Lubricating structure for OHC engine

一种润滑结构、发动机的技术,应用在发动机元件、阀附件的润滑、机器/发动机等方向,能够解决飞溅、难滑油、滑油不充分等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

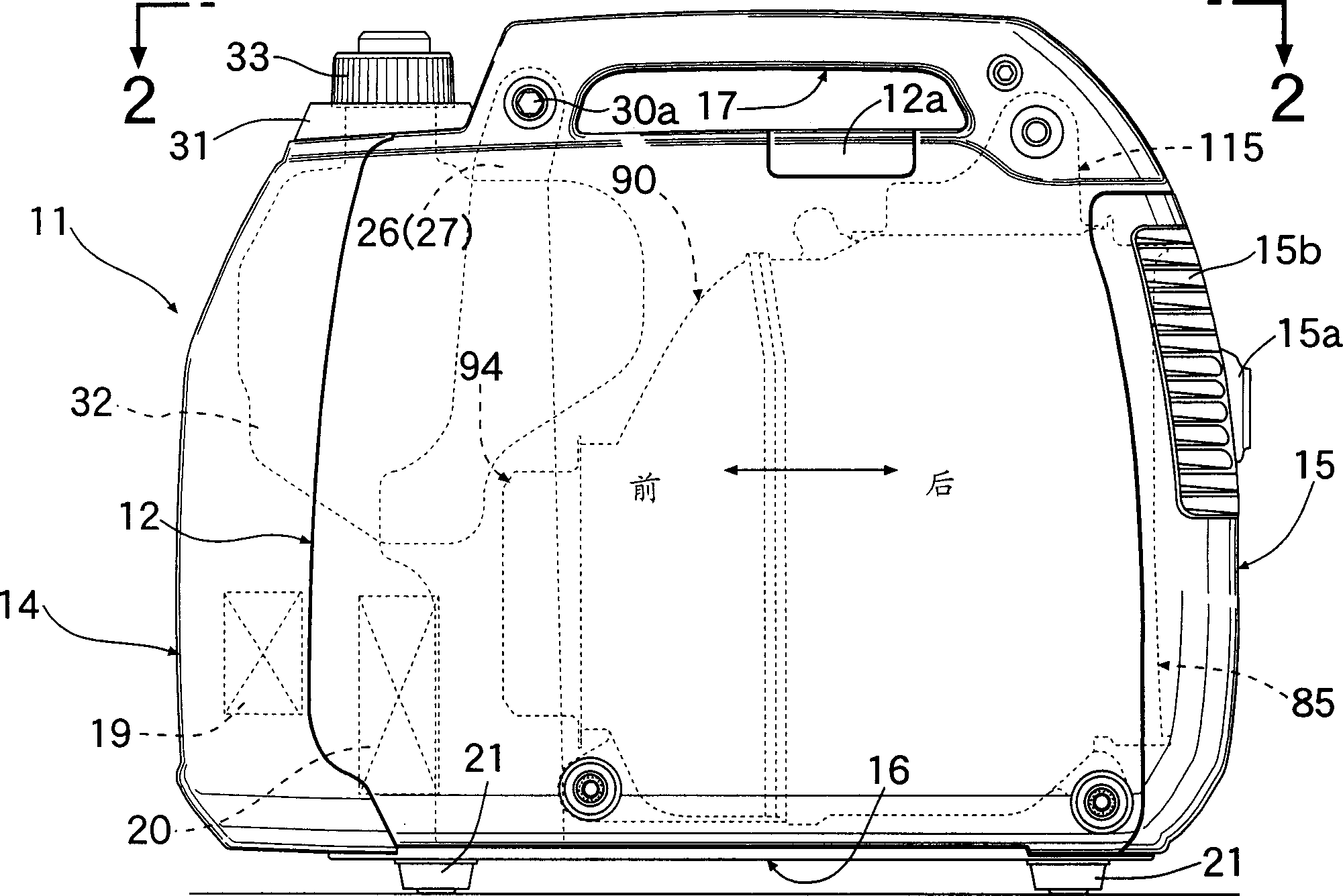

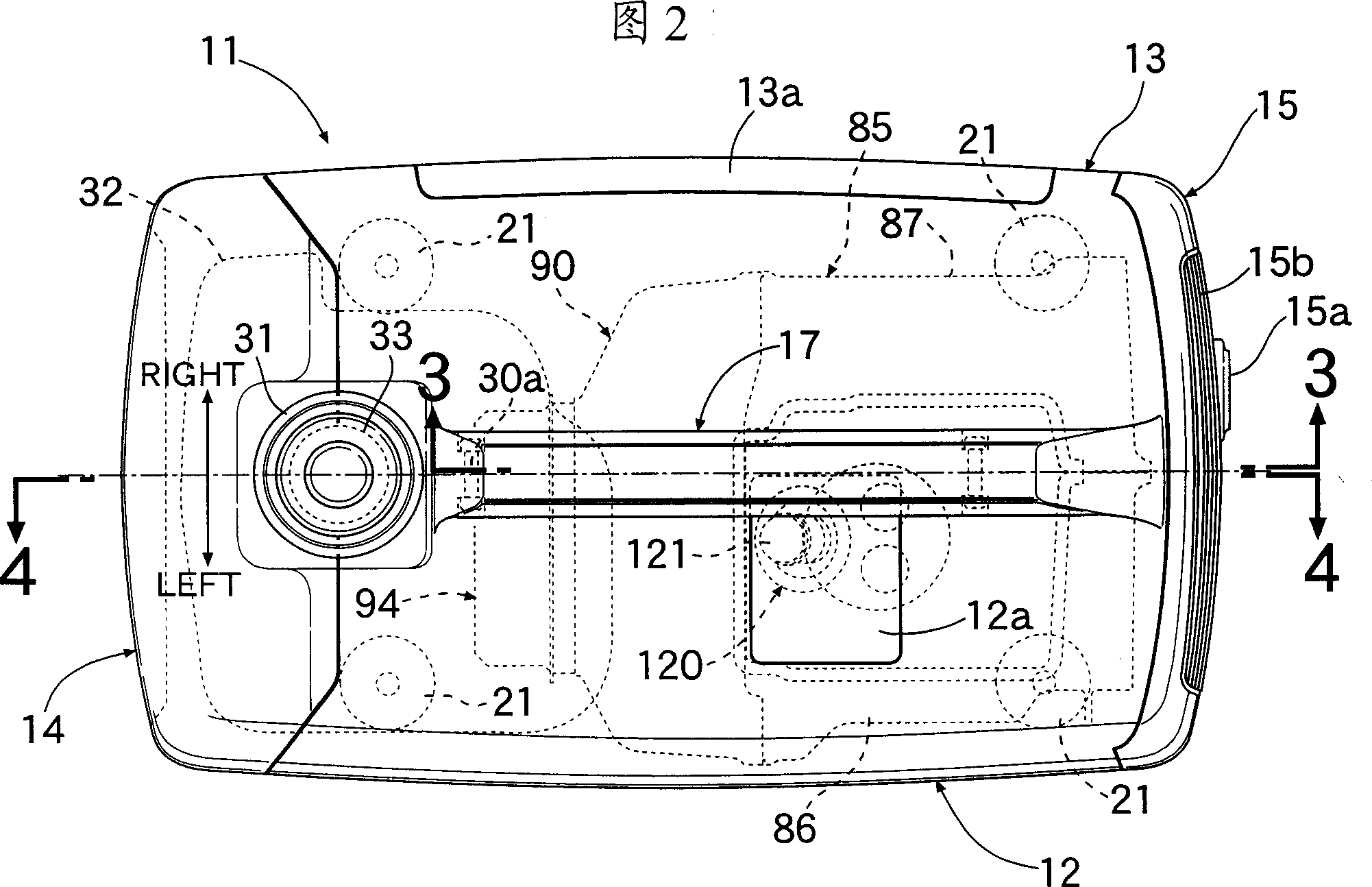

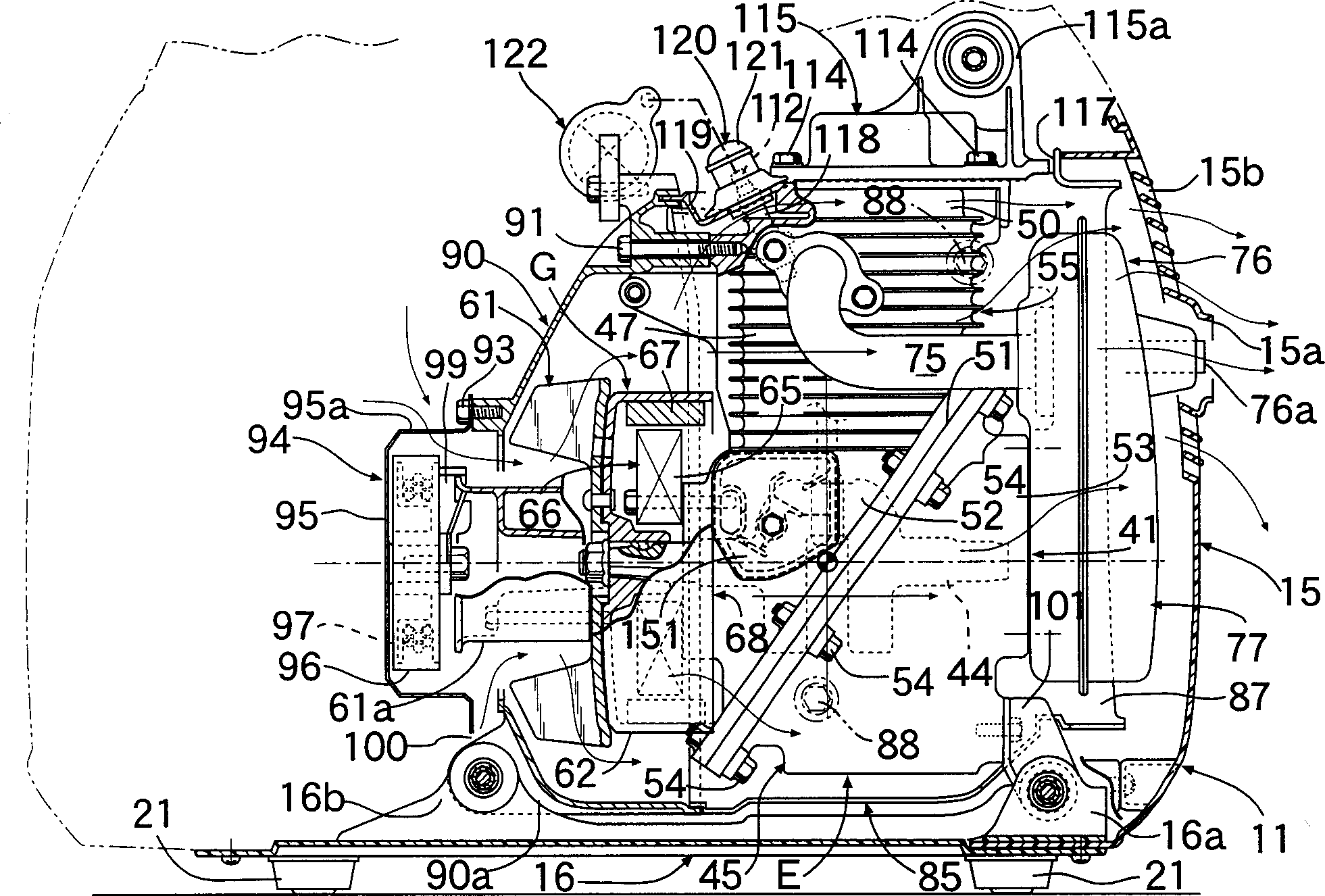

[0026] The following will refer to Figures 1 to 14 An embodiment of the present invention will be described. refer to figure 1 To 4, the synthetic resin casing 11 forms the housing of the portable engine generator set, which is a portable engine-driven machine. The casing 11 is formed of a left side cover 12 , a right side cover 13 , a front cover 14 , a rear cover 15 , and a bottom cover 16 connected to each other. There is a carrying handle 17 on the top of the left and right side covers 12 and 13, so as to carry the engine generator set. Radial reinforcement ribs 17a are formed in the carrying handle 17 as shown in FIG. 4 .

[0027] The left side cover 12 has a cap 12a which can be opened and closed for spark plug replacement. The right side cover 13 has a cap 13a which can be opened and closed for maintenance. The front cover 14 has a control panel 18 . On the inner surface of the control panel 18 is a control unit for controlling the operation of the engine E and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com