Drawing type preparation equipment and preparation method of hollow filter stick

A pull-out filter rod technology, applied in the direction of e-liquid filter elements, applications, tobacco, etc., can solve problems such as gaps, composite effects, and poor follow-up application effects, and achieve the effect of uniform delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A kind of drawing type preparation method of hollow filter rod, comprises the following steps:

[0049] The two groups of fiber tows are respectively opened on the upper opener and the lower opener of the double-layer opener;

[0050]Spray glyceride to the tow after opening;

[0051] Fill the annular cavity of the high-pressure nozzle with high-pressure air, and the high-pressure air is ejected from the nozzle through the through hole on the inner wall of the annular cavity, forming a local negative pressure, sucking the tow, and realizing the high-pressure delivery of the tow;

[0052] Subsequently, the tow is conveyed into the forming hot mold, heated and shaped under the action of high-temperature steam, and then enters the forming cold mold assembly to fully cool;

[0053] The shaped filter rods are cut, plated, and solidified to obtain hollow filter rods.

[0054] In some embodiments, the pressure of the high-pressure gas fed into the high-pressure nozzle is 0.02...

Embodiment

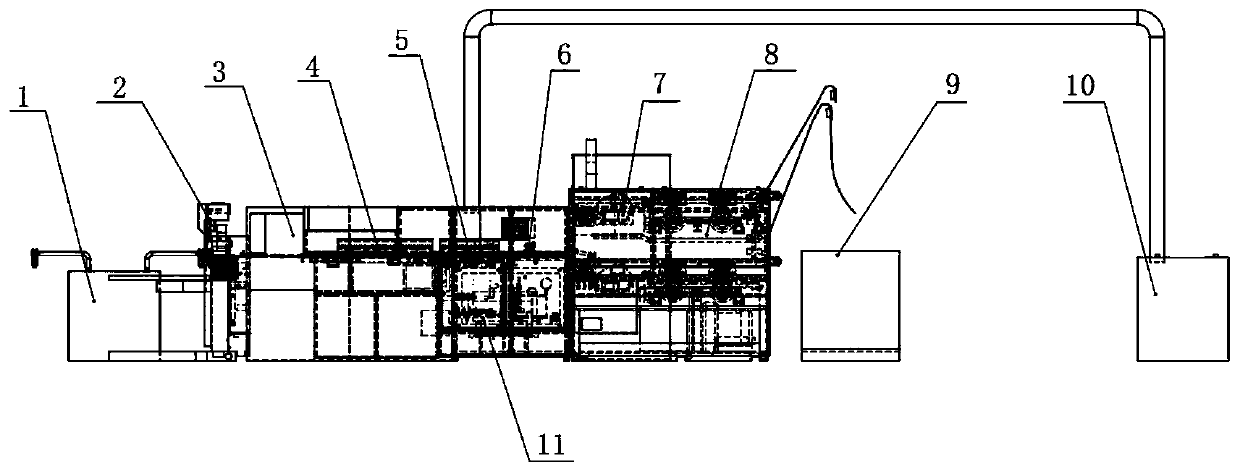

[0059] Such as figure 1 As shown, a drawing-type preparation equipment for hollow filter rods includes a double-layer opener 8, a high-pressure wire feeder 6, a forming module 5, a bong assembly 4, a cutter head box 3, and a tray loading machine arranged in sequence. 2 and cold dryer 1.

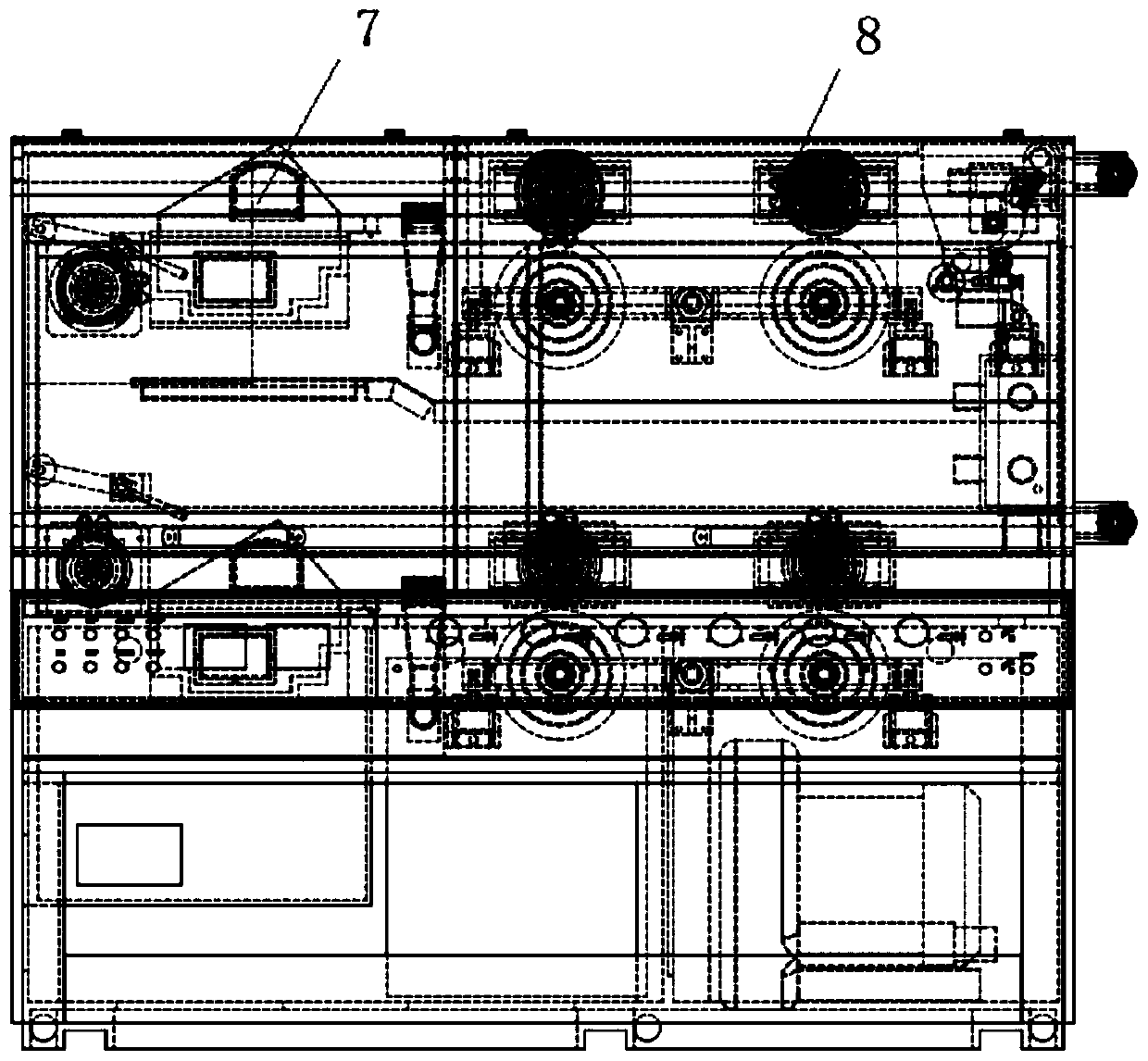

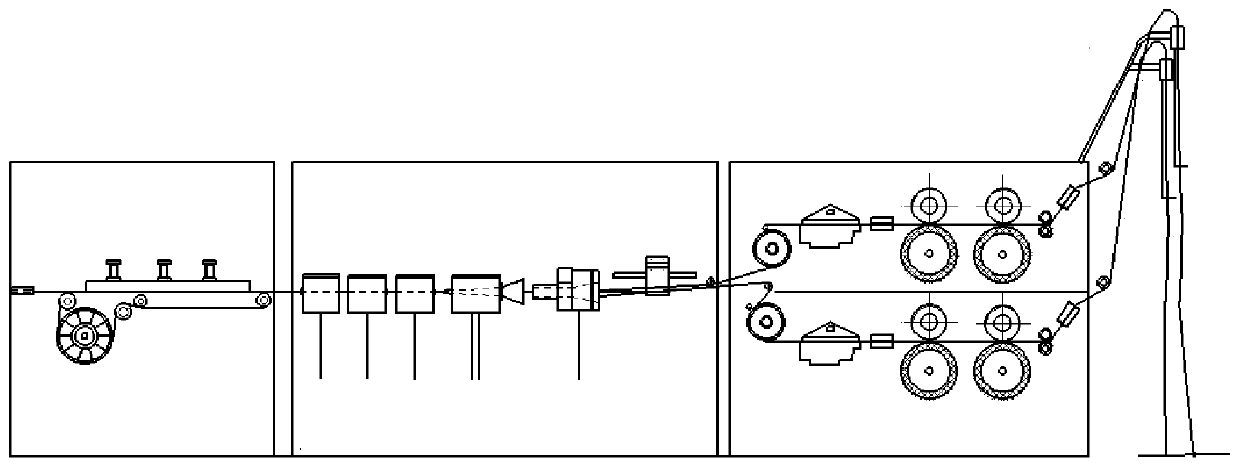

[0060] Such as figure 2 and image 3 As shown, the double-layer opening machine 8 includes an upper layer opening mechanism and a lower layer opening mechanism; both the upper layer opening mechanism and the lower layer opening mechanism are provided with a threaded roller servo drive mechanism and a glyceride spraying chamber 7 in sequence. The thread roller servo drive mechanism is driven by a motor to rotate, providing power for the movement of the tow. The bottom of the glyceride spray chamber 7 is provided with a spray head, and the circulation pump is connected to the bottom of the glyceride spray chamber 7 and the spray head respectively. The circulation pump pumps the glyceride i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com