Tunnel construction equipment

A tunnel construction and equipment technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as easy splashing of concrete mixture, increased impact force of valves, deformation of closed valves, etc., to avoid deformation, reduce impact force, and prevent impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] like Figure 1-Figure 5 Shown:

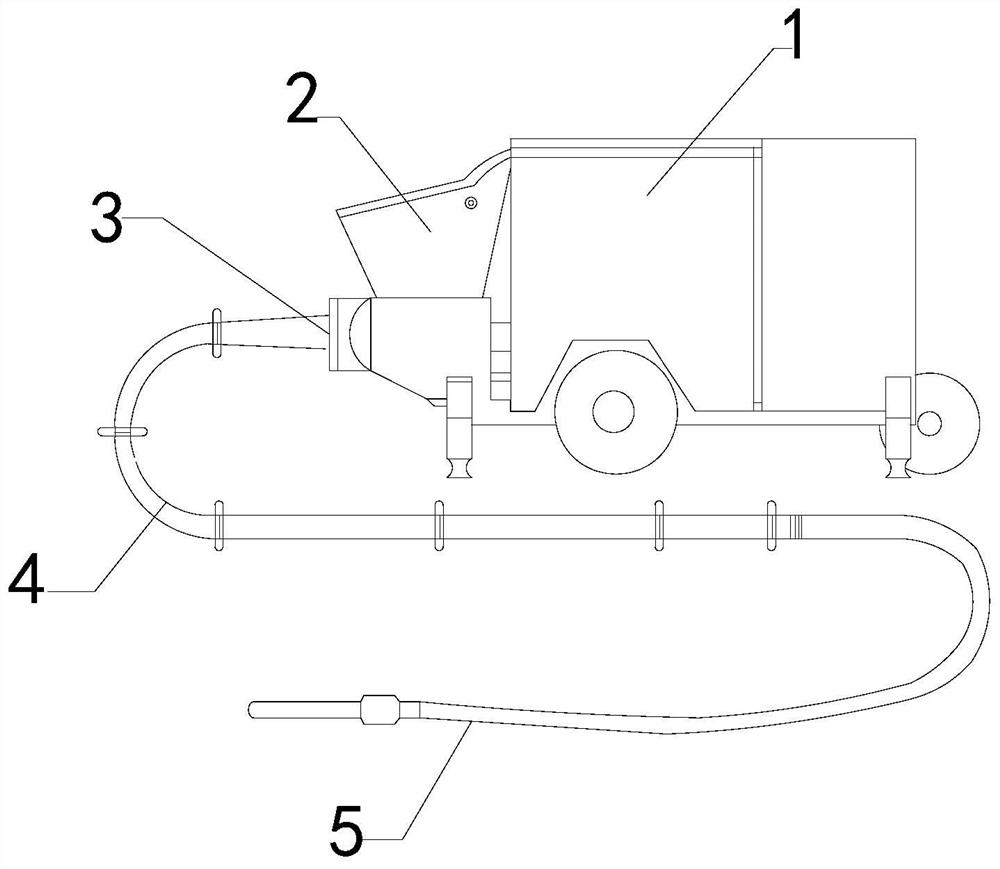

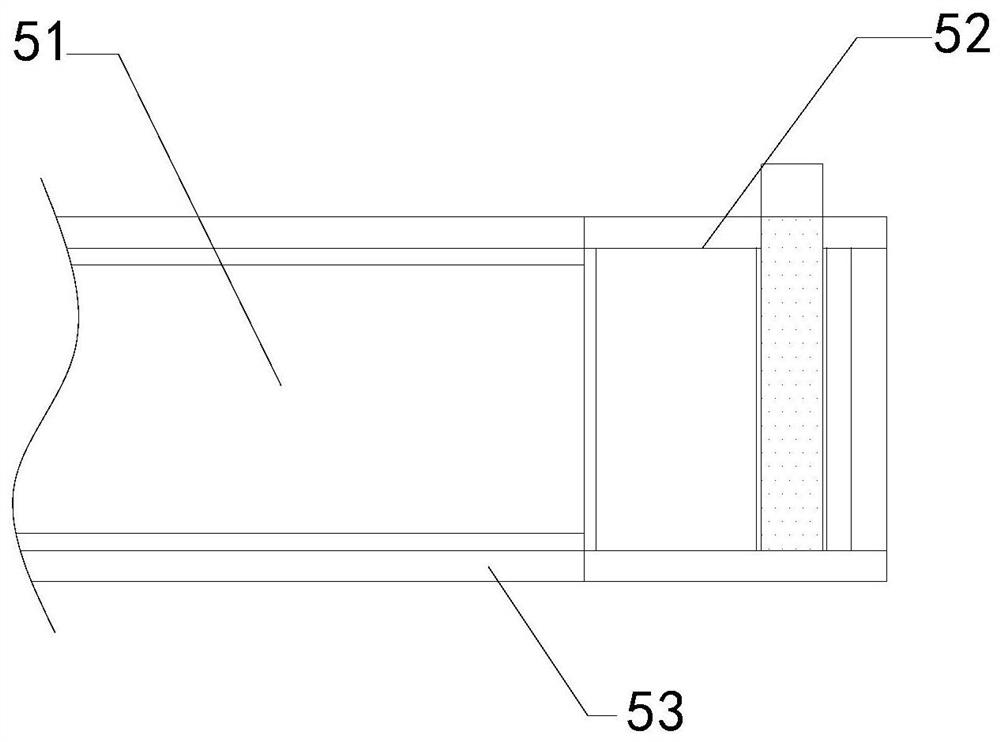

[0024] The present invention is a kind of tunnel construction equipment, its structure comprises motorized box 1, agitator 2, connecting pipe 3, transfer pipe 4, nozzle mechanism 5, described agitator 2 is installed on the left side of motorized box 1, and described connecting pipe 3 Connected to the lower end of the agitator 2, the transfer pipe 4 is embedded on the outside of the connecting pipe 3, the nozzle mechanism 5 is connected to the outer end of the transfer pipe 4, and the nozzle mechanism 5 is provided with a flow pipe 51 and a movable mechanism 52 , a smooth wall 53, the flow tube 51 is attached to the inside of the movable mechanism 52, the outside of the movable mechanism 52 is attached to the inside of the smooth wall 53, the flow tube 51 is connected to the left end of the transfer pipe 4, and the movable mechanism 52 The surface is equipped with a rotary switch.

[0025] Wherein, the movable mechanism 52 is provided w...

Embodiment 2

[0031] like Figure 6-Figure 7 Shown:

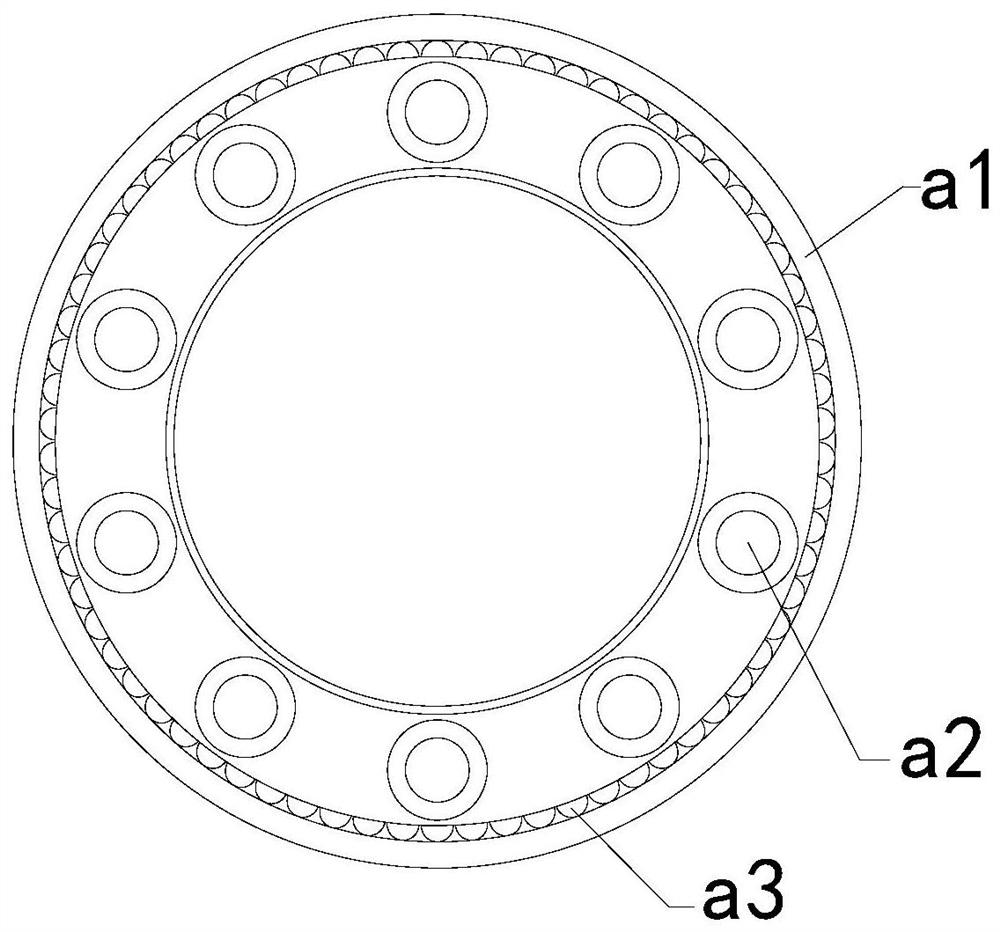

[0032] Wherein, the rotating mechanism w2 is provided with a magnetic block w21, a rotating shaft w22, a gap ring w23, and a rotating plate w24. The magnetic block w21 is attached to the outside of the rotating shaft w22, and the gap ring w23 is attached to the magnetic block w21. The outer side of the rotating plate w24 is fixed on the outer side of the gap ring w23, the rotating shaft w22 is located on the central axis of the valve w1, and the magnetic block w21 surrounds symmetrically around the rotating shaft w22.

[0033] Wherein, the rotating plate w24 is provided with a force bar b1 and a guide plate b2, the force bar b1 is attached to the surface of the guide plate b2, the side of the guide plate b2 is attached to the outer side of the gap ring w23, the The stress bar b1 has a triangular structure, and the guide plate b2 has a curved structure, which bears force on the concrete mixture and reduces resistance to the valve w1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com