Conveying mechanism for waste plastic machining machine

A technology for processing machinery and waste plastics, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of slow processing effect, low processing efficiency, poor pretreatment effect of waste plastics, etc., to reduce manual operations, Improved handling and plastic spatter prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

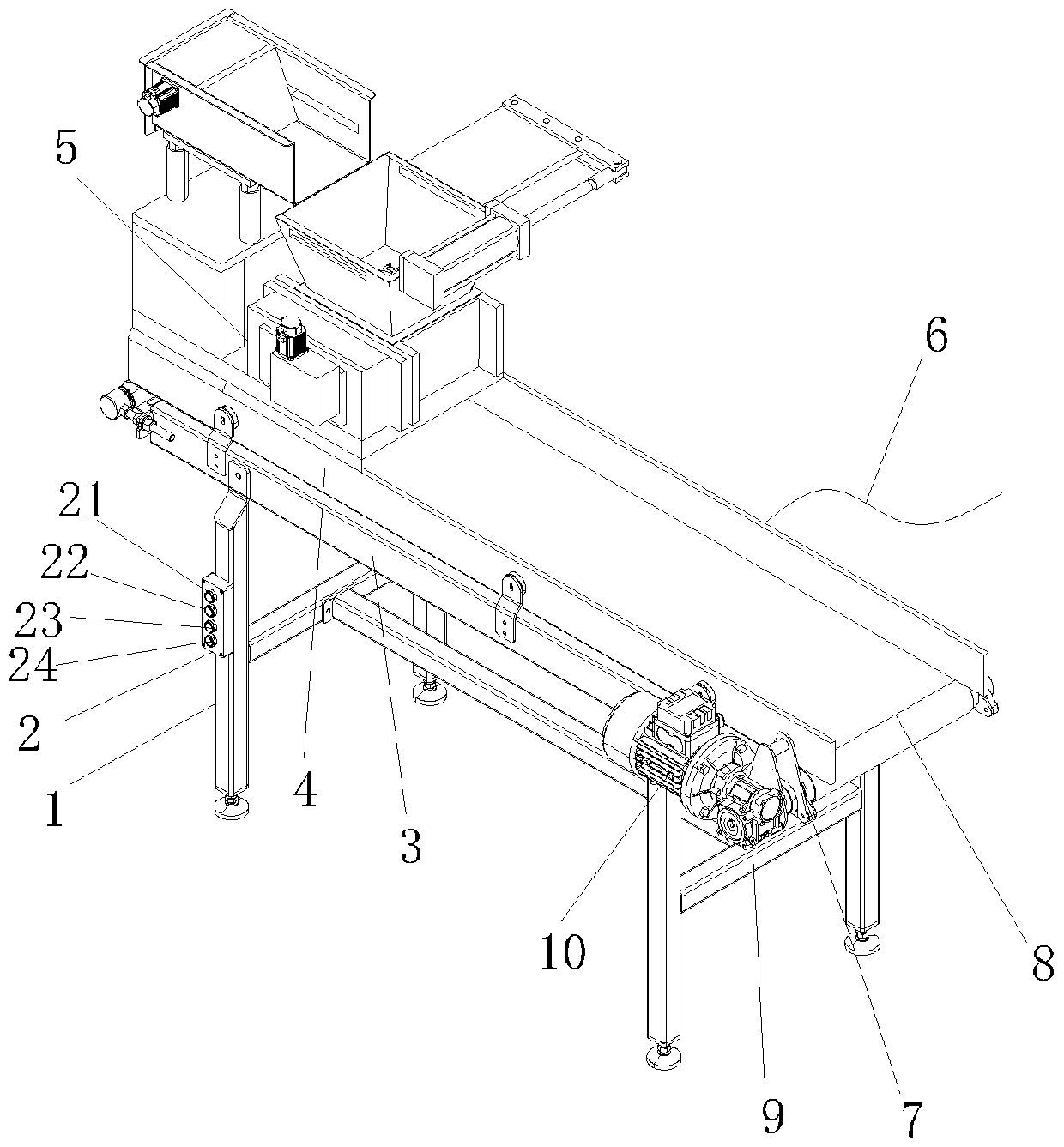

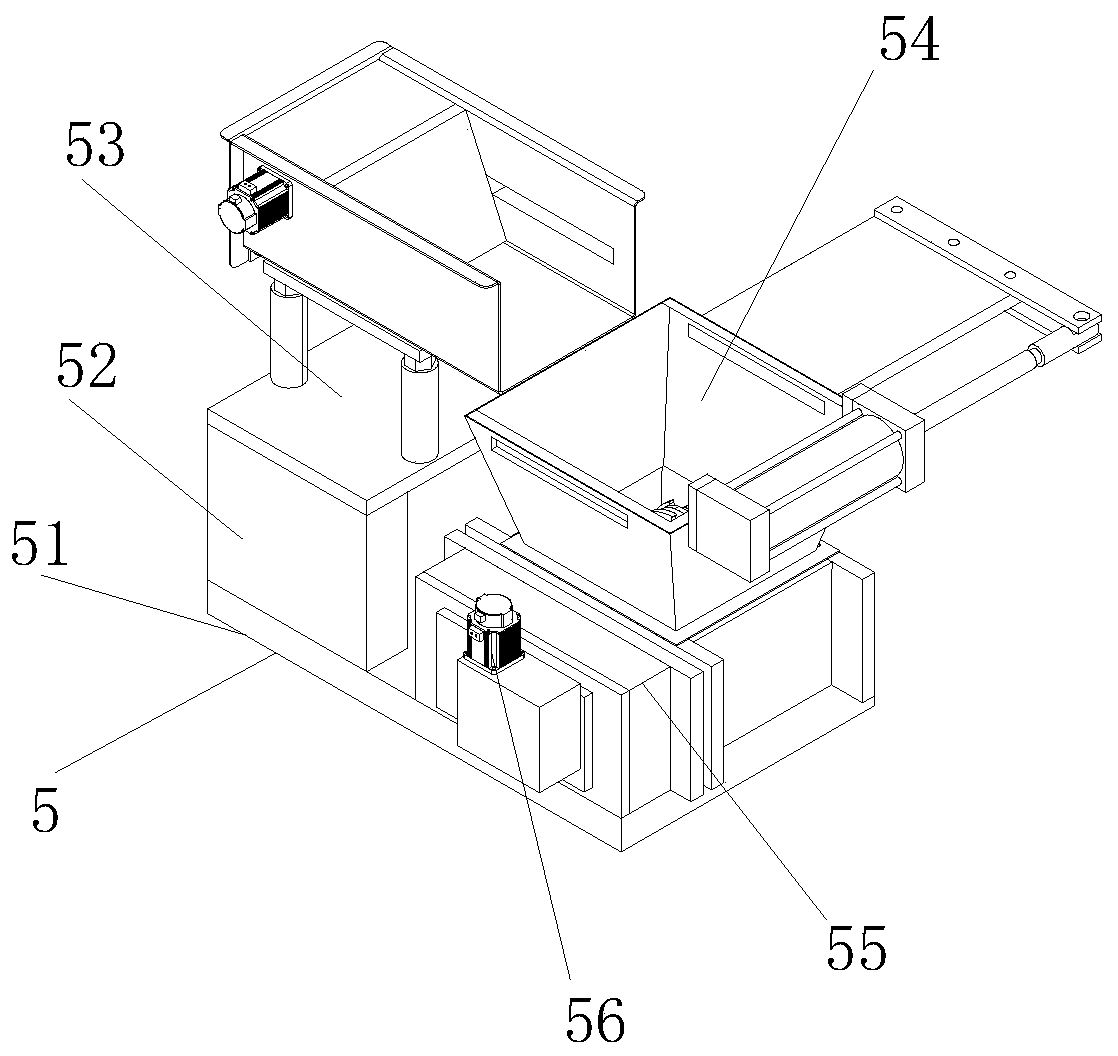

[0031] see figure 1 , the present invention provides a transport mechanism for waste plastic processing machinery through improvement, including a bracket 1, a controller 2, a side plate 3, a guard plate 4, a pretreatment device 5, a power cord 6, a rotating shaft 7, a conveyor belt 8, The reducer 9, the first motor 10, the controller 2 is fixed on the left end of the front end of the bracket 1, and the front end of the controller 2 is sequentially provided with a first switch 21, a second switch 22, a third switch 23 and a fourth switch from top to bottom 24. The controller 2 is electrically connected to the power line 6, the first switch 21 is electrically connected to the first motor 10 through the controller 2, the second switch 22 is electrically connected to the second motor 56 through the controller 2, and the third switch 23 is controlled by The controller 2 is electrically connected with the third motor 535, the fourth switch 24 is electrically connected with the elec...

Embodiment 2

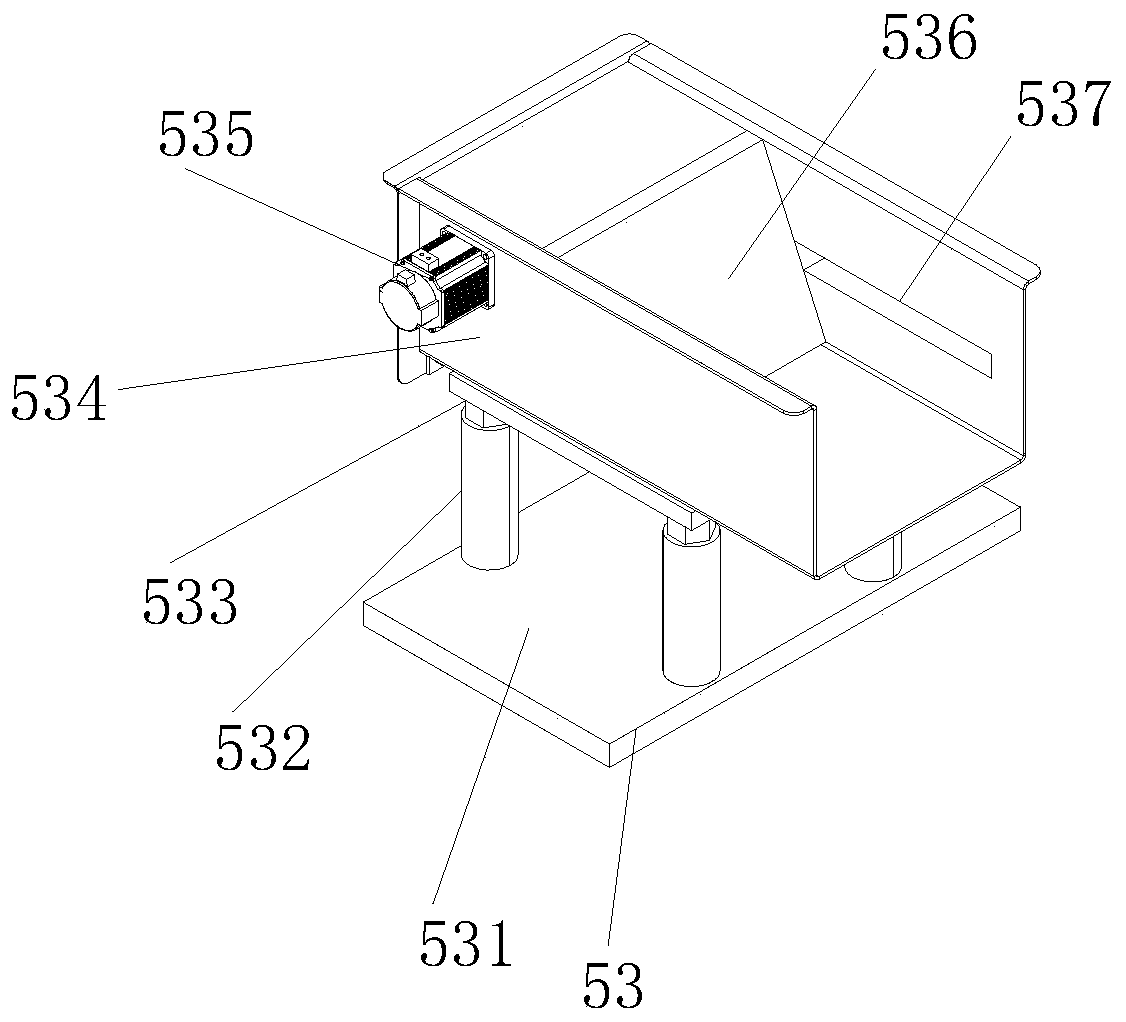

[0038] The present invention provides a conveying mechanism for waste plastic processing machinery through improvement. The push-out plate 536 is fixedly welded with a sliding block in the middle of the front and rear ends. The slide block is inserted into the chute 537. It provides stability, and the guiding effect is good, and there will be no deviation; the left and right ends of the back of the box body 5381 are welded with struts, and the box body 5381 is fixed with the left rear end of the protective frame 534 through the struts, which can be placed in the box body 5381 internal components provide a stable supporting force for the movement; the left end of the middle part of the moving part 5384 is provided with an arc-shaped groove, and the inner width of the arc-shaped groove is larger than the outer diameter of the toggle rod 5383, and the height of the toggle rod 5383 is greater than that of the moving part 5384 The thickness is 1.5cm, which is more convenient for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com