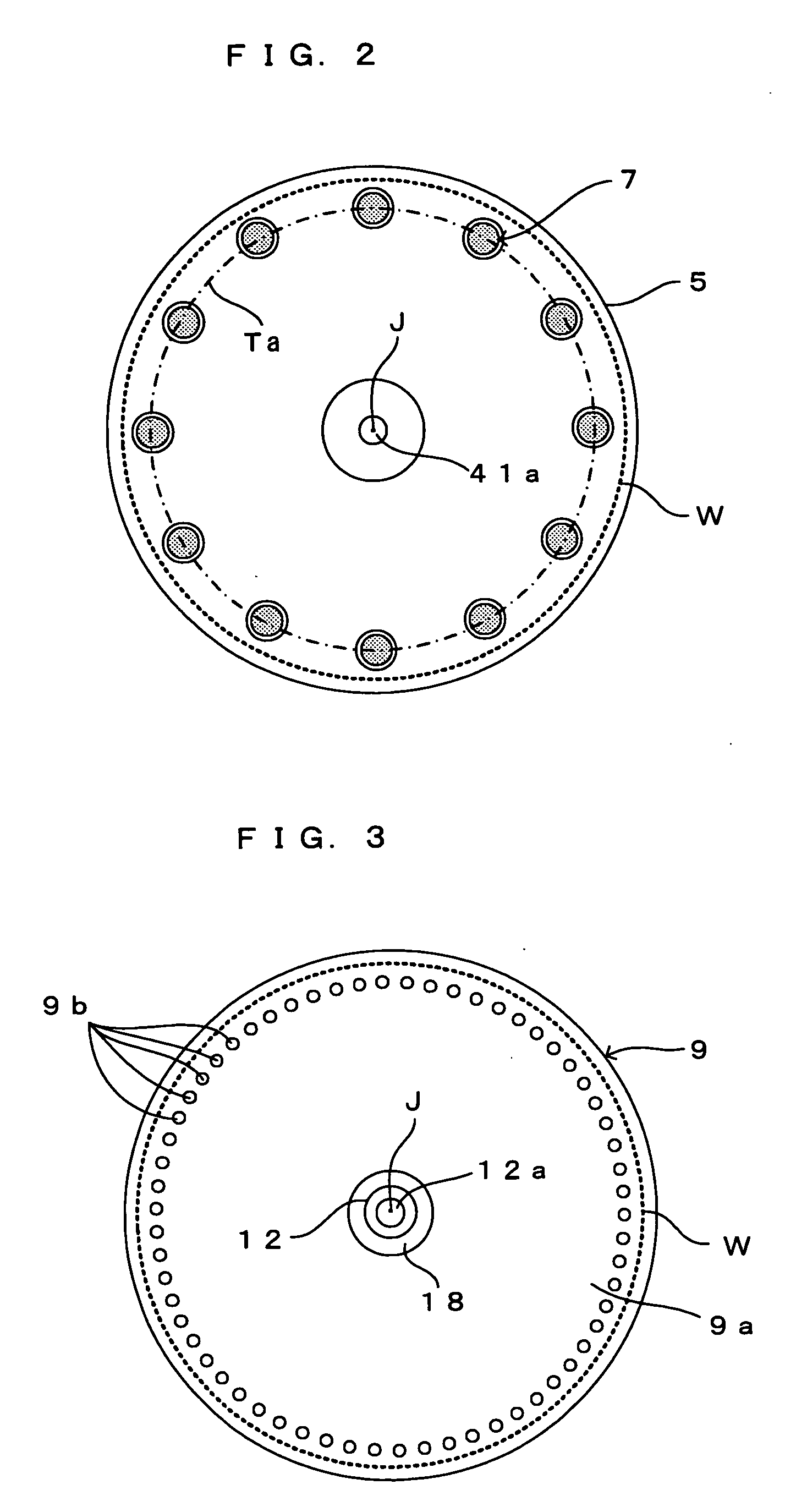

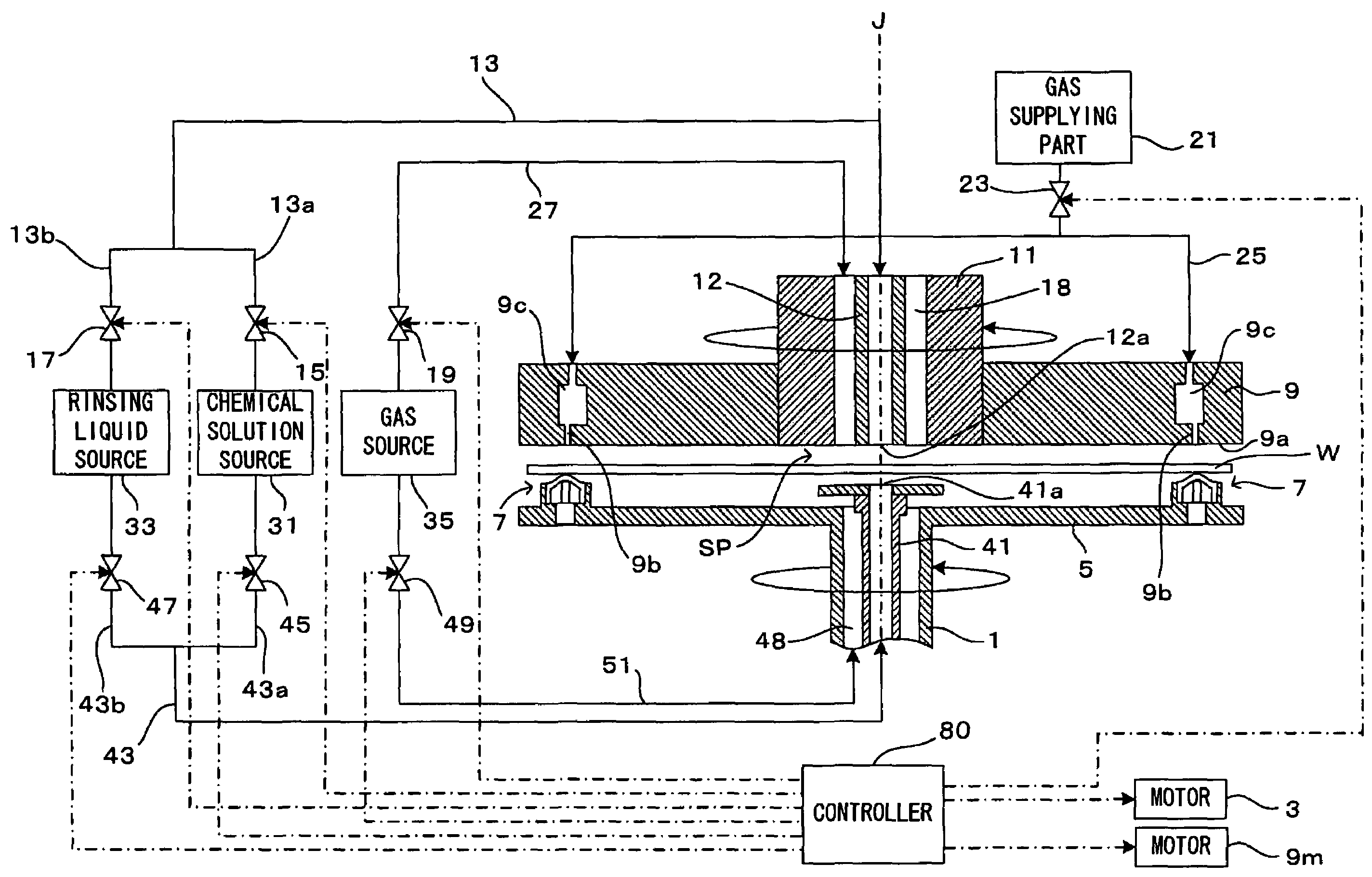

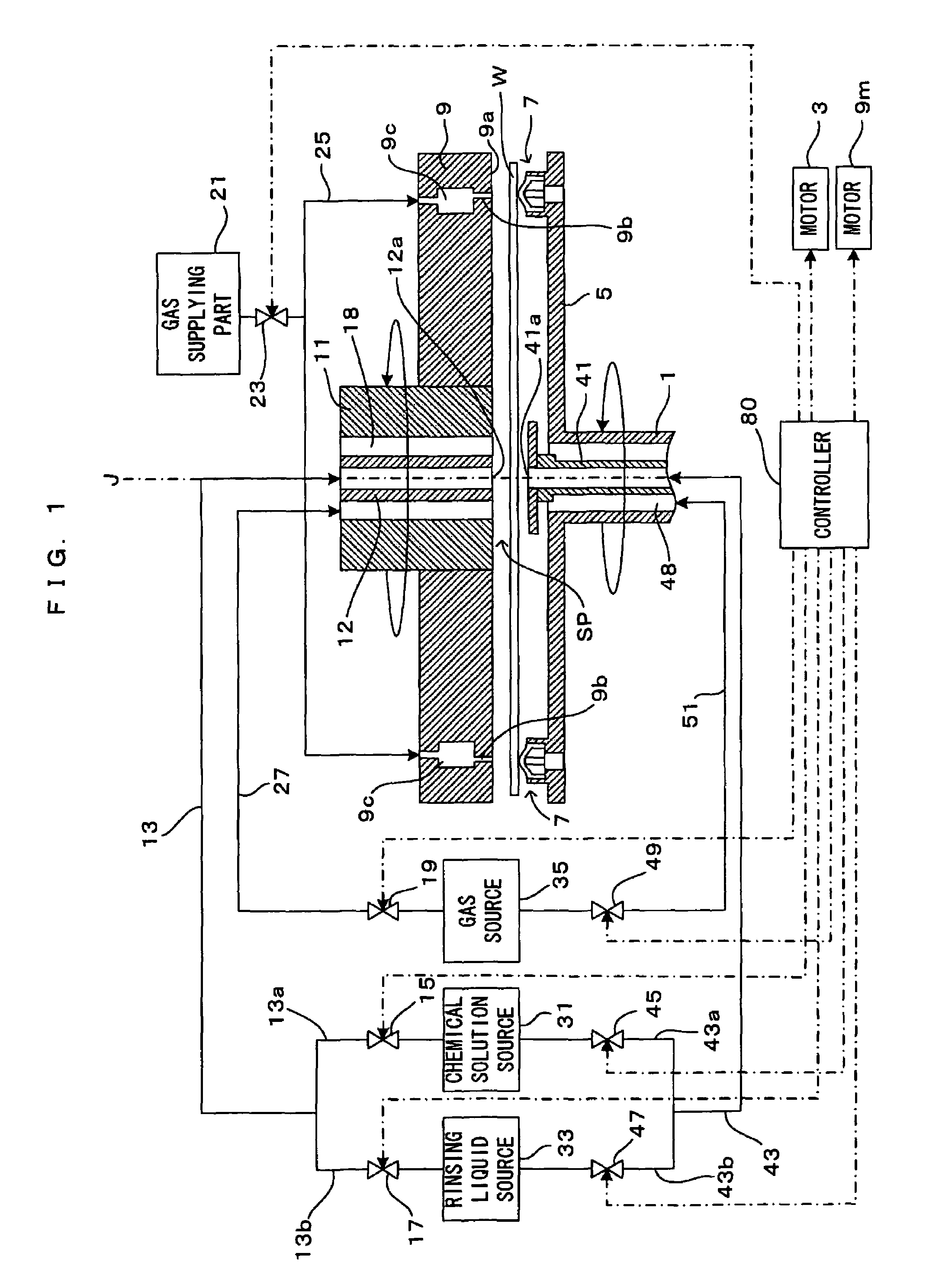

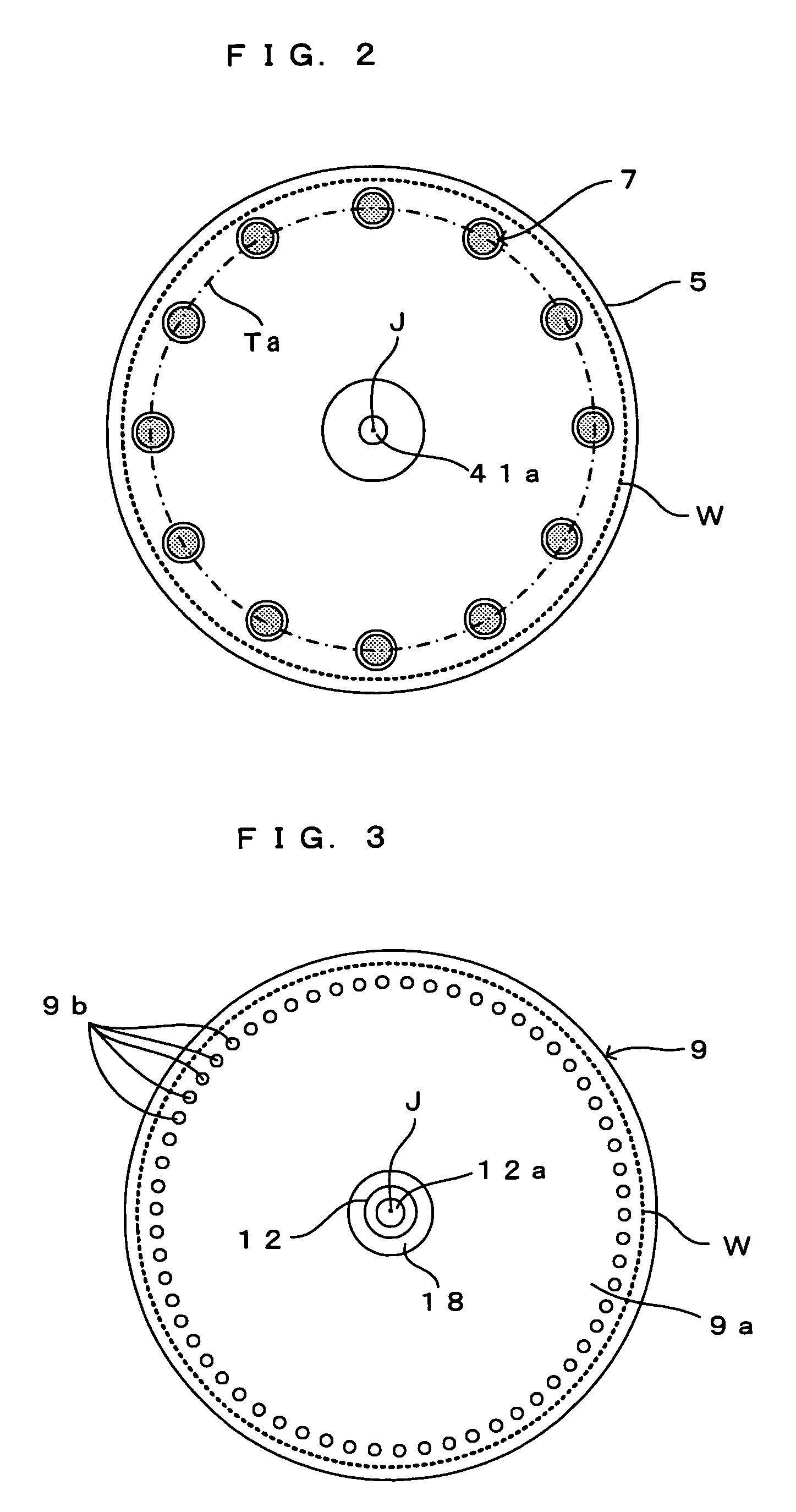

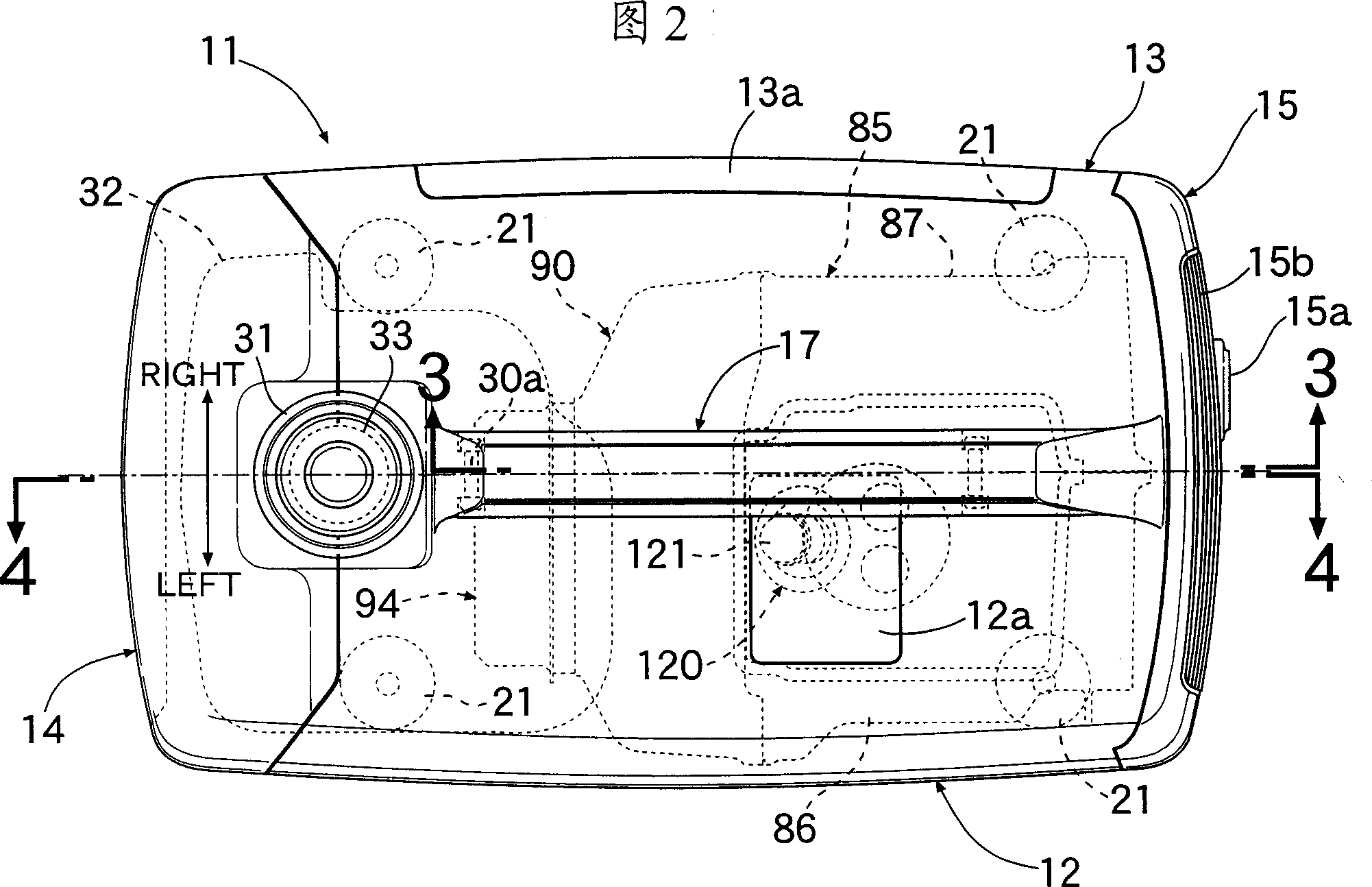

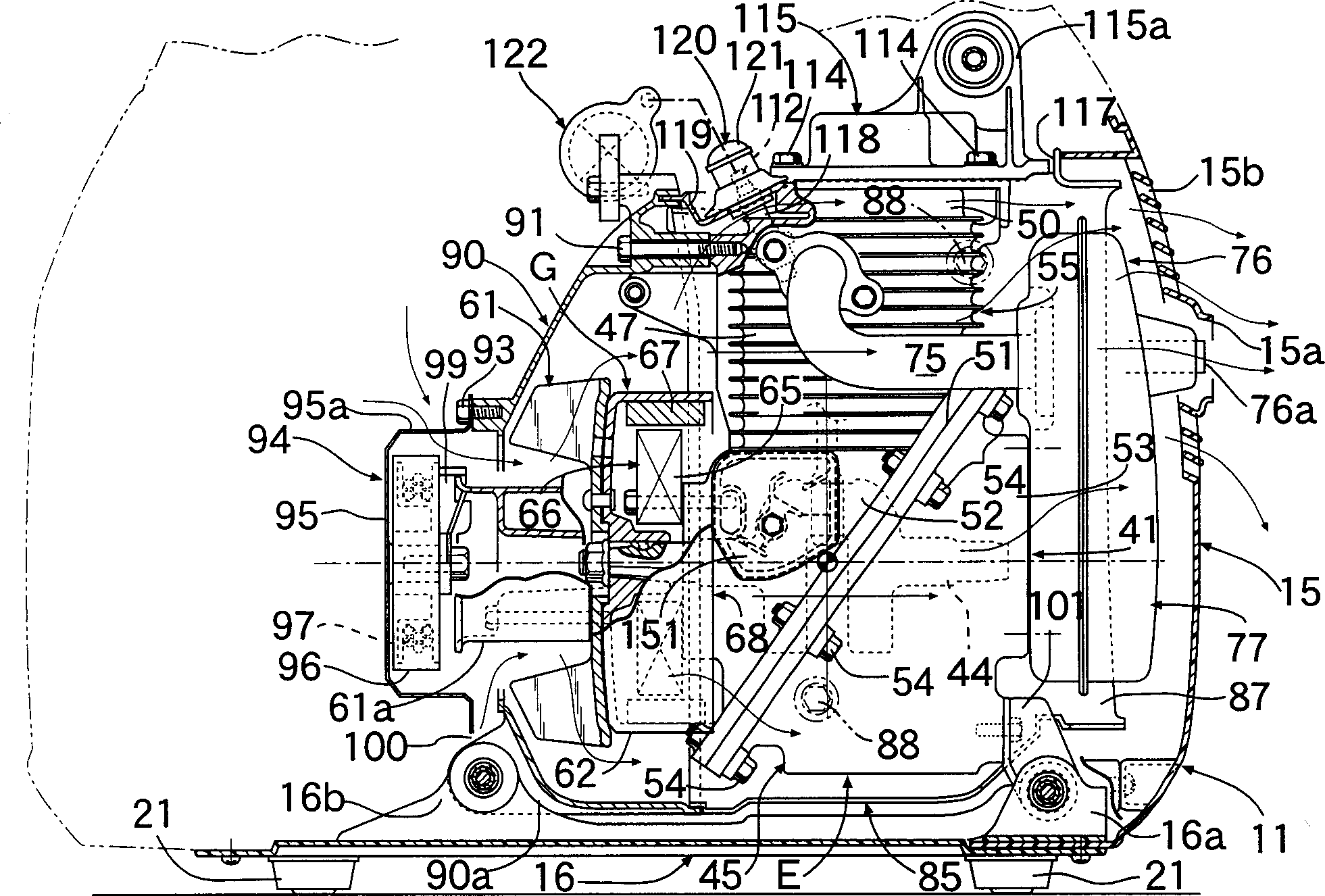

Substrate processing apparatus and method

ActiveUS20050276921A1Easy to splashEffectively prevent re-adheringPretreated surfacesSemiconductor/solid-state device manufacturingEngineeringInert gas

In the vicinity of a rim portion of a spin base 5, a plurality of supports 7 which abut on a bottom rim portion of a substrate W and support the substrate W are formed projecting toward above from the spin base 5. The substrate W is supported horizontally by the plurality of supports 7, with a predetermined distance ensured from the spin base 5 which opposes the bottom surface of the substrate W. Into the space which is created between the top surface of the substrate W and an opposing surface 9a of an atmosphere blocker plate 9, inert gas is ejected from a plurality of gas ejection outlets 9b which are formed in the opposing surface 9a. The inert gas thus supplied to the top surface of the substrate W presses the substrate W against the supports 7 and the substrate W is held at the spin base 5.

Owner:DAINIPPON SCREEN MTG CO LTD

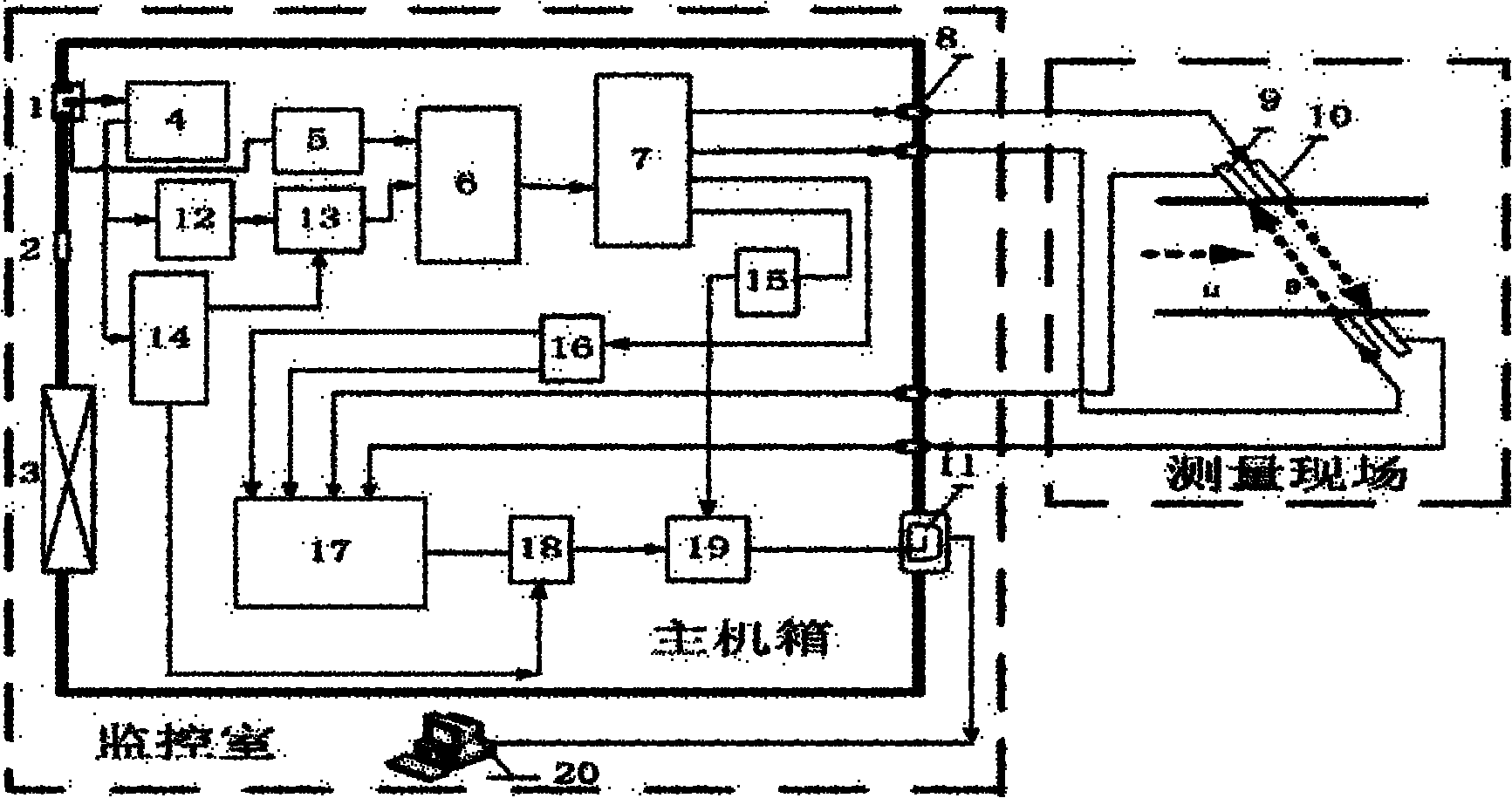

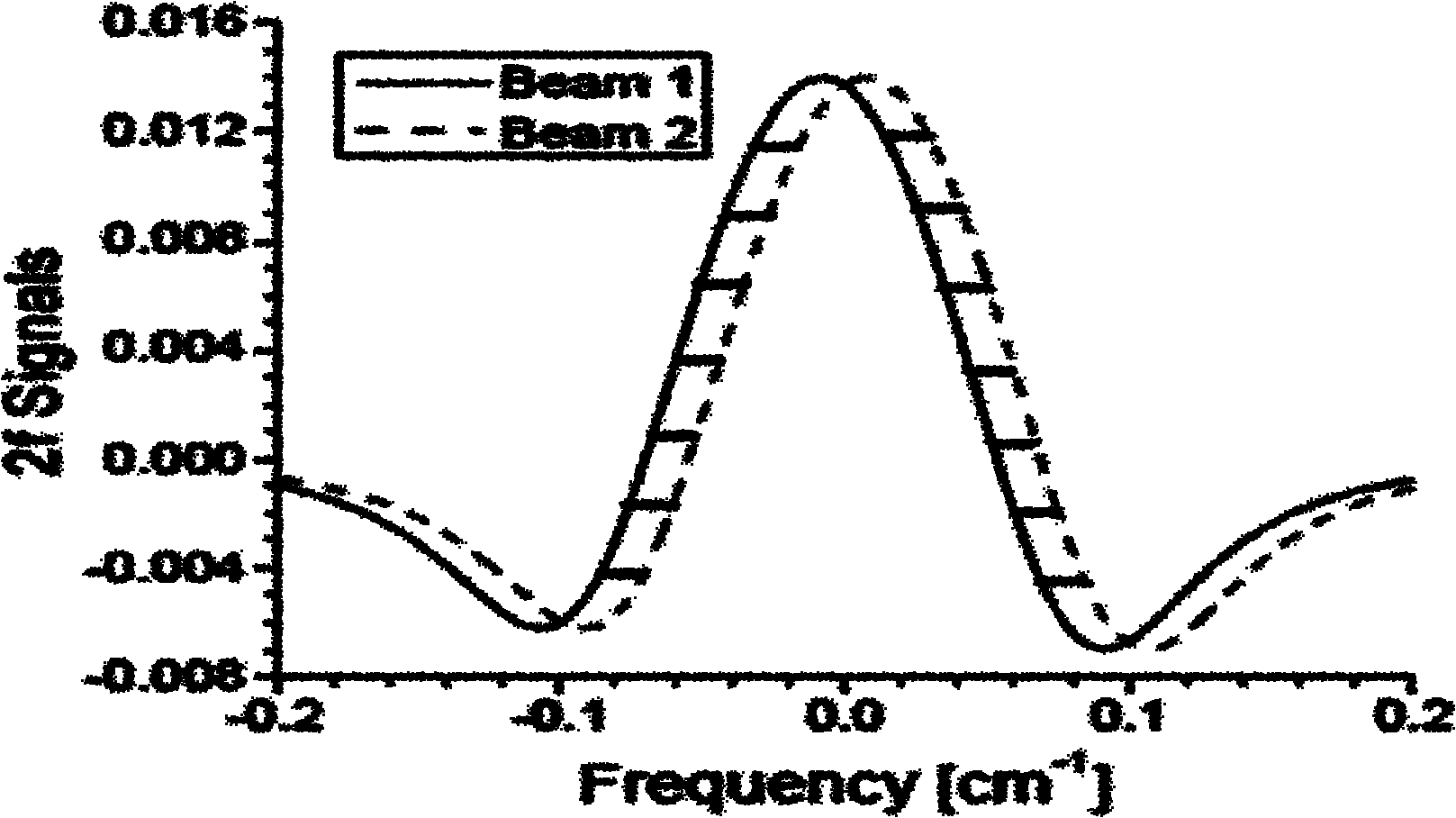

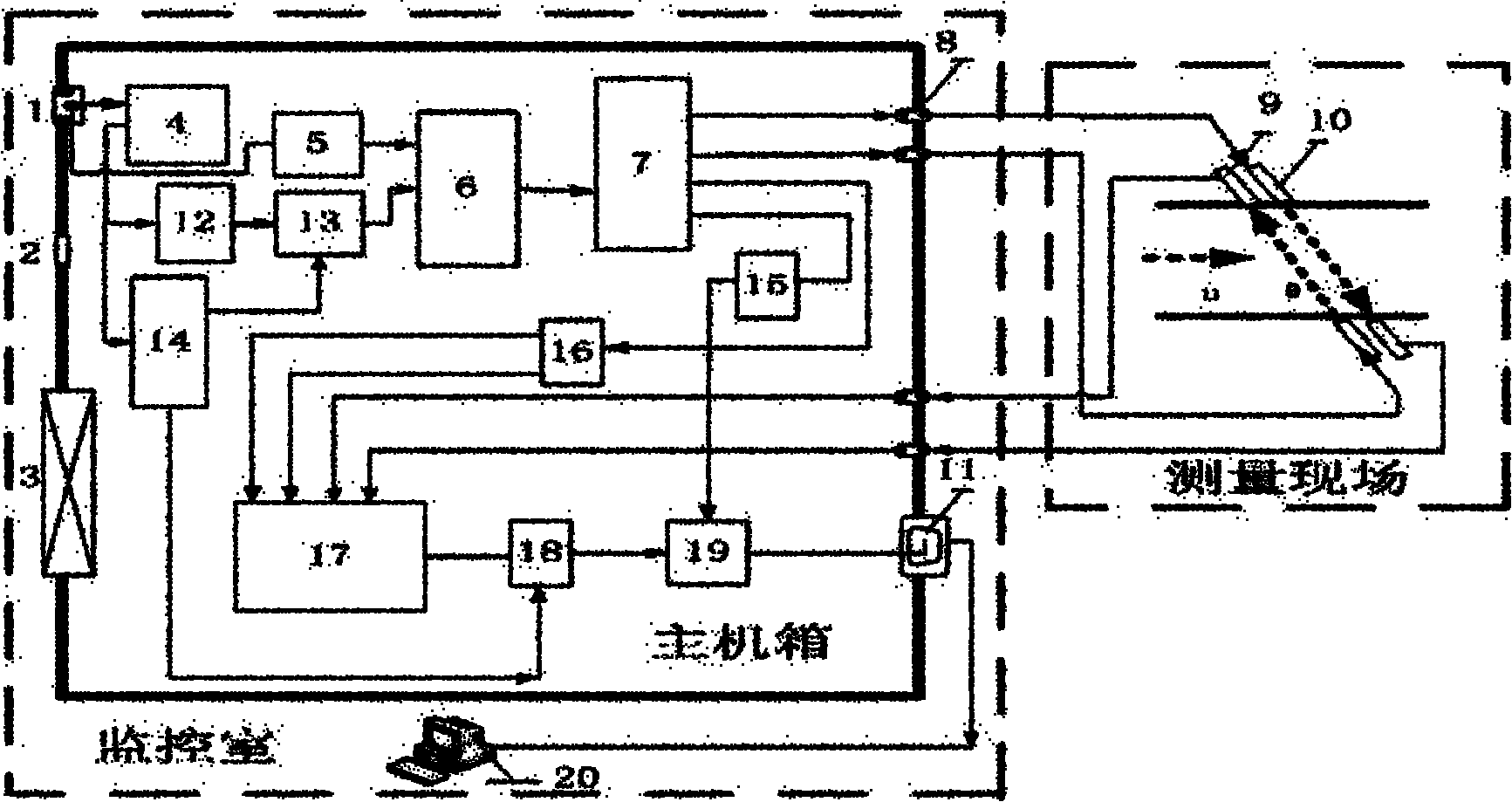

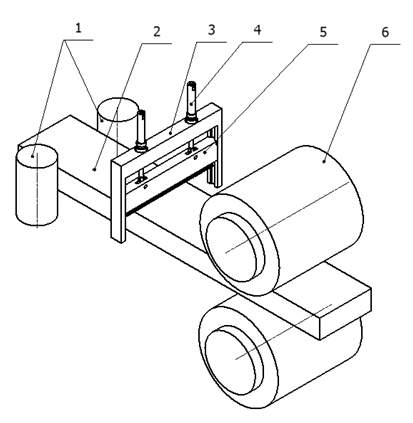

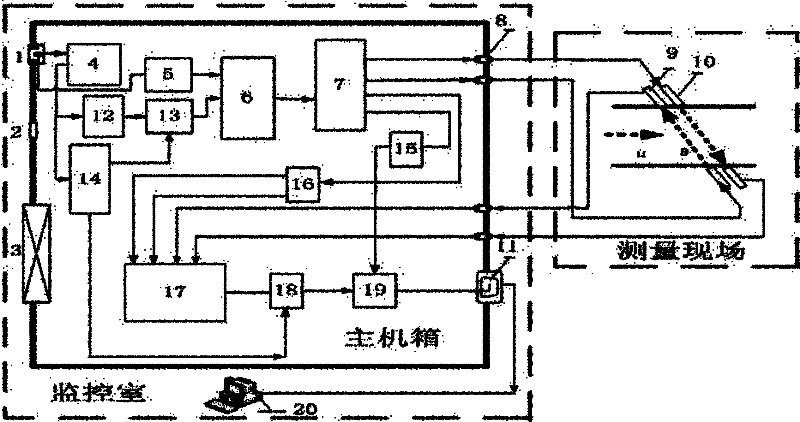

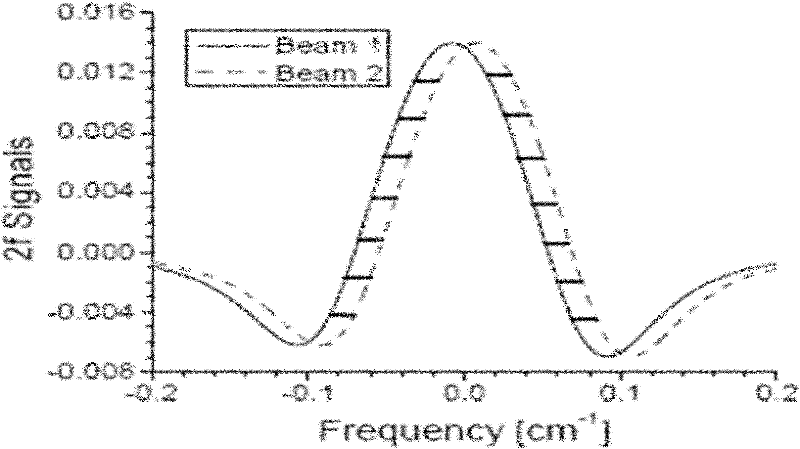

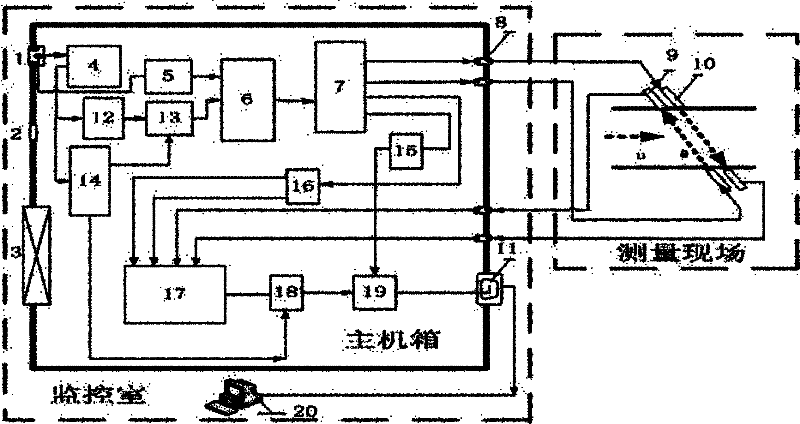

Gas flow rate survey meter based on tunable diode laser absorption spectroscopy technology

ActiveCN102135547AImprove spatial resolutionHigh measurement accuracyAbsorption/flicker/reflection spectroscopyFluid speed measurementData acquisitionNon invasive

The invention discloses a gas flow rate survey meter based on the tunable diode laser absorption spectroscopy technology, comprising a red-light light source, a laser, a signal generator, a laser launcher, a laser receiving device, an optical-fiber interferometer, a data acquisition card, a detector, a locking amplifier and a data processing and displaying module. The gas flow rate survey meter works in an all optical fiber mode, which facilitates the remotely transmission of a signal. Compared with the prior art, the gas flow rate survey meter based on the optical method disclosed by the invention has the advantages of non-invasive monitoring object, high spatial resolution, high dynamic response, high measurement precision and big measurement range. The gas flow rate survey meter is easy to install, prevents dust, prevents from splashing, corroding and shocking and is suitable for monitoring industrial emission with high temperature, high dust content and high toxicity and corrosivity. The gas flow rate survey meter also can be used for measuring high-speed airflow of which the flow velocity reaches thousands of meters / second, and can be used for detecting airplane engines.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

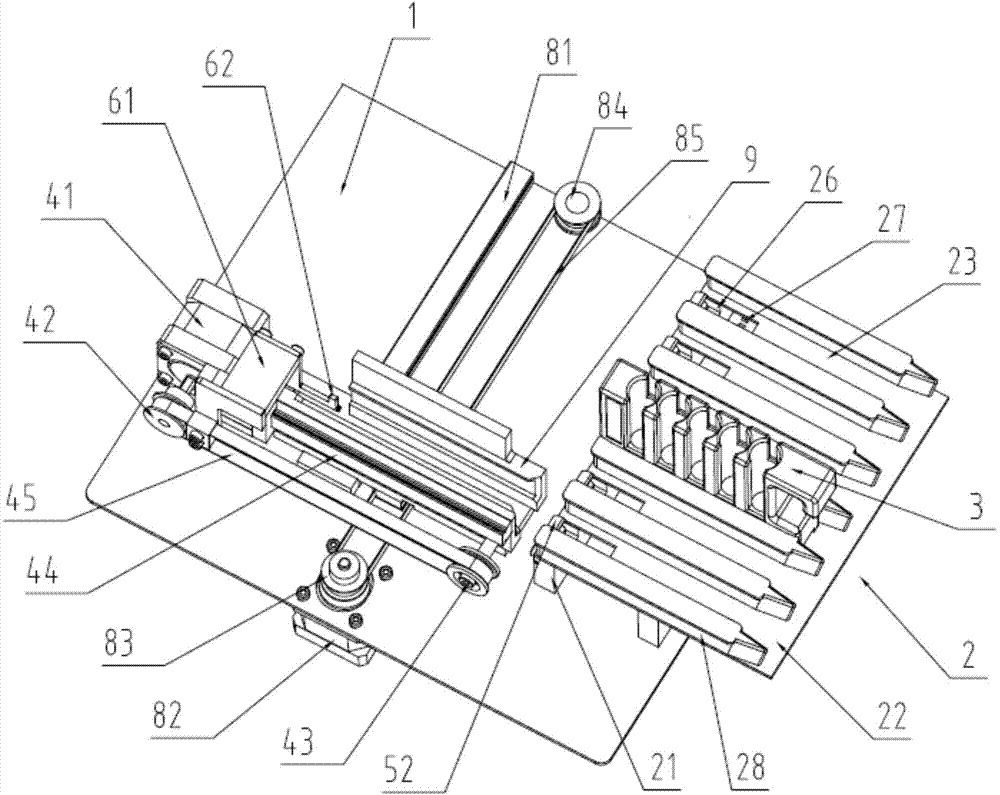

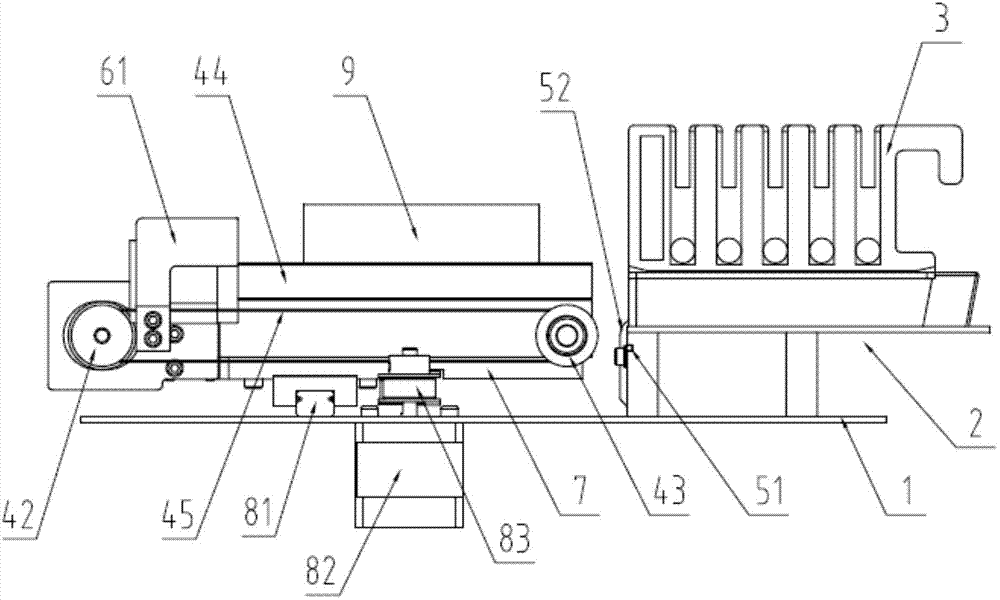

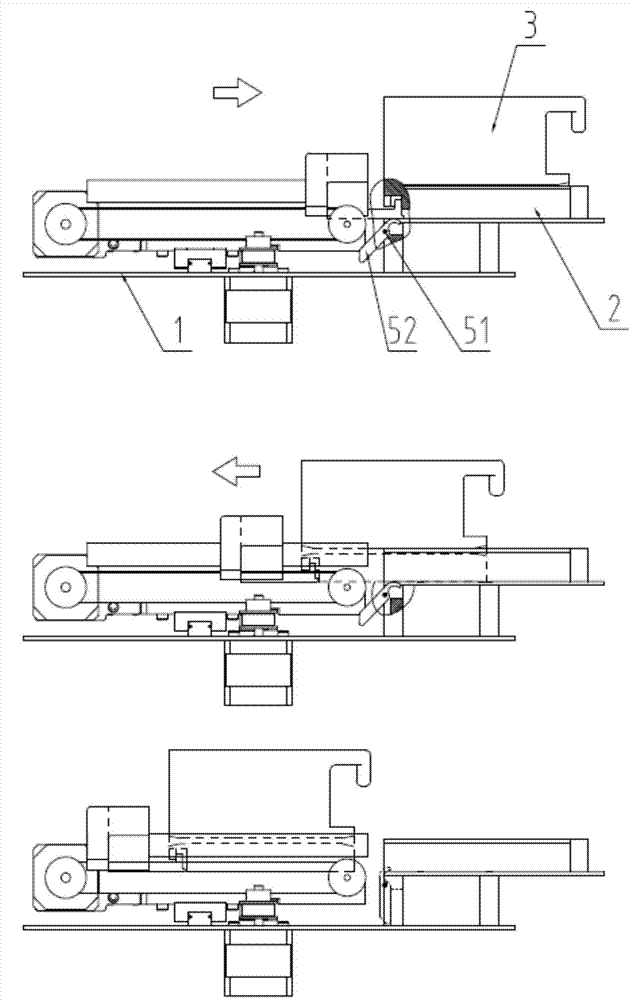

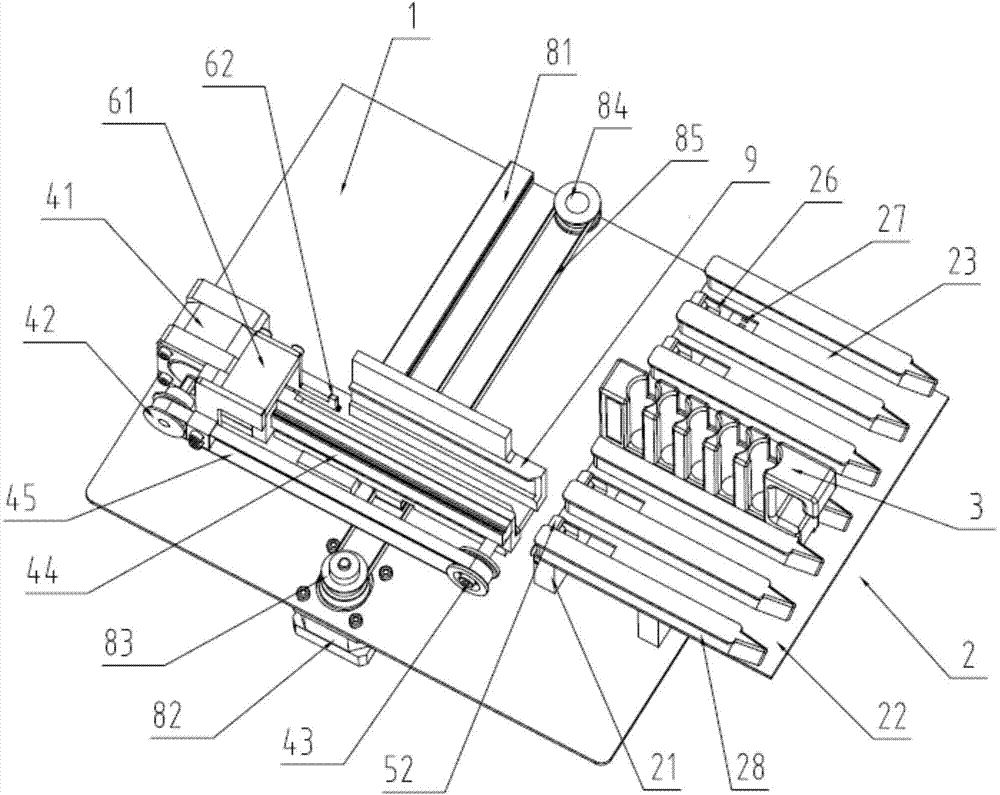

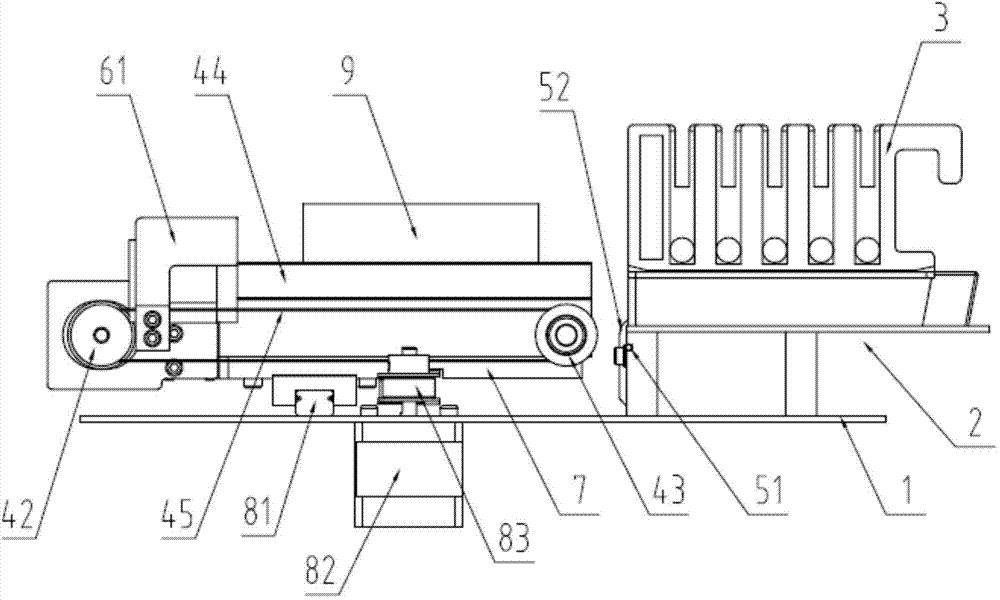

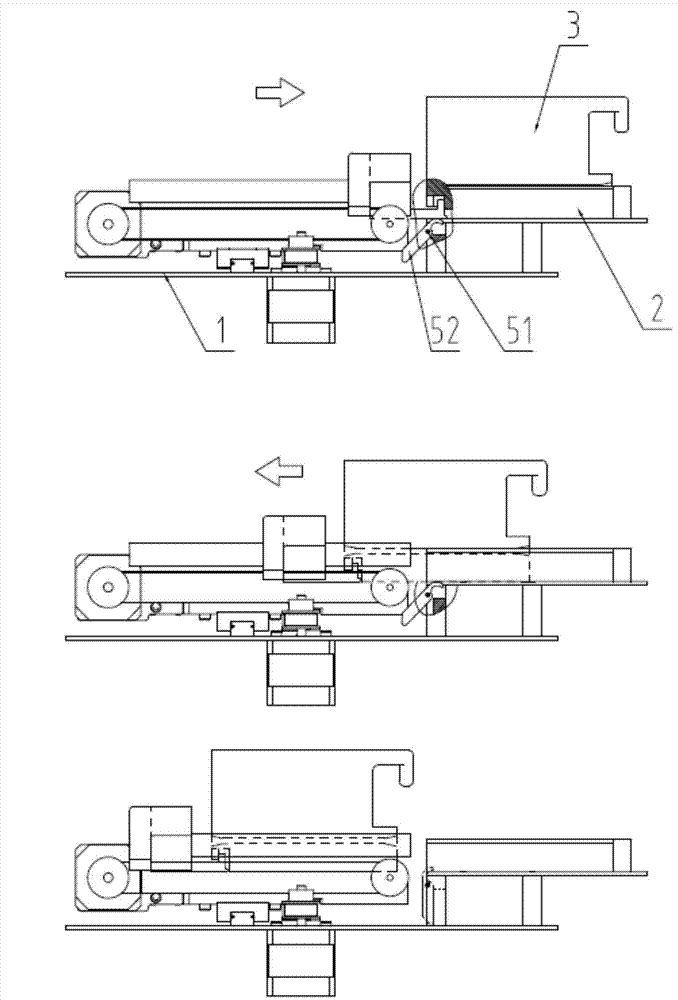

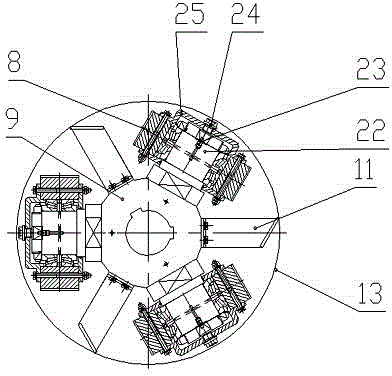

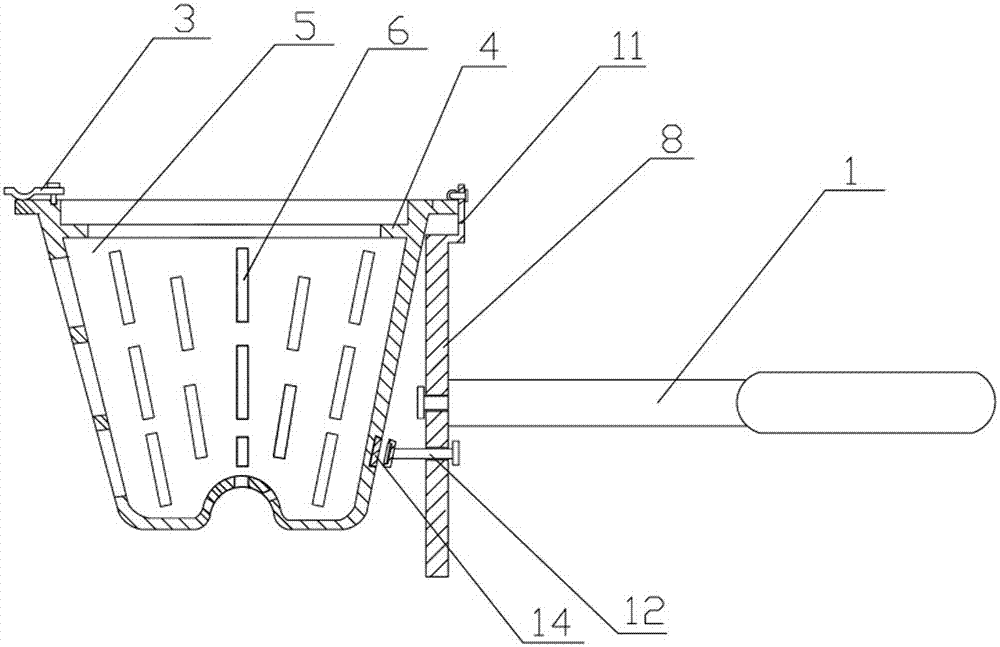

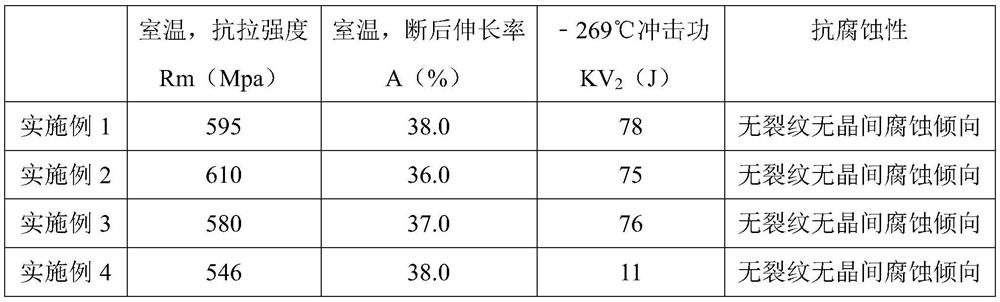

Sample system of chemiluminescent immunoassay instrument

ActiveCN103884854APrecise positioningReduce shakingMaterial analysisAutomatic controlChemiluminescent immunoassay

The invention discloses a sample system of a chemiluminescent immunoassay instrument. The sample system comprises a base, wherein a sample rack is mounted on the base, a leftward-rightward pushing mechanism is mounted on the base in front of the sample rack, a test-tube rack is mounted on the sample rack, a stopping device is arranged at the front end of the sample rack, a stopping block of the stopping device is located at the front end of the test-tube rack so as to limit the forward movement of the test-tube rack, a supporting seat is mounted on the leftward-rightward pushing mechanism, a forward-backward pushing mechanism is mounted on the supporting seat, a grabbing mechanism is arranged on the forward-backward pushing mechanism, a grabbing hook of the grabbing mechanism directly faces to the stopping block of the stopping device, when the grabbing mechanism moves backwards, the grabbing hook shifts the stopping block and hooks the front end of the test-tube rack, and when the grabbing mechanism returns forwards, the grabbing hook drives the test-tube rack to move forwards. According to the sample system of the chemiluminescent immunoassay instrument, accurate locating can be realized through the action of magnetic force, so that the test-tube rack is stably mounted on the sample rack; the grabbing mechanism can simultaneously unlock the stopping device and grab the test-tube rack, so that automated control is realized.

Owner:CHONGQING KEYSMILE BIOLOGICAL TECH CO LTD

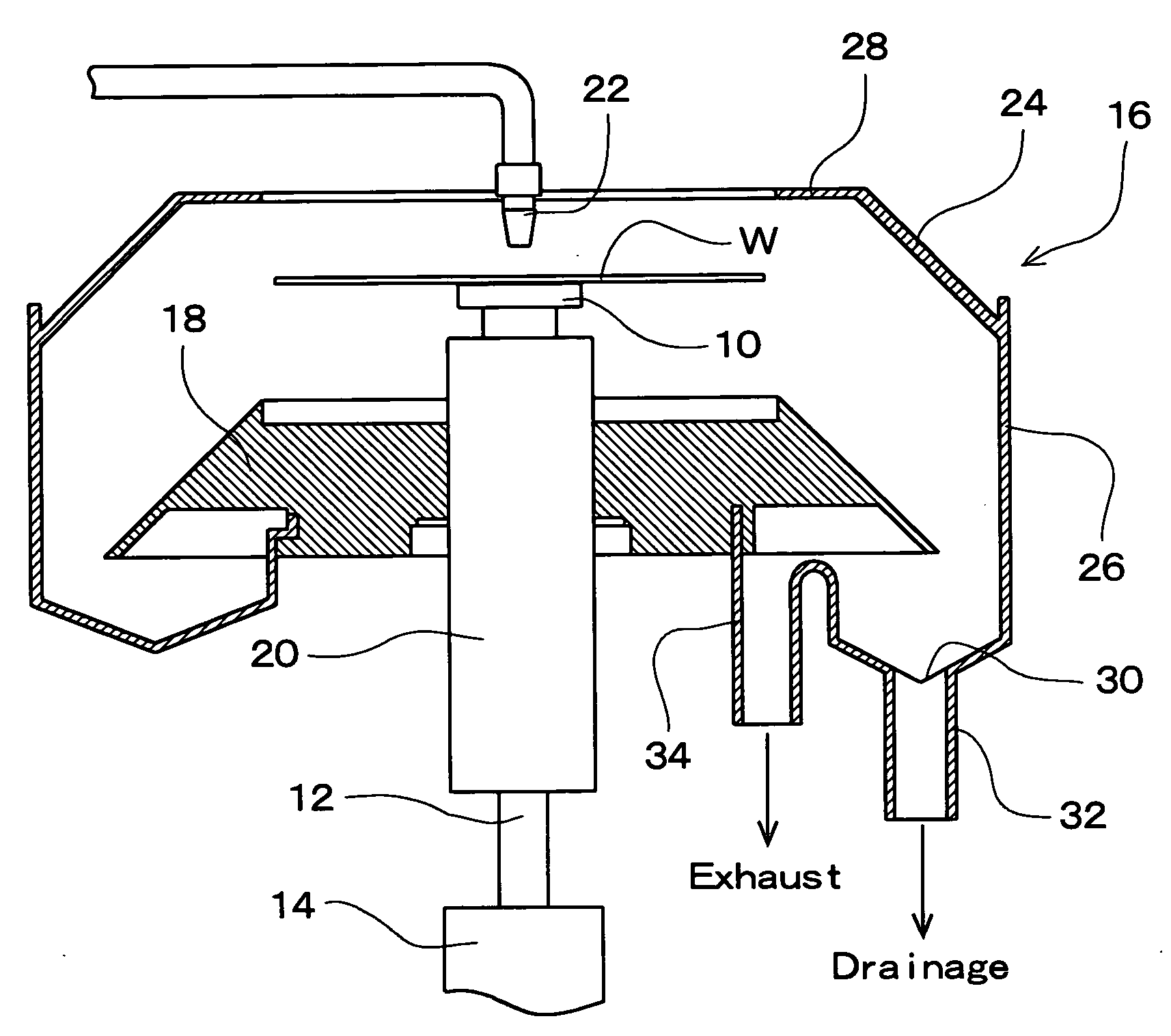

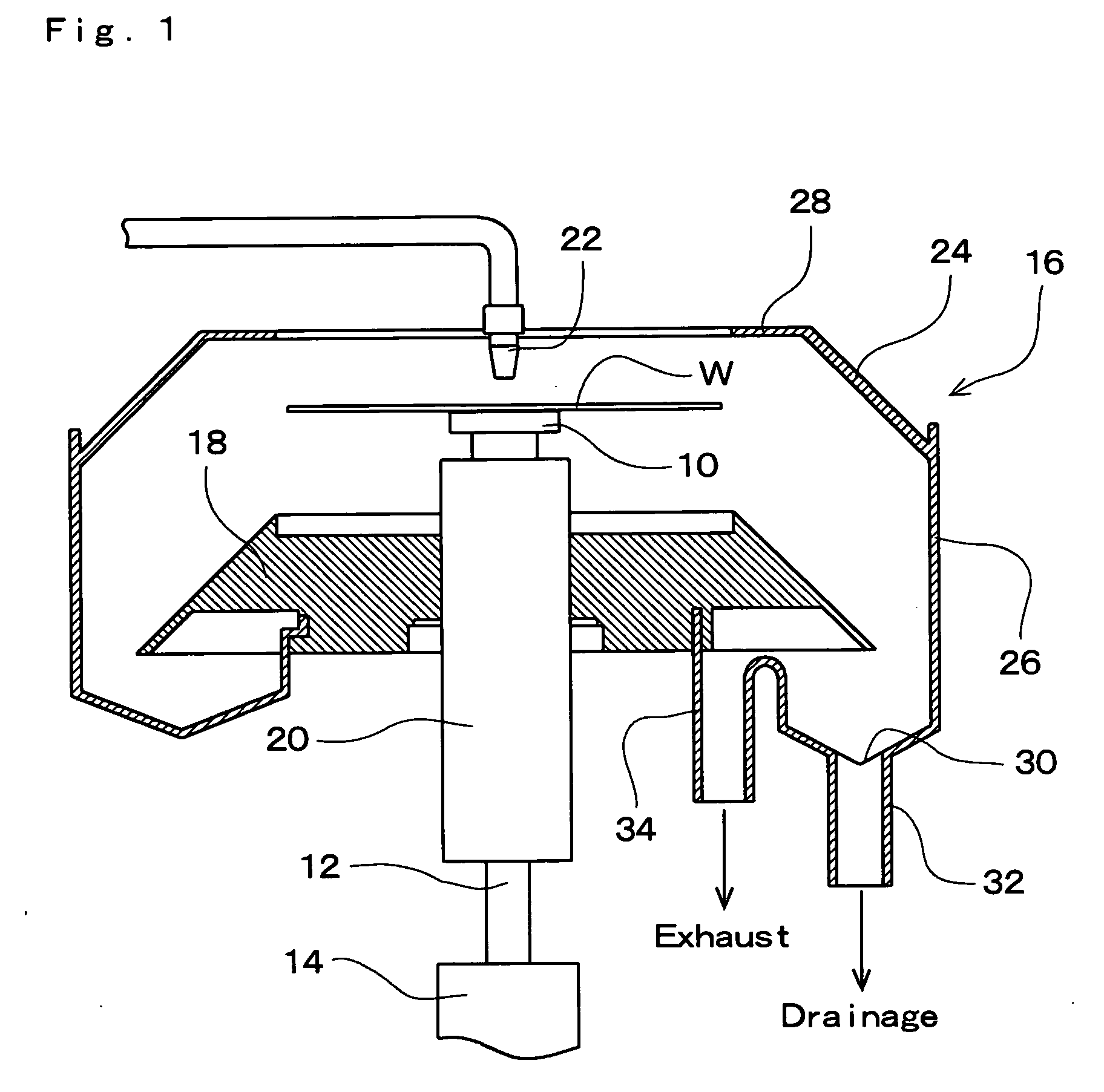

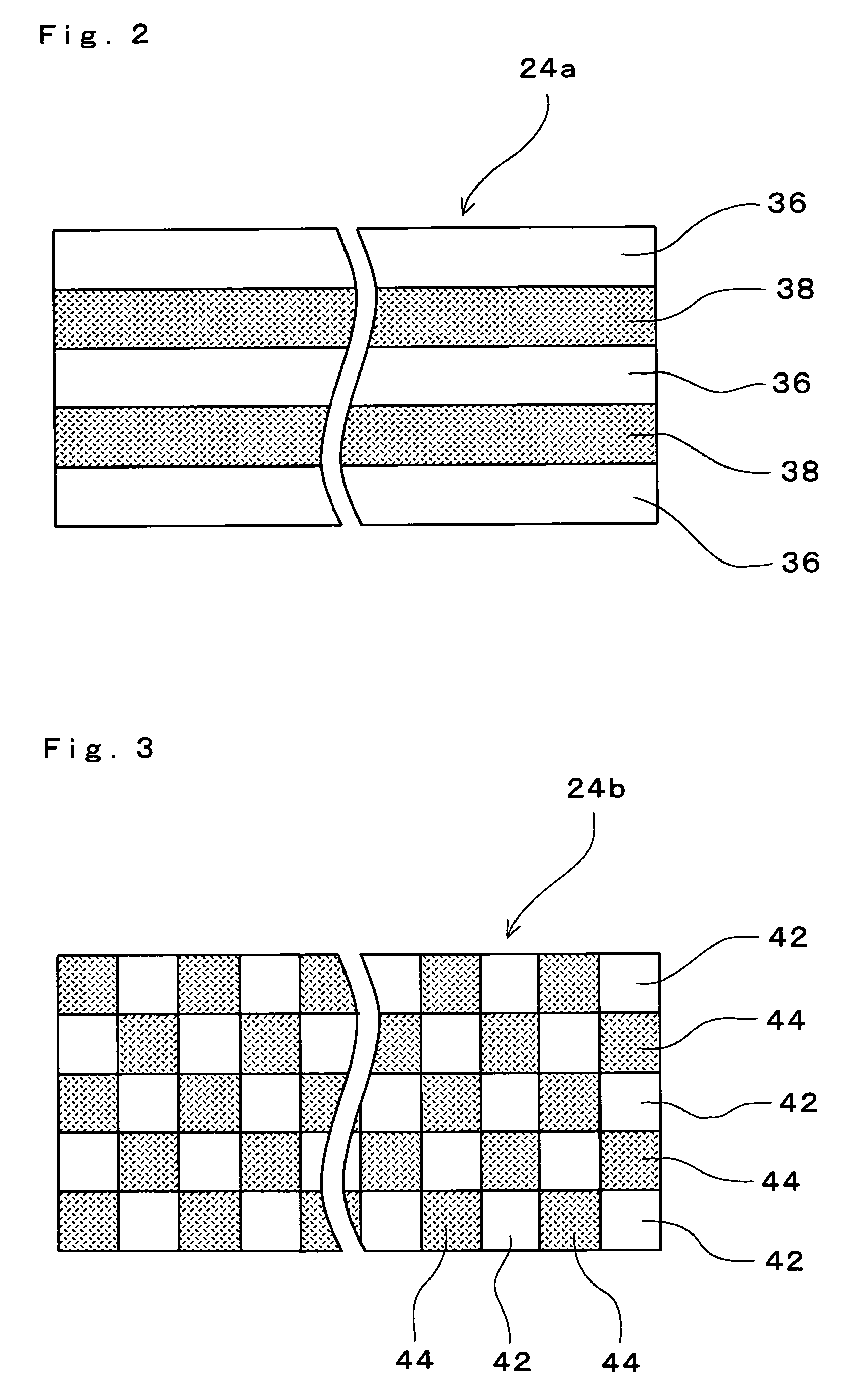

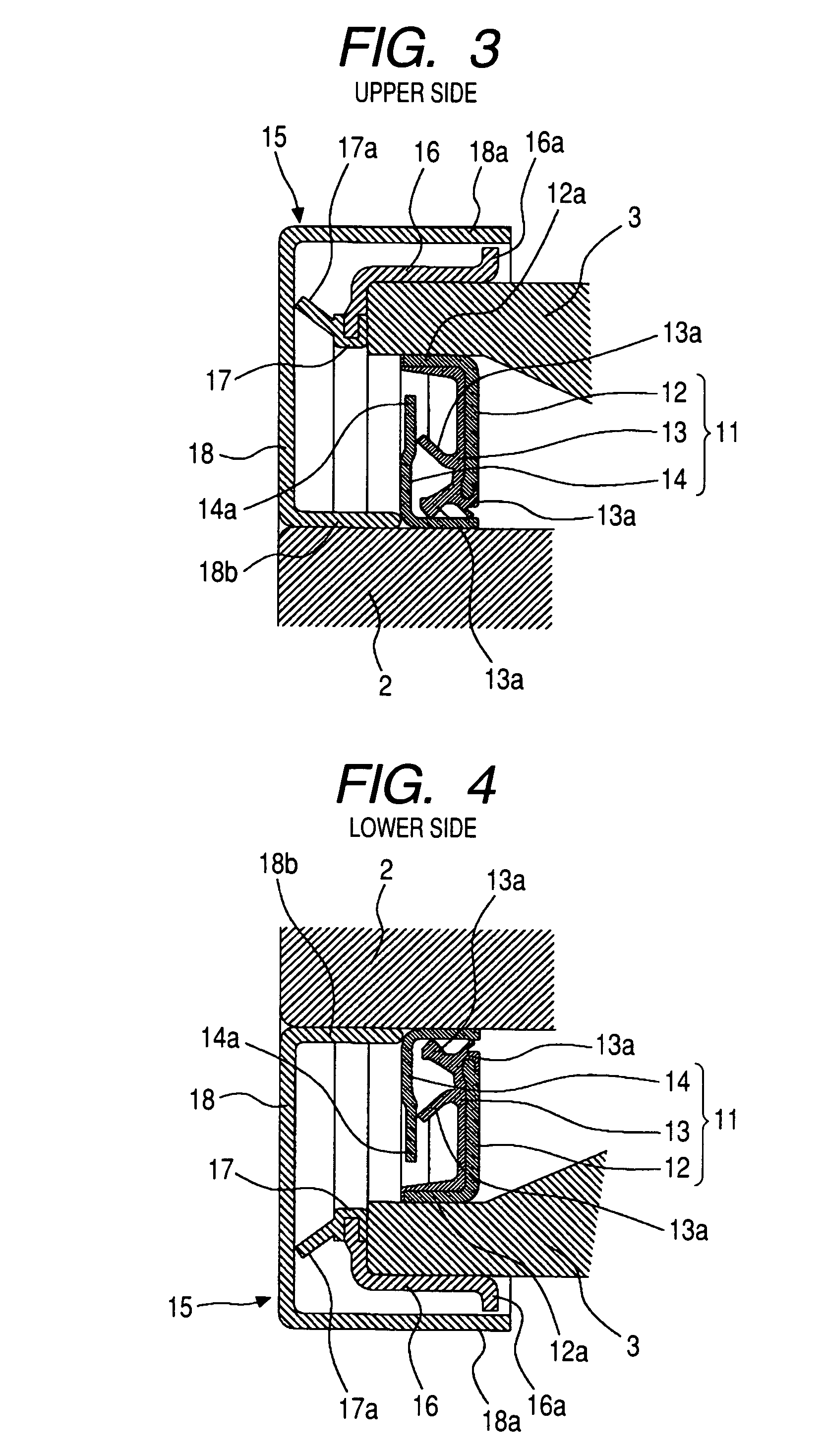

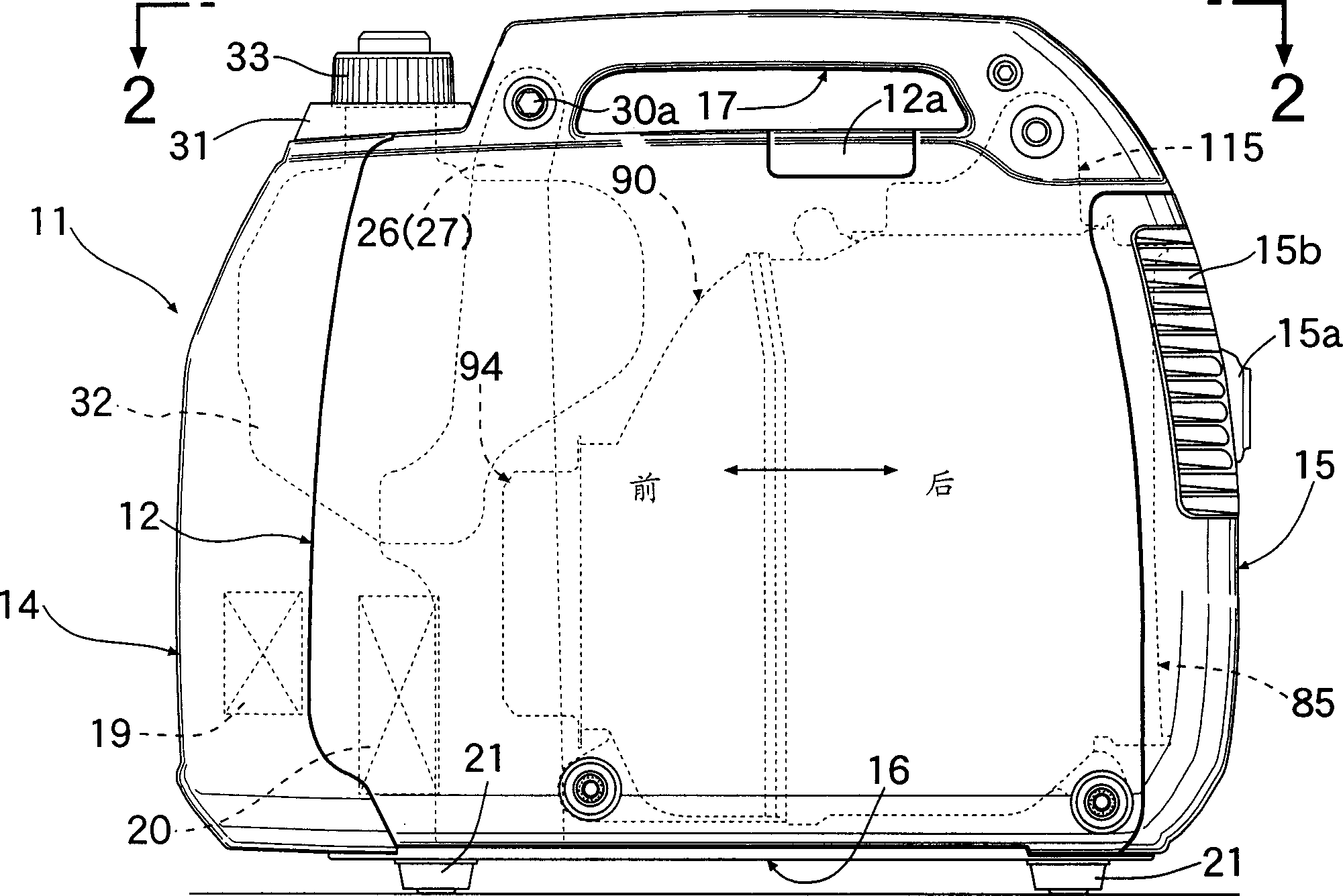

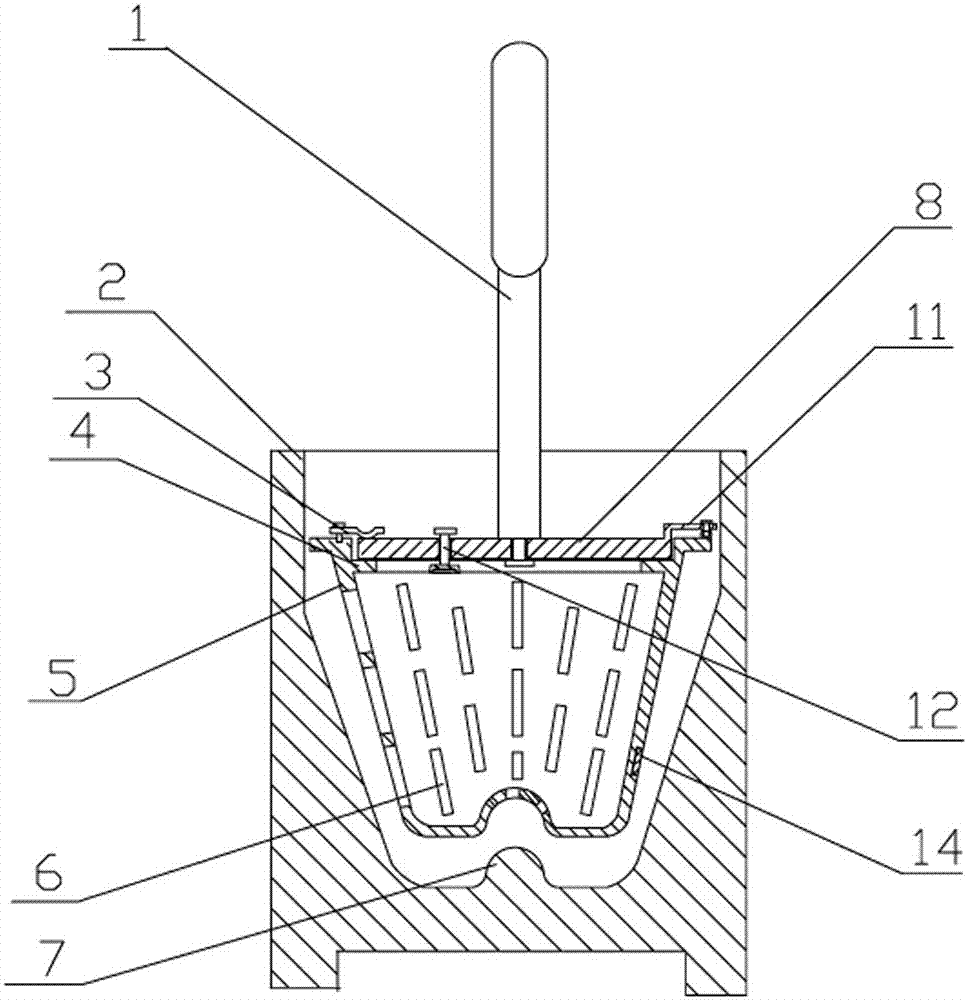

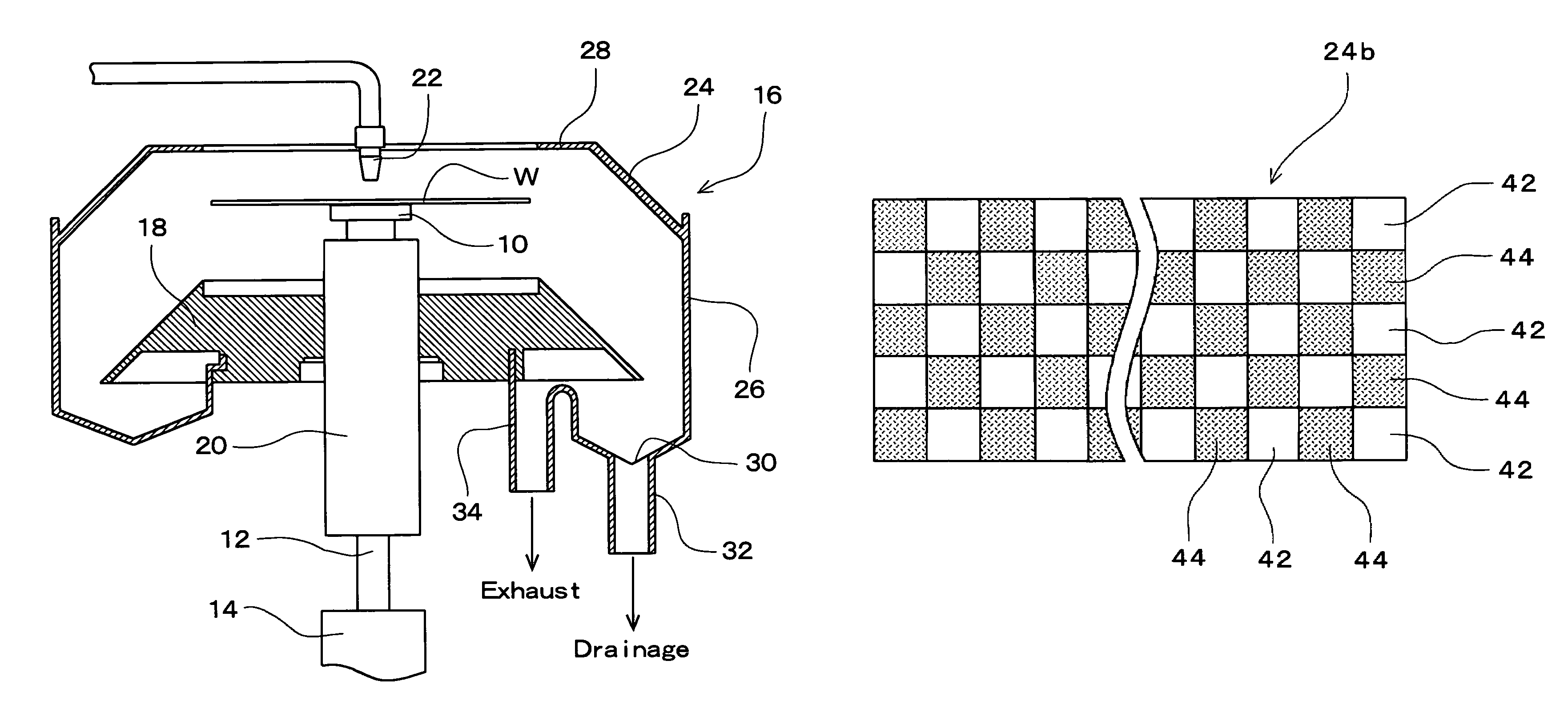

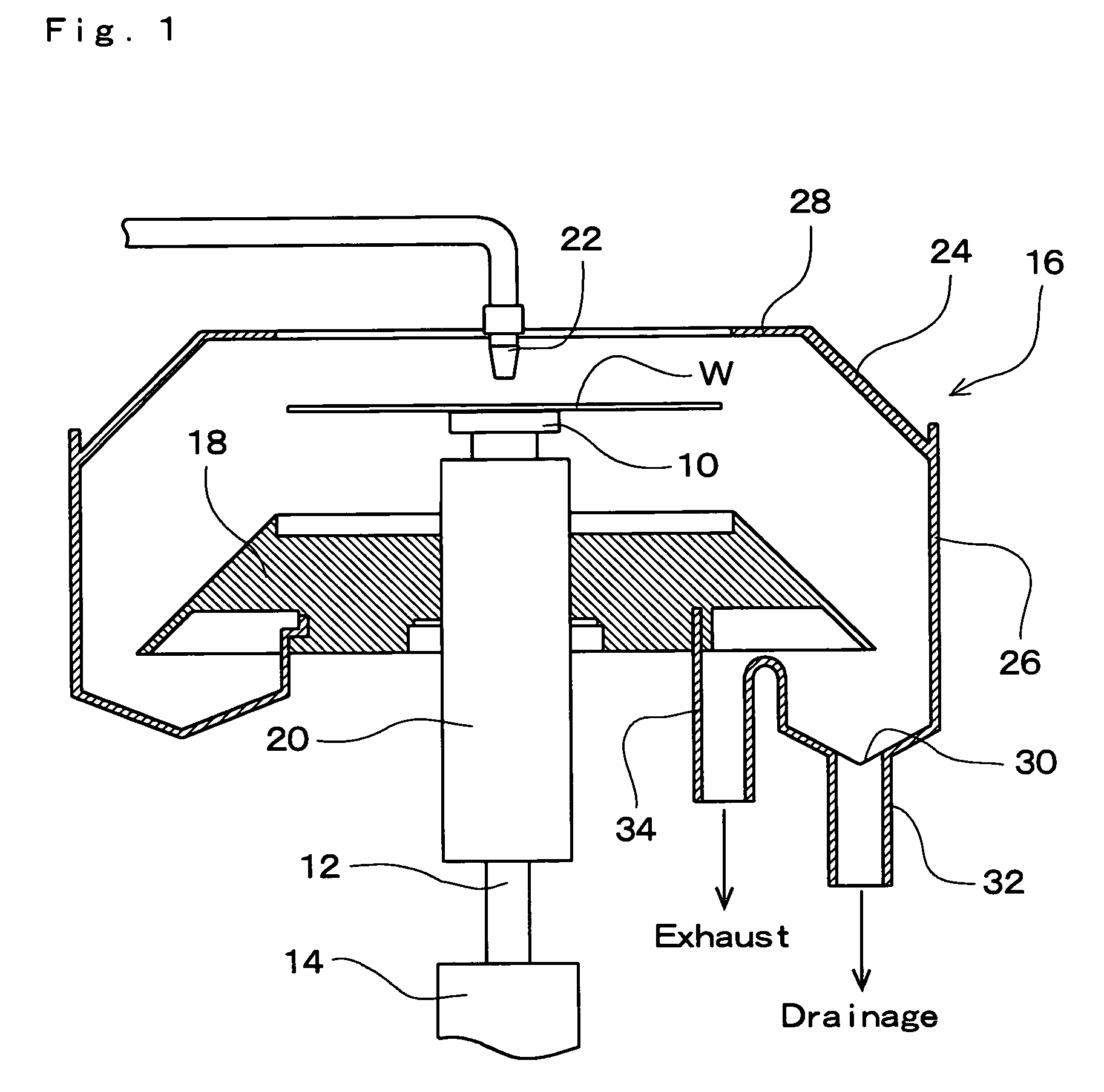

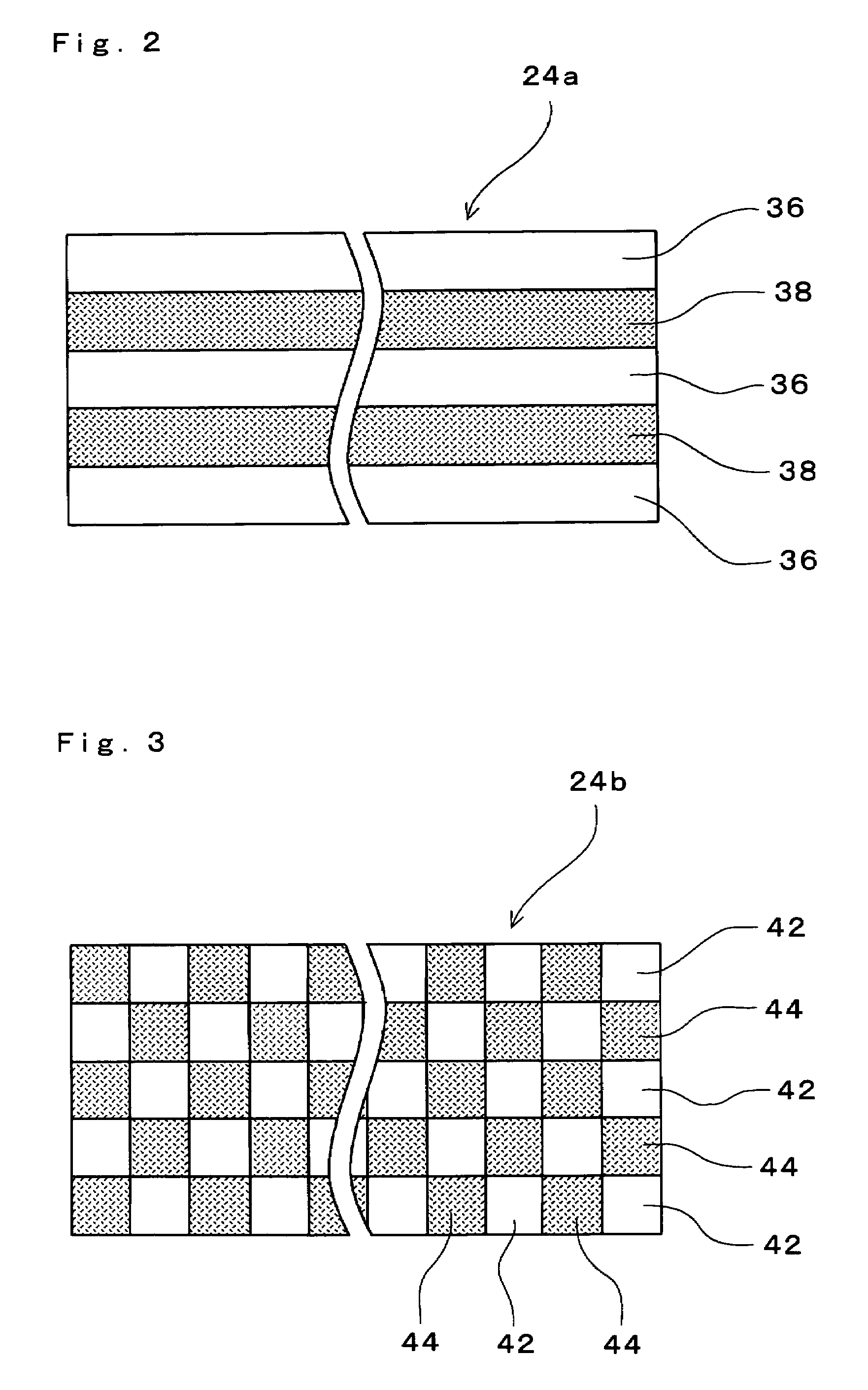

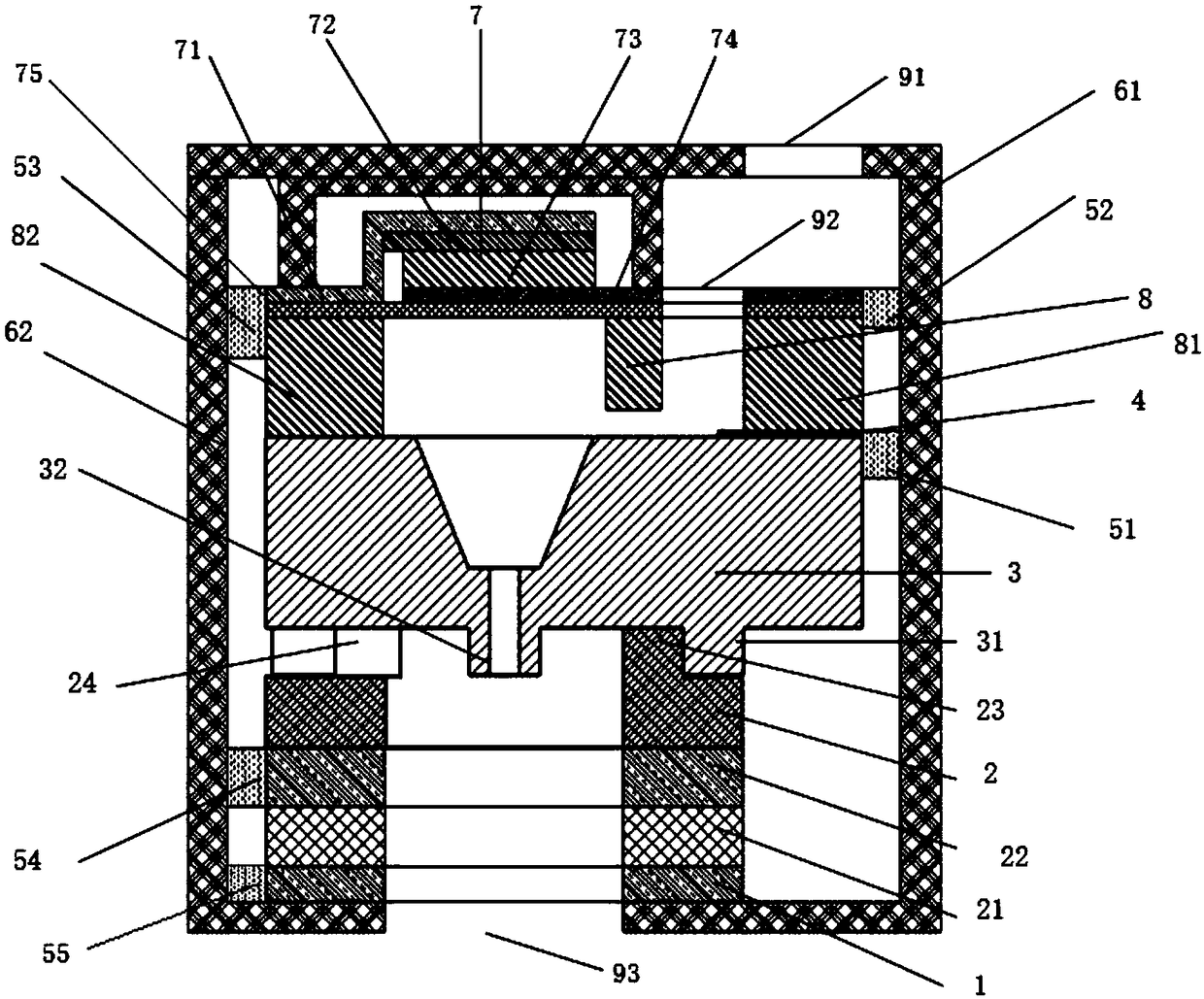

Substrate rotation type treatment apparatus

ActiveUS20060102069A1Reduce splashEasy to splashLiquid surface applicatorsPhotomechanical apparatusBiomedical engineeringSubstrate surface

An apparatus causes a substrate to rotate and supplies a treatment liquid to a substrate surface to make a treatment, without concern that a mixed substance is eluted from a cup in the use for a long time, or a thin film comes off from an inside wall surface to be contamination-causing substances even if the cup made of a water-repellent material for collecting a treatment liquid becomes hydrophilic. A cup 16 disposed to surround the sides and underside of a substrate W rotating while being held by a spin chuck 10, and serving to collect a treatment liquid diffused from the substrate to the surroundings, is made of a plastic material. Further, an inside wall surface of an upper-side cup part 24 of the cup 16, being a portion on which the treatment liquid having been diffused from the substrate impinges, is roughened to be a hydrophilic surface.

Owner:DAINIPPON SCREEN MTG CO LTD

Sample system of chemiluminescent immunoassay instrument

ActiveCN103884857APrecise positioningReduce shakingMaterial analysisAutomatic controlChemiluminescent immunoassay

The invention discloses a sample system of a chemiluminescent immunoassay instrument. The sample system comprises a base, wherein a sample rack is mounted on the base, a leftward-rightward pushing mechanism is mounted on the base in front of the sample rack, a test-tube rack is mounted on the sample rack, a stopping device is arranged at the front end of the sample rack, a stopping block of the stopping device is located at the front end of the test-tube rack so as to limit the forward movement of the test-tube rack, a supporting seat is mounted on the leftward-rightward pushing mechanism, a forward-backward pushing mechanism is mounted on the supporting seat, a grabbing mechanism is arranged on the forward-backward pushing mechanism, a grabbing hook of the grabbing mechanism directly faces to the stopping block of the stopping device, when the grabbing mechanism moves backwards, the grabbing hook shifts the stopping block and hooks the front end of the test-tube rack, and when the grabbing mechanism returns forwards, the grabbing hook drives the test-tube rack to move forwards. According to the sample system of the chemiluminescent immunoassay instrument, accurate locating can be realized through the action of magnetic force, so that the test-tube rack is stably mounted on the sample rack; the grabbing mechanism can simultaneously unlock the stopping device and grab the test-tube rack, so that automated control is realized.

Owner:CHONGQING KEYSMILE BIOLOGICAL TECH CO LTD

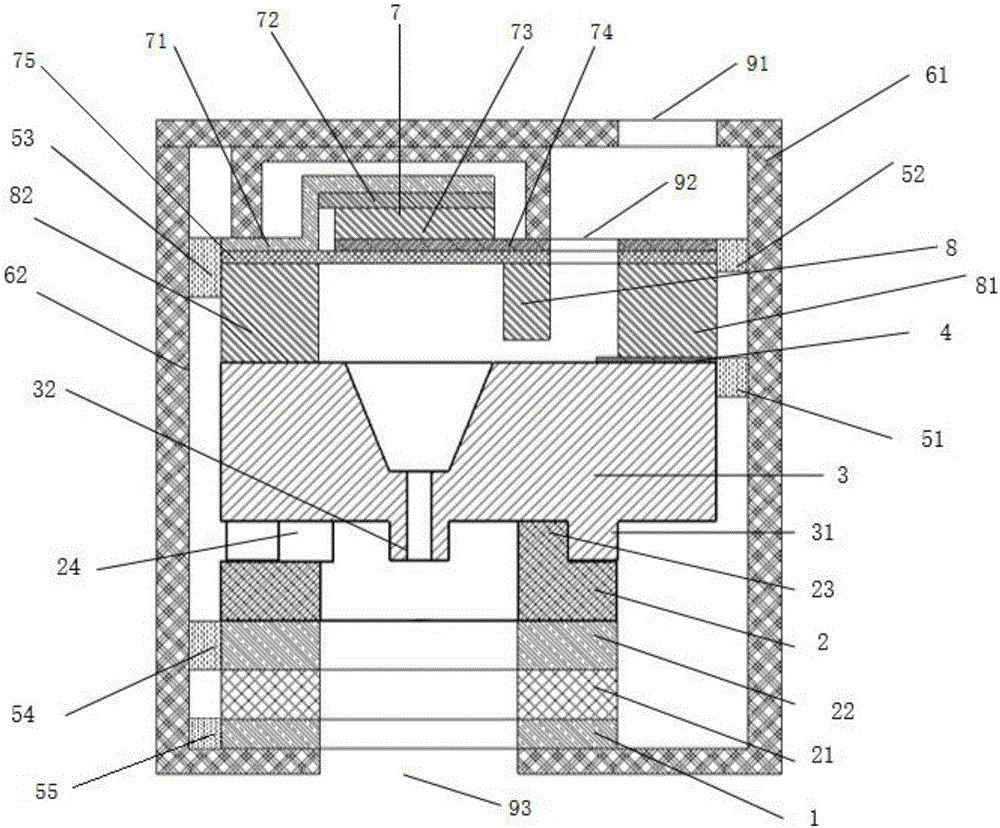

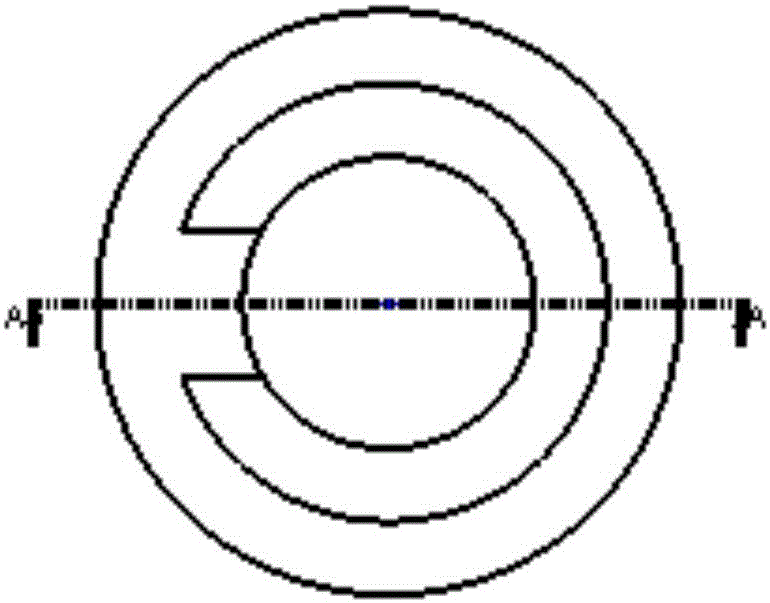

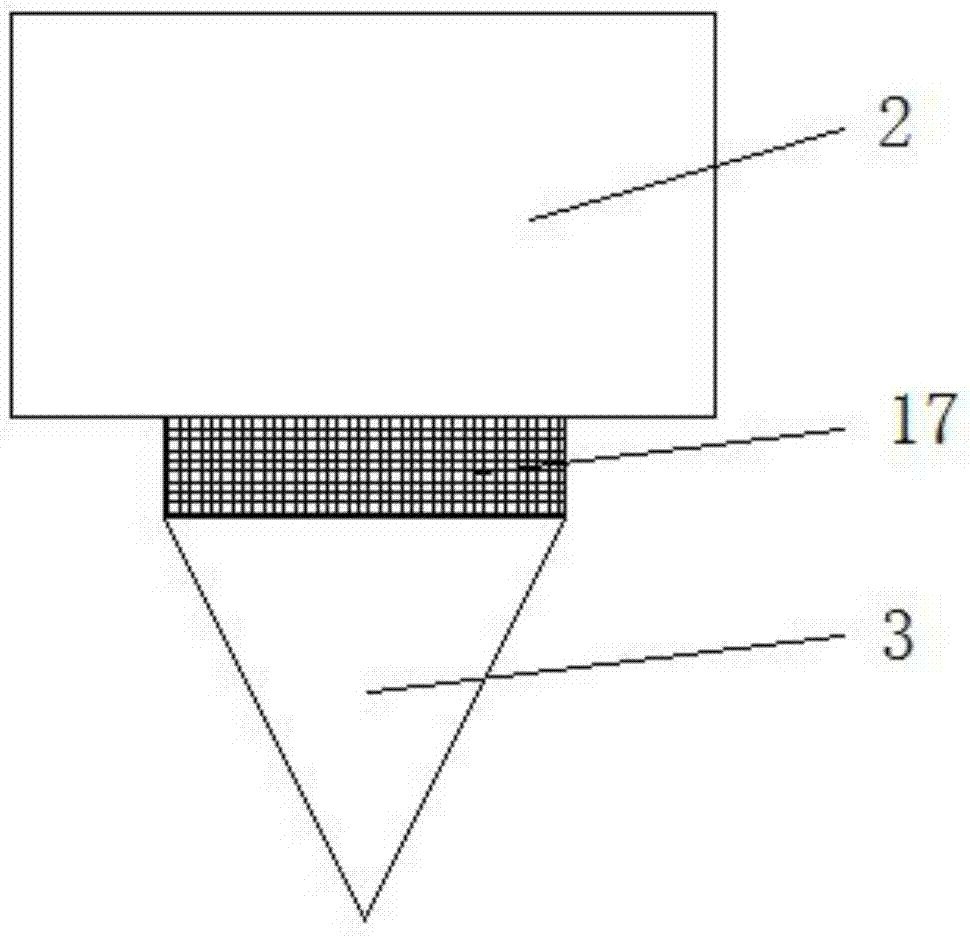

Piezoelectric type integrated spray head used for electrofluid jet printing

The invention relates to the field of electrofluid jet printing equipment, in particular to a piezoelectric type integrated spray head used for electrofluid jet printing. The piezoelectric type integrated spray head comprises an outer bracket, a piezoelectric structure, a spray head, a lower electrode supporting ring and a lower electrode ring, wherein the piezoelectric structure is positioned above the spray head; an upper electrode is arranged on the upper part of the spray head; the lower electrode supporting ring and the lower electrode ring are sequentially arranged below the spray head; after the piezoelectric structure, the upper electrode and a lower electrode are electrified, electric fields are formed between the spray head and the lower electrode ring, so that a solution forms Taylor cones on the spray head. The piezoelectric type integrated spray head overcomes the defect that existing electric jet printing equipment cannot meet high-frequency spraying, can realize high-frequency high-resolution printing; and the lower electrode is integrated to the spray head end, so that the whole jet printing system is more flexible, and a base plate with a complex shape can be used to print. The piezoelectric type integrated spray head further has the advantages of being simple in structure, low in manufacturing cost, suitable for large-scale production and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Substrate processing apparatus and method

ActiveUS7608152B2Easy to splashEffectively prevent re-adheringPretreated surfacesElectrostatic cleaningEngineeringInert gas

Owner:DAINIPPON SCREEN MTG CO LTD

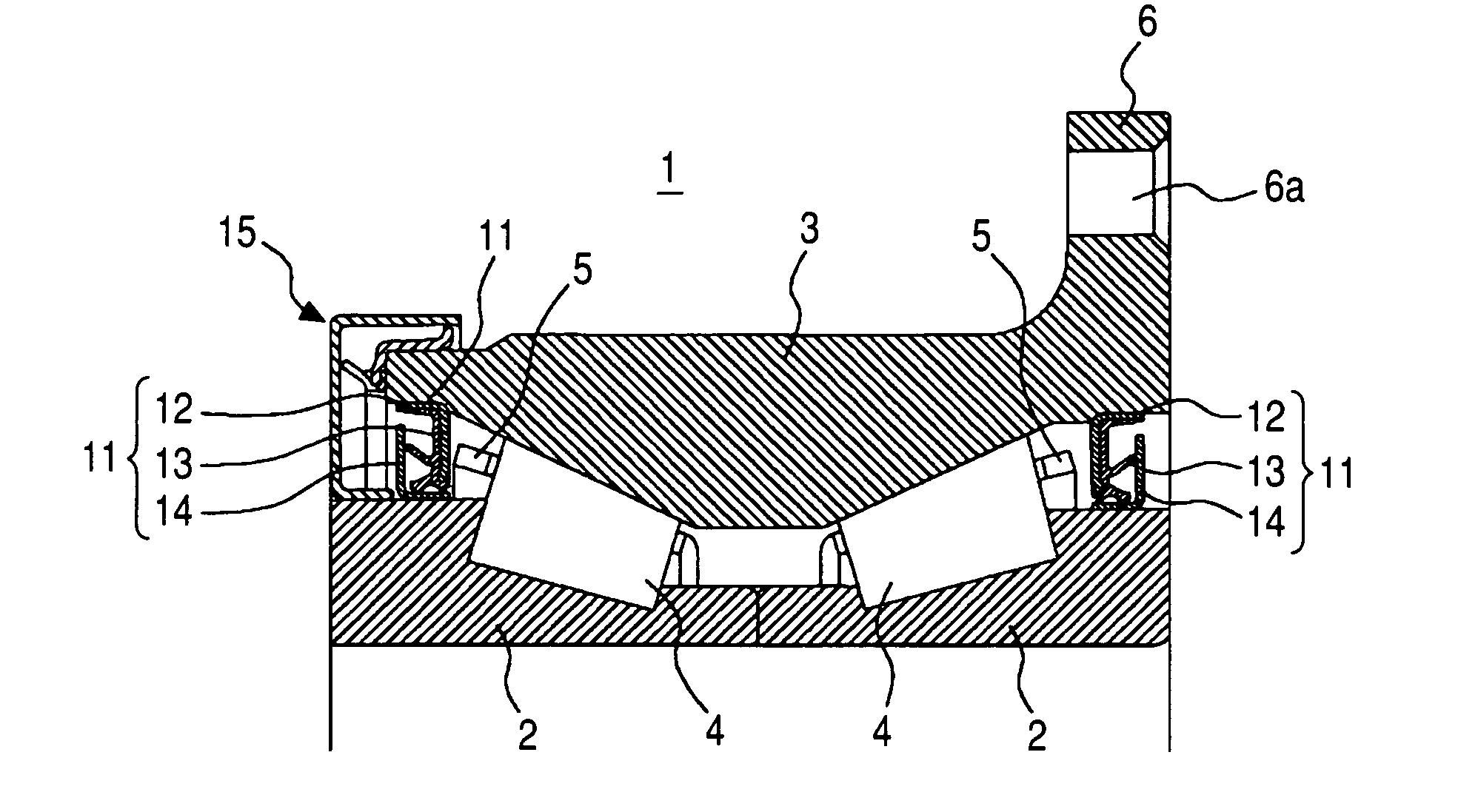

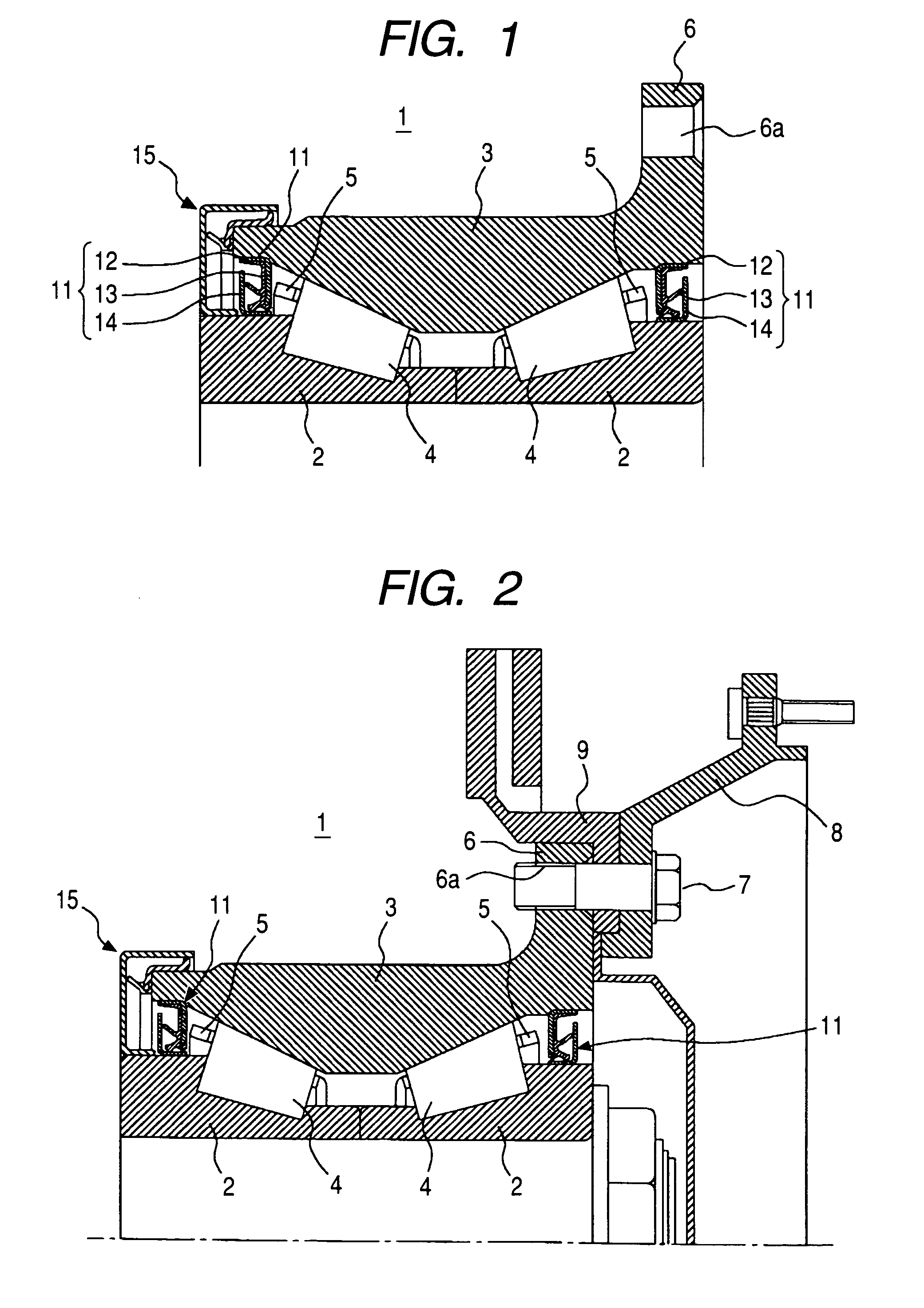

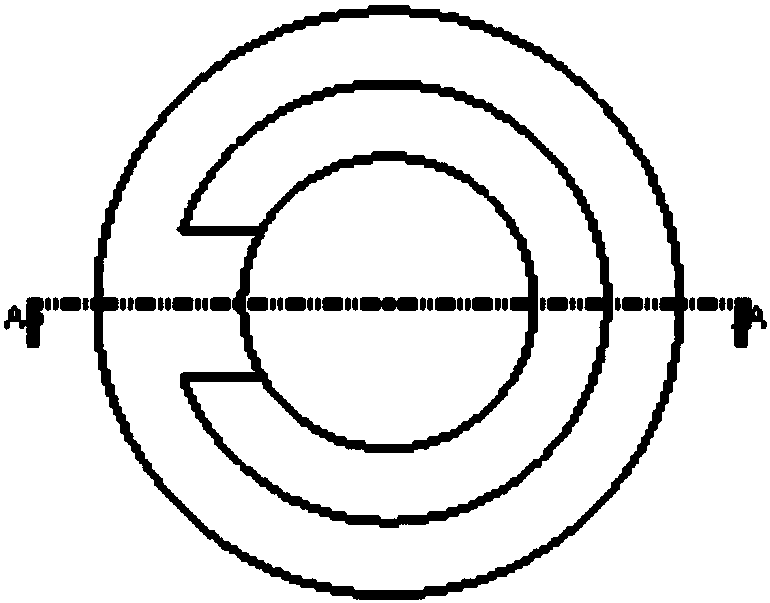

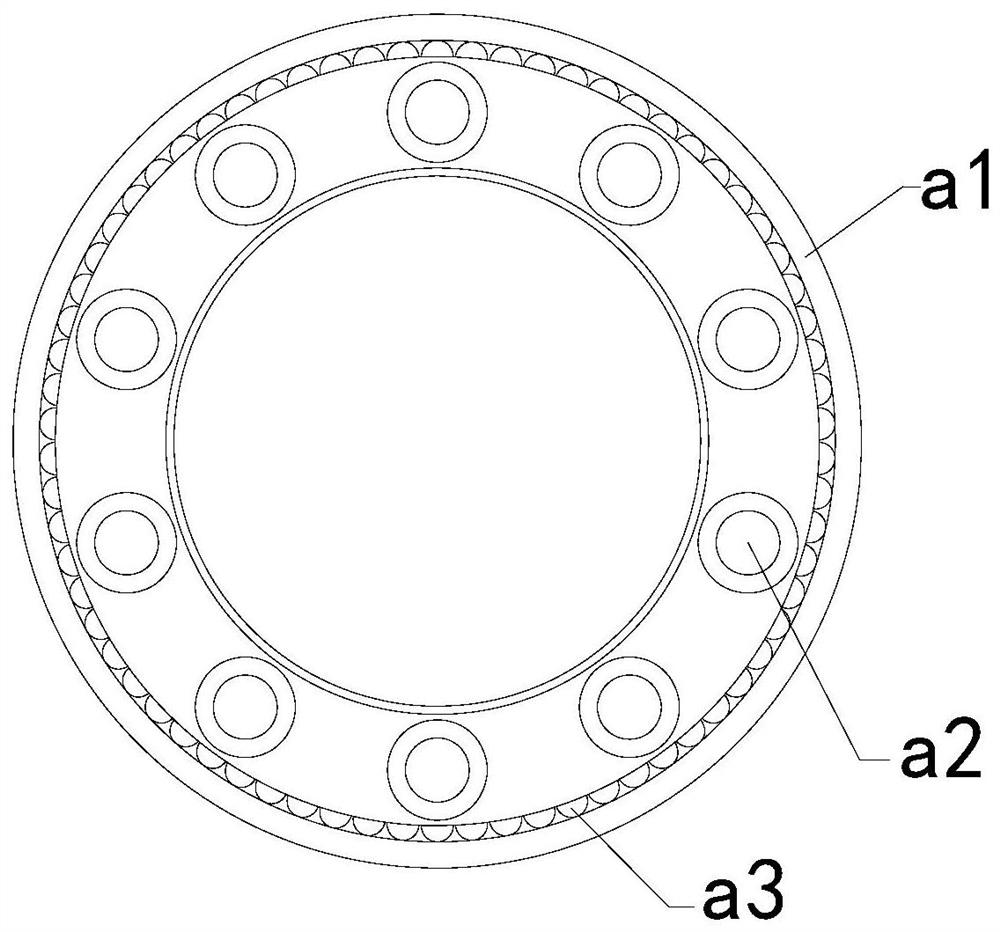

Bearing apparatus for axle

An inner ring, an outer ring, a circular cone roller constituting a rolling elements arranged between the inner ring and the outer ring, a first seal member arranged at an opening portion between the inner ring and the outer ring, and a second seal member arranged on an outer side in an axial direction of the first seal member are provided, the second seal member includes a core fixed to the outer ring, an elastic ring-like member fixedly attached to the core and having at least one lip, and an outward attached slinger having a section in a channel-like shape fixed to the inner ring to cover the core and the elastic ring-like member and having a portion of a section in an L-like shape and a circular cylinder shape portion.

Owner:JTEKT CORP +1

Method and device for removing surface scale of copper and copper alloy ingot before rolling

InactiveCN102357542AConvenient for centralized collectionReduce dispersionWork treatment devicesMetal rolling arrangementsHydraulic cylinderMetallurgy

The invention discloses a method and device for removing surface scale of copper and copper alloy ingot before rolling. The method comprises the following steps of: before rolling, performing bilateral rolling with certain rolling reduction on the edge of the copper and copper alloy ingot with a vertical roller, so as to sufficiently loosen the primary scale generated on the surface of the copper and copper alloy ingot in the heating process; and scraping and brushing the copper and copper alloy ingot with loose primary scale on the surface with a steel brush. The device comprises vertical rollers sequentially arranged at the front end of a hot mill and a steel brush device, wherein two vertical rollers are symmetrically arranged on the two sides of the copper and copper alloy ingot; and the steel brush device comprises a bracket, a steel brush and a hydraulic cylinder, wherein the steel bush and hydraulic cylinder are mounted on the bracket. Through the invention, the relatively thick primary scale on the surface of the copper and copper alloy ingot after the heating and before the rolling can be effectively removed, thus the production cost is reduced, and the yield and production efficiency of the copper plate belt product are effectively improved.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

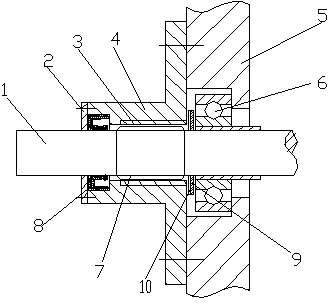

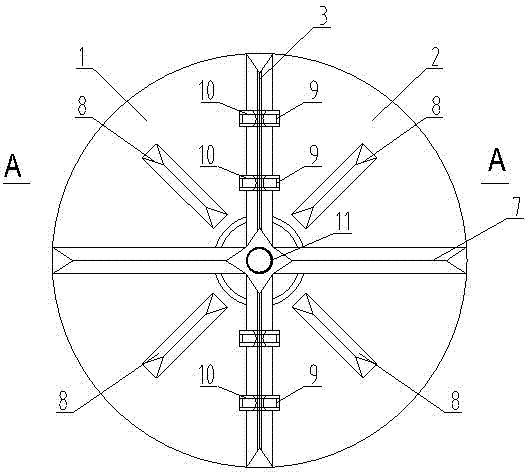

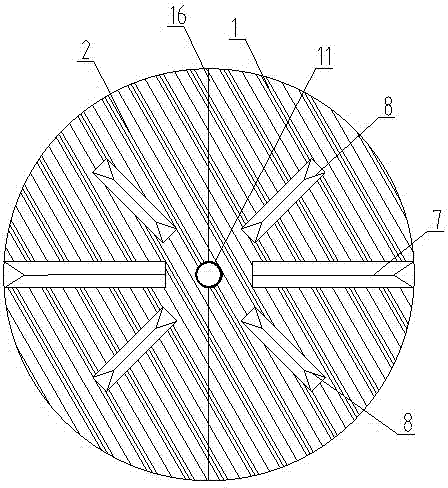

Combined type dynamic seal transmission assembly

InactiveCN103775647AExtended service lifeReduce oil seal burdenEngine sealsGearing detailsLubricationEngineering

The invention discloses a combined type dynamic seal transmission assembly. The combined type dynamic seal transmission assembly comprises a case, a transmission shaft and a shaft seal which is sleeved on the transmission shaft to seal the inside and outside of the case. The transmission shaft is arranged inside the shaft seal to form a threaded seal shaft section, the case is provided with a threaded shaft hole which is in clearance fit with the threaded seal shaft section, and the thread extension direction of the threaded seal shaft section and the threaded shaft hole is from inside to outside and is identical to the rotation direction of the transmission shaft. According to the combined type dynamic seal transmission assembly, when the transmission shaft rotates at a high speed, by means of the thrust effect of the threaded seal shaft section and the threaded shaft hole, lubricant oil inside gaps can be pumped back to the case to avoid that large amounts of lubricant oil achieves the oil sealing effects and accordingly to reduce oil seal load; meanwhile, through the centrifugal effect of an oil slinger, neighboring lubricant oil can be thrown onto the outer circumference to facilitate splash lubrication and prolong the service life of bearings; soft oil sealing materials achieve relatively good adaptability and accordingly avoid leakage of lubricant oil due to primary assembling problems. The combined type dynamic seal transmission assembly is applicable to a transmission device with the transmission shaft rotating in one direction.

Owner:TIANJIN QIXING PRECISION MACHINERY

Novel butting type bird resisting cover for high-voltage transmission line

InactiveCN103579981AGuaranteed safe operationImprove toleranceOverhead installationForeign matterBird droppings

The invention discloses a novel butting type bird resisting cover for a high-voltage transmission line. The novel butting type bird resisting cover comprises a cover body which is in a disc shape, a main reinforcing rib is arranged on the upper surface of the cover body, the cover body is divided into a left cover main body and a right cover main body, the left cover main body and the right cover main body are respectively in a semicircular shape, and the left cover main body and the right cover main body are connected at the position of the main reinforcing rib in a clamped mode through a bolt. The novel butting type bird resisting cover for the high-voltage transmission line prevents high-voltage line insulator breakdown caused by bird damage, improves the resistance of the insulator of the high-voltage transmission line, and ensures the safety operation of the line. The novel butting type bird resisting cover for the high-voltage transmission line is directly arranged above a line suspension insulator string to prevent bird droppings and foreign matters from falling off.

Owner:STATE GRID CORP OF CHINA +2

Lubricating structure for OHC engine

An OHC engine includes a valve operating system installed in a valve operating chamber formed between a cylinder head and an end cover connected to the cylinder head. The valve operating system includes a valve operating cam, which is matched and connected with an intake valve and an exhaust valve. The OHC engine also includes a synchronous transmission arranged between the valve operating system and the crankshaft, the synchronous transmission includes a driven wheel and a transmission belt, the driven wheel rotates with the valve operating cam, and the transmission belt runs around The driven wheel, in this way, the lubricating oil in the crankcase can move with the transmission belt and supply the valve operating chamber. The end cap has an arcuate curved cover portion for covering the upper portion of the driven wheel. The curved cover part integrally includes a plurality of oil splashing ribs on the driven wheel, the oil splashing ribs are arranged at intervals along the rotation direction of the driven wheel, and protrude toward the side closer to the conveying belt, so that the lubricating oil can be evenly distributed. Supply all parts of the valve operating system.

Owner:HONDA MOTOR CO LTD

Household gas-liquid delivery device for rapidly preparing ozone water, and ozone water preparation device

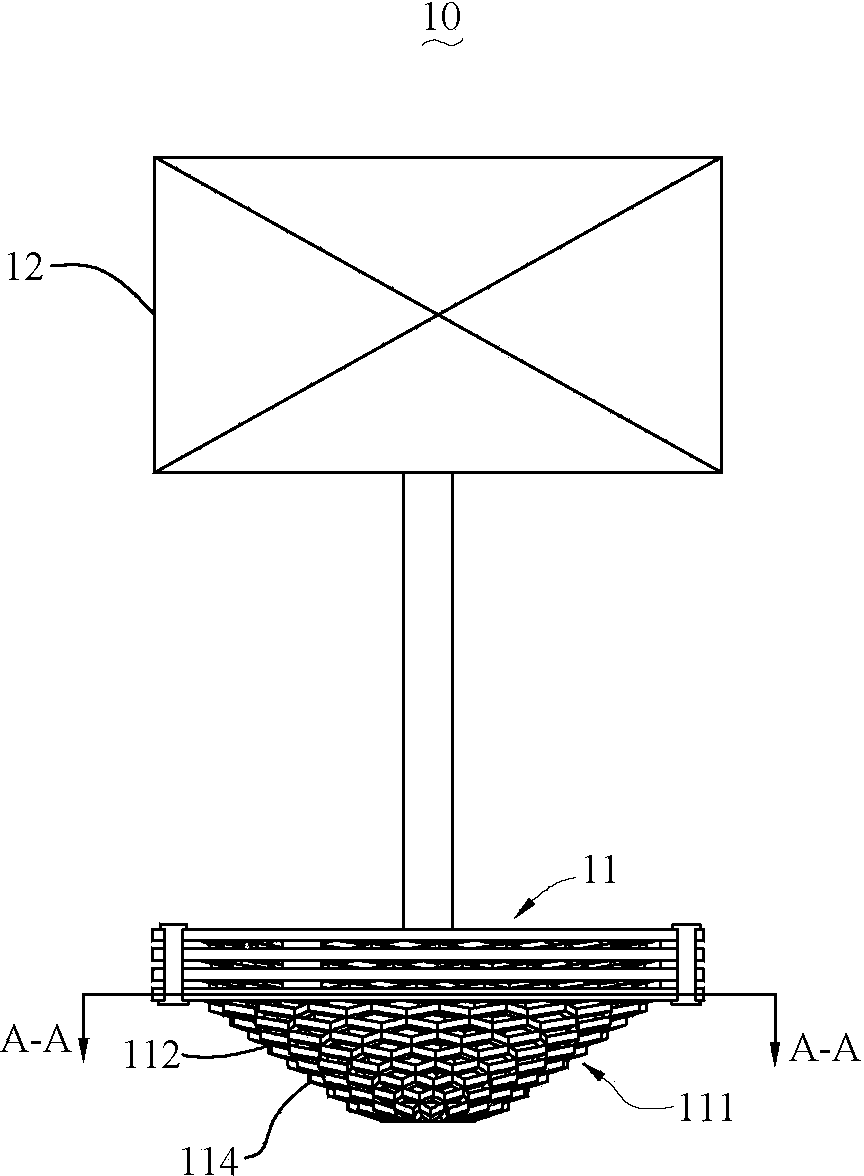

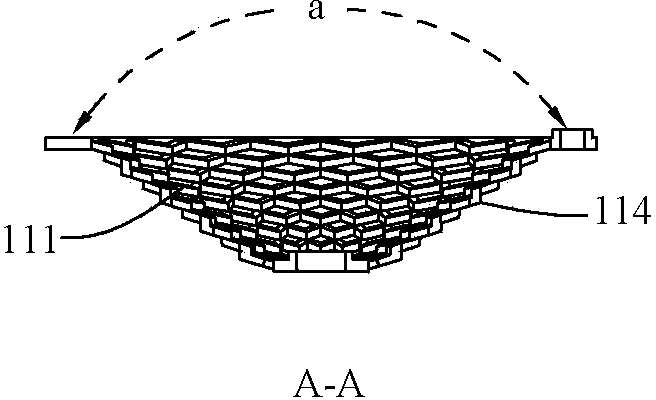

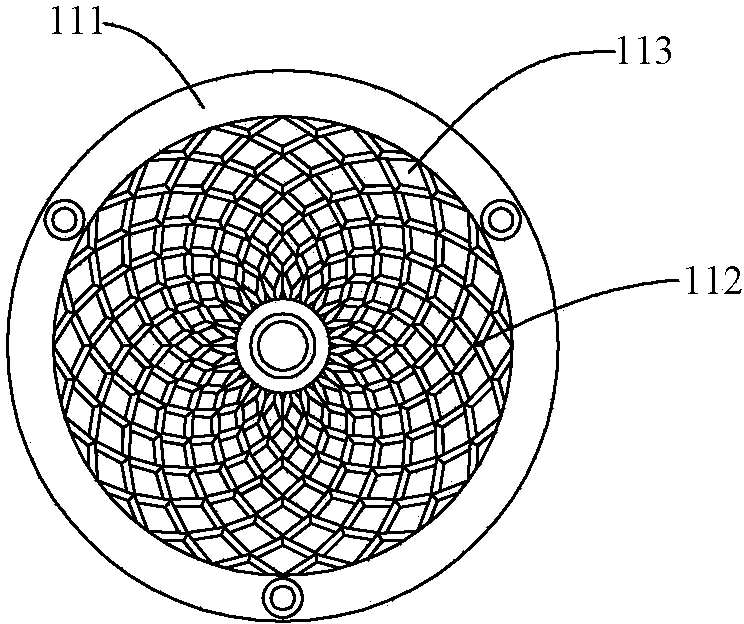

ActiveCN103418257AHigh speedGuaranteed uniformityMixing methodsRotary stirring mixersEnvironmental engineeringWater resource management

The invention relates to a household gas-liquid delivery device for rapidly preparing ozone water, and an ozone water preparation device. The gas-liquid delivery device comprises a centrifugal gas-liquid mixing part with an inverted umbrella shape, and a rotation dynamic part used for driving the centrifugal gas-liquid mixing part to rotate rapidly. The rotation dynamic part is connected to the centrifugal gas-liquid mixing part through a rotation shaft. The centrifugal gas-liquid mixing part stirs water to flow fast, such that ozone water is drawn into water and bubbles are formed. The centrifugal gas-liquid mixing part comprises a plurality of separation ribs refining the bubbles. When the centrifugal gas-liquid mixing part with the inverted umbrella shape rotates, a negative-pressure absorption effect is formed, and ozone is absorbed into the inverted umbrella. Turbulence formed by rapid flow of water draws the ozone gas into water, such that speed for ozone to enter water is increased. Ozone bubbles in water meet the separation ribs, and are further refined into tiny ozone bubbles by the separation ribs. Therefore, contact area of ozone and water is increased, and dissolution efficiency is improved.

Owner:JOYOUNG CO LTD

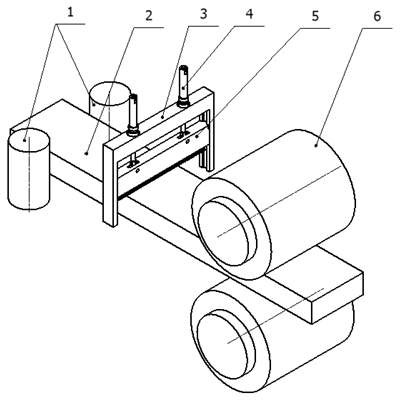

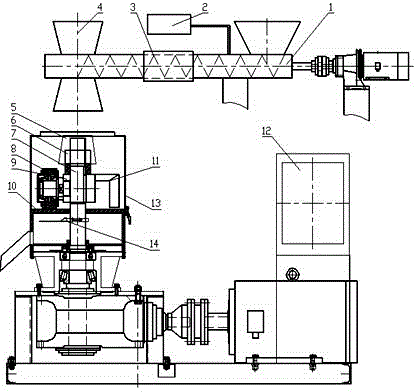

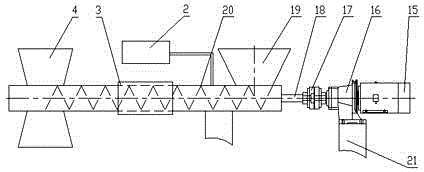

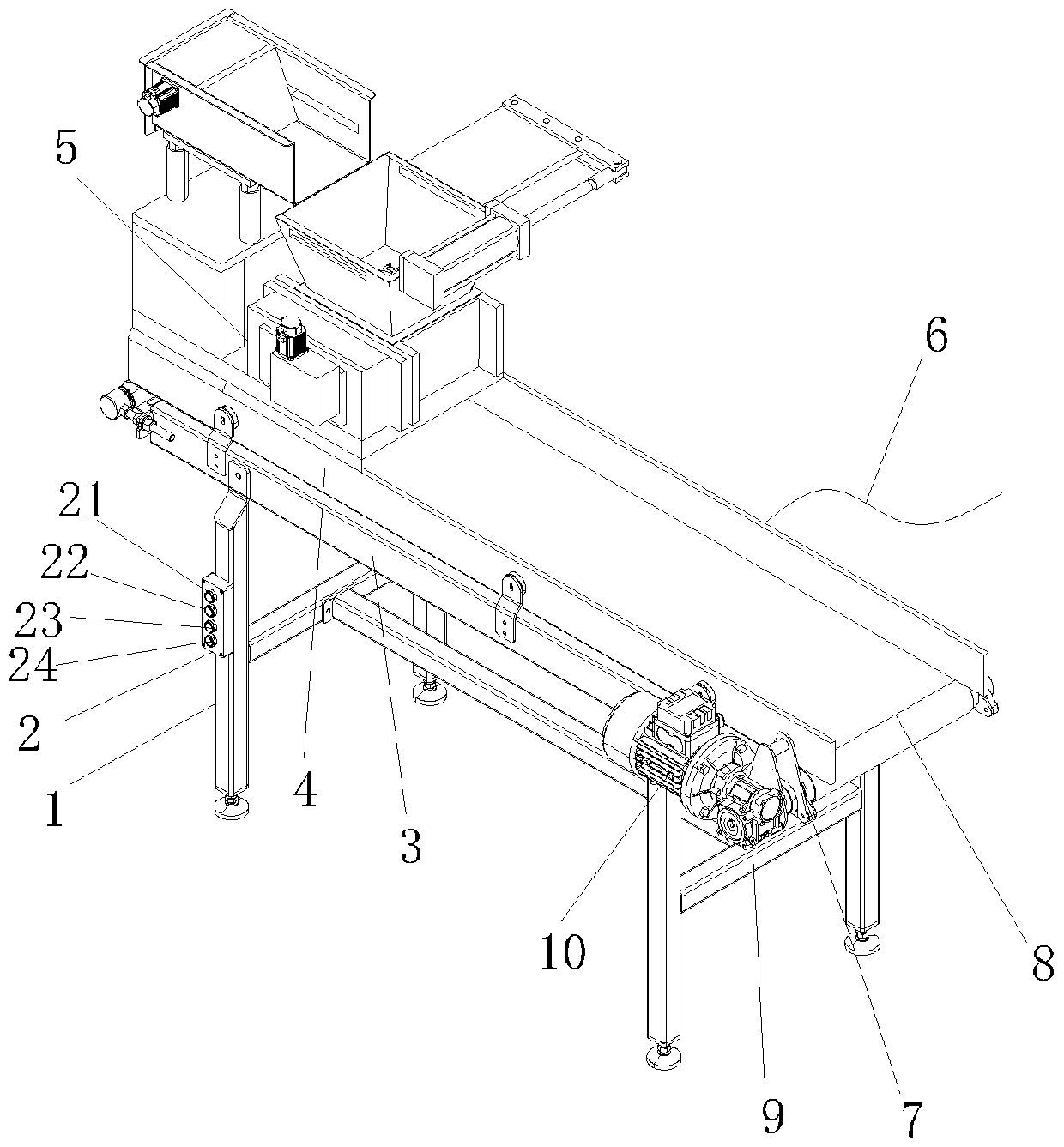

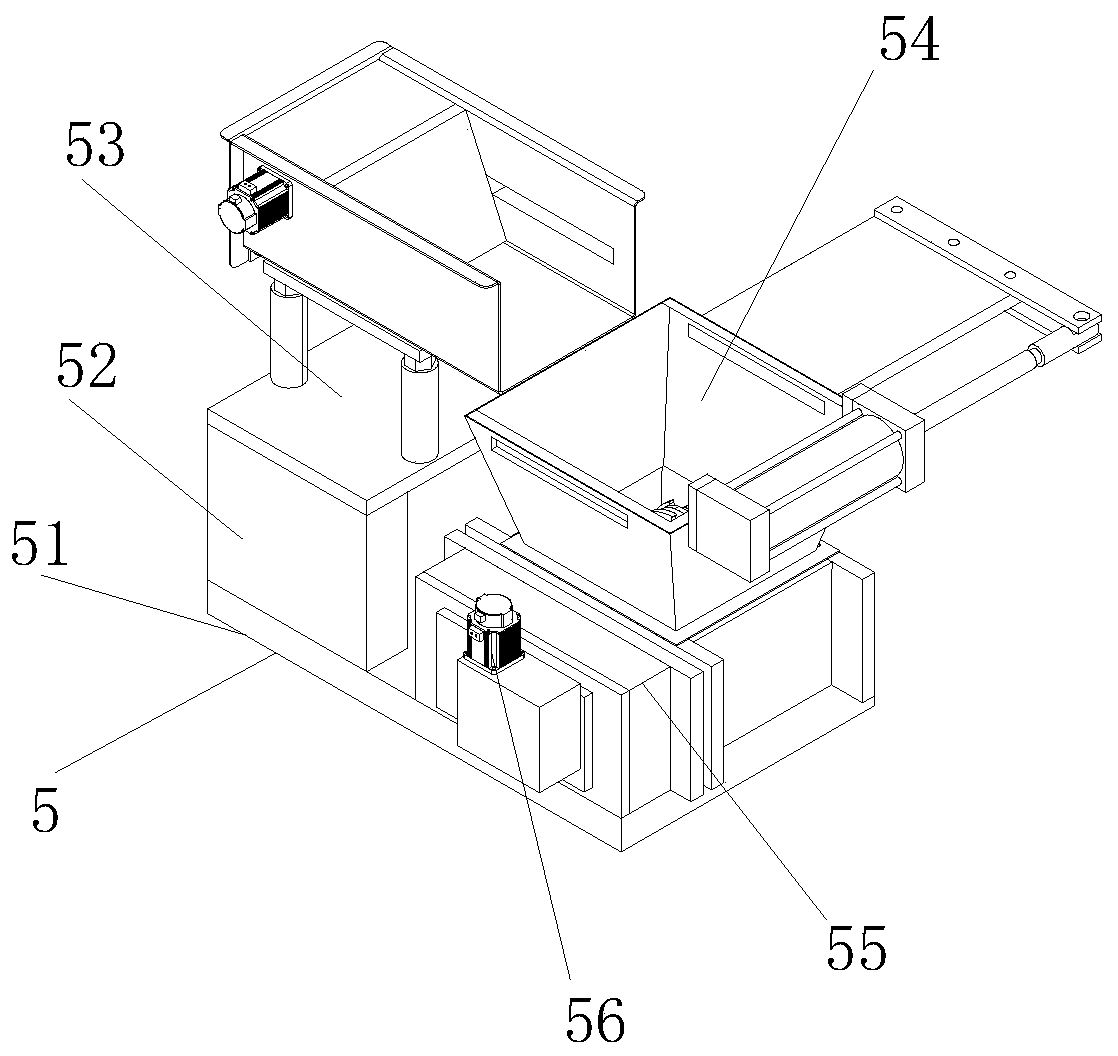

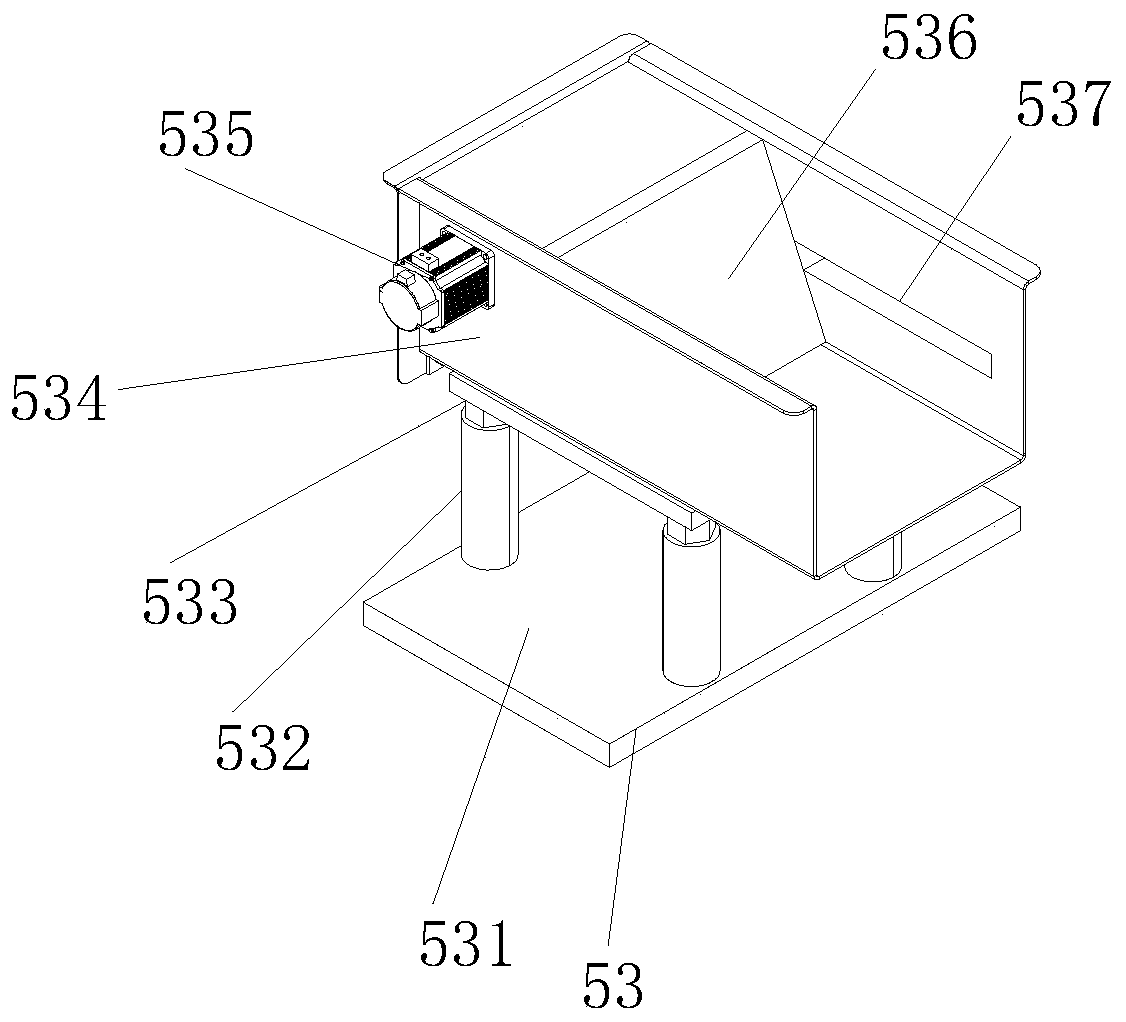

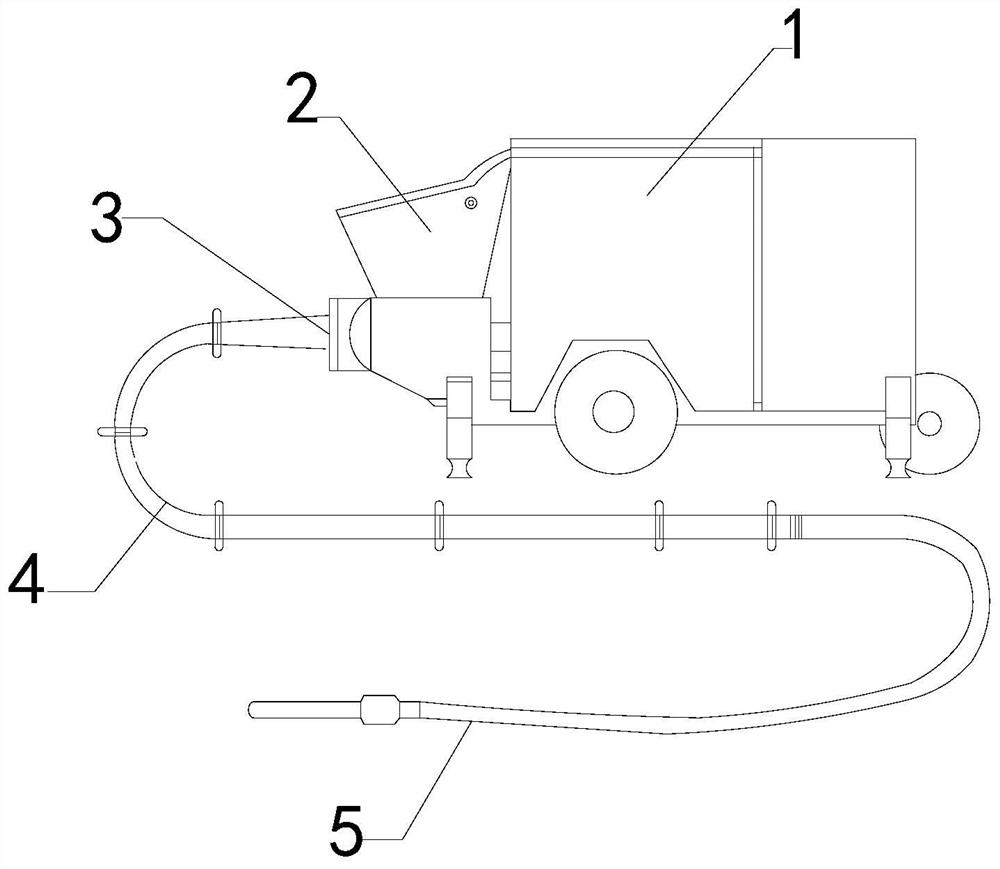

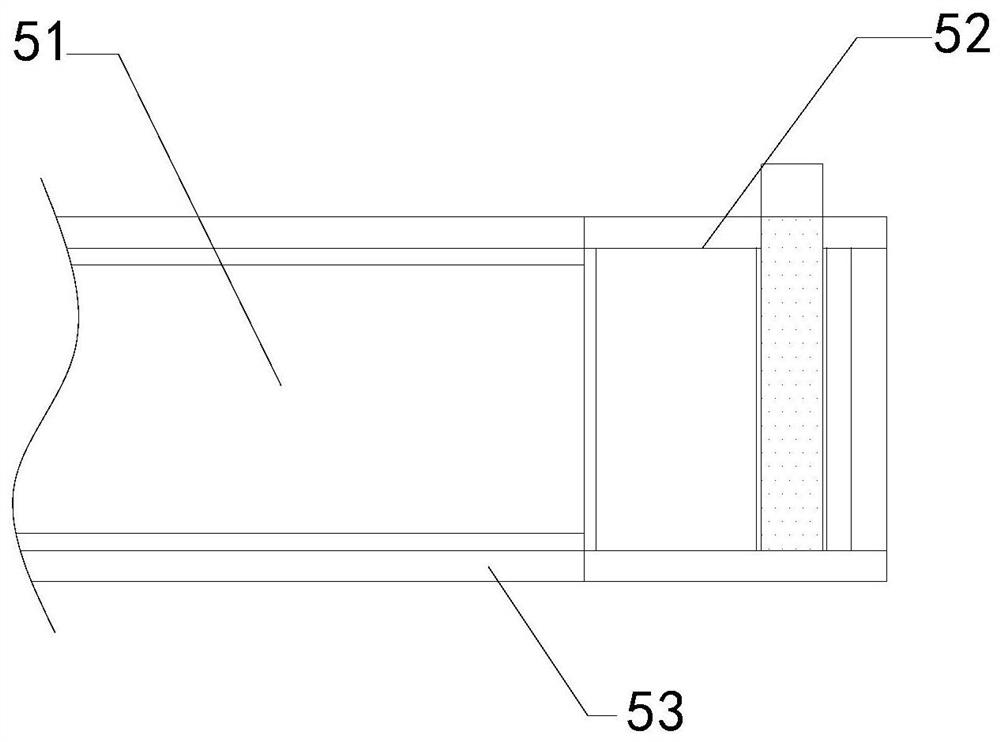

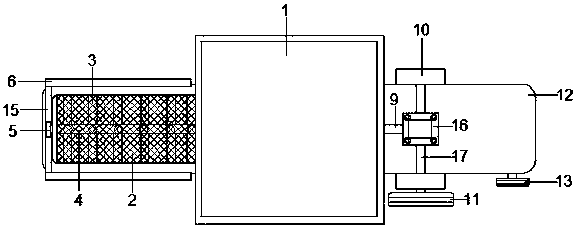

Flat-mold biomass granulating apparatus with raw material pre-optimization function

ActiveCN104959076AEasy to splashEvenly distributedGranulation by pressingFeed devicesEngineeringPre treatment

The invention discloses a flat-mold biomass granulating apparatus with a raw material pre-optimization function, belonging to the technical field of biological energy machinery. The flat-mold biomass granulating apparatus comprises a granulator and a controller; a material paddle-type conveyer is arranged before the granulator; automatic temperature-adjusting and automatic humidity-adjusting devices are arranged on the paddle-type conveyer; a feed inlet of the granulator is connected with a discharge outlet of the conveyer; the granulator comprises a main shaft; a pressure roller rack is in upward-and-downward sliding connection with the main shaft through keys and provided with a pressure roller shaft which is perpendicular to the direction of the main shaft; pressure rollers are rotatably connected with the pressure roller shaft through bearings; a mold is fixedly arranged below the pressure roller; a self-pressure adjusting device is arranged above and connected with the pressure roller rack; a rotary material distributing device is mounted on the part of the pressure roller rack between two pressure rollers; and a main shaft drive unit is connected with the main shaft. The flat-mold biomass granulating apparatus can pretreat a feed, improves molding speed and molding quality and has reduced dependence on auxiliary equipment.

Owner:ANYANG GEMCO ENERGY MACHINERY

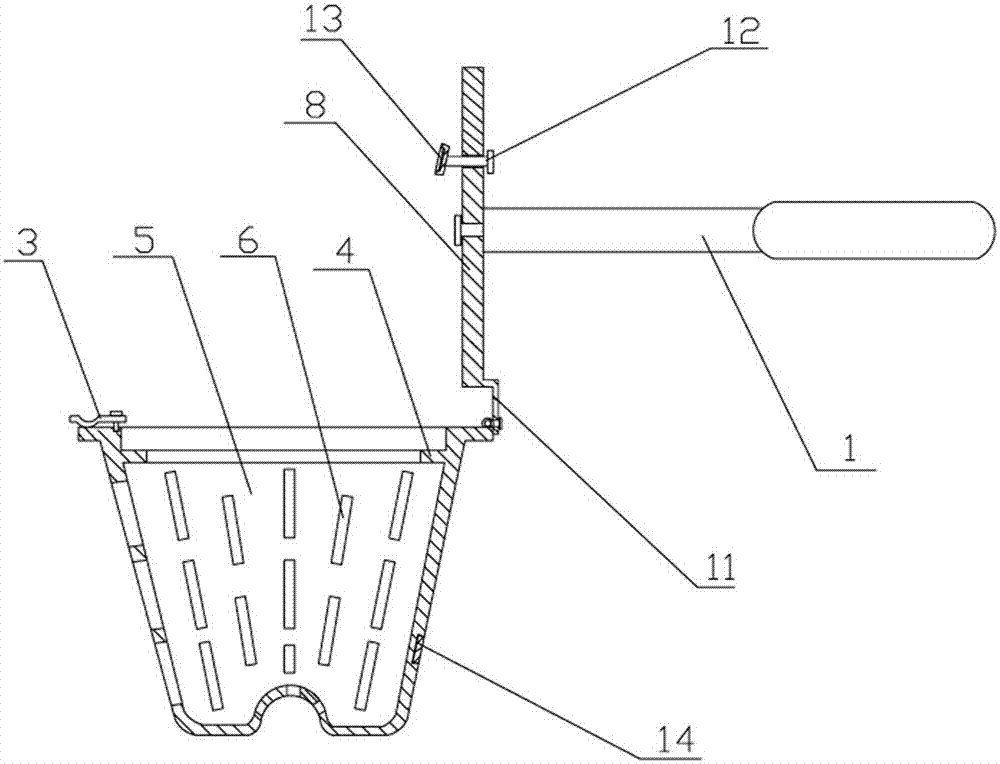

Garlic smashing device

The invention discloses a garlic smashing device. The garlic smashing device comprises a pot body and a garlic hammer, the inner side wall of the pot body is in an inverted conical shape, the garlic hammer comprises a hammer head part and a handle part which is fixed at the upper end of the hammer head part, the hammer head part comprises a hammer body which has a storage cavity and a cover body, the upper end surface of the hammer body is provided with several rotary pressing plates arranged at equal intervals, the inner side wall of the hammer body is provided with an annular boss which is used for supporting the cover plate, one side of the cover body is hinged to the upper end surface of the hammer body cavity, the outer wall of the hammer body is matched with the shape of the inner wall of the pot body, and the outer wall of the hammer body is further provided with several feeding holes which are communicated with the storage cavity and are in strip shapes; the hammer part moves up and down in the pot body to smash garlic, the mashed garlic is squeezed out of the feeding holes in the side wall of the hammer body, then the mashed garlic falls in the storage cavity in the hammer body, when the smashed garlic needs to be poured out, the smashed garlic can be poured out as long as the cover plate is opened through the rotary pressing plates; meanwhile, the residual smashed garlic in the hammer body cavity can be cleaned, and thus the garlic smashing device is very convenient.

Owner:邳州市景鹏创业投资有限公司

Substrate rotation type treatment apparatus

ActiveUS7311781B2Splashing of the hydrophilic treatment liquid is decreasedReduce splashLiquid surface applicatorsPhotomechanical apparatusPlastic materialsBiomedical engineering

An apparatus causes a substrate to rotate and supplies a treatment liquid to a substrate surface to make a treatment, without concern that a mixed substance is eluted from a cup in the use for a long time, or a thin film comes off from an inside wall surface to be contamination-causing substances even if the cup made of a water-repellent material for collecting a treatment liquid becomes hydrophilic. A cup 16 disposed to surround the sides and underside of a substrate W rotating while being held by a spin chuck 10, and serving to collect a treatment liquid diffused from the substrate to the surroundings, is made of a plastic material. Further, an inside wall surface of an upper-side cup part 24 of the cup 16, being a portion on which the treatment liquid having been diffused from the substrate impinges, is roughened to be a hydrophilic surface.

Owner:DAINIPPON SCREEN MTG CO LTD

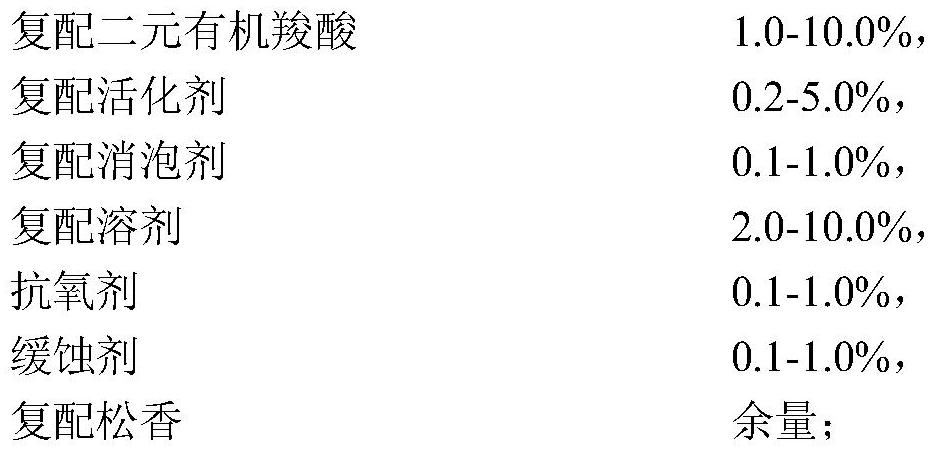

Solder wire soldering flux capable of reducing splashing and preparation method thereof

ActiveCN111906472AStrong viscous resistanceEffective protectionWelding/cutting media/materialsSoldering mediaCompound organicOrganic acid

The invention relates to a solder wire soldering flux capable of reducing splashing and a preparation method thereof. The soldering flux is composed of the following components in percentage by weightof 1.0-10.0% of compound organic acid, 0.2-5.0% of compound activator, 0.1-1.0% of compound defoamer, 2.0-10.0% of compound solvent, 0.1-1.0% of antioxidant, 0.1-1.0% of corrosion inhibitor and the balance of compound rosin. The preparation method comprises the following steps of heating, stirring and melting the compound rosin, adding the compound organic acid and the low-melting-point indissolvable activator, adding the solution dissolved with the high-melting-point dissolvable activator, the antioxidant and the corrosion inhibitor, finally adding the compound defoamer, performing continuous stirring at the constant temperature of 145-165 DEG C, performing full dissolving, and performing uniform mixing, thereby obtaining the soldering flux. The soldering flux is high in activity, easy to tin during welding, low in corrosion, small in residue and high in insulation resistance, the splashing number and the splashing distance of the soldering flux and tin beads in the welding process of a lead-free tin wire can be greatly reduced, the RoHS instruction is met, and the reliability of electronic and electrical products after welding is guaranteed.

Owner:云南锡业新材料有限公司

Coating of austenitic stainless steel electrode, electrode, preparation method and application

ActiveCN112658532AExcellent slag removal performanceArc stabilizationEnergy inputWelding/cutting media/materialsFerrosiliconManganese

The invention discloses a coating of an austenitic stainless steel electrode, the electrode, a preparation method and an application, and solves the problems that the existing electrode is poor in mechanical property and difficult to meet the welding requirement. The raw materials of the coating of the electrode comprise the following raw materials in parts by weight: 7.0-10.0 parts of marble, 0.5-1.5 parts of barium carbonate, 2.0-4.0 parts of fluorite, 3.0-5.0 parts of fluoride, 4.0-6.0 parts of rutile, 0.5-2.0 parts of mica, 0.5-1.5 parts of electrolytic manganese, 0.5-1.5 parts of ferrotitanium, 0.5-1.5 parts of ferrosilicon, 3.0-5.0 parts of ferrochromium, 3.0-5.0 parts of metallic nickel, 0.0-1.5 parts of ferro-molybdenum, 0.5-1.0 part of nitride ferrochrome sodium carbonate and 0.2-0.5 part of sodium carbonate. The electrode further comprises an iron-chromium-nickel-molybdenum-manganese-nitrogen alloy core wire. The coating has the advantages of excellent mechanical properties of deposited metal, capability of meeting the special requirements of required welding and the like.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

A Piezoelectric Integrated Nozzle for Electrofluid Printing

The invention relates to the field of electrofluid jet printing equipment, in particular to a piezoelectric type integrated spray head used for electrofluid jet printing. The piezoelectric type integrated spray head comprises an outer bracket, a piezoelectric structure, a spray head, a lower electrode supporting ring and a lower electrode ring, wherein the piezoelectric structure is positioned above the spray head; an upper electrode is arranged on the upper part of the spray head; the lower electrode supporting ring and the lower electrode ring are sequentially arranged below the spray head; after the piezoelectric structure, the upper electrode and a lower electrode are electrified, electric fields are formed between the spray head and the lower electrode ring, so that a solution forms Taylor cones on the spray head. The piezoelectric type integrated spray head overcomes the defect that existing electric jet printing equipment cannot meet high-frequency spraying, can realize high-frequency high-resolution printing; and the lower electrode is integrated to the spray head end, so that the whole jet printing system is more flexible, and a base plate with a complex shape can be used to print. The piezoelectric type integrated spray head further has the advantages of being simple in structure, low in manufacturing cost, suitable for large-scale production and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Movable type spot welding machine capable of reducing welding slag splashing

Disclosed is a movable type spot welding machine capable of reducing welding slag splashing. The movable type spot welding machine capable of reducing welding slag splashing comprises a welding transformer, an air cylinder and a connecting disc. A rear cover is fixedly installed on the outer surface of one side of the welding transformer, an auxiliary handle is fixedly installed on the outer surface of the lower end of the welding transformer, and a cable is fixedly installed on the outer surface of one side of the rear cover. An air valve is fixedly installed on the outer surface of one sideof the air cylinder, and a handle is fixedly installed on the outer surface of the upper end of the air cylinder. A welding button and an auxiliary stroke button are arranged on the outer surface of the lower end of the handle, and the welding button is arranged on one side of the auxiliary stroke button. According to the movable type spot welding machine capable of reducing welding slag splashing, due to the fact that the auxiliary handle, power arms and rubber gaskets are arranged, usage and movement of the spot welding machine can be facilitated, welding arms can tightly press a workpiece,welding slag splashing is reduced, the phenomenon that due to the fact that an electrode tip is excessively stressed, the damage is caused can also be avoided, and the better application prospect canbe achieved.

Owner:绍兴意诺贸易有限公司

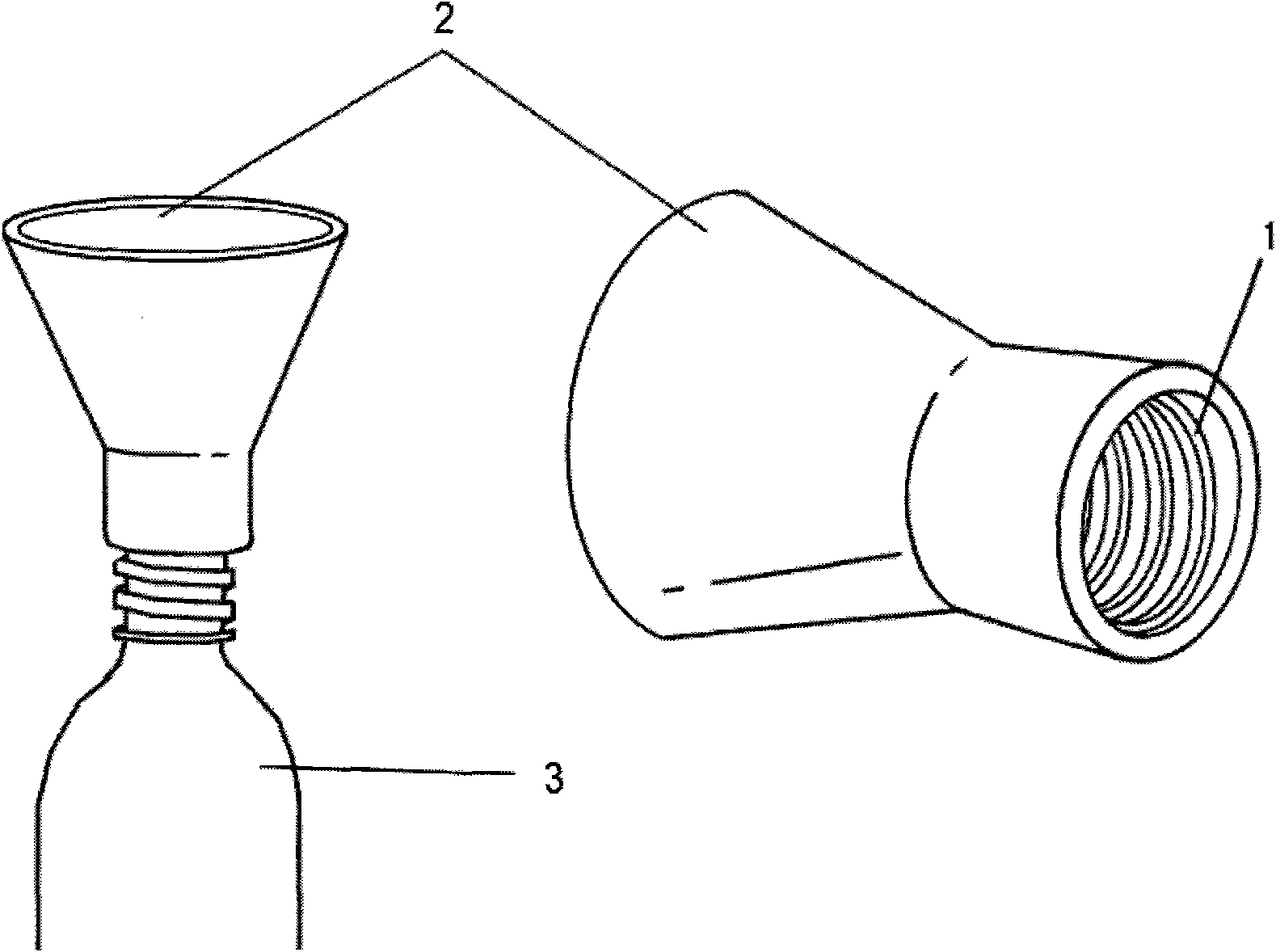

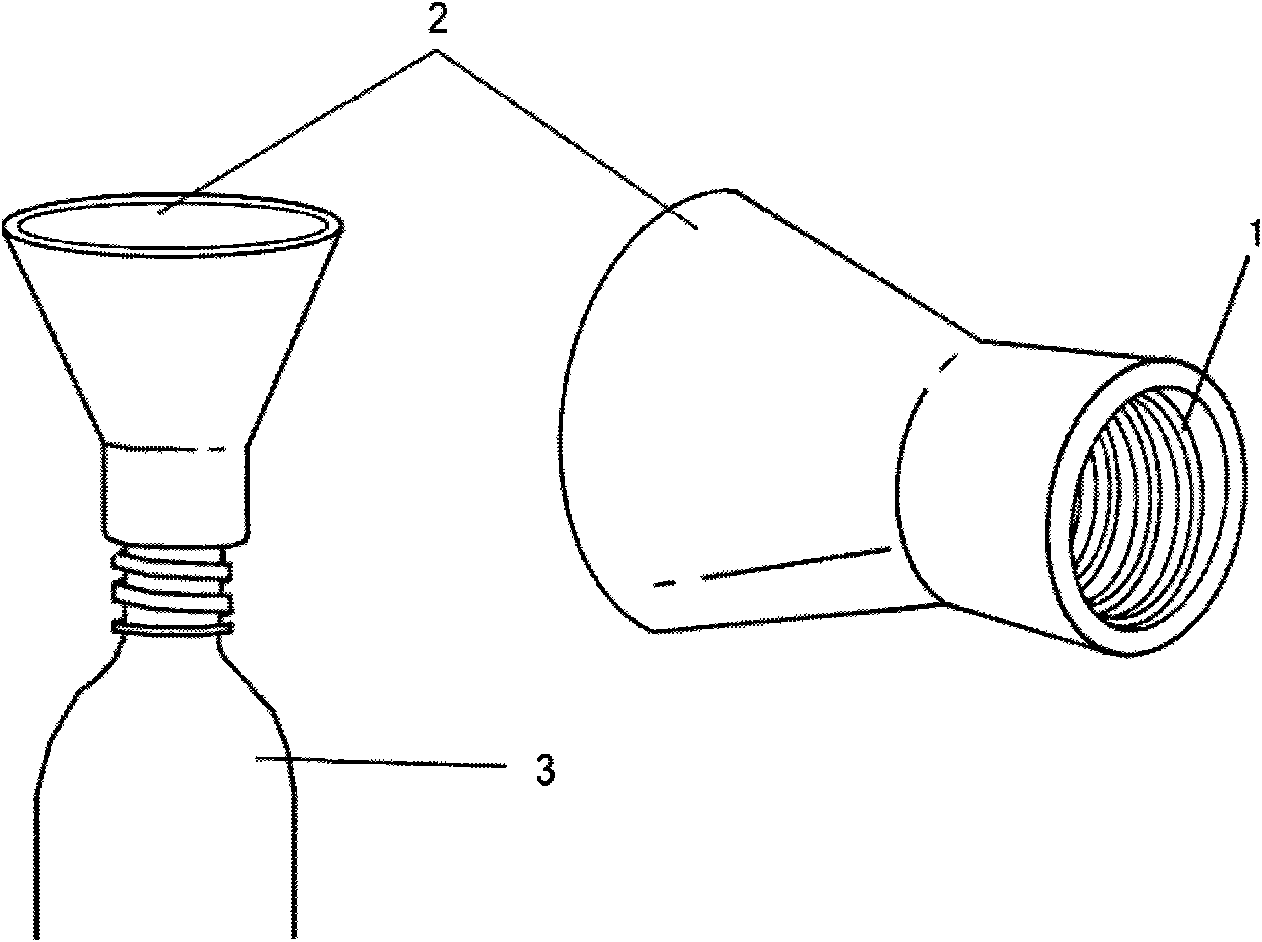

Flexible universal threaded funnel

The invention relates to a flexible universal threaded funnel which is a flexible mechanism made of an elastic material. The smaller opening at one side of the flexible universal threaded funnel is provided with a threaded part which can be matched with the standard threaded bottleneck of a universal mineral water bottle, and the bigger opening for the pouring of liquid is at the other side.

Owner:NANTONG XINYING DESIGN SERVICE

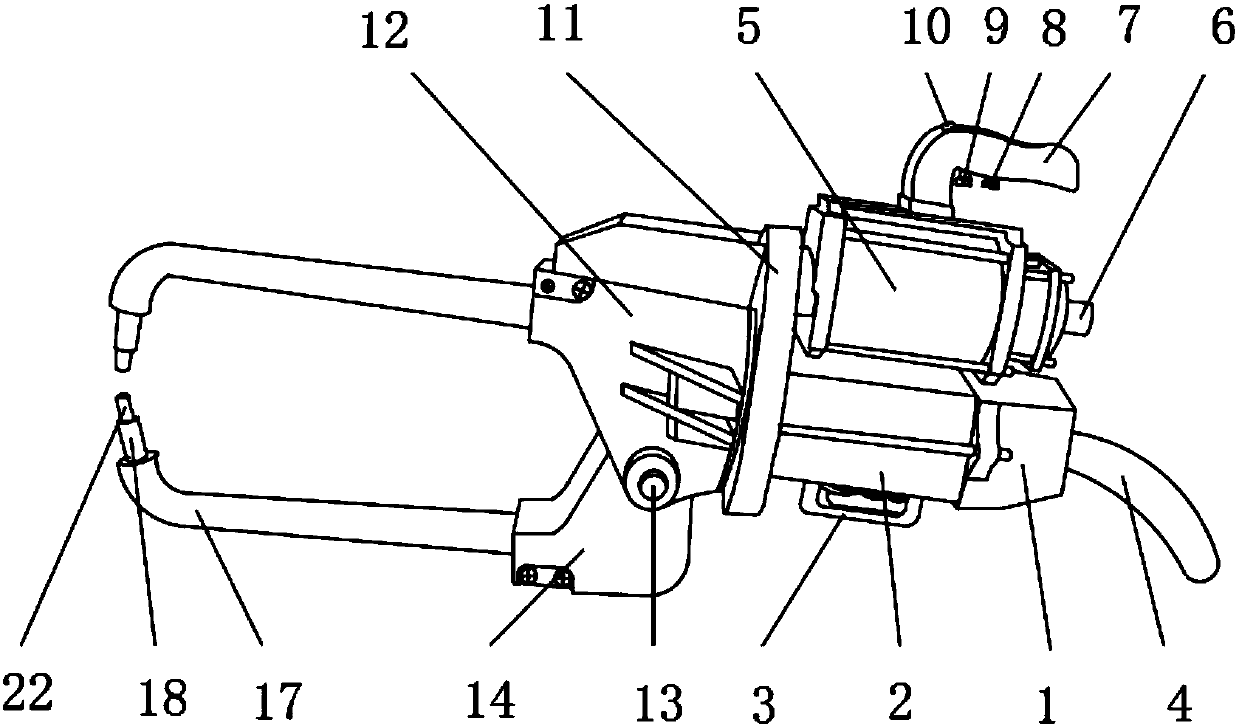

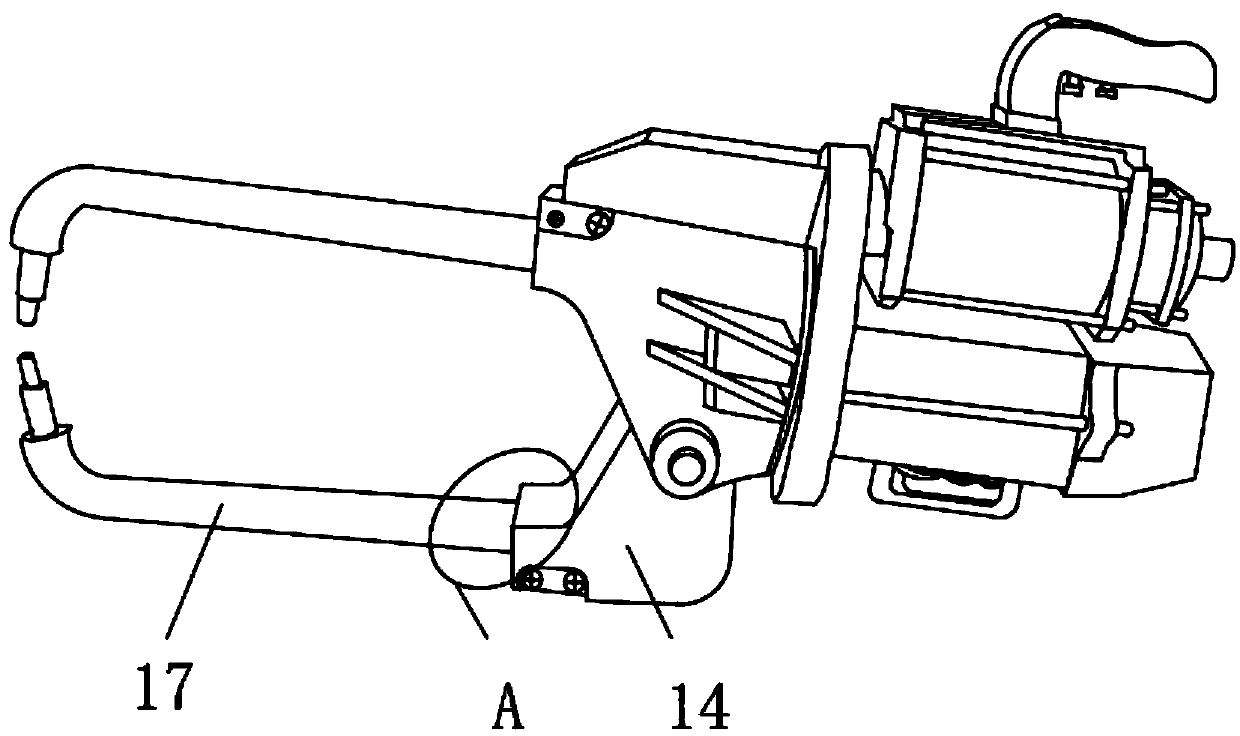

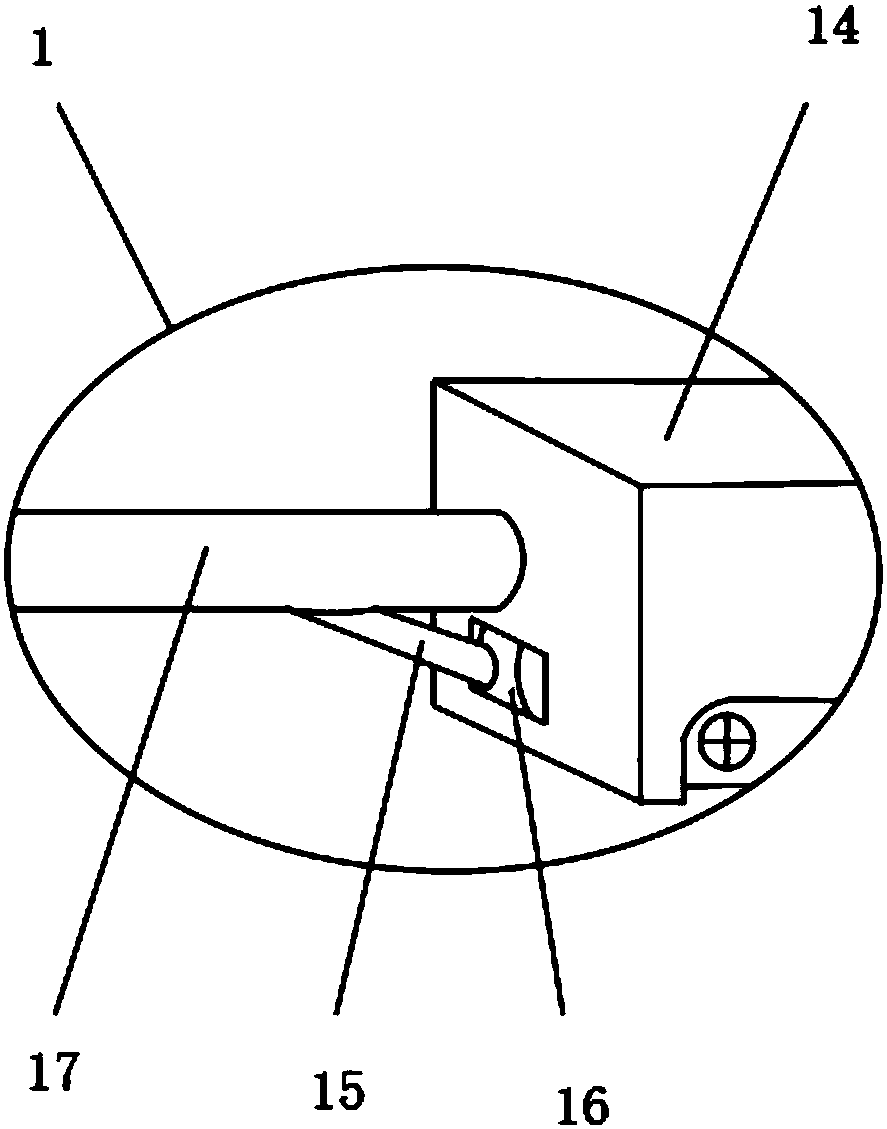

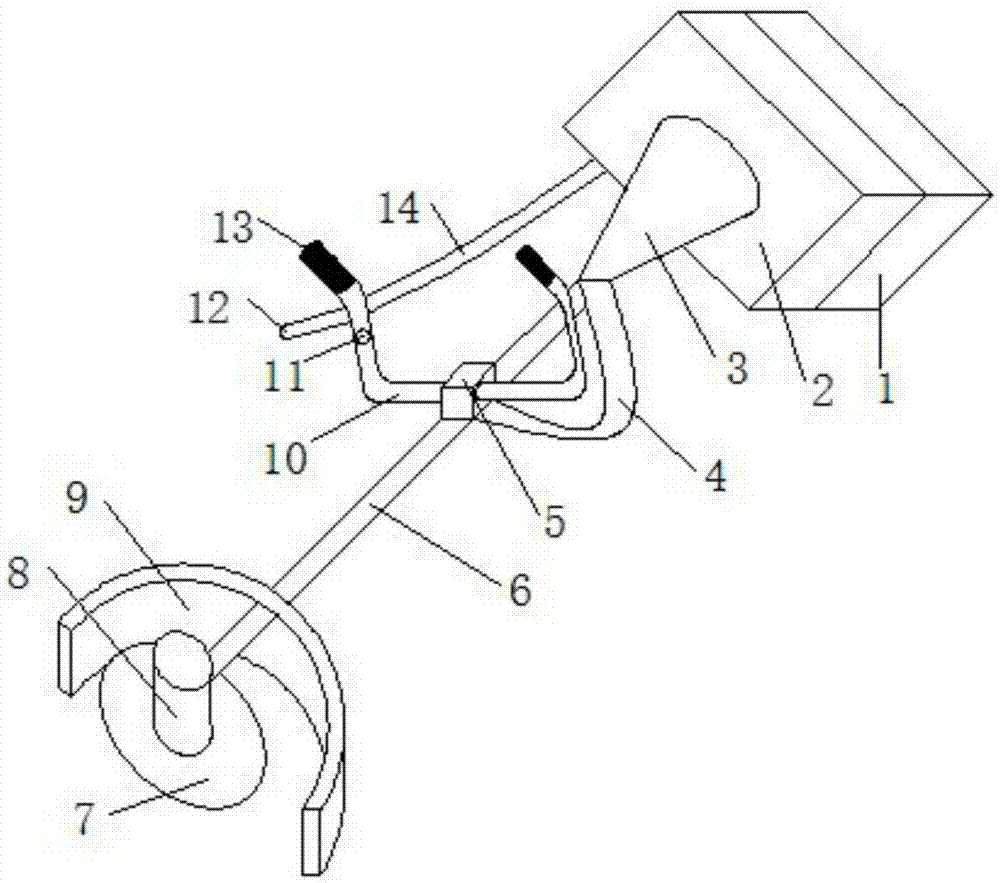

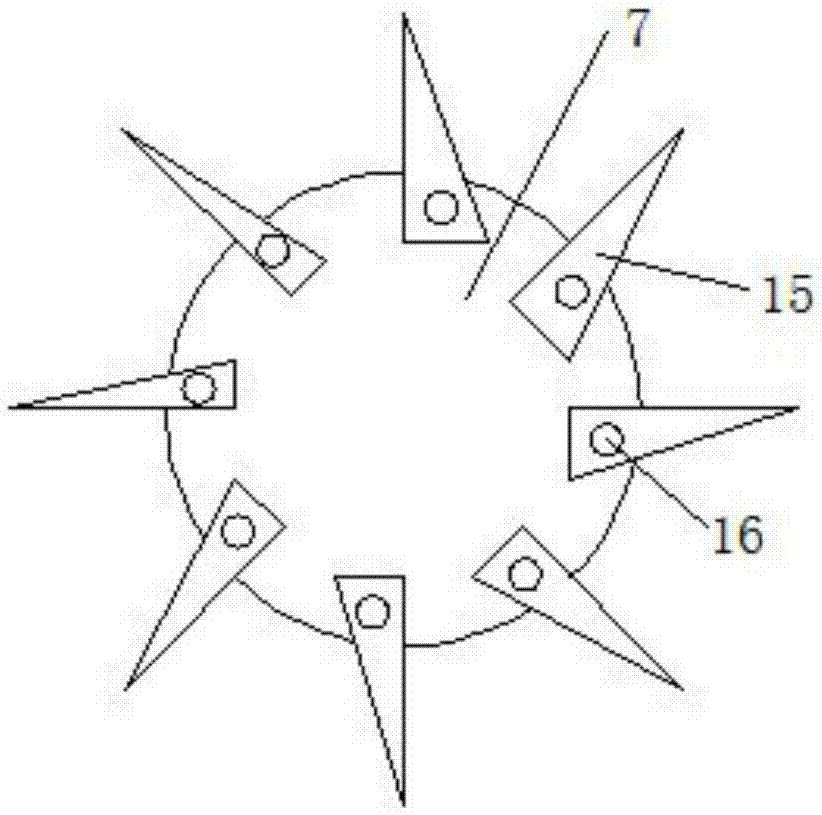

Shoulder hung type mower

The invention discloses a shoulder-mounted lawnmower, which comprises a gasoline engine, an output seat, a fixed seat, a gear box, and a handrail. The guide rod is fixedly installed on the fixed seat, and the upper end of the guide rod is fixedly installed with an output seat. A gasoline engine is fixedly installed on the output seat, an oil tank is provided on one side of the gasoline engine, the bottom end of the guide rod is fixedly connected with the gear box, and the gear box is fixedly connected with the blade wheel through the transmission shaft, and the handrail passes through The fixed seat is fixedly installed on the fixed seat, and the armrest is provided with an ignition switch and a throttle controller, and the throttle controller is connected with the gasoline engine through a throttle line, and a strap is arranged between the fixed seat and the output seat. The shoulder-mounted lawn mower is safe, reliable, and easy to maintain. When people want to leave, lift the handle up, and the throttle controller will not be pressured, and the throttle cable will be tightened, so the lawn mower is in a standby state. The utility model has the advantages of simple structure, small volume, reasonable design, low energy consumption and easy popularization and use.

Owner:重庆正柱电子工程有限公司

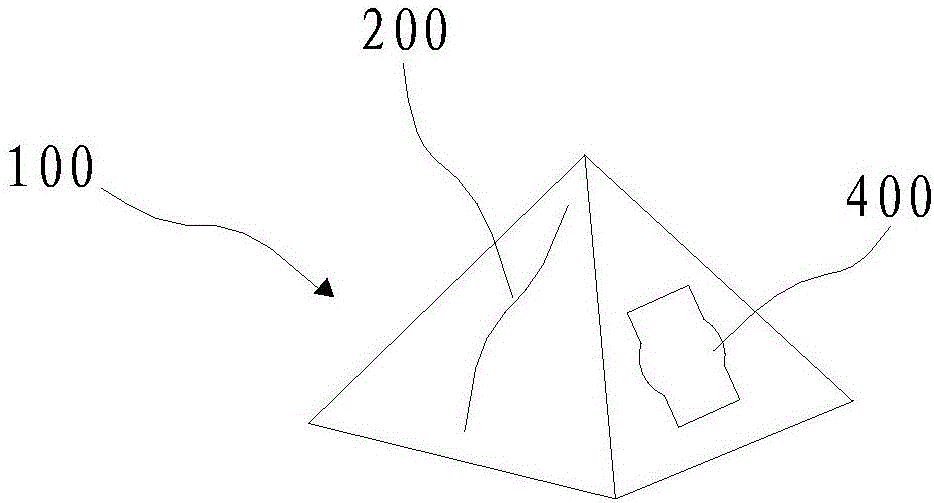

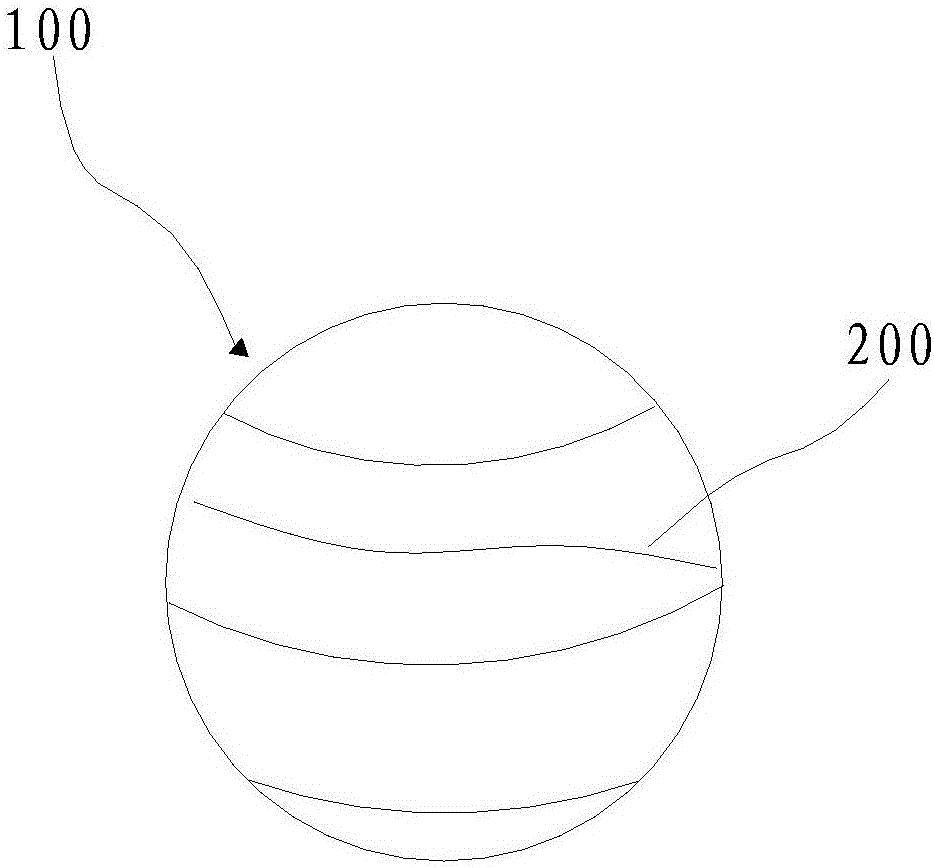

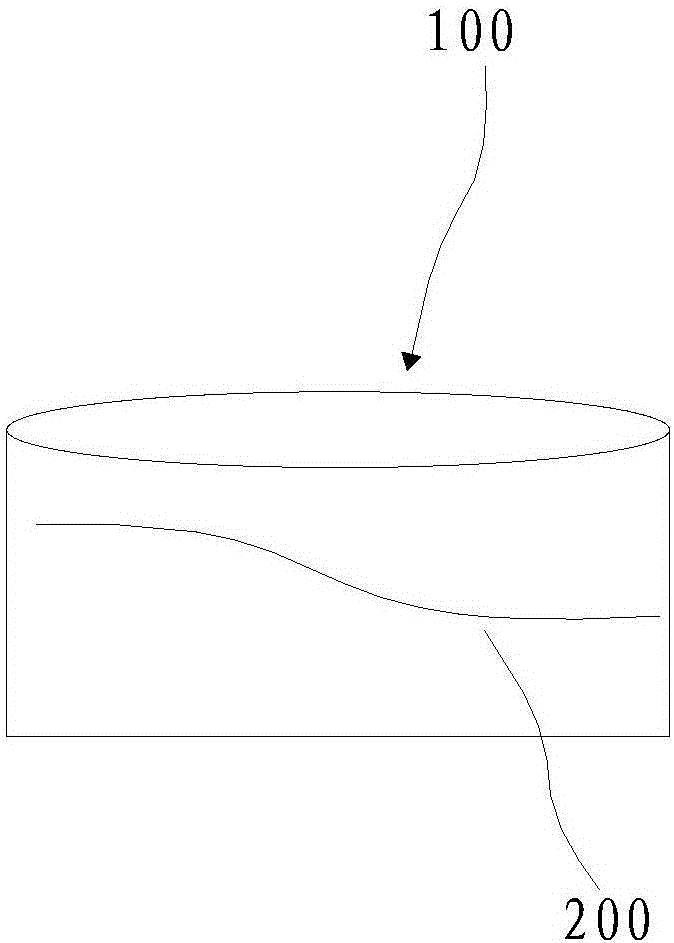

Splash-proof particle and splash-proof method of splash-proof particle

The invention discloses a splash-proof particle and splash-proof method of splash-proof particle, comprising the particle itself, wherein the particle itself comprises at least one dirt bearing portion and at least one part; the dirt bearing portion and cladding portion are connected with each other to form a joint portion. When the particle itself is in the non-service state, the cladding portion wraps the dirt bearing portion to form a compressed structure; when the particle itself is in the service state, the cladding portion and dirt bearing portion unfold and form a splash-proof structure relative to the joint portion. Where it is necessary to use the splash-proof particle, the splash-proof particle is put in to closestool when the cladding portion and dirt bearing portion expand in water. Subsequently, the splash-proof structure is unfolded and formed relative to the joint portion, floating on the surface of water. Thereby, the splash-proof particle and splash-proof method of splash-proof particle exerts the function of holding excreta so as to prevent water from splashing and staining user's body and realize good splash-proof effects. Besides, the splash-proof particle is simple in method of application, low in cost, clean and healthy.

Owner:杨旭东

Conveying mechanism for waste plastic machining machine

InactiveCN111217115AReduce deliveryThe conveying mechanism is improved by installing a pretreatment on the left end of the top of the guard plateConveyorsLoading/unloadingReciprocating motionElectric machinery

The invention discloses a conveying mechanism for a waste plastic machining machine. The conveying mechanism for the waste plastic machining machine comprises a support. According to the conveying mechanism for the waste plastic machining machine, a pretreatment device is installed at the left end of the top of a protection plate, external charge equipment can be cooperated in the pretreatment device to pretreat conveyed waste plastics, and large plastics are broken to reach a uniform size, and then are conveyed by a conveying belt; a feeding mechanism is arranged at an upper end in the pretreatment device, and controlled by an independent motor, the motor enables a belt wheel to transmit, then a push mechanism installed inside is enabled to carry out reciprocating motion, so that materials are stably pushed off in a reciprocating manner, and cannot be discharged in one process to be treated; and a breaking mechanism is arranged at the right end of the pretreatment device, a stopping mechanism is installed on the breaking mechanism, and when the breaking mechanism receives and breaks the materials, the plastics are liable to splash during breaking, and the stopping mechanism is capable of stopping the top of the breaking mechanism, and preventing the occurrence of safety accidents due to the splashing of the plastics.

Owner:肖贤通

High-strength anti-cracking aluminum alloy welding wire for welding joint

InactiveCN107214432AHigh yield strengthHigh hardnessWelding/cutting media/materialsSoldering mediaUltimate tensile strengthImpurity

The invention discloses a high-strength anti-cracking aluminum alloy welding wire for a welded joint. The high-strength anti-cracking aluminum alloy welding wire comprises, by mass, Mg, B, Li, Cu, Si, Ti, Cr, Mn, Fe, V, Sr, Na, Zr, Nb, Mo, Pr, Ce, Nd, and the balance Al and inevitable impurities. The high-strength anti-cracking aluminum alloy welding wire for the welded joint, provided by the invention, is reasonable in component, little in splash in the welding process, compact in deposited metal structure and free of pores and cracks. The welded joint has the advantages of high strength, good anti-cracking property, large base metal bonding strength and the like. The overall performance of a metal component is improved.

Owner:安徽飞弧焊业股份有限公司

Gas flow rate survey meter based on tunable diode laser absorption spectroscopy technology

ActiveCN102135547BImprove spatial resolutionHigh measurement accuracyAbsorption/flicker/reflection spectroscopyFluid speed measurementData acquisitionNon invasive

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Tunnel construction equipment

ActiveCN111720144AReduce impactAvoid deformationUnderground chambersTunnel liningArchitectural engineeringAgitator

The invention discloses tunnel construction equipment. The tunnel construction equipment structurally comprises a motor box, a stirrer, a connecting pipe, a connecting pipe and a spray head mechanism,the spray head mechanism is provided with a flowing pipe, a movable mechanism and a smooth wall, a concrete mixture flows in the flowing pipe, so that a spring rod is compressed, the impact force ona rotation mechanism is reduced, the deformation caused by excessive impact on a valve is avoided, the valve slides during impact, the inertia force of the concrete mixture is buffered, so that the impact force on the valve is reduced, when the concrete mixture impact a rotating mechanism in the rotation mechanism, a force strip is acted, so that a bent guide plate is stressed, an acting force angle of a rotating plate is consistent, the rotating plate rotates by taking a rotating shaft as a center point under the repulsive force of a magnetic block, the impact force is decelerated while rotating, the concrete mixture is prevented from forming rebound force, the internal impact is prevented, and the concrete mixture of the stirrer is prevented from splashing easily.

Owner:湖南启力隧道机械有限公司

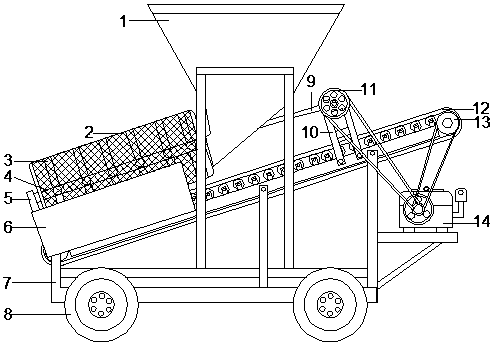

Sand sieving equipment for buildings and working method thereof

The invention relates to the technical field of building instruments and particularly relates to sand sieving equipment for buildings and a working method thereof. The sand sieving equipment comprisesa hopper, a filter sieve, a support rod, a rotating shaft, a bearing pedestal, a baffle, a main body, a moving wheel, a first transmission shaft, a mounting rack, a first transmission wheel, a conveyor belt, a second transmission wheel, a diesel engine, a cross rod, a transmission box and a second transmission shaft, wherein the hopper is supported in the middle part of the top of the main body,and the conveyor belt is arranged on the main body below the hopper; the second transmission shaft is mounted above one side of the conveyor belt through the mounting rack, and the first transmissionwheel is mounted at one end of the second transmission shaft; and the transmission box is arranged in the middle part of the second transmission shaft, and one end of the first transmission shaft is connected with the second transmission shaft through the transmission box. Through structural improvement, the sand sieving equipment has the advantages that the sand sieving efficiency is high, the labor intensity of workers is reduced, and a large quantity of fine sand can be supplied, so that the problems and defects of the existing devices are effectively solved.

Owner:陈彬

Electric welding electrode

InactiveCN101559542ASimple welding processStable welding processWelding/cutting media/materialsSoldering mediaCopperImpurity

The invention discloses an electric welding electrode which consists of a welding core, a copper pipe and a coating from inside to outside. The welding core, the copper pipe and the coating account for the following percentages of the total mass of the electric welding electrode respectively: 36 percent to 40 percent; 33 percent to 37 percent; and 23 percent to 31 percent. The welding core is made of H08A steel and the coating is the coating of a J422 welding electrode; the components of the copper pipe are as follows (account for percentages of the total mass of the copper pipe): 0.21 to 1.34 percent of C; 1.28 to 3.59 percent of Mn; 0.53 to 0.98 percent of Ni; 0.38 to 0.7 percent of Si; 0.32 to 0.7 percent of Cr; 0.86 to 2.7 percent of P; 0.075 to 0.09 percent of S; and the balance of Cu and unavoidable impurities.

Owner:张好文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com