Patents

Literature

57results about How to "Uniform film quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

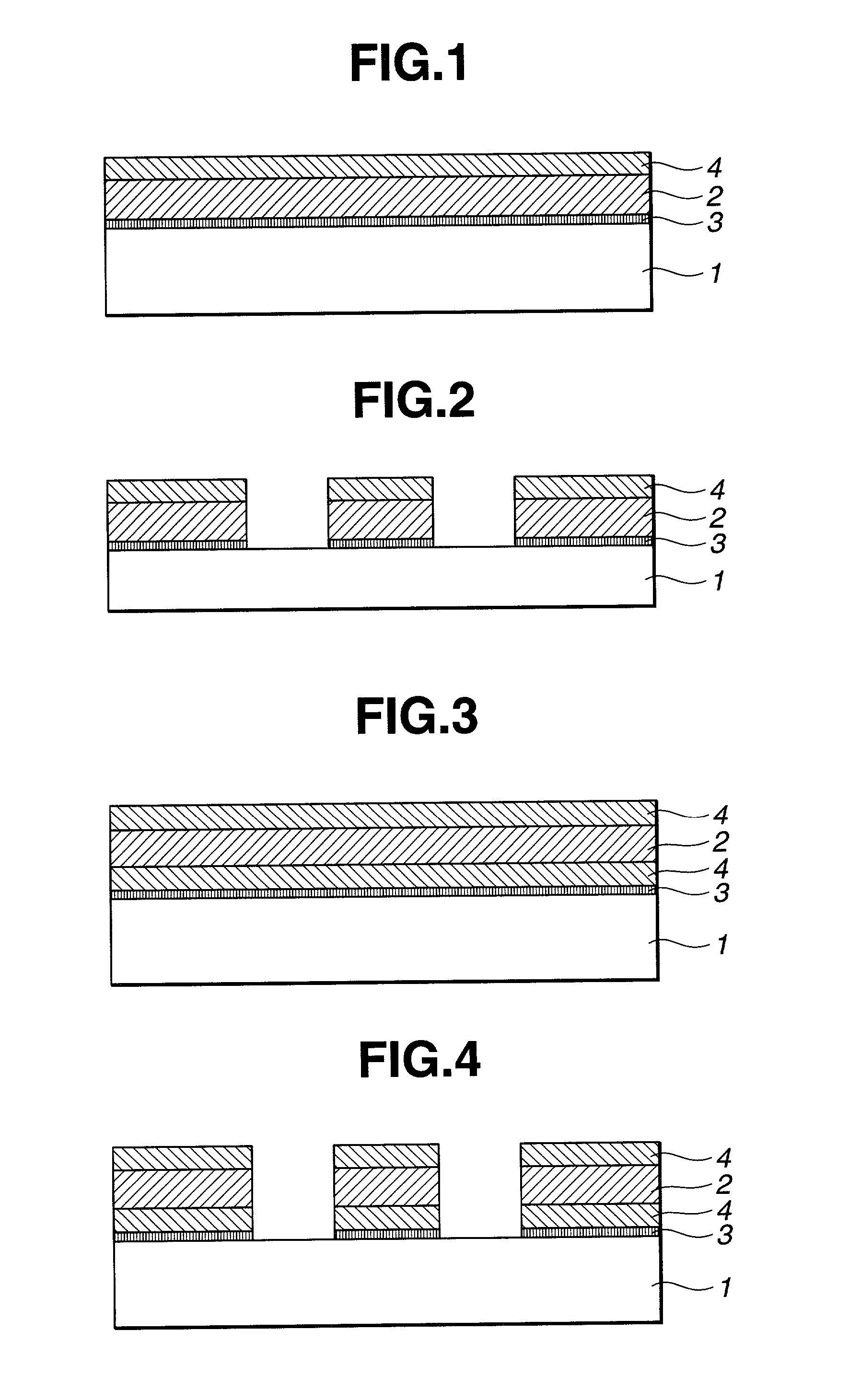

Method for forming layer constituted by repeated stacked layers

ActiveUS9018093B2High wet etching selectivityUniform film qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingThin membraneSecondary layer

A method for forming a layer constituted by repeated stacked layers includes: forming a first layer and a second layer on a substrate under different deposition conditions to form a stacked layer, wherein the film stresses of the first and second layers are tensile or compressive and opposite to each other, and the wet etch rates of the first and second layers are at least 50 times different from each other; and repeating the above step to form a layer constituted by repeated stacked layers, wherein the deposition conditions for forming at least one stacked layer are different from those for forming another stacked layer.

Owner:ASM IP HLDG BV

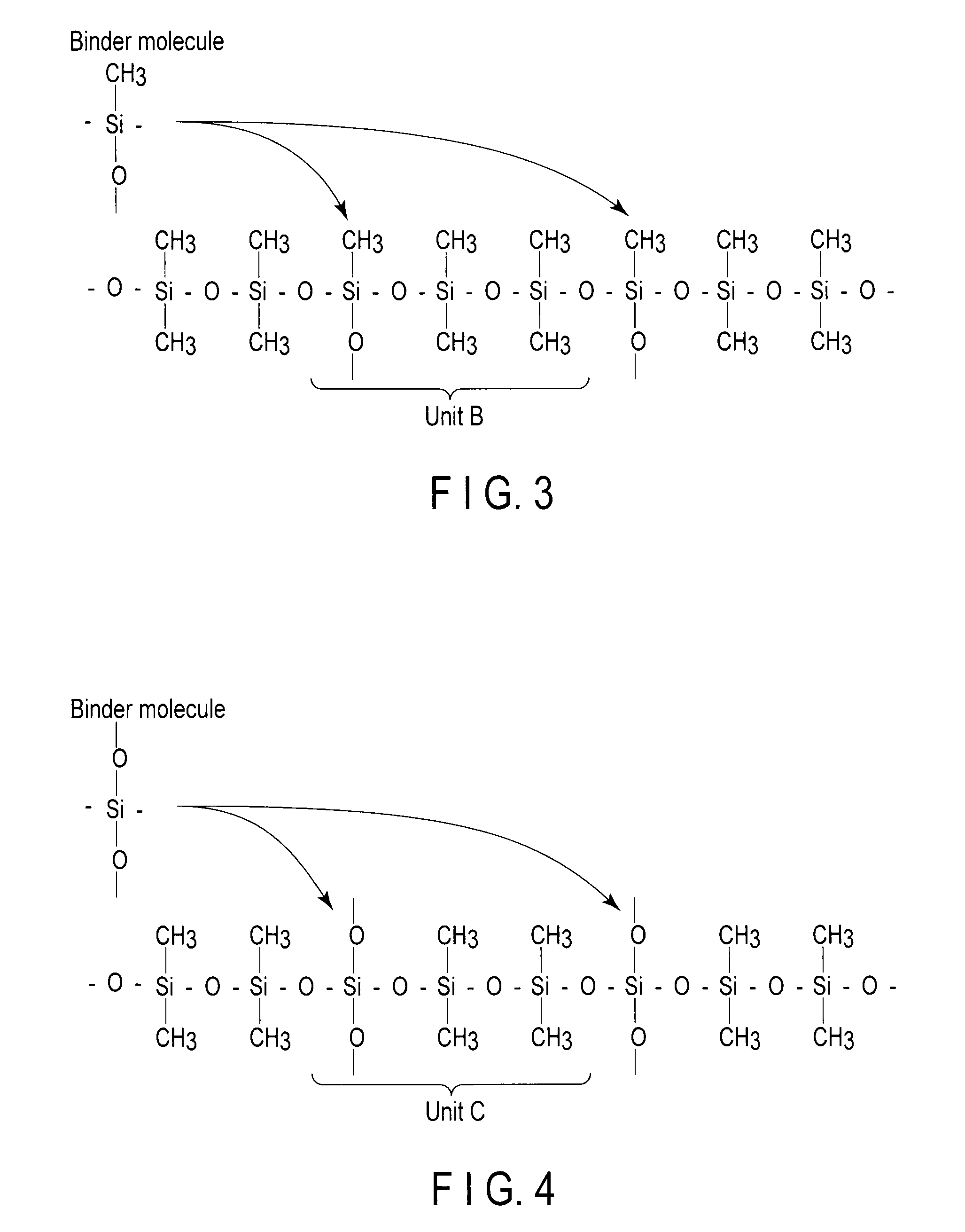

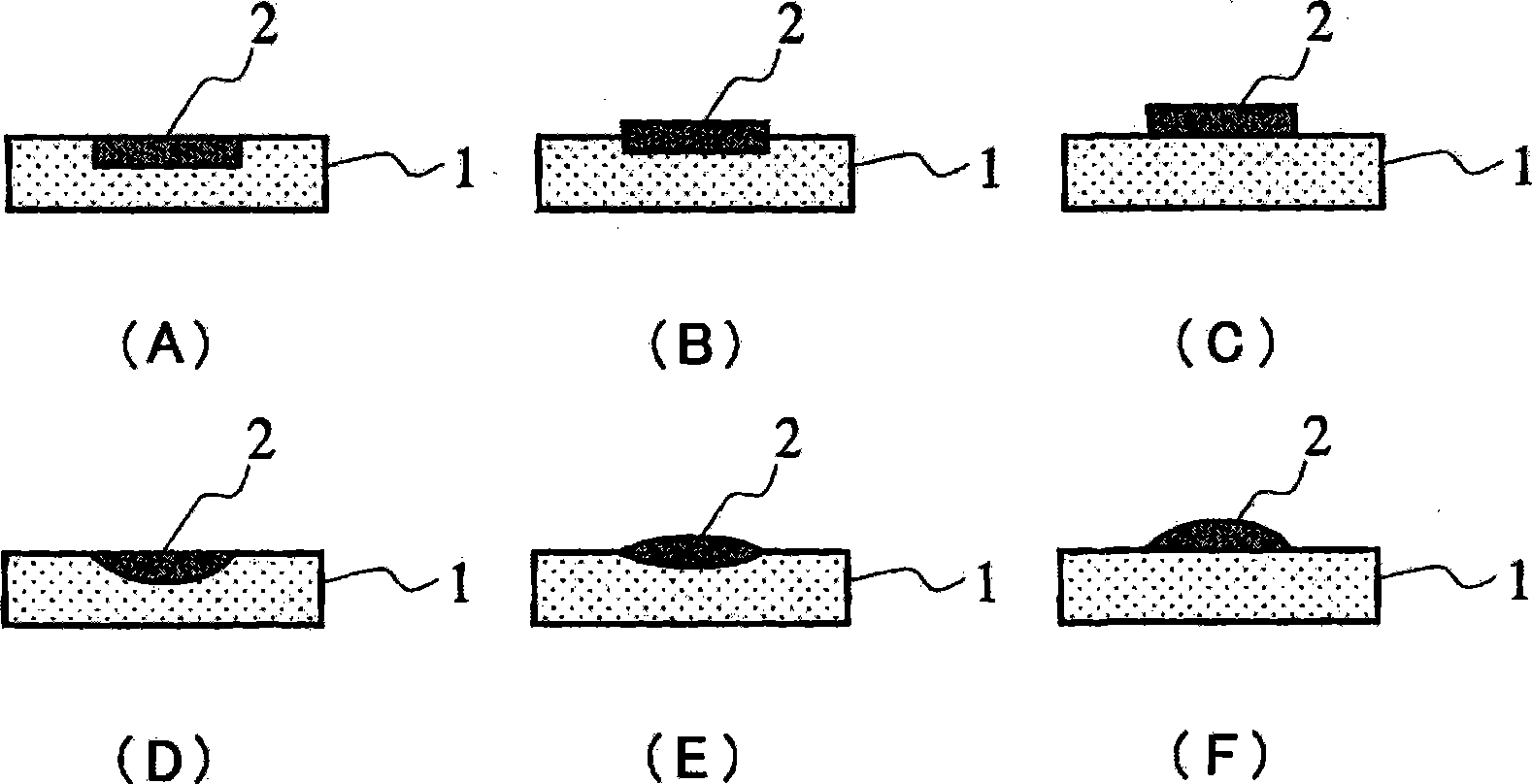

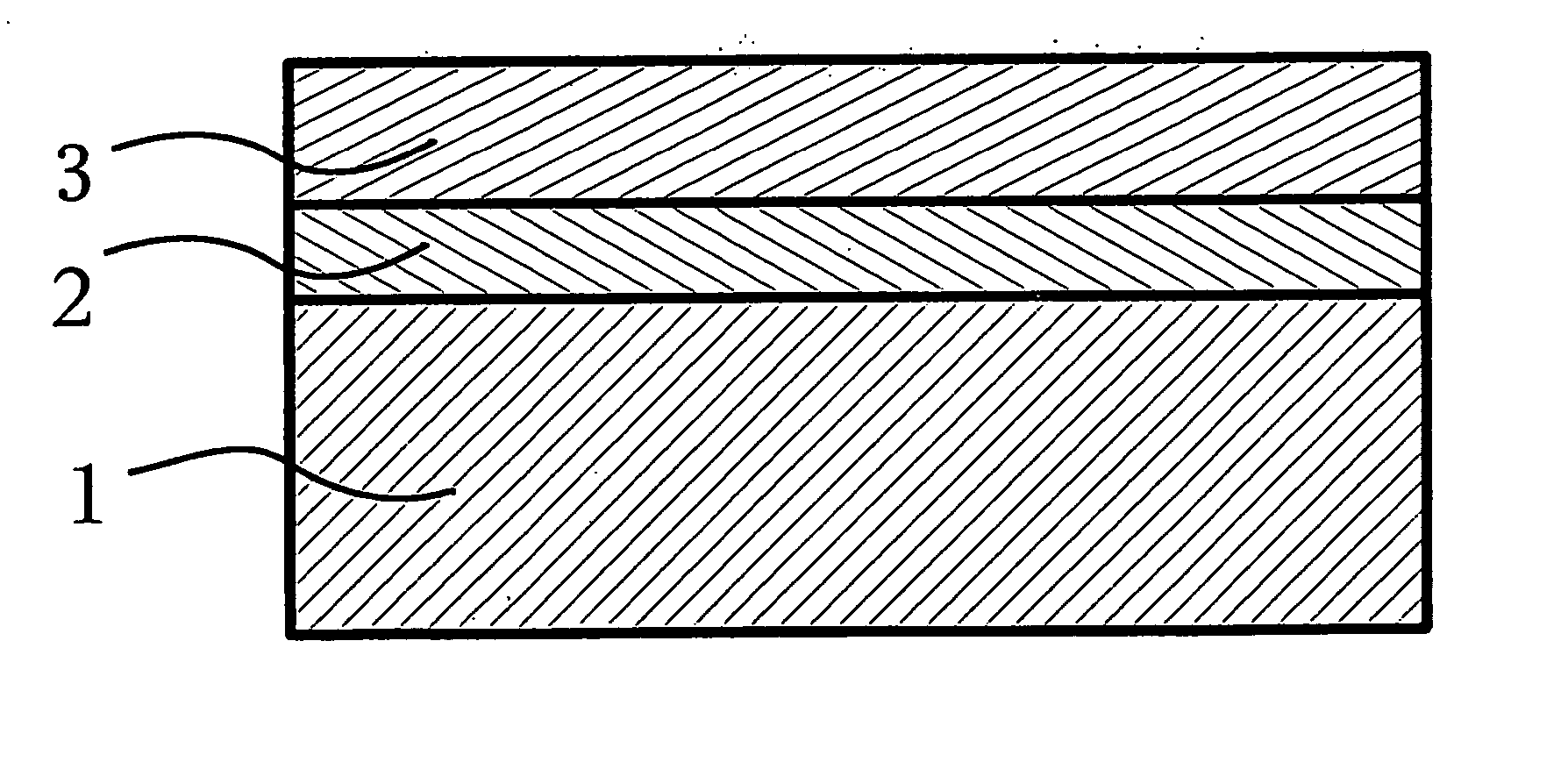

Low dielectric constant insulating film and method for forming the same

InactiveUS8828886B2Improve resistance to damageLow dielectric constantSemiconductor/solid-state device manufacturingChemical vapor deposition coatingArea ratioPolymer

Disclosed is a low dielectric constant insulating film formed of a polymer containing Si atoms, O atoms, C atoms, and H atoms, which includes straight chain molecules in which a plurality of basic molecules with an SiO structure are linked in a straight chain, binder molecules with an SiO structure linking a plurality of the straight chain molecules. The area ratio of a signal indicating a linear type SiO structure is 49% or more, and the signal amount of the signal indicating Si(CH3) is 66% or more.

Owner:TOHOKU UNIV

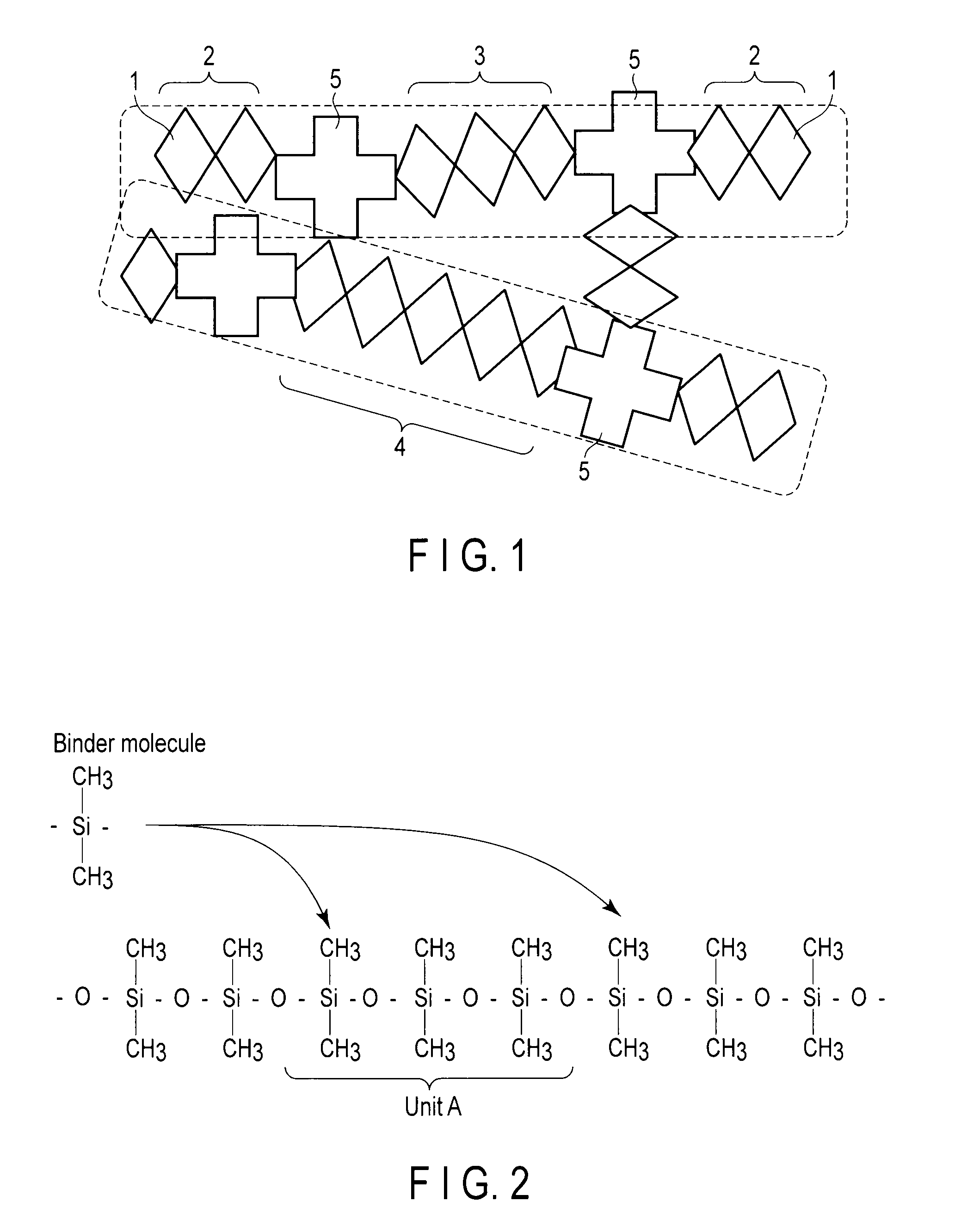

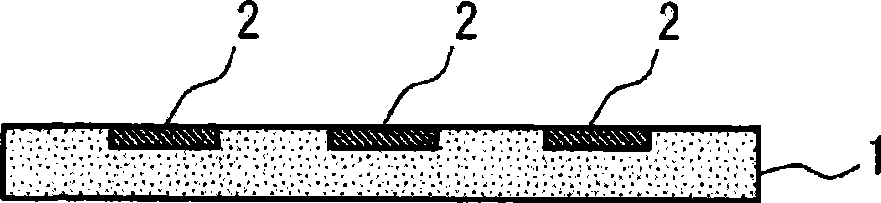

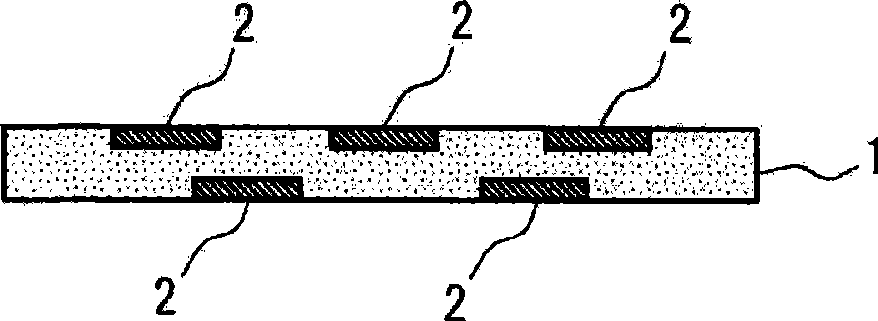

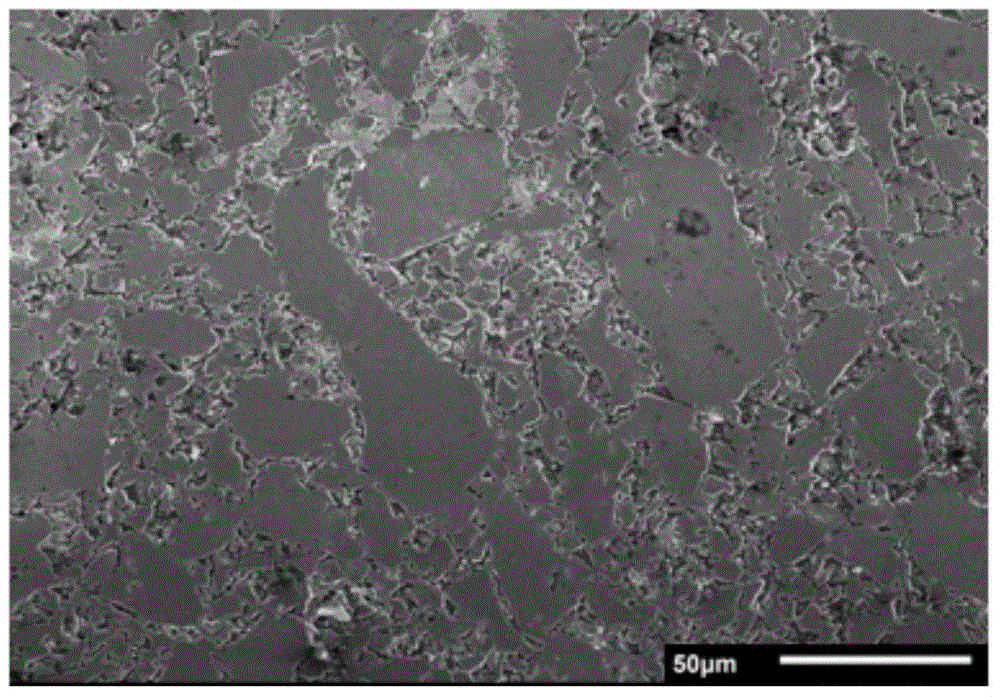

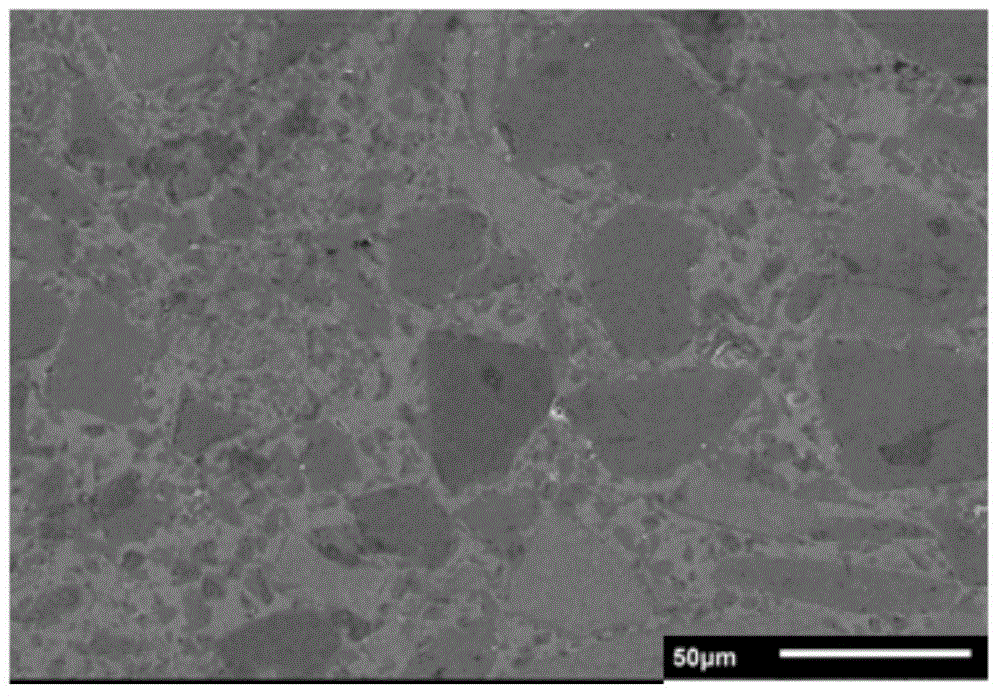

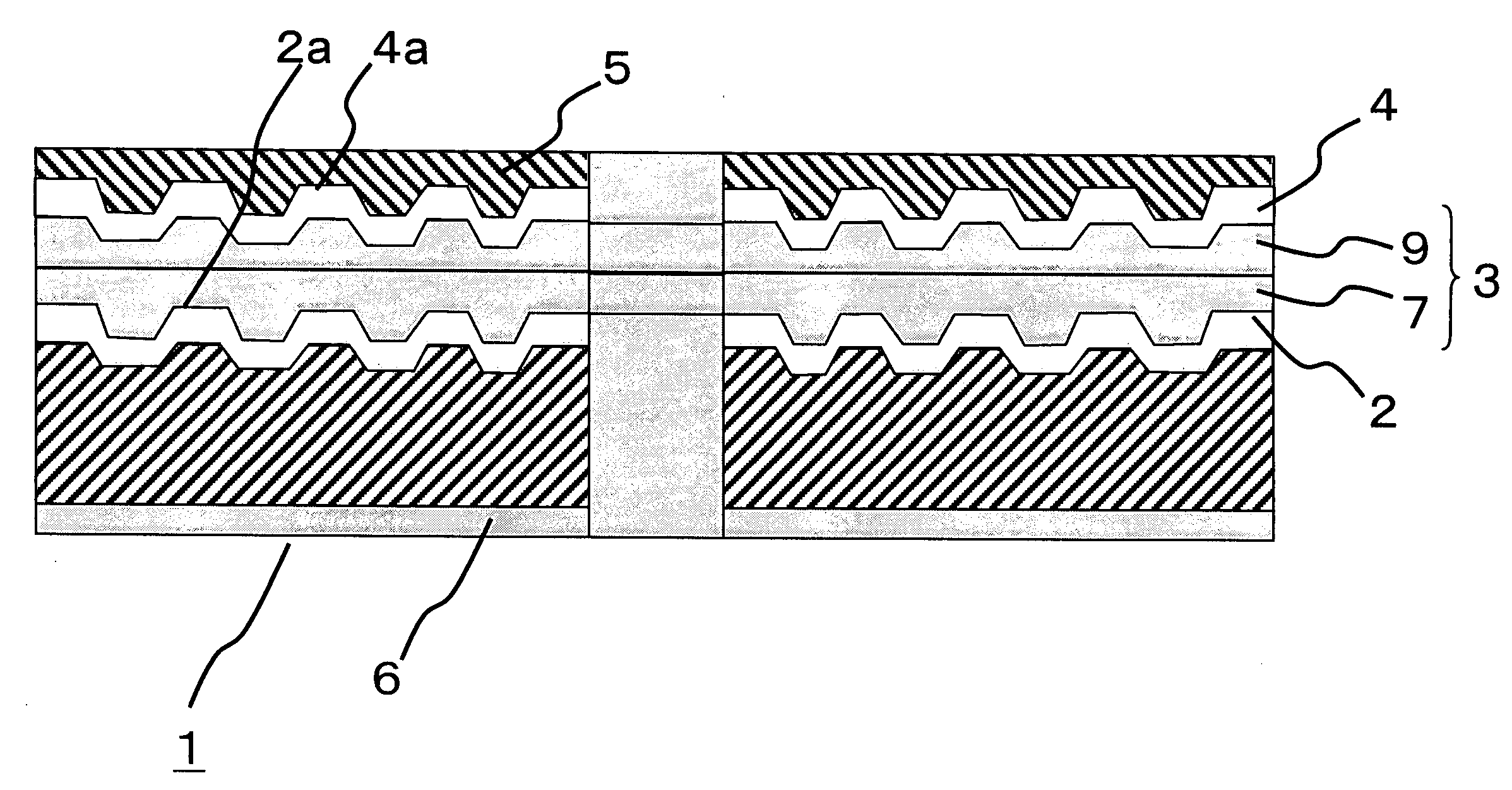

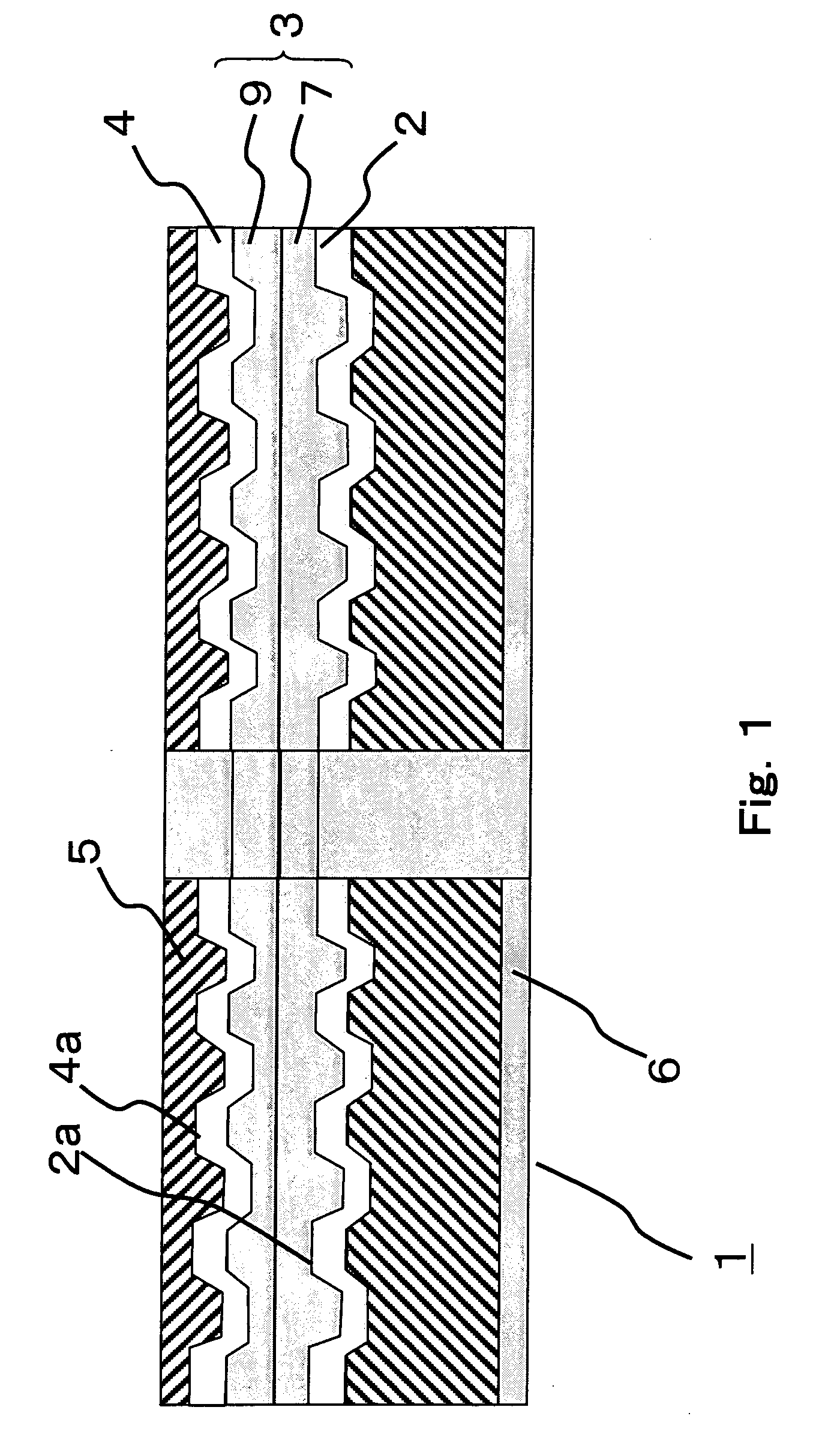

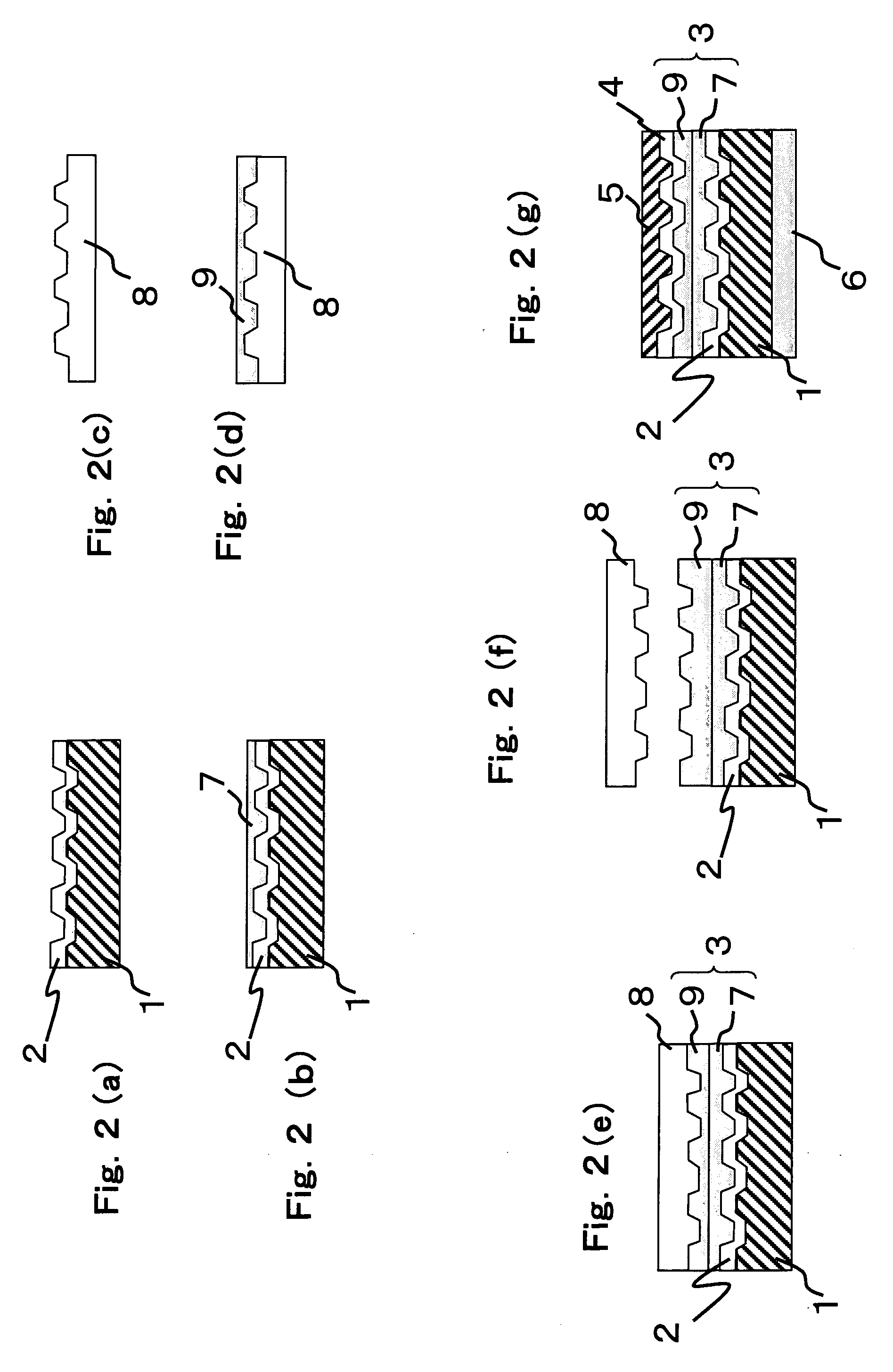

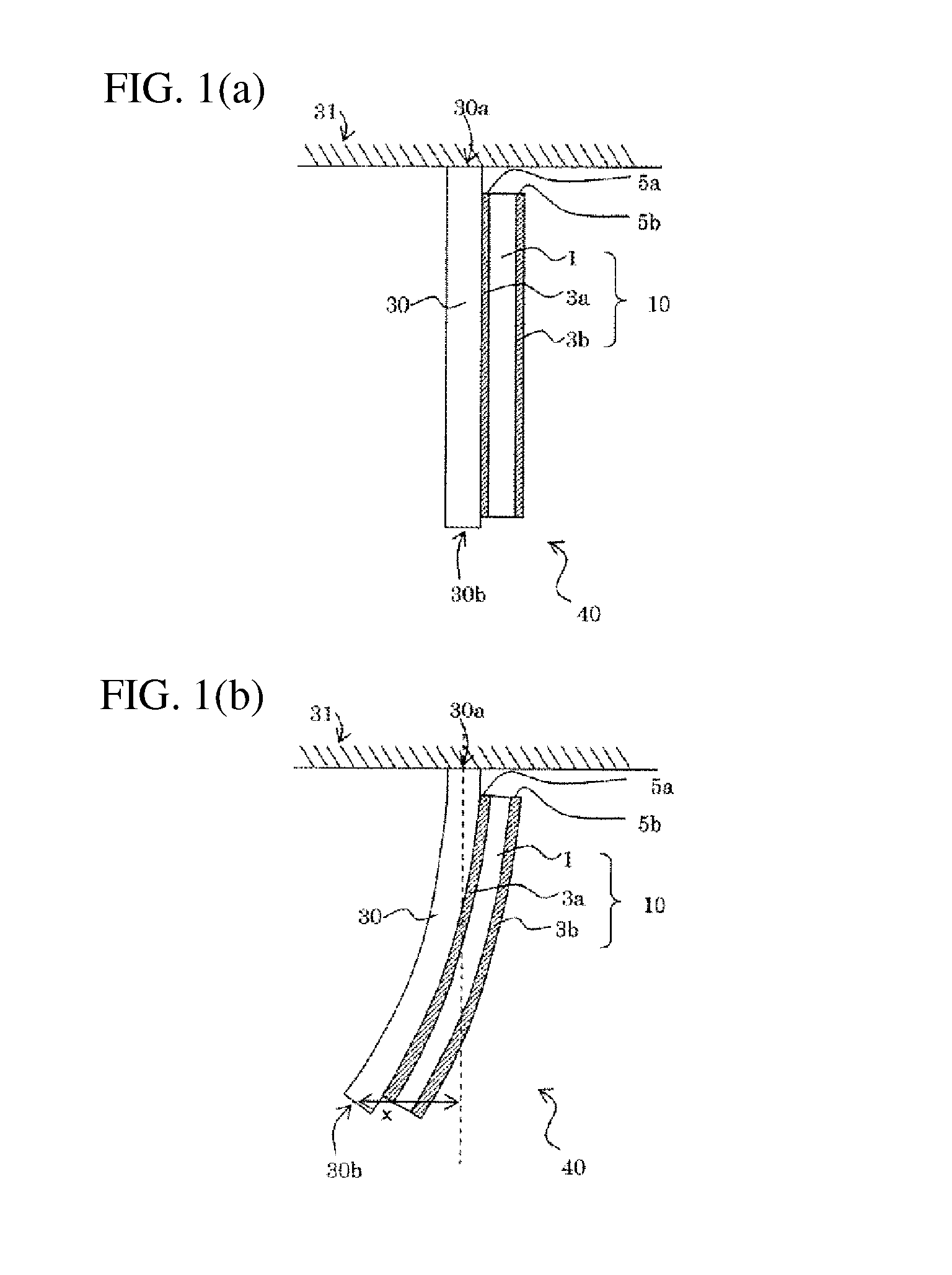

Porous film and multilayer assembly using the same

InactiveCN101384425ASmall widthImprove adhesionLayered productsPrinted circuit manufactureAdhesive beltPorous layer

To provide a porous-film layered product which has excellent porousness, has flexibility, and is excellent in handleability and formability; and a process for producing the layered product. [MEANS FOR SOLVING PROBLEMS] The porous-film layered product comprises a base and, superposed on at least one side thereof, a porous layer having many fine interconnecting pores having an average pore diameter of 0.01-10 [mu]m, and is characterized by suffering no interfacial separation between the base and the porous layer when examined in a tape peeling test by the following method. Tape peeling test A 24 mm-wide masking tape [Film Masking Tape No. 603(#25)] manufactured by Teraoka Seisakusho Co., Ltd. is applied to the surface of the porous layer of the porous-film layered product and press-bonded thereto with a roller having a diameter of 30 mm and a load of 200 gf. Thereafter, this sample is subjected to a T-peel test with a tensile tester at a peeling rate of 50 mm / min.

Owner:DAICEL CHEM IND LTD

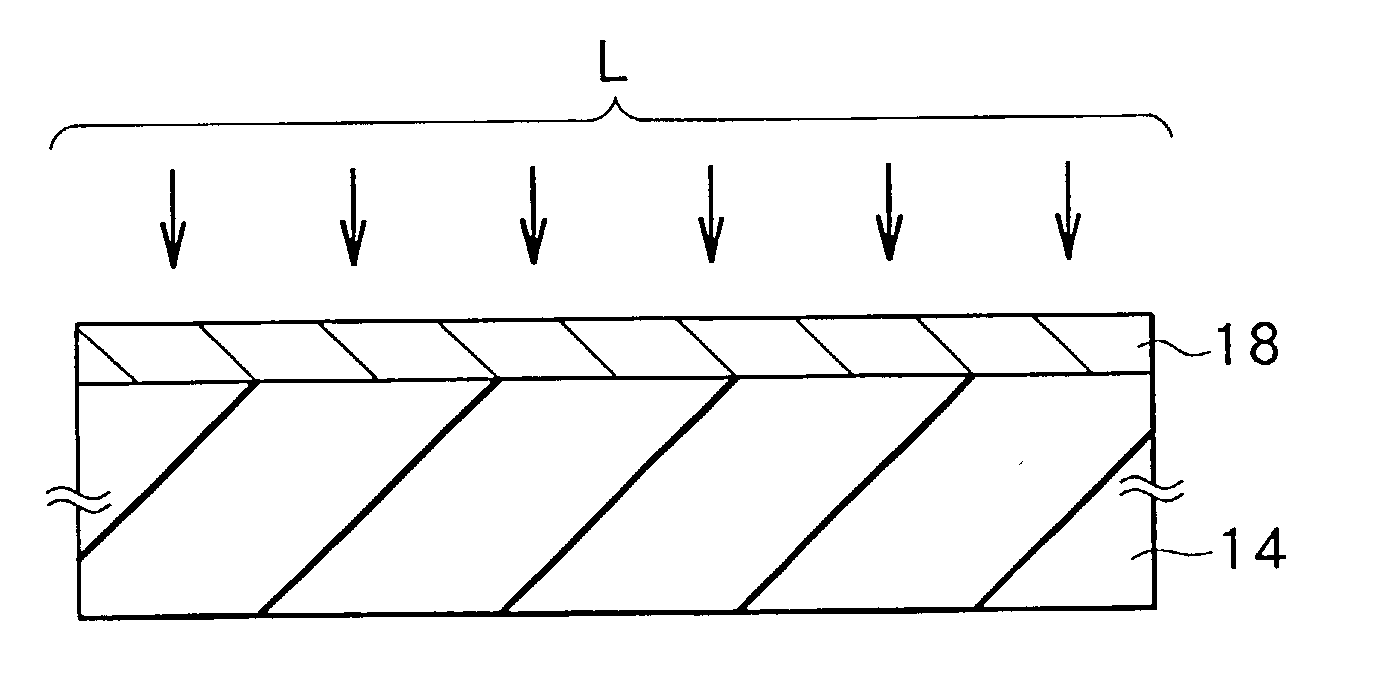

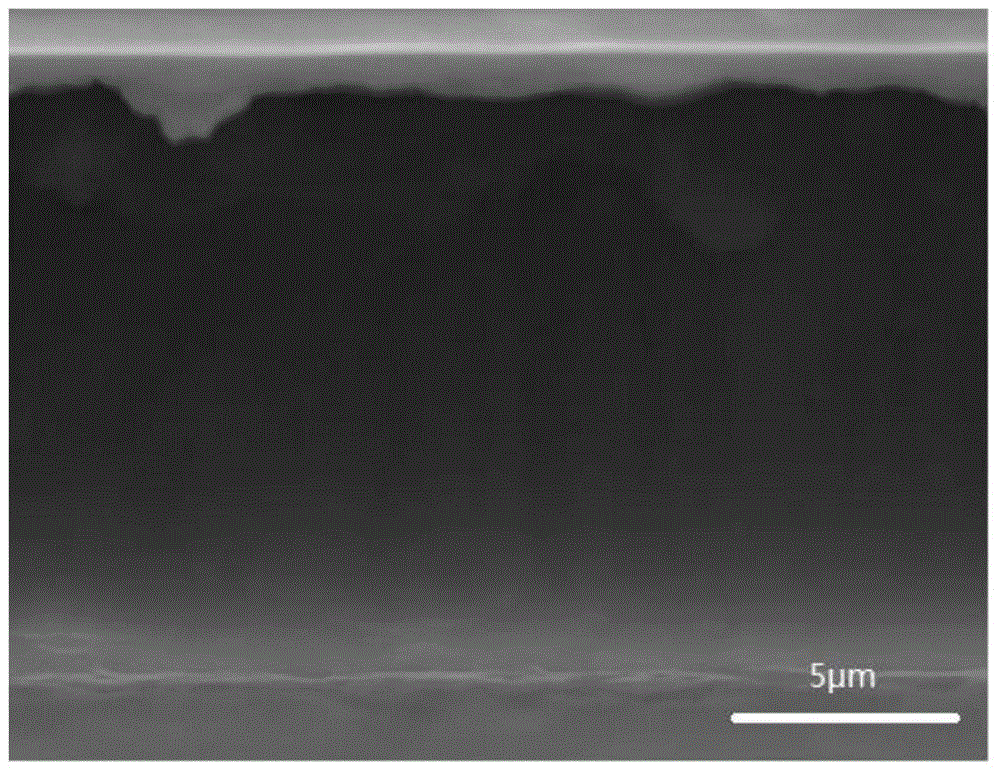

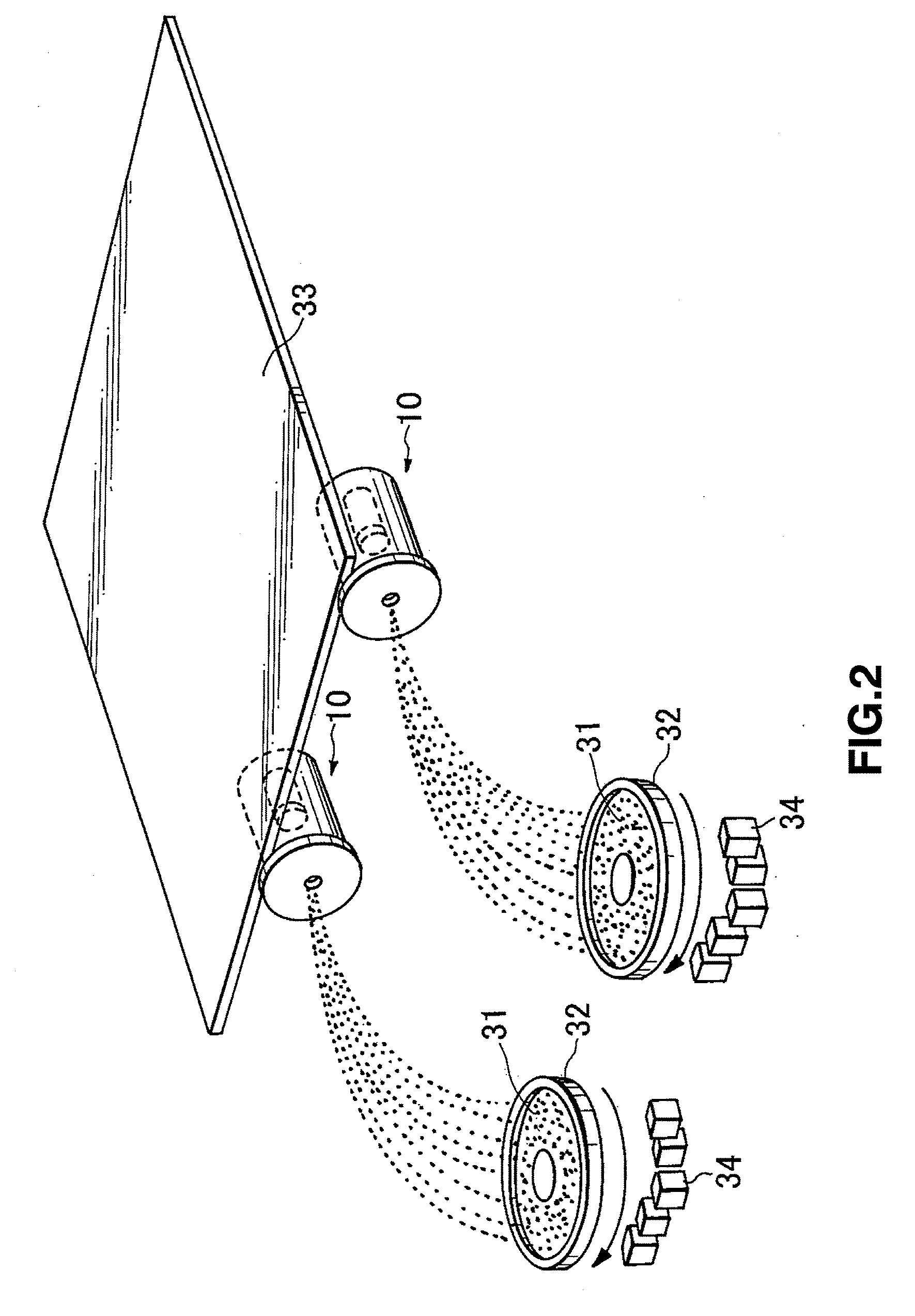

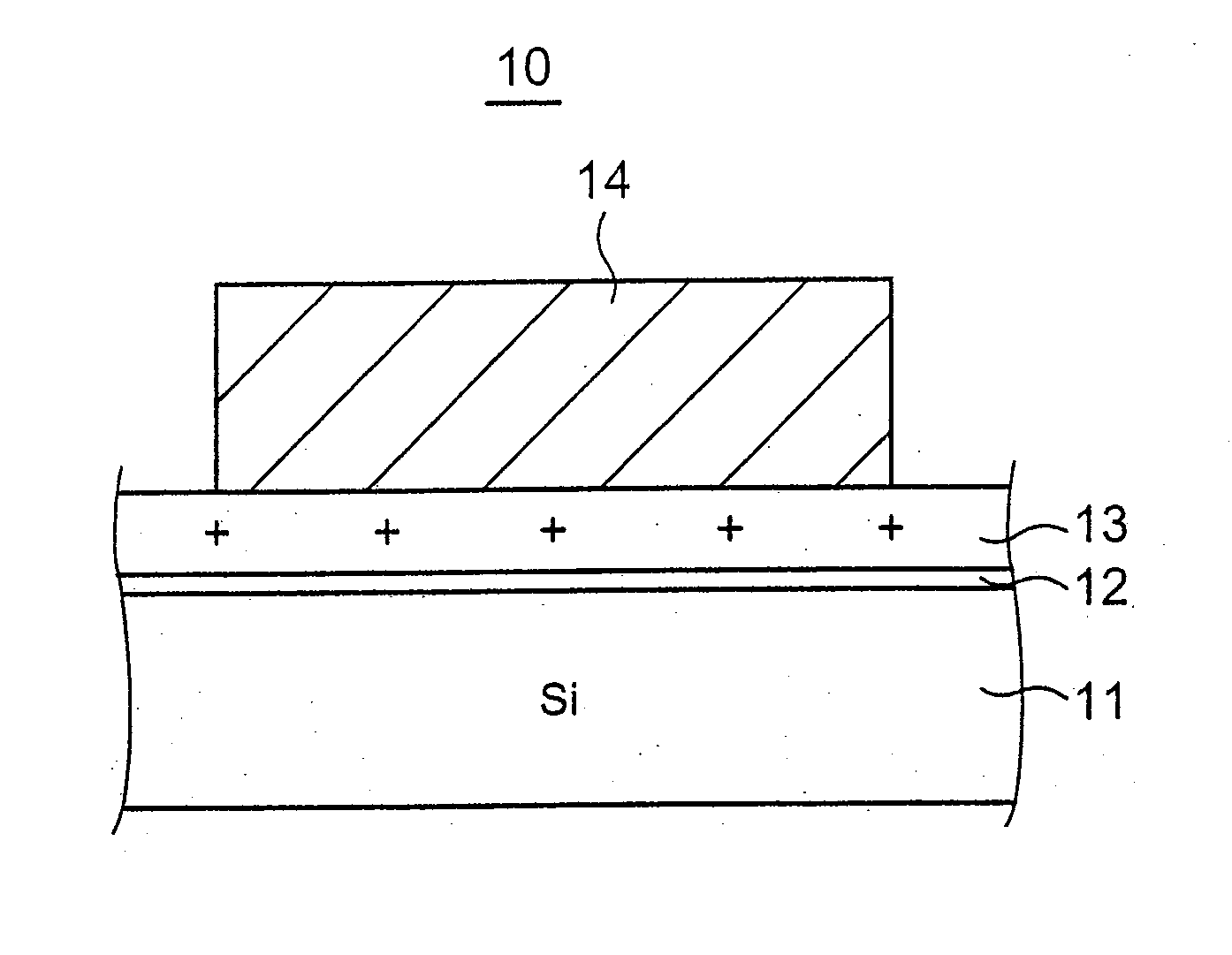

Group III nitride compound semiconductor thin film and deposition method thereof, and semiconductor device and manufacturing method thereof

InactiveUS20030039866A1Uniform film qualitySimple methodLaser detailsVacuum evaporation coatingLattice defectsDislocation

A Group III nitride compound semiconductor thin film which can be deposited on any given substrate to have uniform film quality and excellent crystalline, and a deposition method thereof. A semiconductor device and a manufacturing method thereof. A poly-crystalline Group III nitride compound thin film is deposited on a substrate by sputtering at a deposition rate of 15 to 200 nm / hour using a Group III nitride compound target in a plazma atmosphere of gas comprising 10 mole % or more nitrogen. Then, the poly-crystalline Group III nitride compound semiconductor thin film deposited on the substrate is irradiated with an excimer pulsed laser with an energy density of about 200 mJ / cm2, in an atmosphere of gas with an oxygen content of 2 mole % or less. Thereby, lattice defects such as grain boundaries or dislocations which occur in the thin film are removed.

Owner:MITAMURA SATOSHI

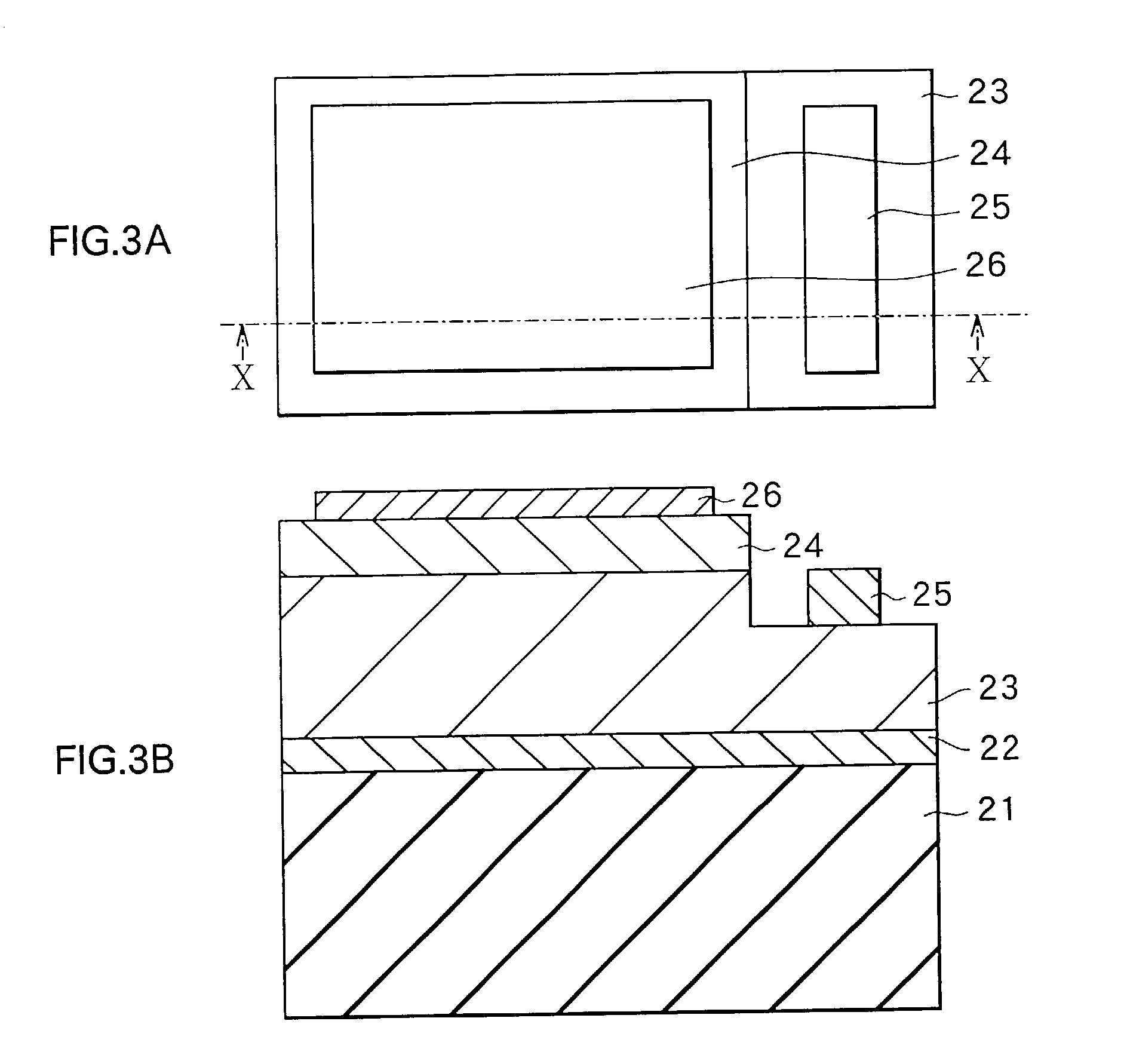

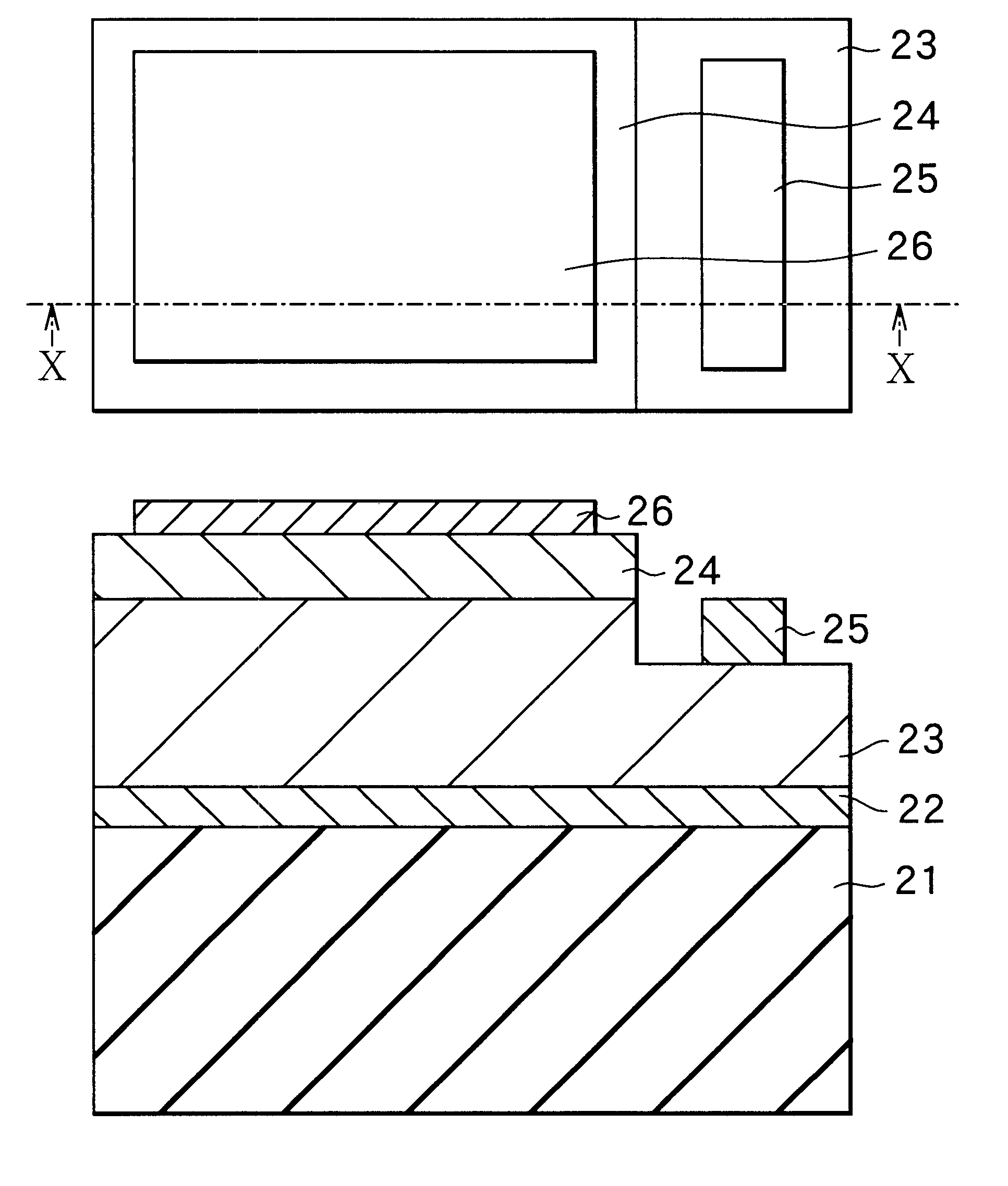

Photomask blank and photomask

InactiveUS20020115003A1Uniform film qualityReduce surface roughnessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusSurface roughnessNitrogen

In the manufacture of a photomask blank, a seed layer of a chromium material containing oxygen, nitrogen and / or carbon is formed on a transparent substrate before a light-shielding film and an antireflective film are deposited thereon. Any film on the seed layer builds up in accordance with fine granular growth, and so the resulting photomask blank has an improved surface roughness, which enables high-sensitivity detection in the process of defect inspection and circuit pattern inspection. By lithographically patterning the photomask blank, a photomask is fabricated.

Owner:SHIN ETSU CHEM IND CO LTD

Group III nitride compound semiconductor thin film and deposition method thereof, and semiconductor device and manufacturing method thereof

InactiveUS6475923B1Uniform film qualitySimple methodLaser detailsLayered productsDislocationGrain boundary

A Group III nitride compound semiconductor thin film which can be deposited on any given substrate to have uniform film quality and excellent crystalline, and a deposition method thereof. A semiconductor device and a manufacturing method thereof. A poly-crystalline Group III nitride compound thin film is deposited on a substrate by sputtering at a deposition rate of 15 to 200 nm / hour using a Group III nitride compound target in a plasma atmosphere of gas comprising 10 mole % or more nitrogen. Then, the poly-crystalline Group III nitride compound semiconductor thin film deposited on the substrate is irradiated with an excimer pulsed laser with an energy-density of about 200 mJ / cm2, in an atmosphere of gas with an oxygen content of 2 mole % or less. Thereby, lattice defects such as grain boundaries or dislocations which occur in the thin film are removed.

Owner:SONY CORP

Protective coat and method for manufacturing thereof

InactiveUS20050037240A1Stable mass productionMaintain good propertiesElectroluminescent light sourcesVacuum evaporation coatingOptoelectronicsOxygen

A method for producing a protective coat formed on the top surface of a substrate, or on the top surface of a thin film layered body formed on the substrate is disclosed, wherein the protective coat comprises silicon oxynitride in which the atomic ratio of Si / O / N is 100 / X / Y (130≦X+Y≦180, 10≦X≦135, 5≦Y≦150), wherein the protective coat is formed by a sputtering method in which silicon nitride is used as a target material, an inert gas is used as a sputtering gas, and N2 is used as a reactive feed gas. The oxygen component of the obtained protective coat comprising the silicon oxynitride is incorporated into the composition of the protective coat by degradation of moisture that was present in the substrate or the thin film layered body or in the reaction apparatus.

Owner:DAI NIPPON PRINTING CO LTD

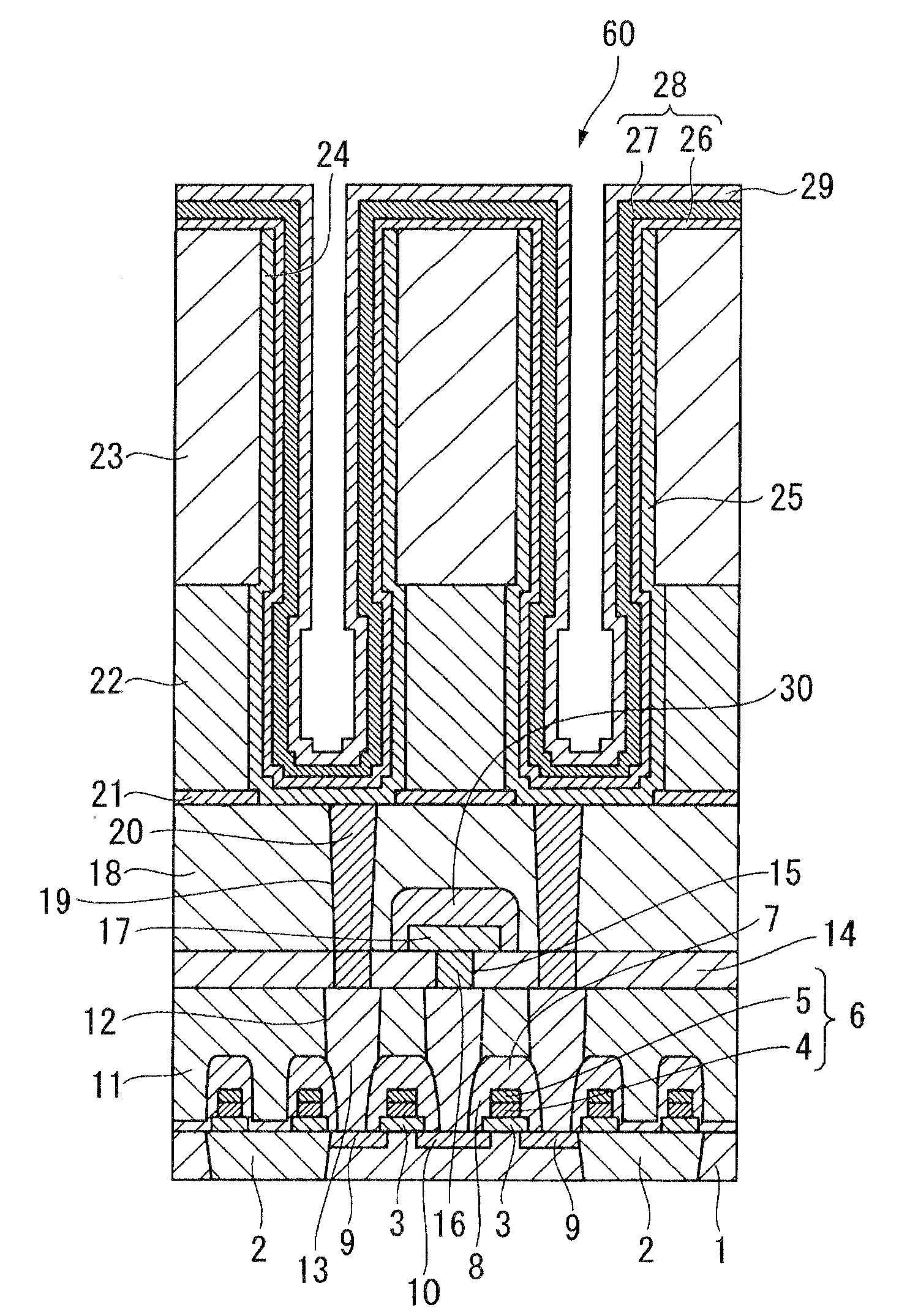

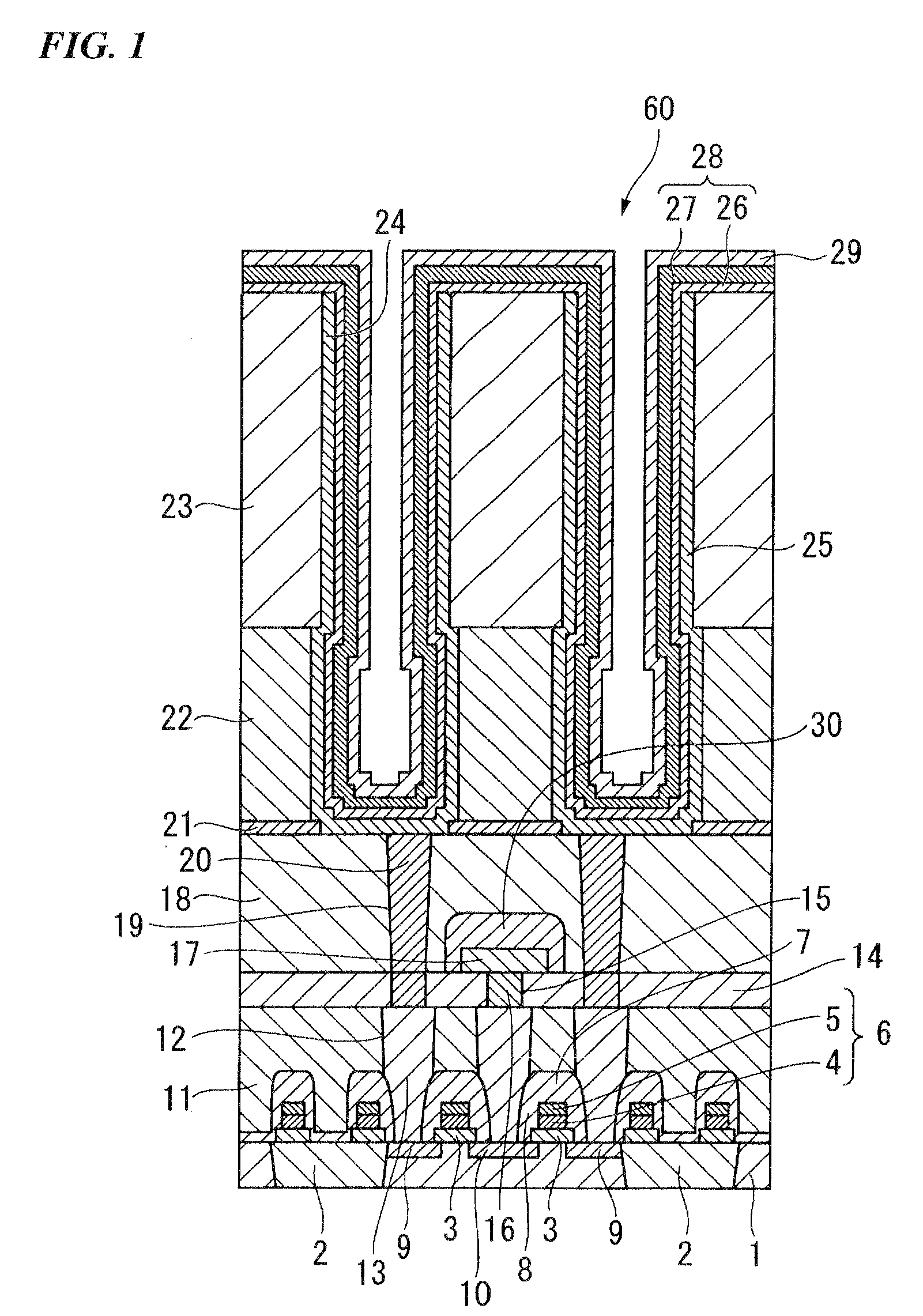

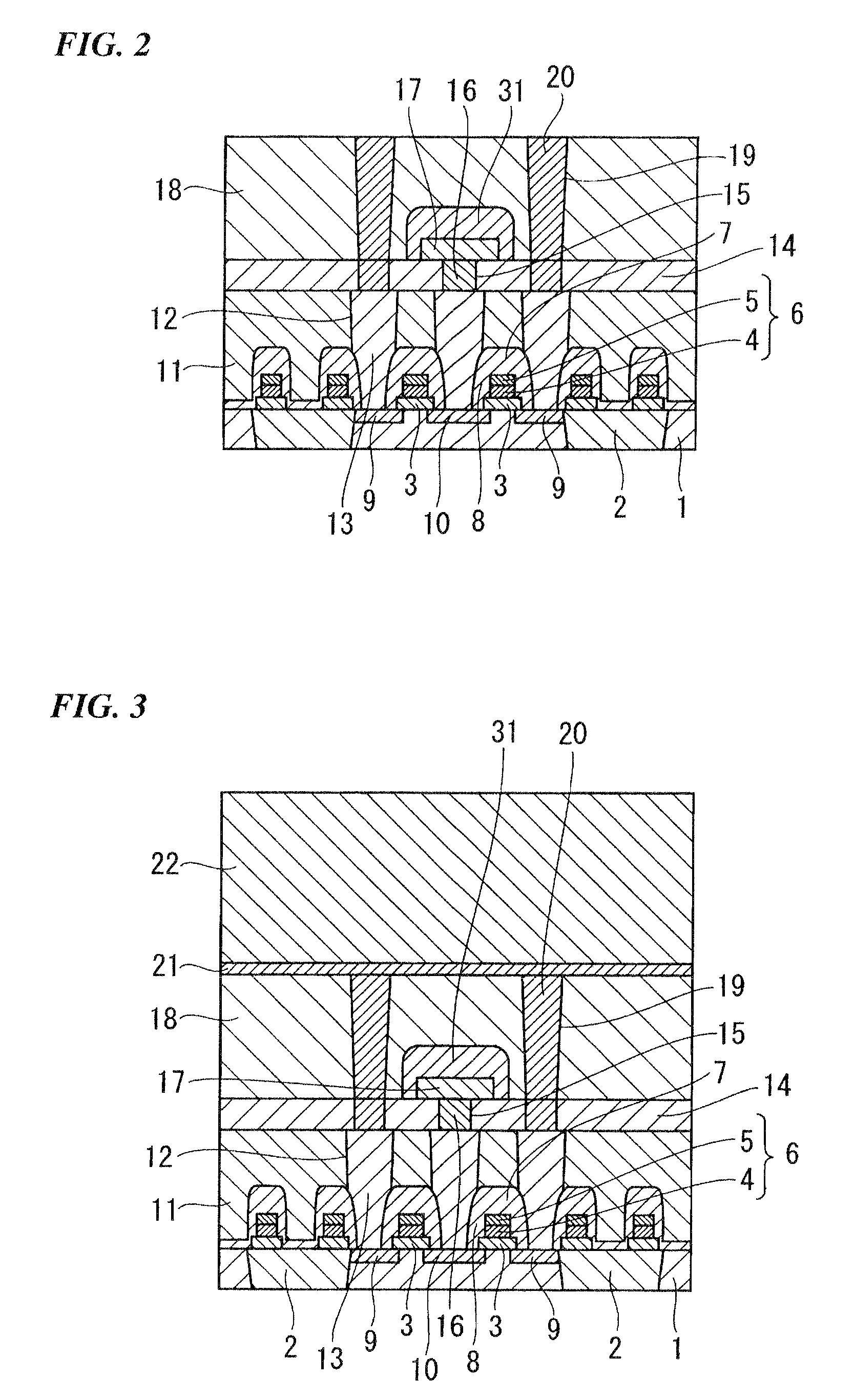

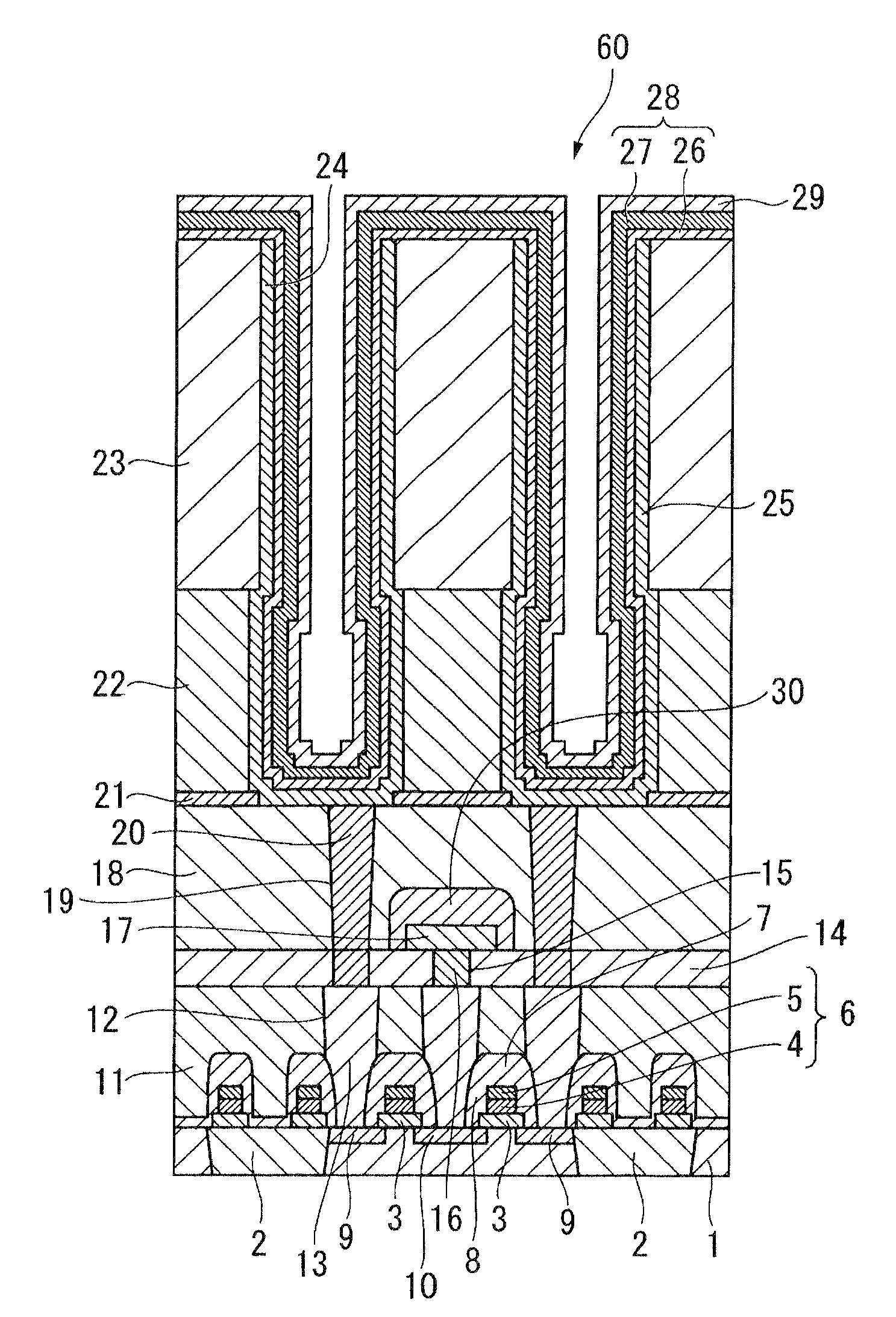

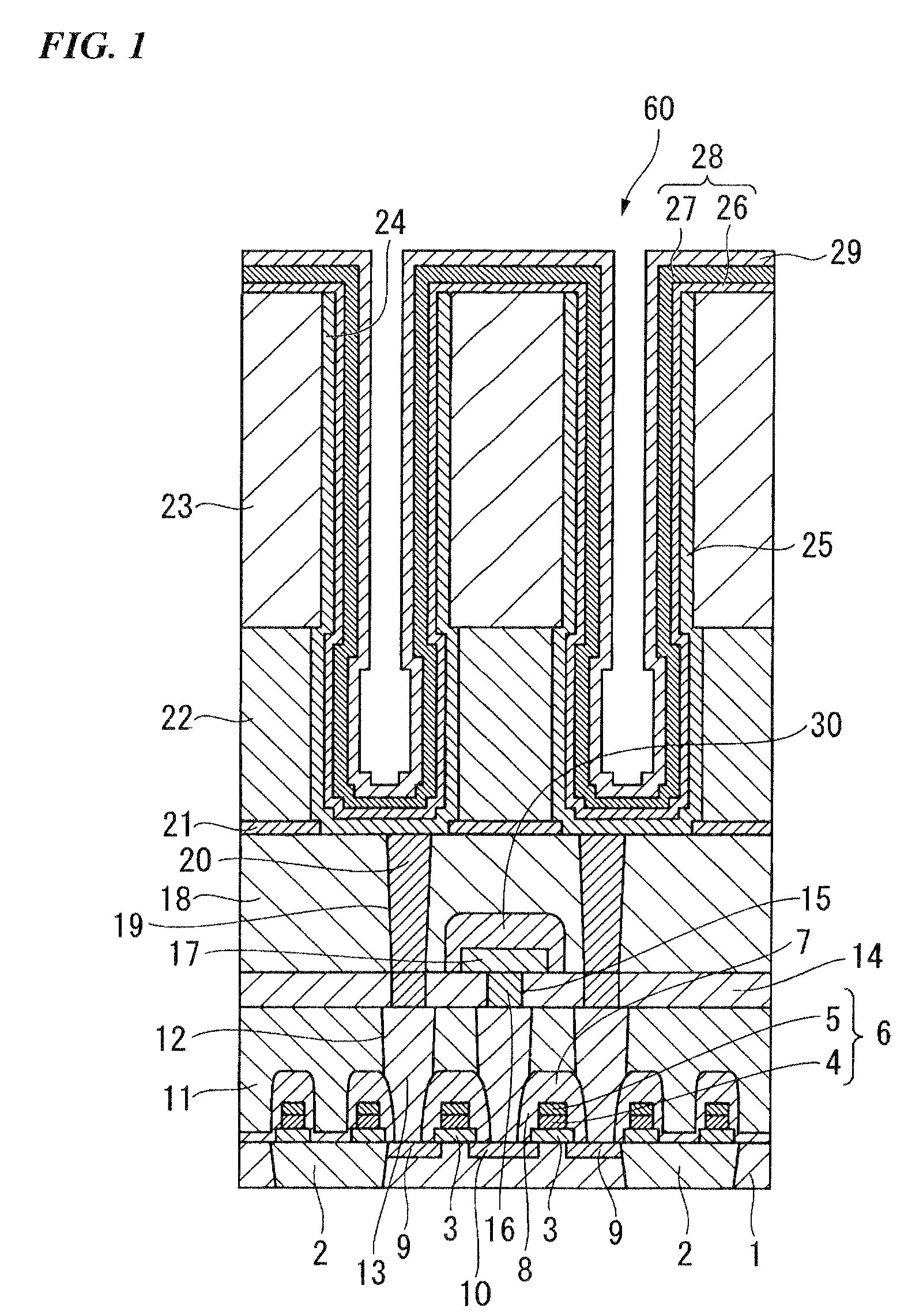

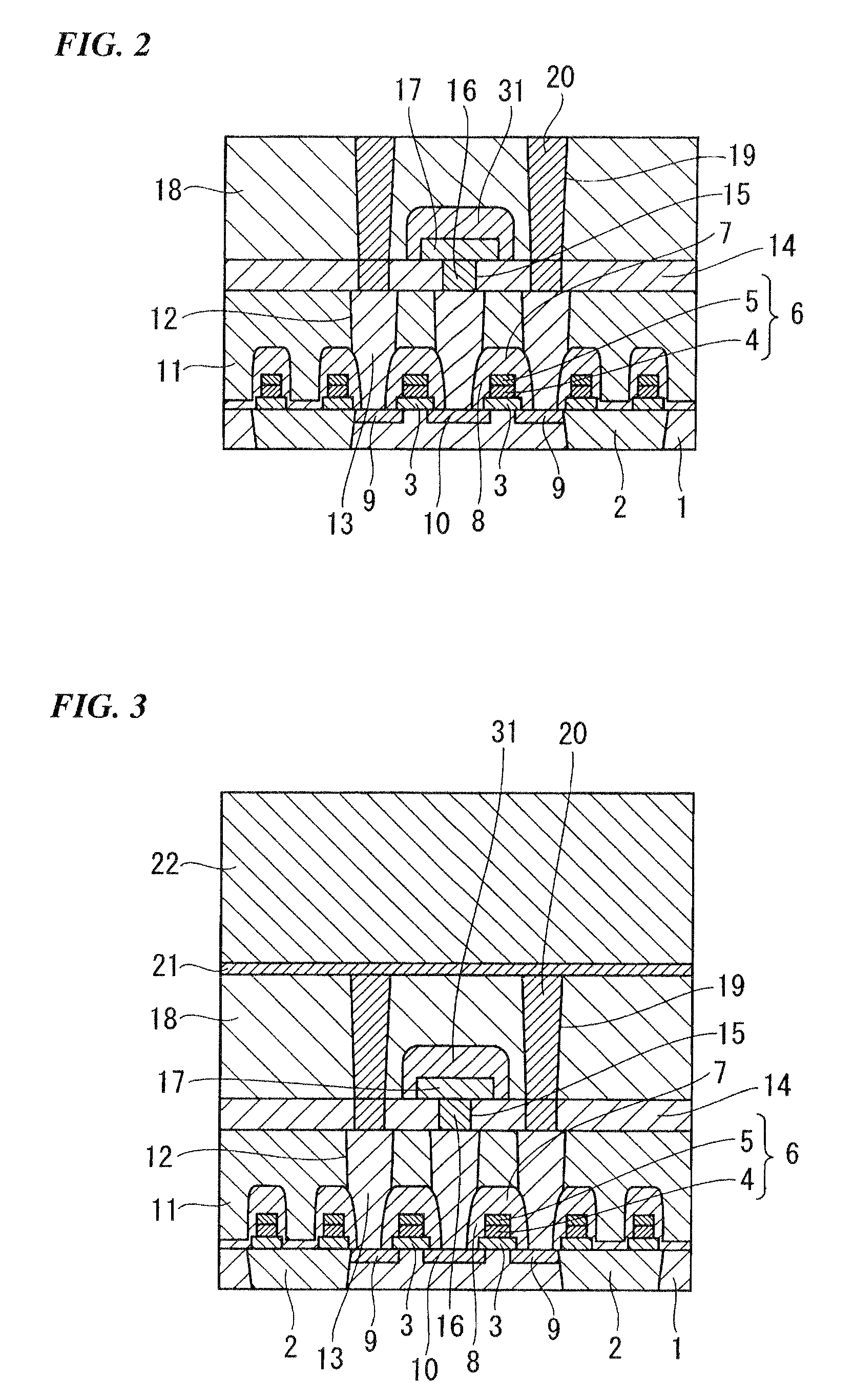

Semiconductor device and method of manufacturing the same

InactiveUS20080157279A1Limited leakage currentLarge capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceDevice material

Disclosed is a method of manufacturing a semiconductor device formed by laminating a capacitor including a bottom metal electrode, a capacitive insulating film, and an upper metal electrode. When the capacitive insulating film is formed by performing a first step of forming a first dielectric layer on the bottom metal electrode by a vapor phase film forming method using a precursor gas that contains constituent elements of a dielectric; and a second step of forming a second dielectric layer on the first dielectric layer by a vapor phase film forming method using a precursor gas that contains constituent elements of a dielectric, a film forming temperature in the first step is set so as to be lower than a film forming temperature in the second step.

Owner:PS4 LUXCO SARL

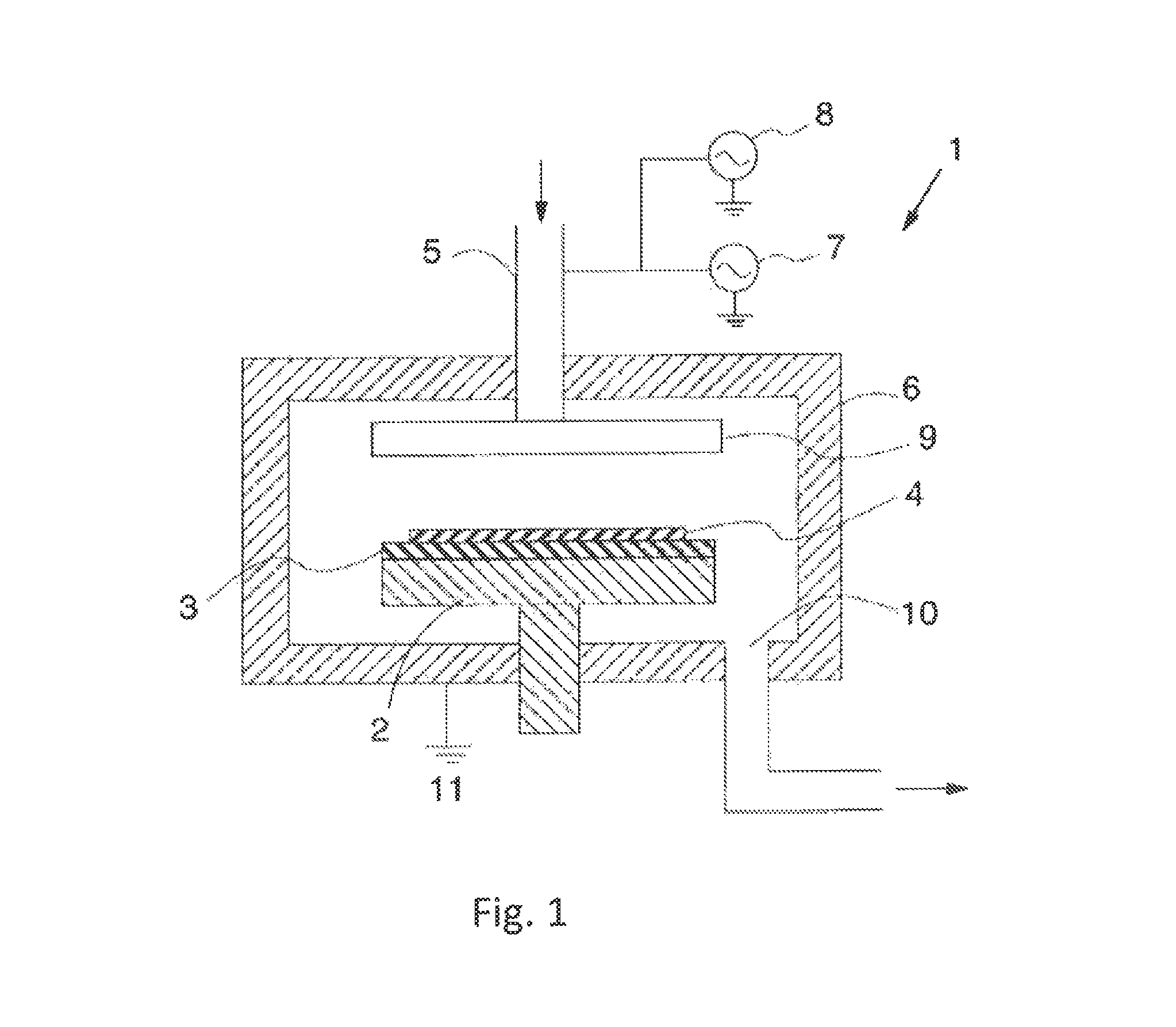

Vapor-deposited film having barrier performance

ActiveUS20140030510A1Uniform film qualityIncrease film densityFlexible coversWrappersGas phaseVolumetric Mass Density

Such a vapor-deposited barrier film is provided that has a vapor-deposited layer having uniform film quality, a high film density and high barrier performance in the initial stage. The vapor-deposited barrier film contains a substrate having on at least one surface thereof at least one layer of a vapor-deposited layer (a). The vapor-deposited layer (a) contains a metal oxide, has a thickness of from 10 to 500 nm, and has an average value of an elemental ratio of oxygen (O) and the metal (oxygen (O) / metal) of 1.20 or more and 1.90 or less and a difference between the maximum value and the minimum value of the (oxygen (O) / metal) of 0.35 or less on analysis of the vapor-deposited layer in the depth direction thereof by an X-ray photoelectron spectroscopy (ESCA) method.

Owner:MITSUBISHI CHEM CORP

Preparation method of RB-SiC (Reaction Bonded Silicon Carbide) substrate reflector surface modification layer

InactiveCN104451580AImprove optical qualityRaise the incident energyVacuum evaporation coatingSputtering coatingReaction bonded silicon carbideSurface cleaning

The invention provides a preparation method of an RB-SiC (Reaction Bonded Silicon Carbide) substrate reflector surface modification layer, and belongs to the technical field of thin film deposition. The method comprises the following steps: I, preparing filming conditions: mounting a Si target on a twin sputtering cathode of a filming machine, performing surface cleaning treatment on the RB-SiC substrate, fixing to a filming machine workpiece clamp, vacuuming the filming machine and roasting the RB-SiC substrate; II, performing surface treatment on the surface of the Si target of the sputtering cathode: introducing Ar gas into the sputtering cathode, and adjusting medium frequency power supply power to perform sputtering pre-treatment on the surface of the Si target; III, preparing the Si modification layer: increasing the medium frequency power supply power and Ar ventilation volume, and depositing the Si modification layer on the RB-SiC substrate by using a medium frequency magnetron sputtering technology. The preparation process is greatly simplified, the compactness of the film layer is high, the film is uniform, the polishing characteristic is obviously improved, and the optical quality of the surface of the polished substrate is greatly improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

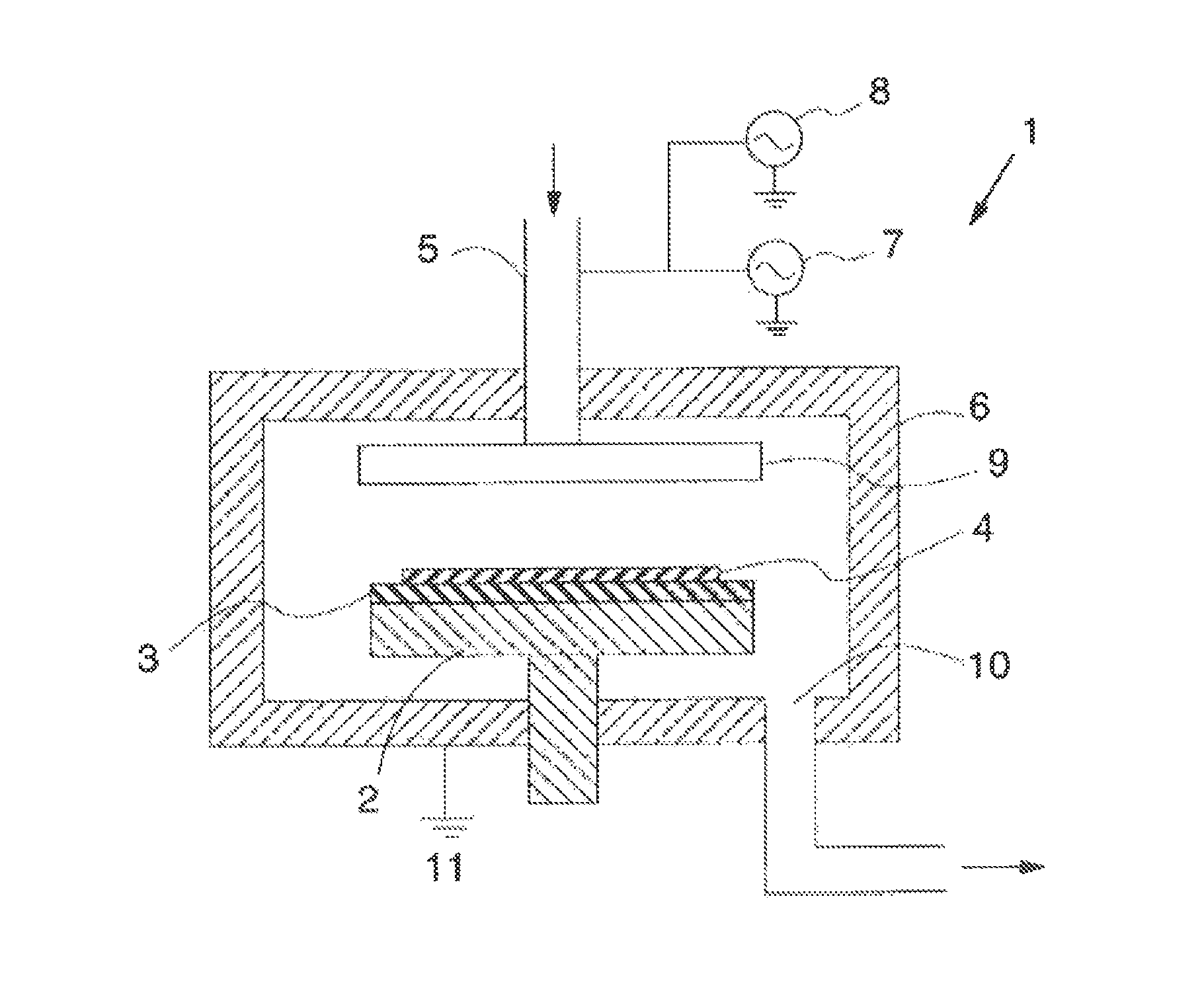

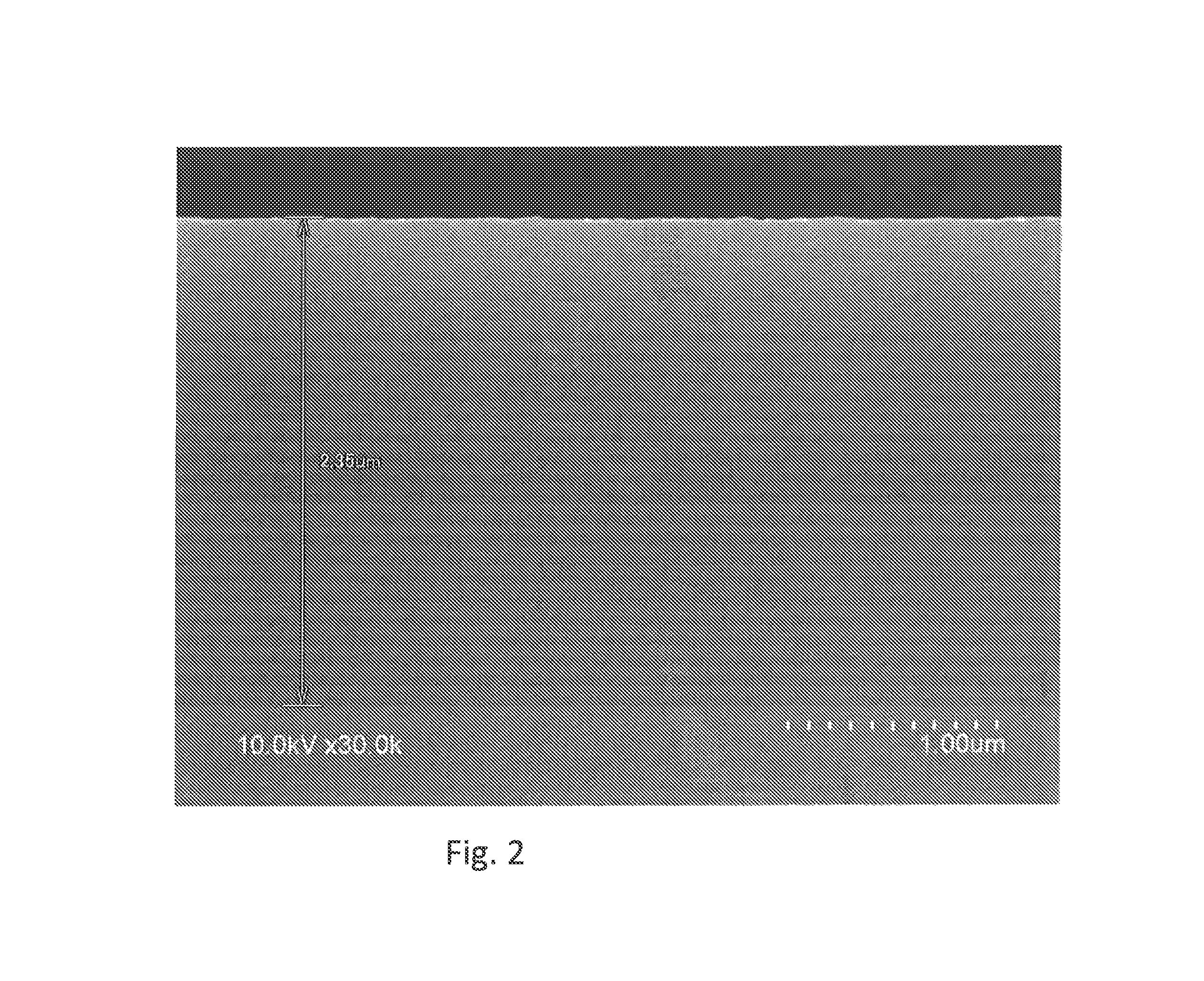

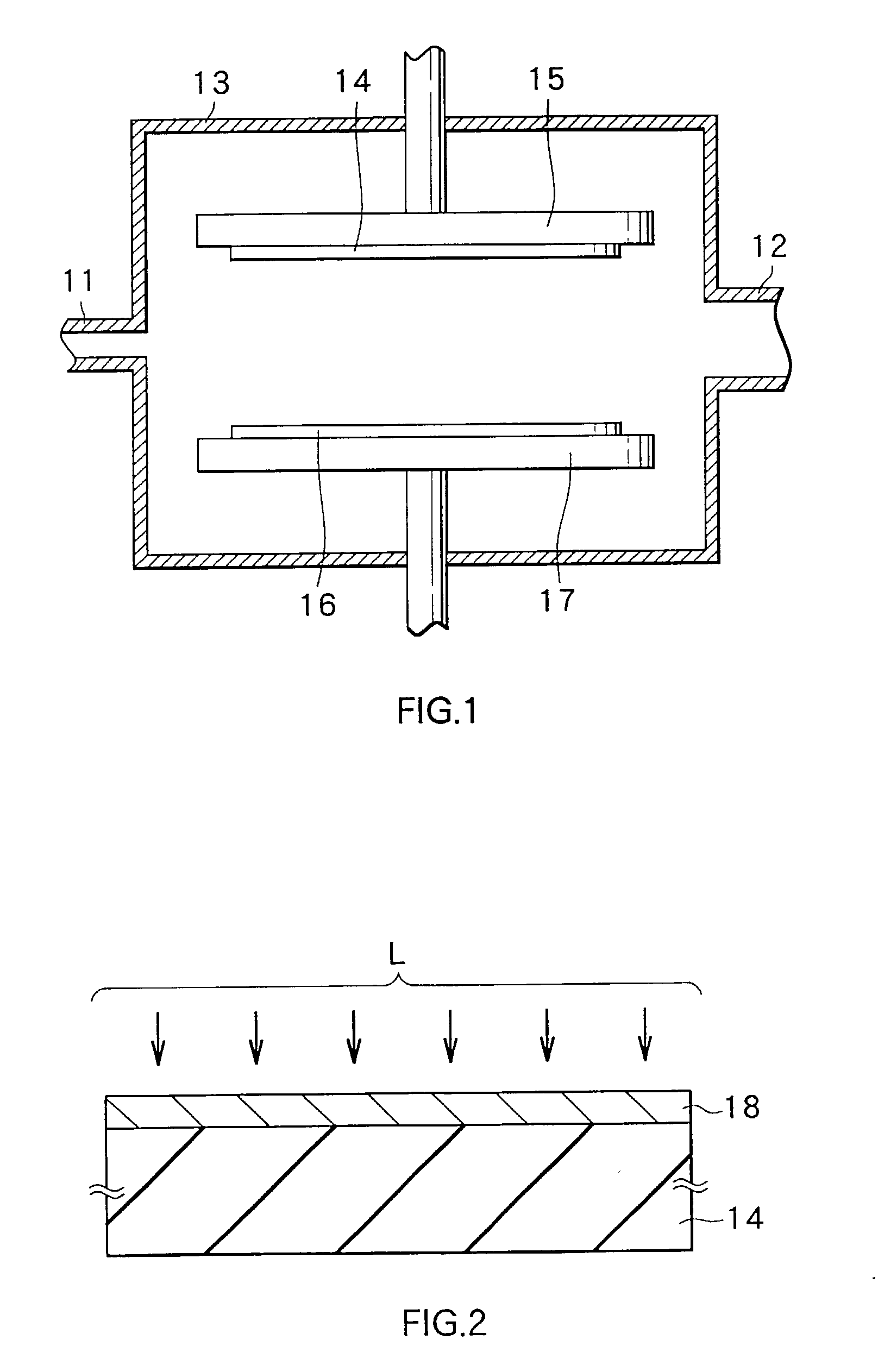

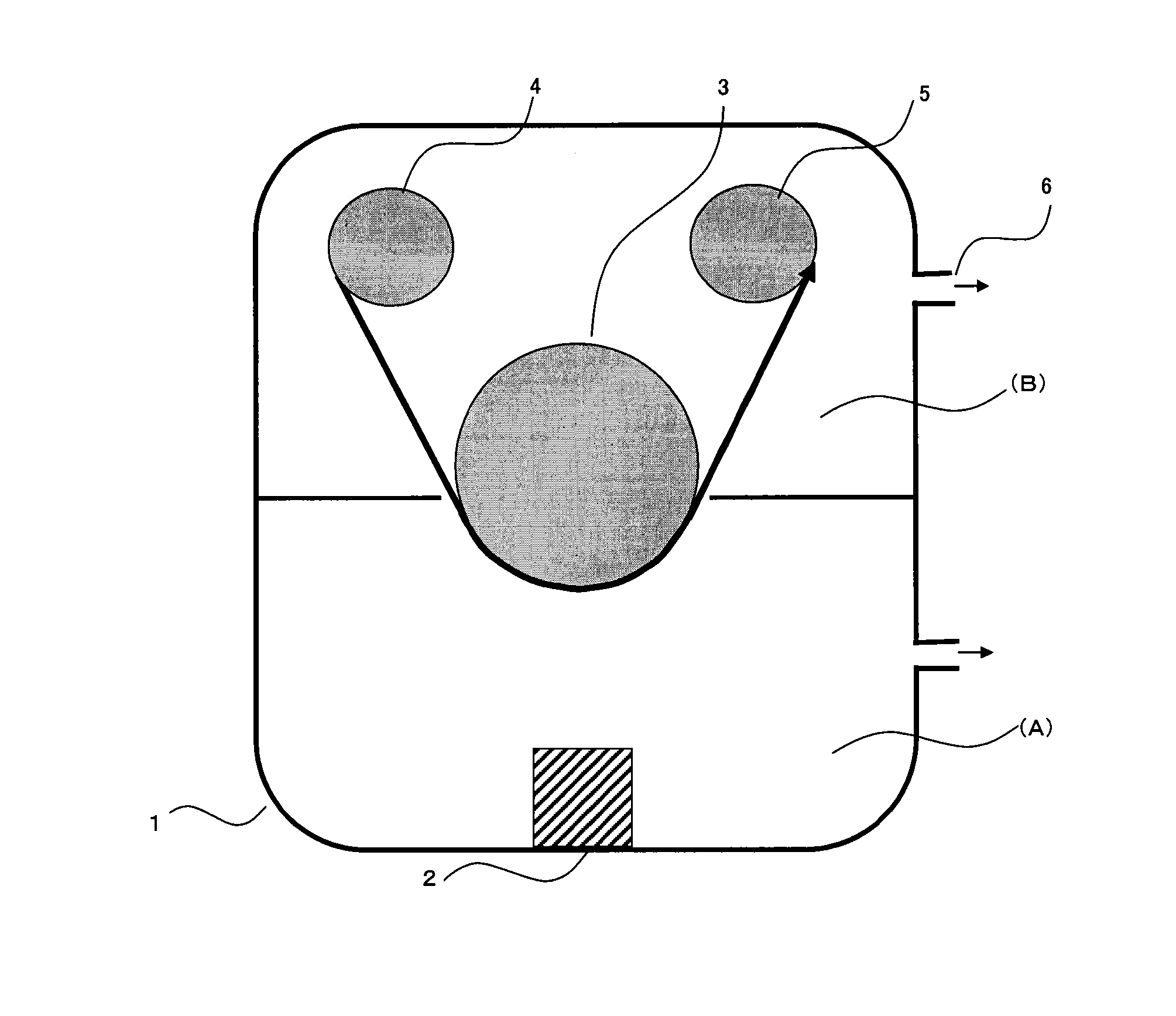

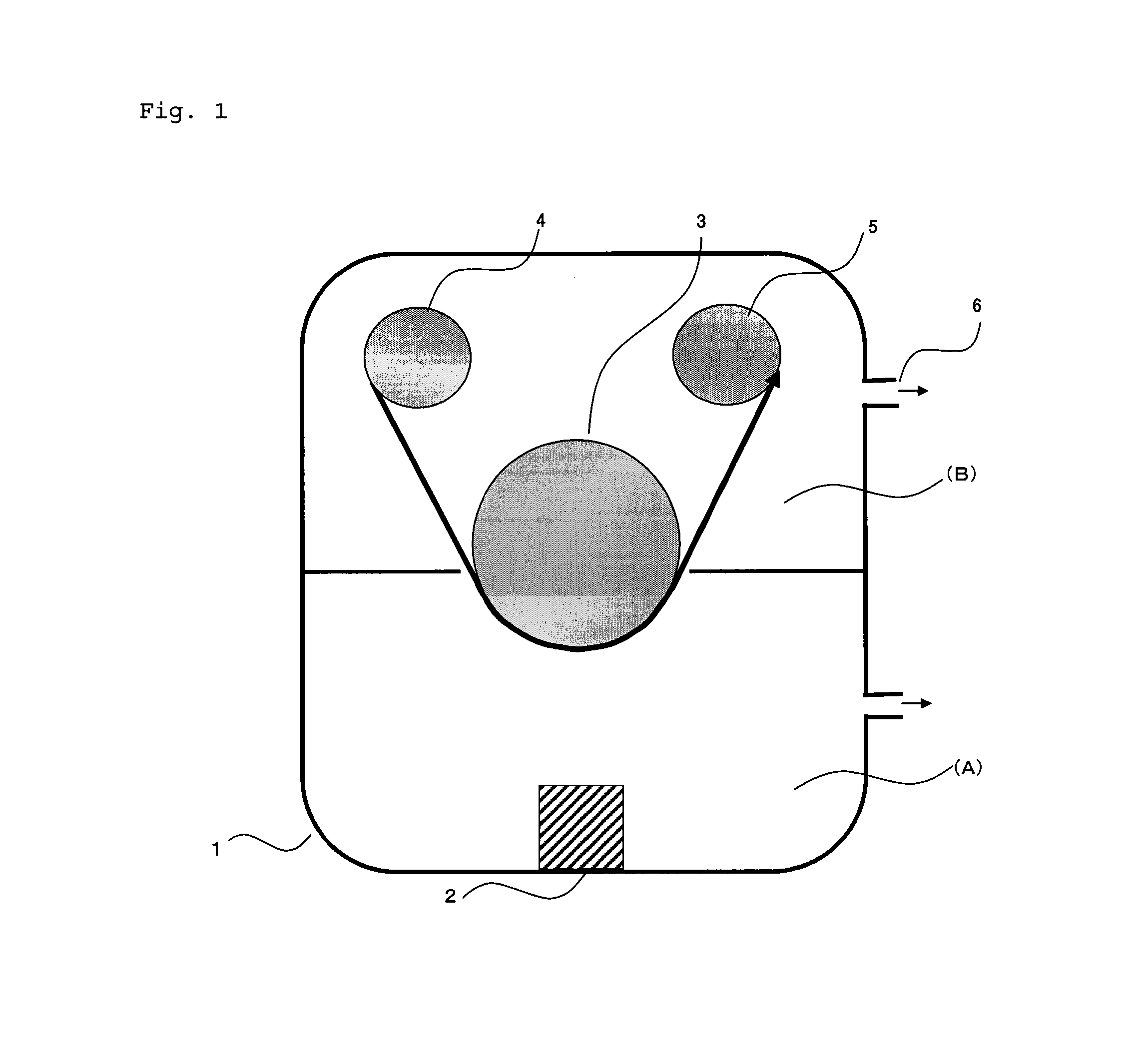

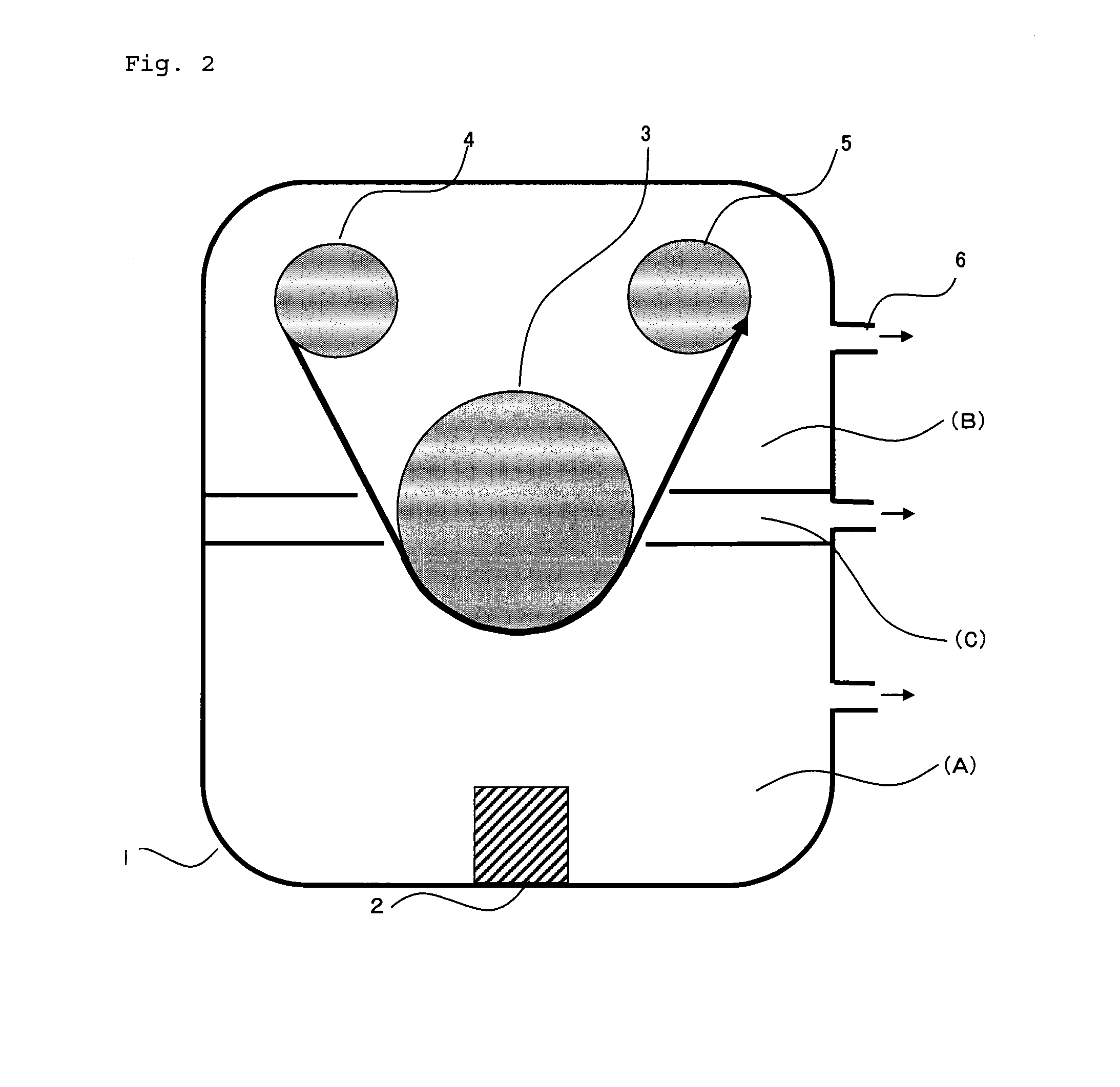

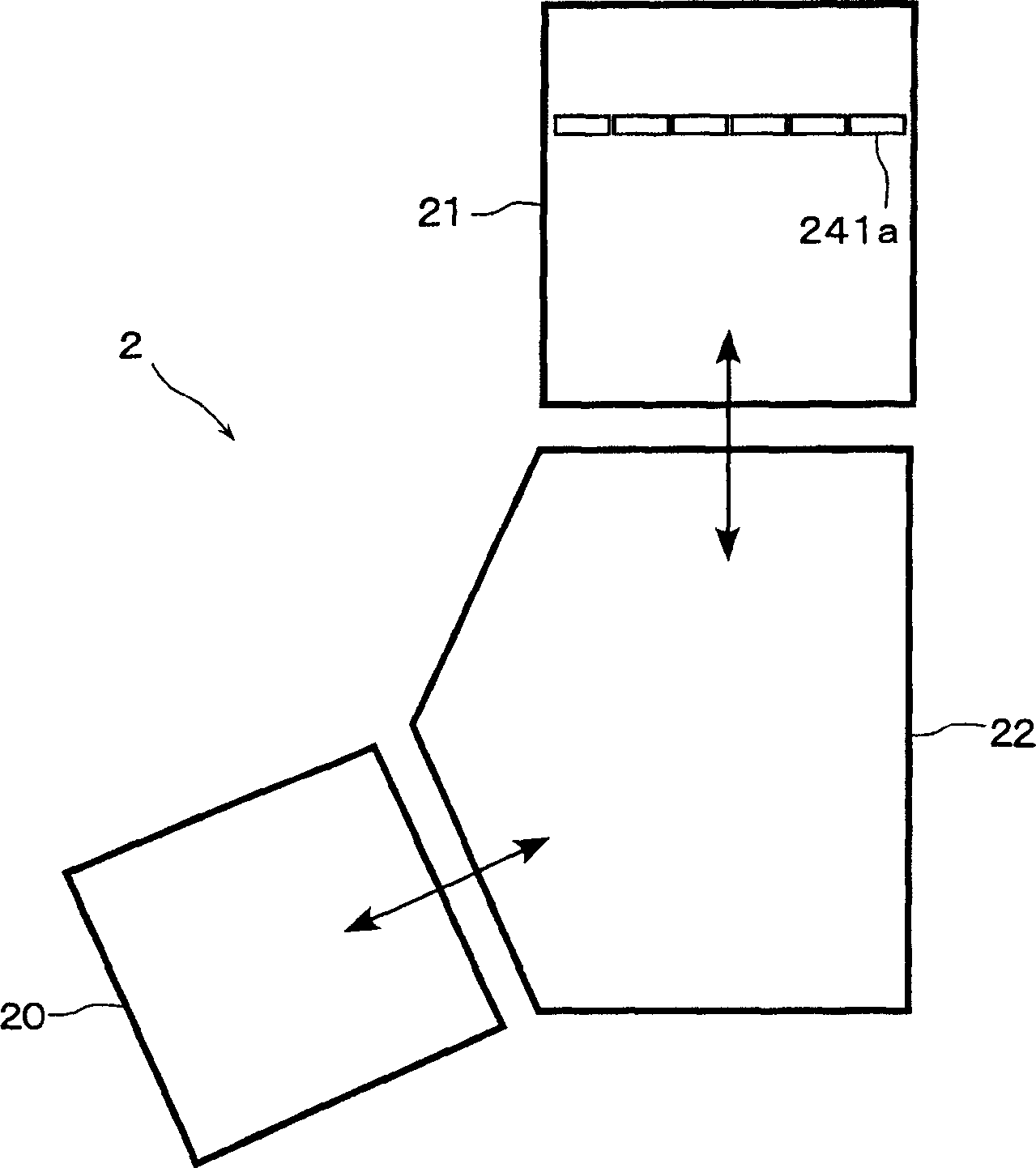

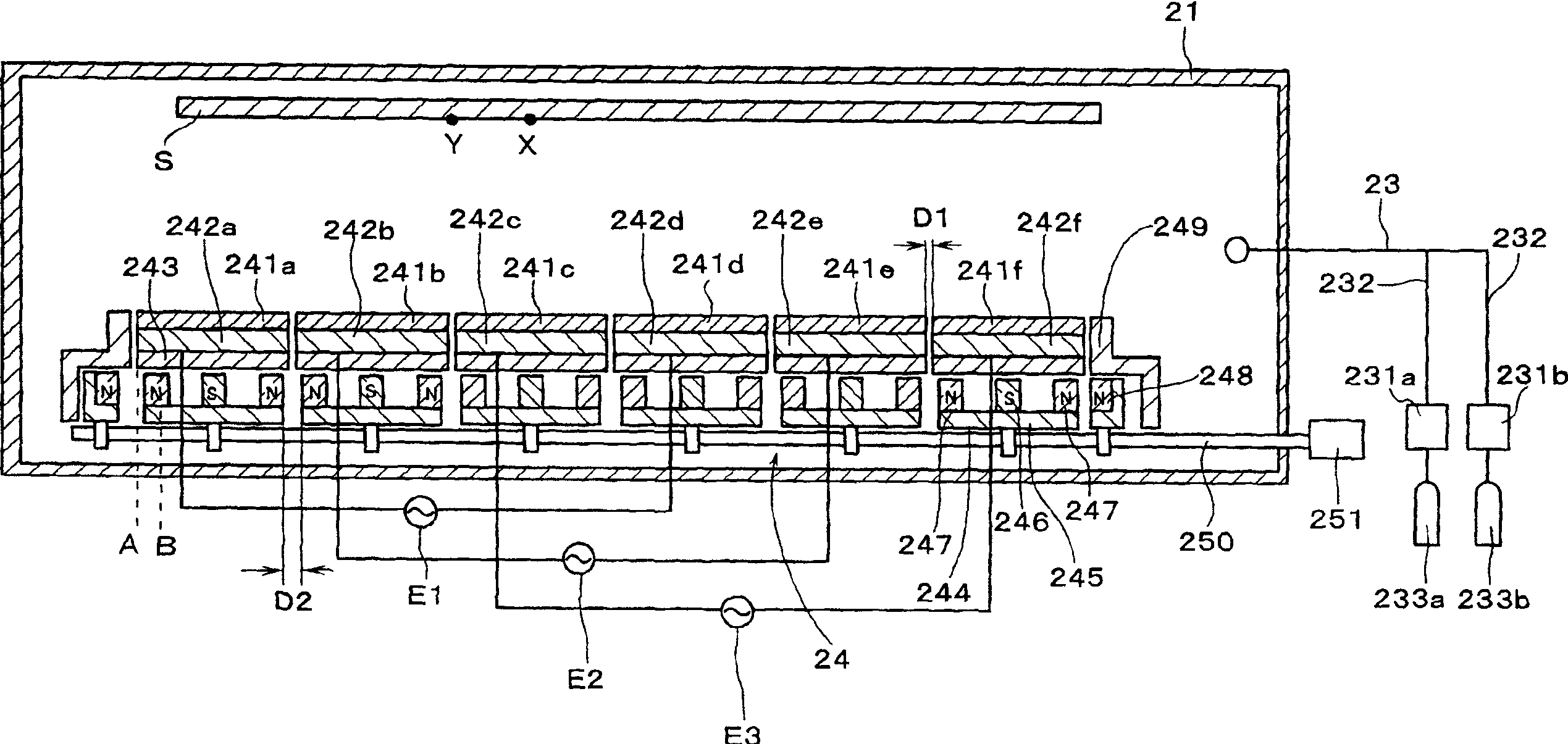

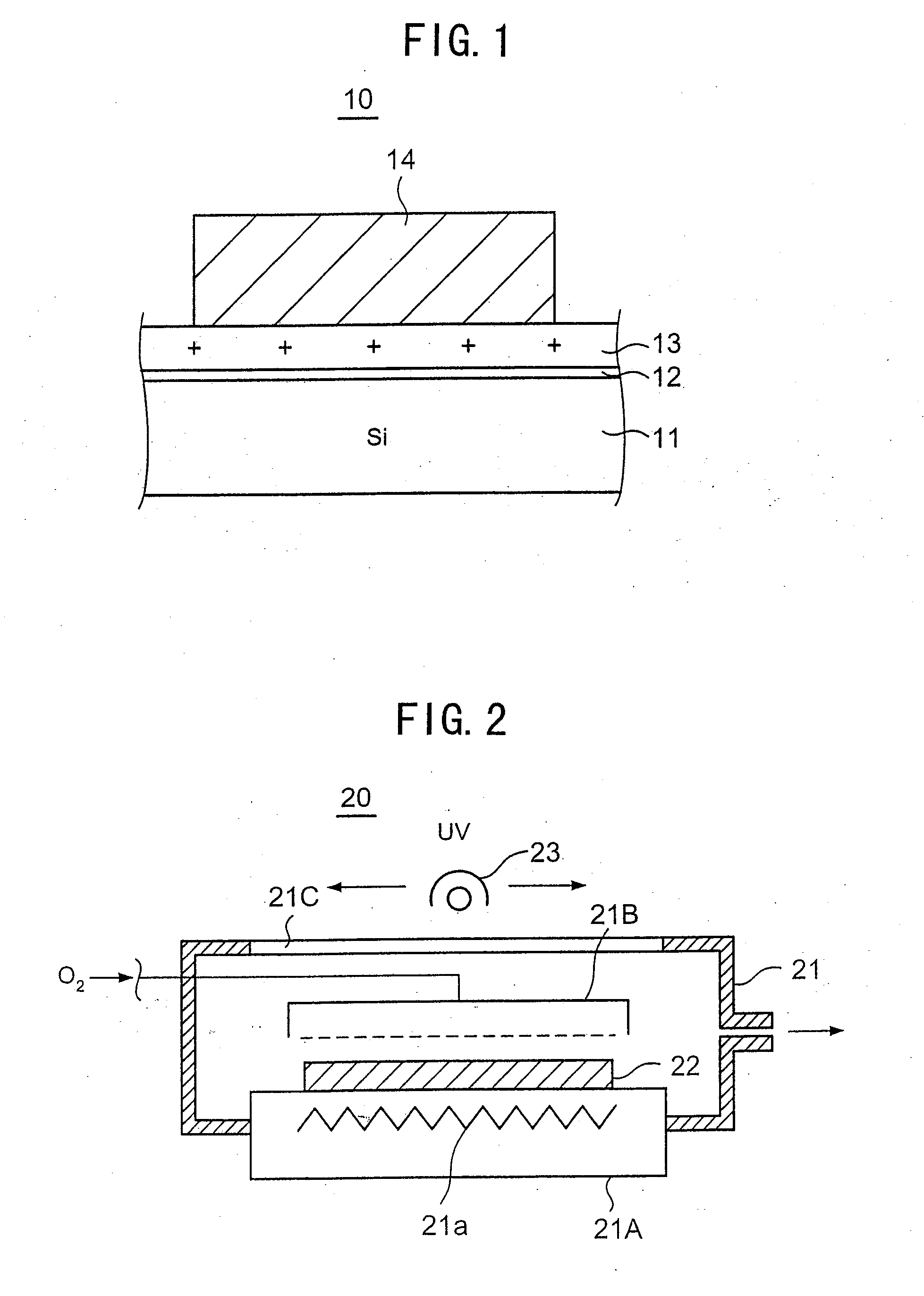

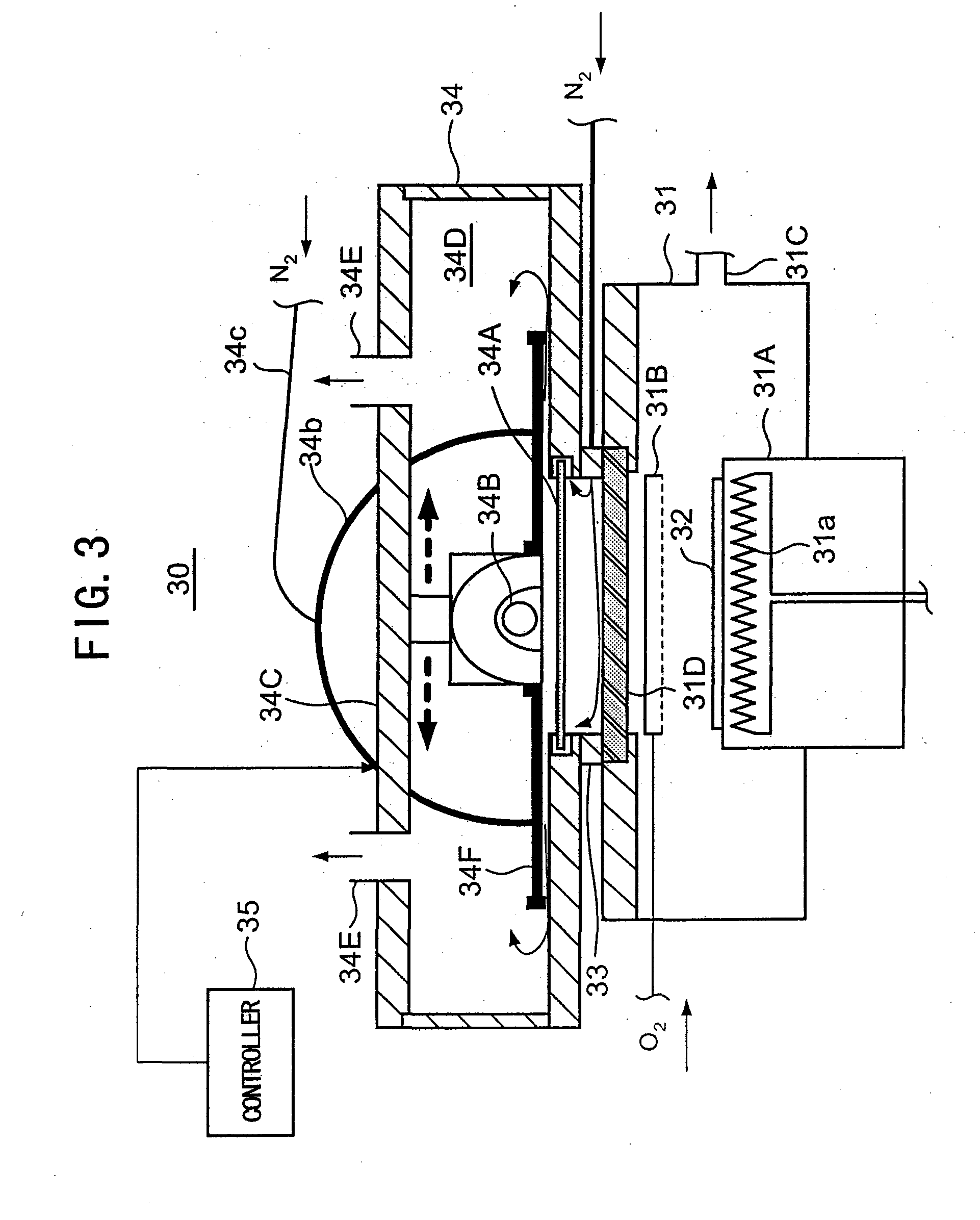

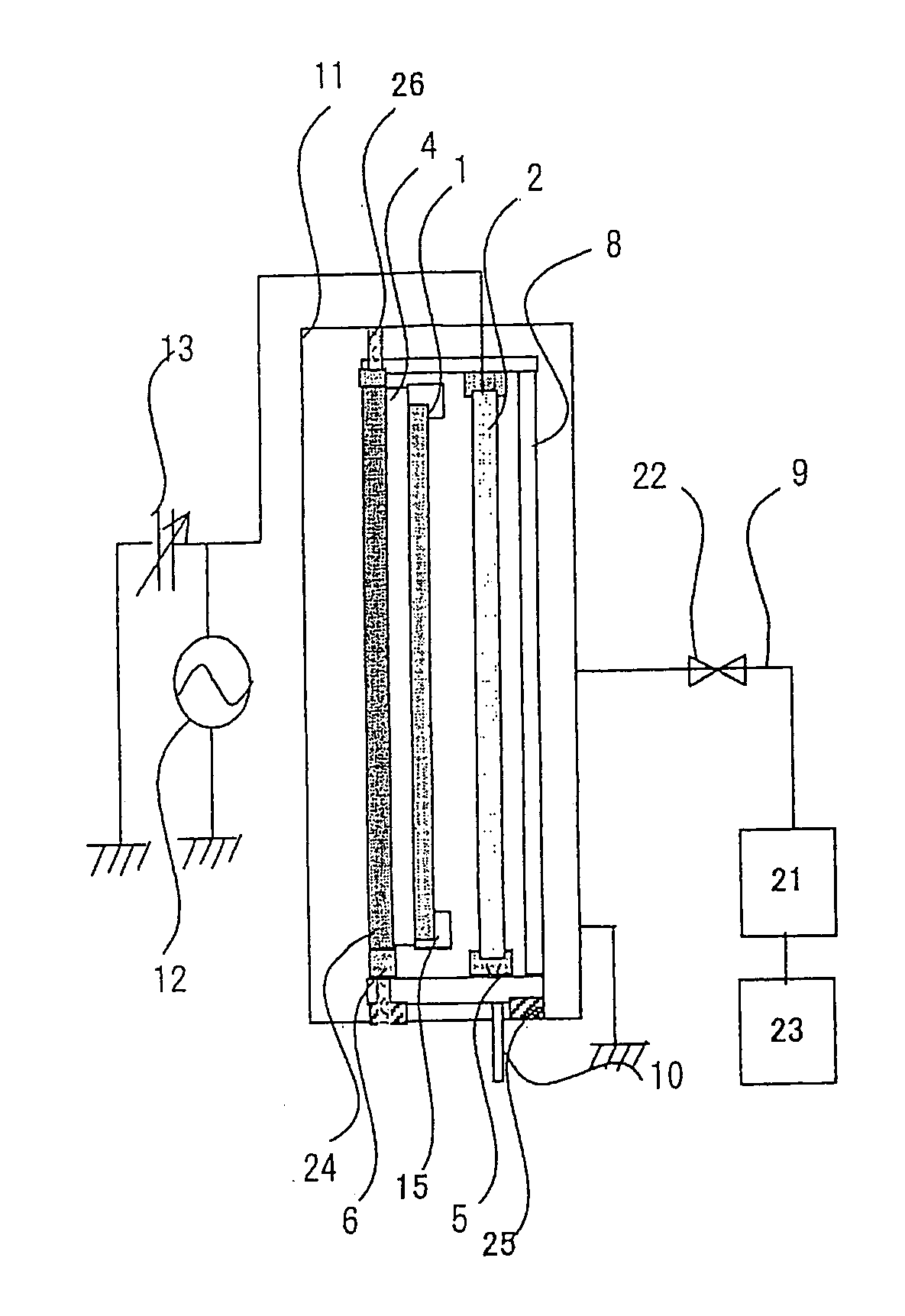

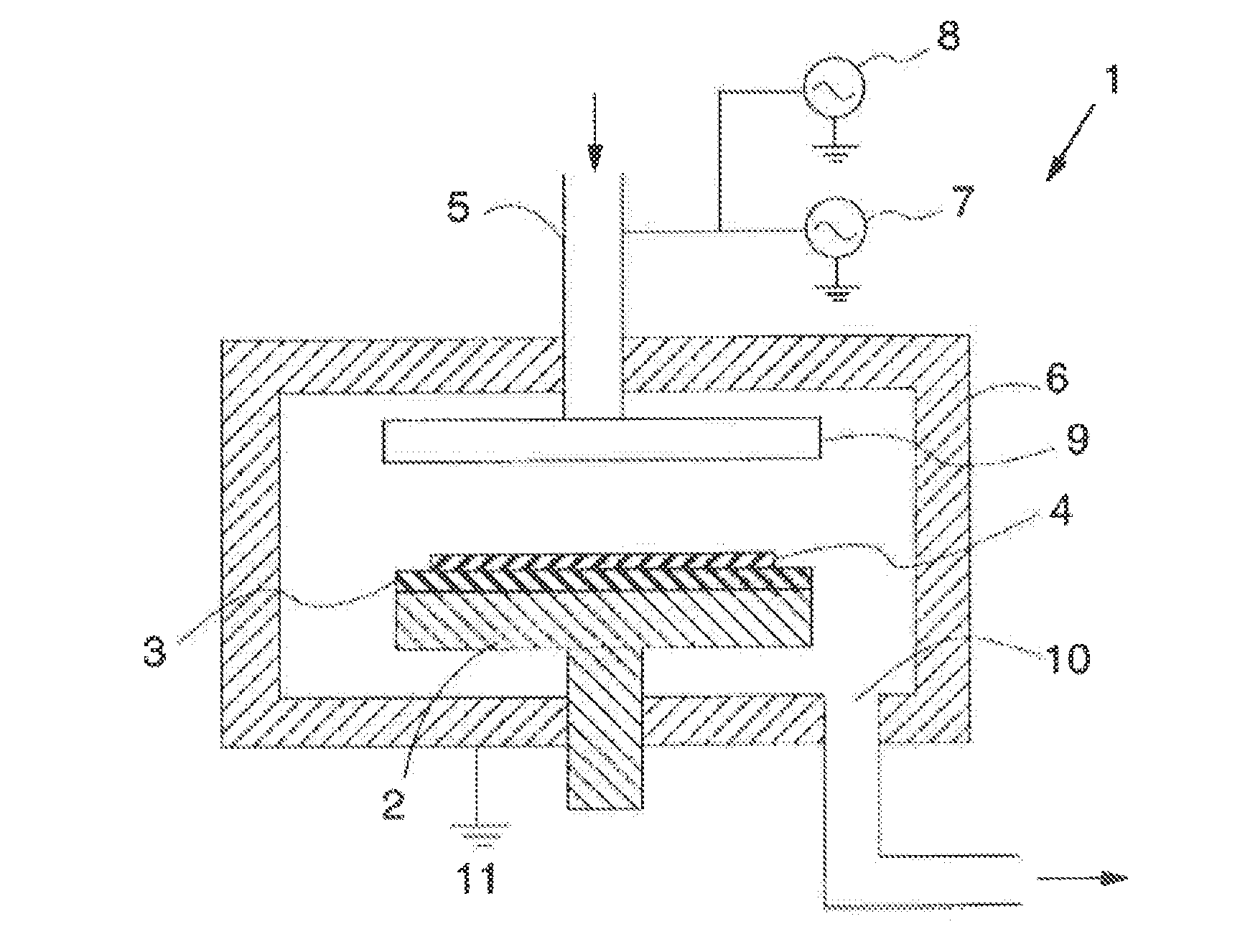

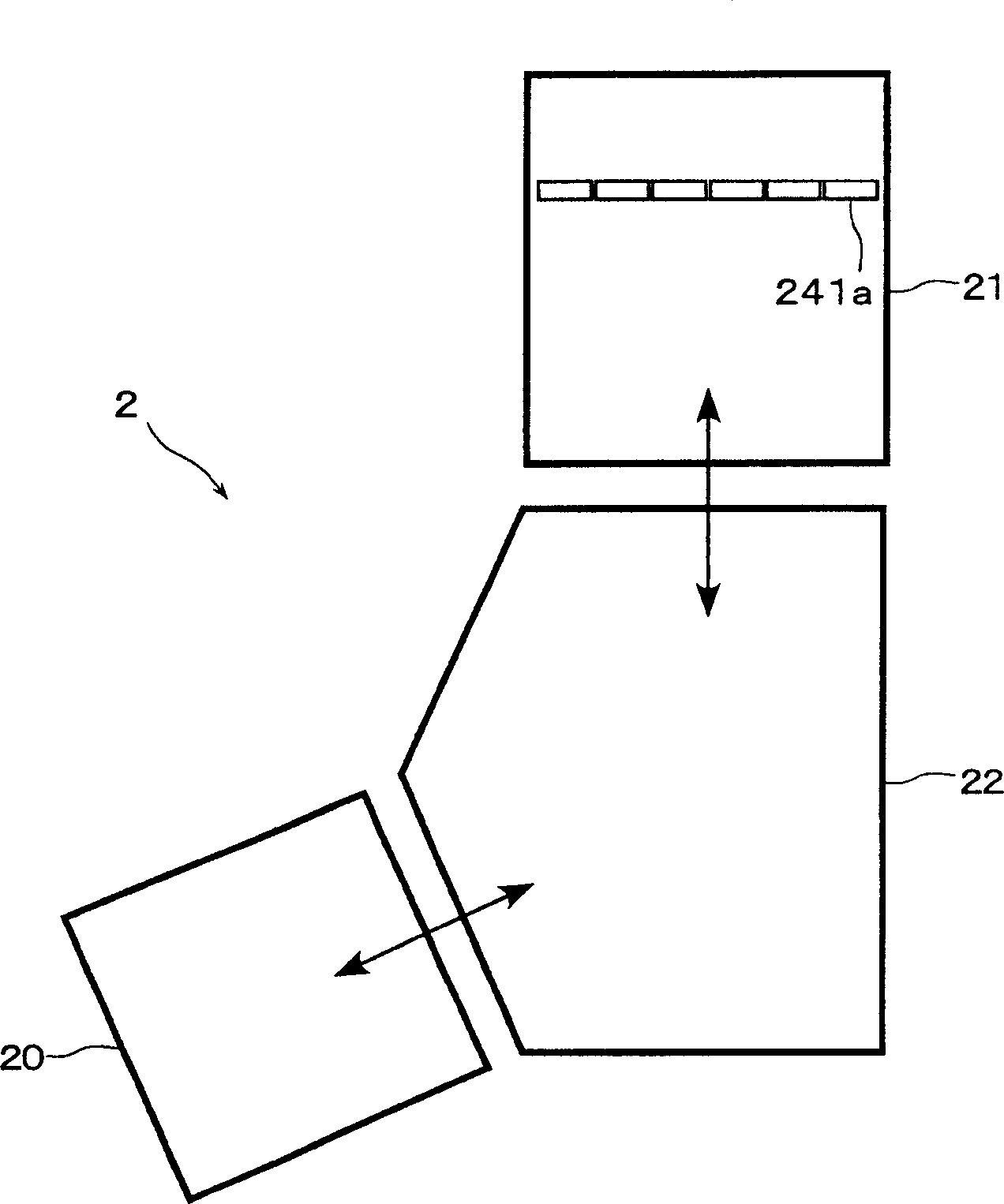

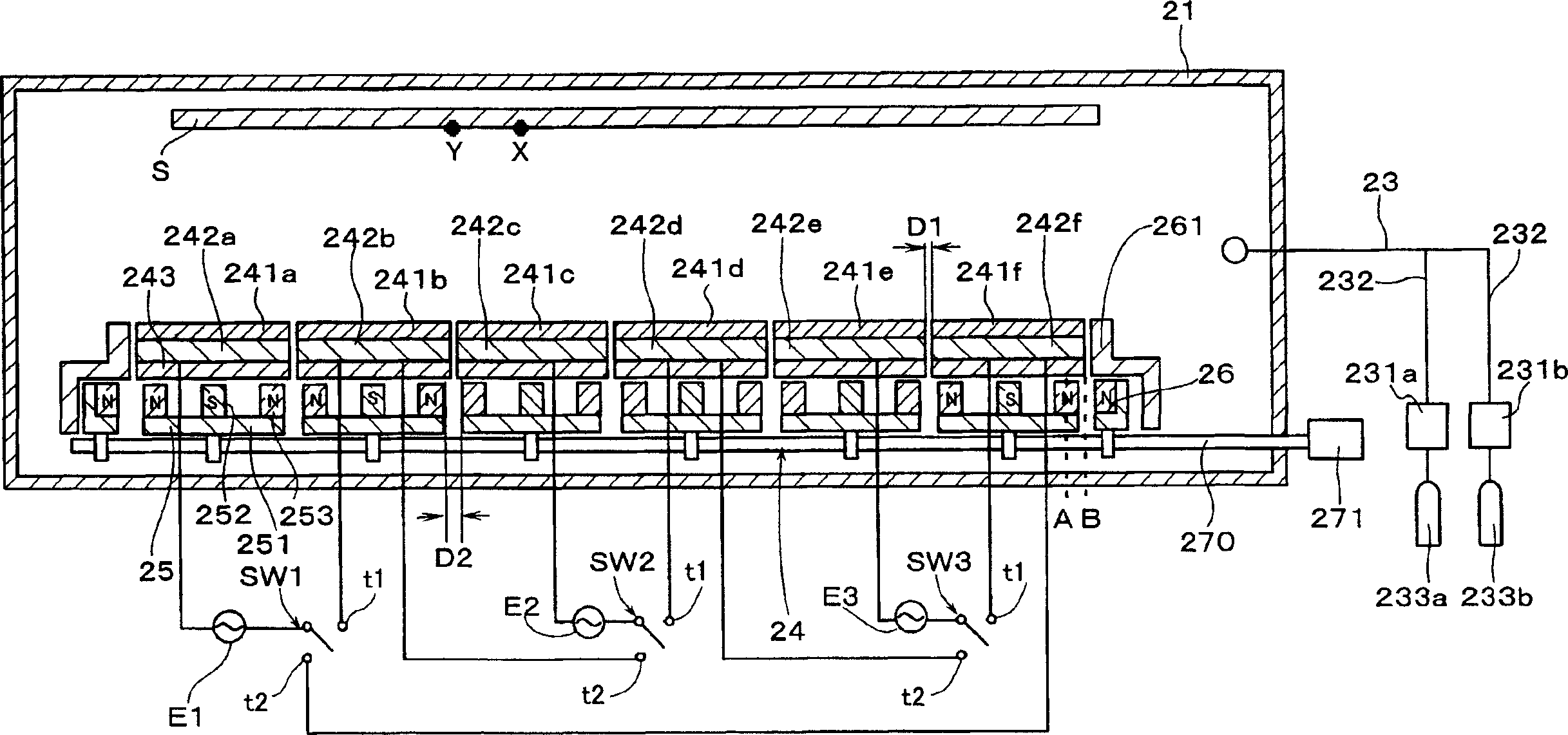

Sputtering device and sputtering method

ActiveCN1904132AUniform film qualityVacuum evaporation coatingSputtering coatingSputteringEngineering

The invention provides a sputtering apparatus capable of preventing any non-erosive area from remaining on a target, and depositing a film of a uniform quality when performing the responsive sputtering. The sputtering apparatus 2 has at least four targets 241 arranged side by side at predetermined intervals in a vacuum chamber 21, and AC power sources E connected to two targets one by one out of the targets arranged side by side so as to alternately apply the negative potential and the positive potential or the grounding potential thereto, and each AC power source E is connected to the two targets 241 not adjacent to each other.

Owner:ULVAC INC

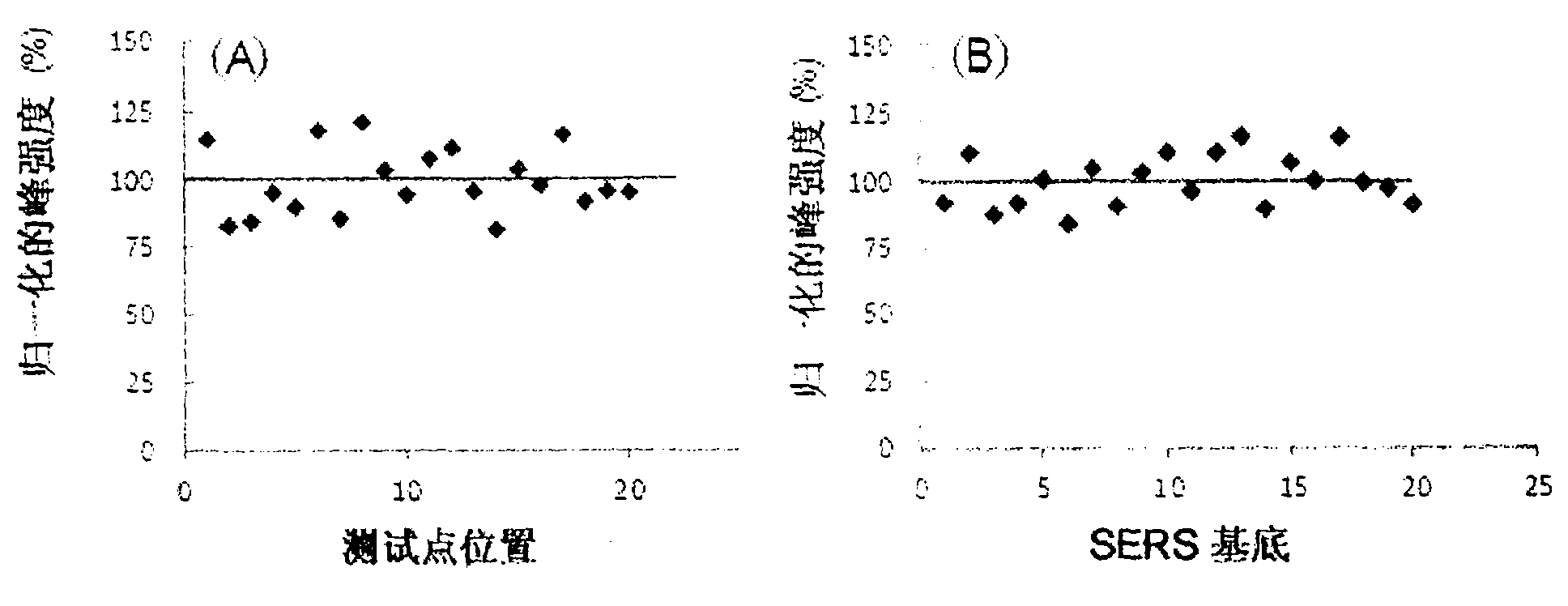

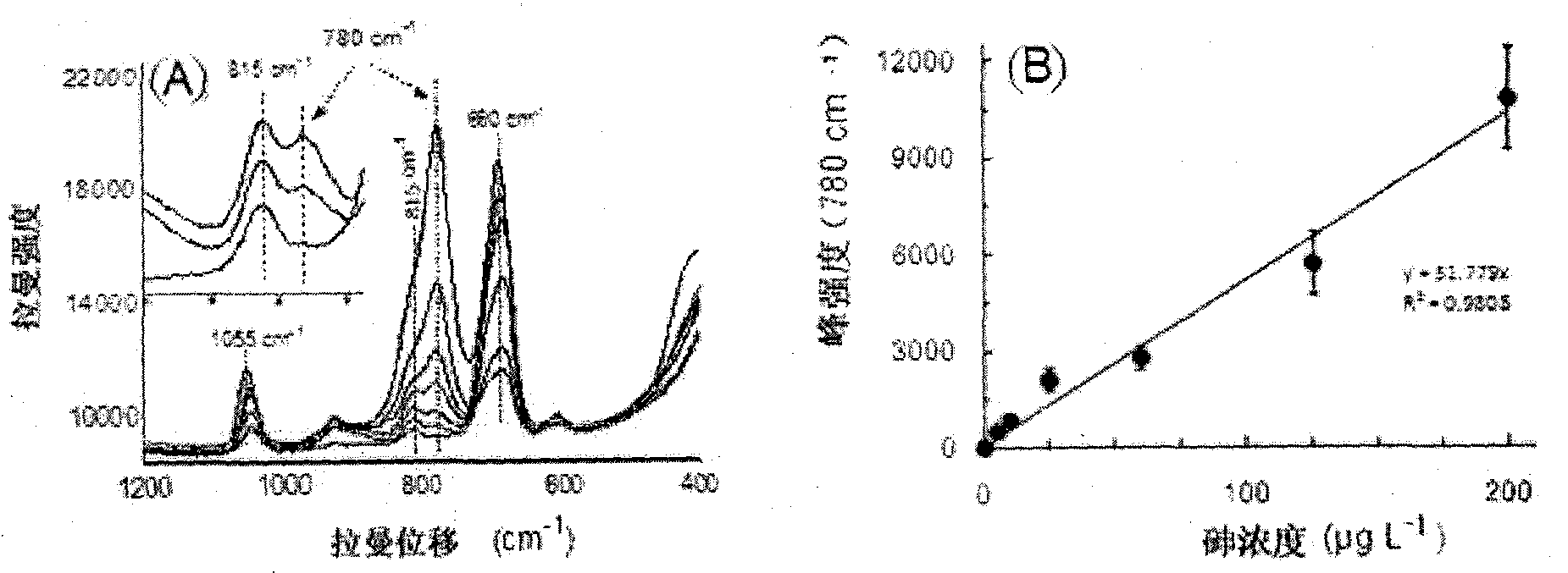

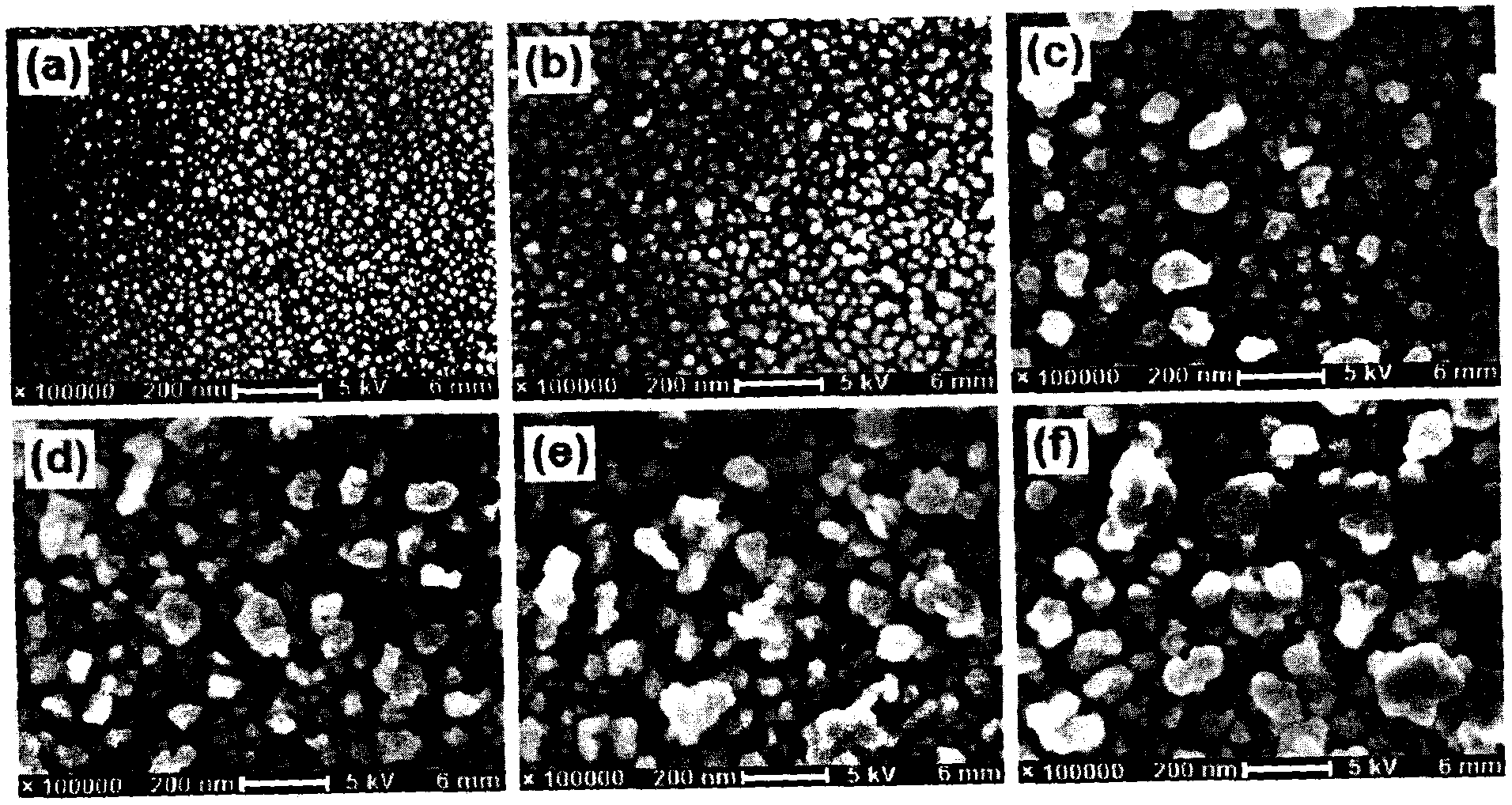

Surface enhanced Raman scattering substrate constructed by electroless deposition and preparation method and application thereof

InactiveCN104251852AAchieve optimizationEasy to optimizeRaman scatteringChemical physicsOptical spectrometer

The invention discloses a surface enhanced Raman scattering (SERS) technique based novel method for simple, rapid and low cost determination of perchlorate radicals in water and a preparation method of a key component SERS substrate. The method comprises the following steps: (1) construction and modification of the SERS substrate; (2) preparation of an SERS measurement sample; and (3) SERS measurement. According to appearance and strength of the characteristic SERS (930 cm<-1>) peak of the perchlorate radical ion, qualitative and quantitative information can be obtained. The SERS substrate provided by the method has excellent properties, including high sensitivity, good reproducibility, stable performance, reproducibility and reuse, etc. Combined with a portable or handheld Raman spectrometer, the method can realize on-site detection and analysis of trace perchlorate radical ions in water, and has very high application prospect and practical value.

Owner:郝聚民

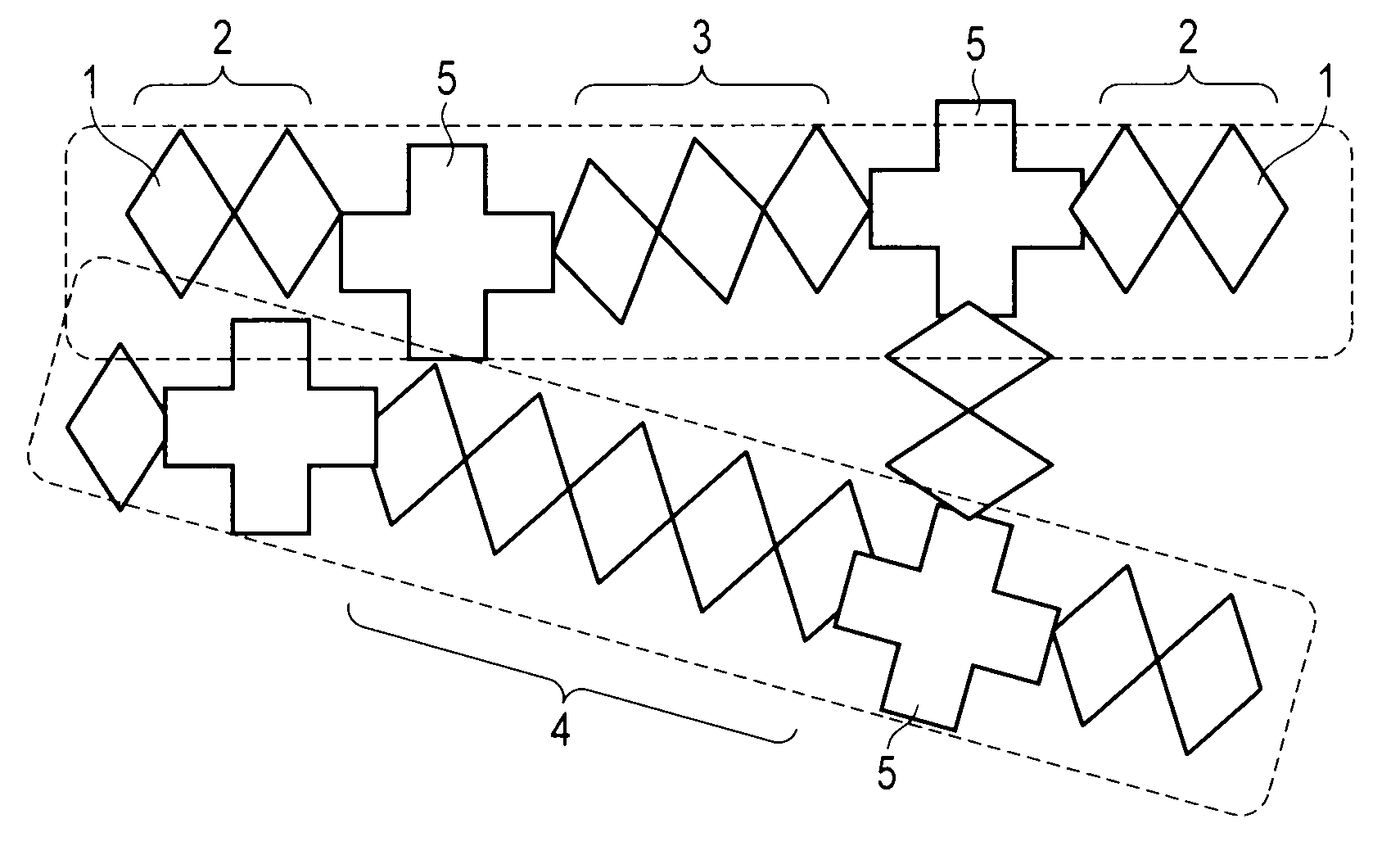

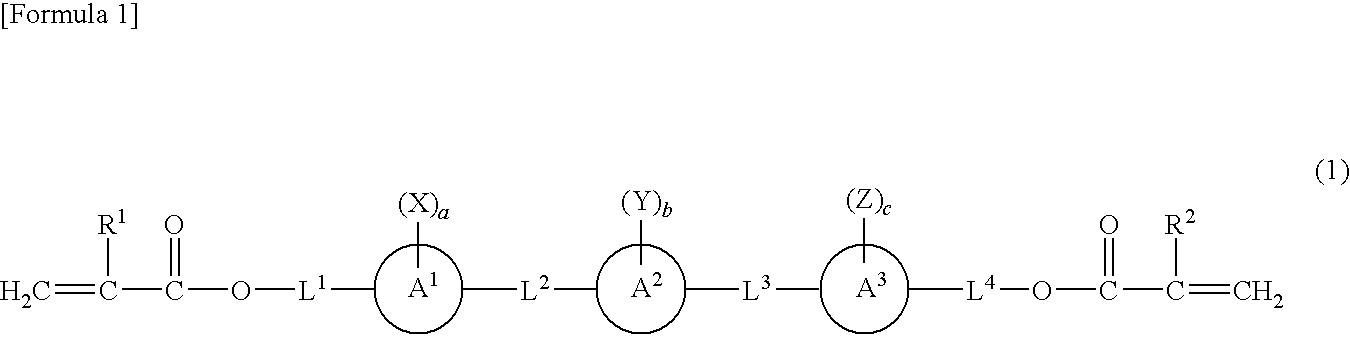

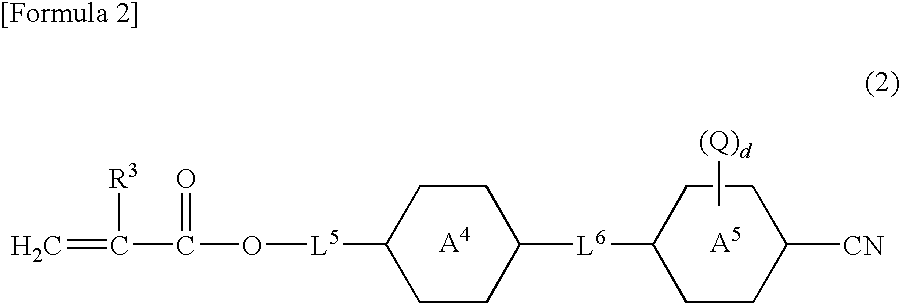

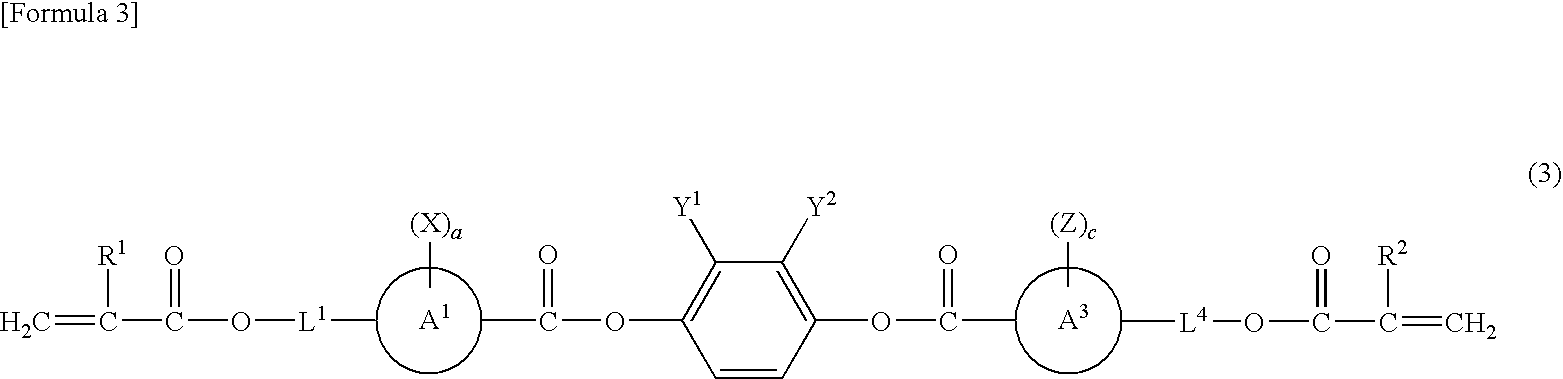

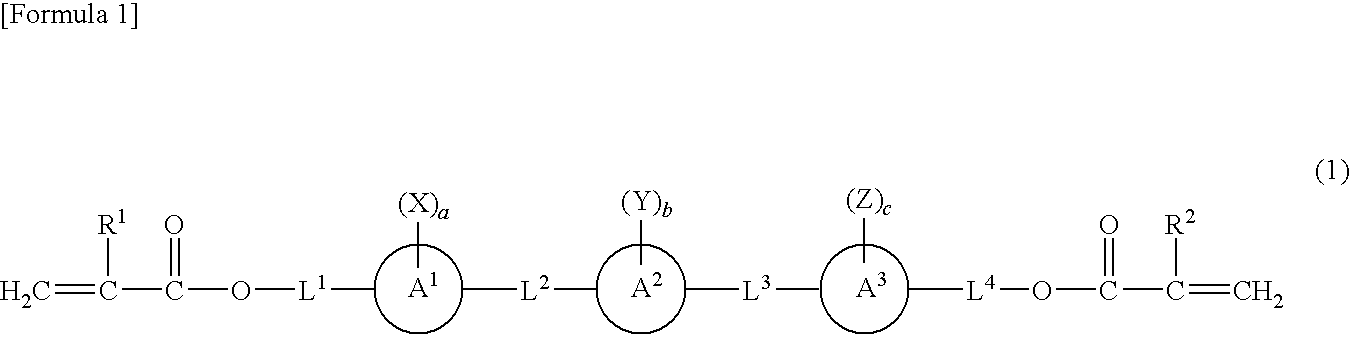

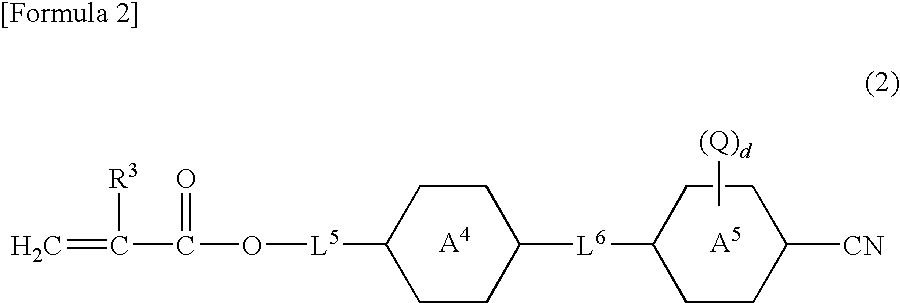

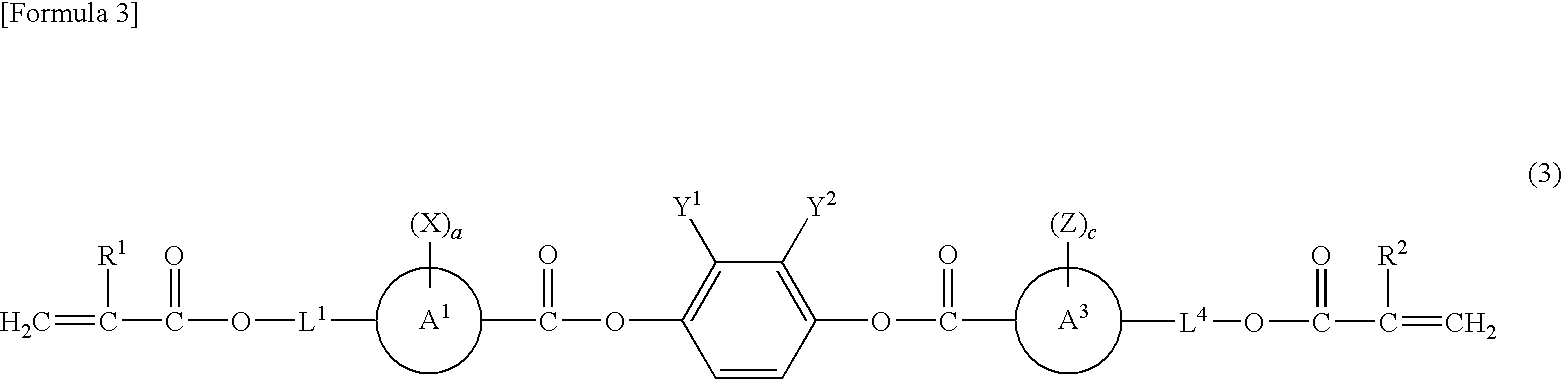

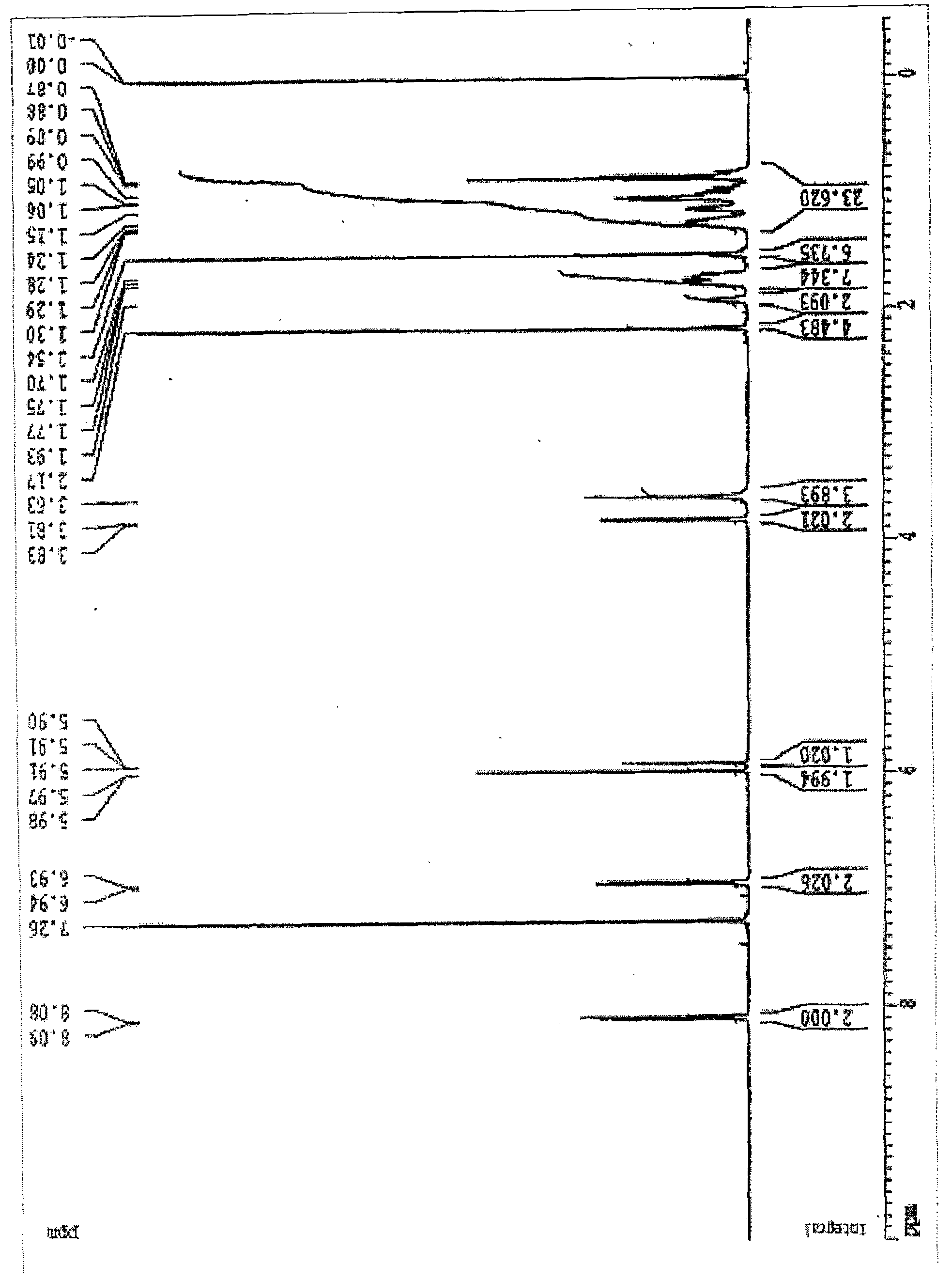

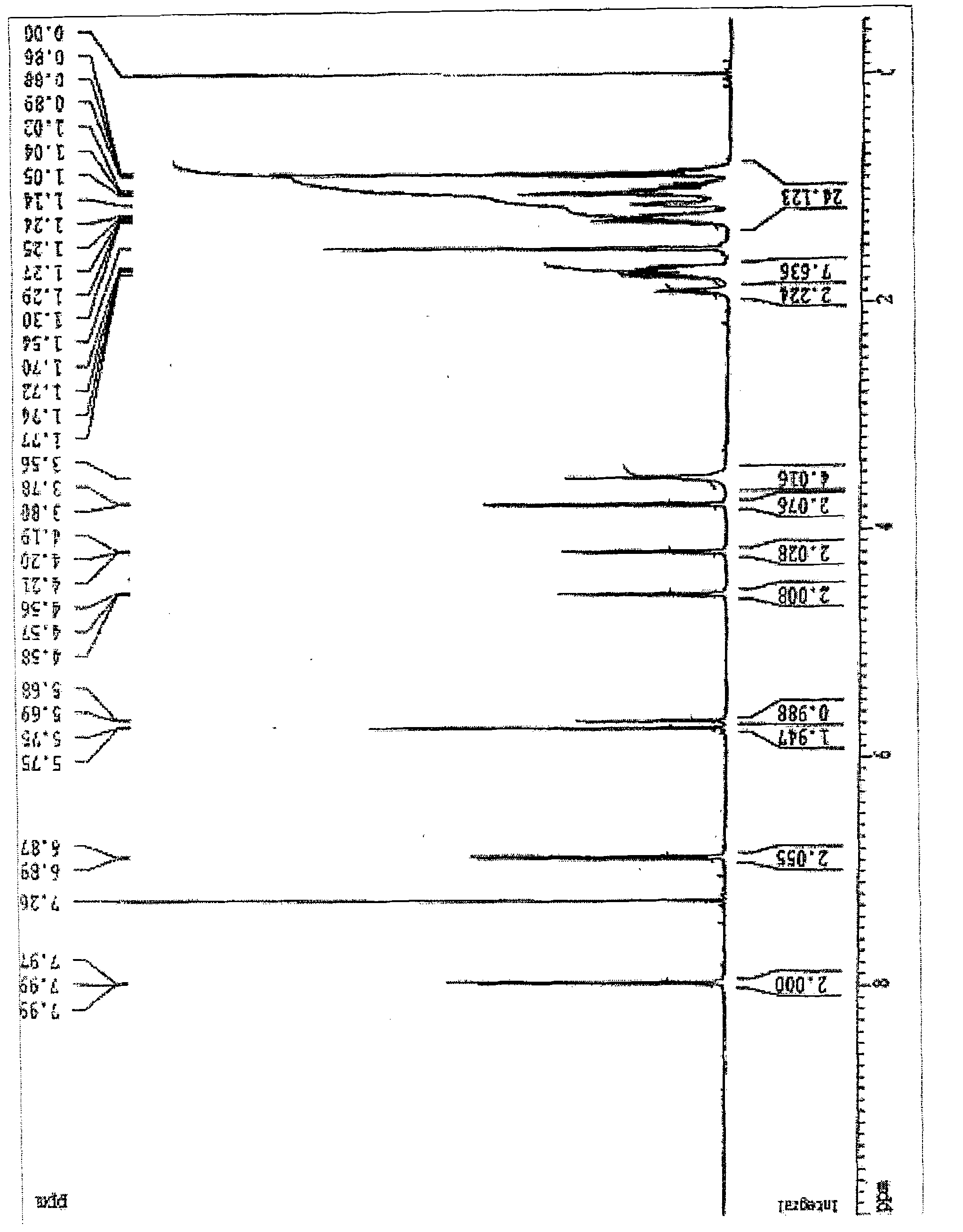

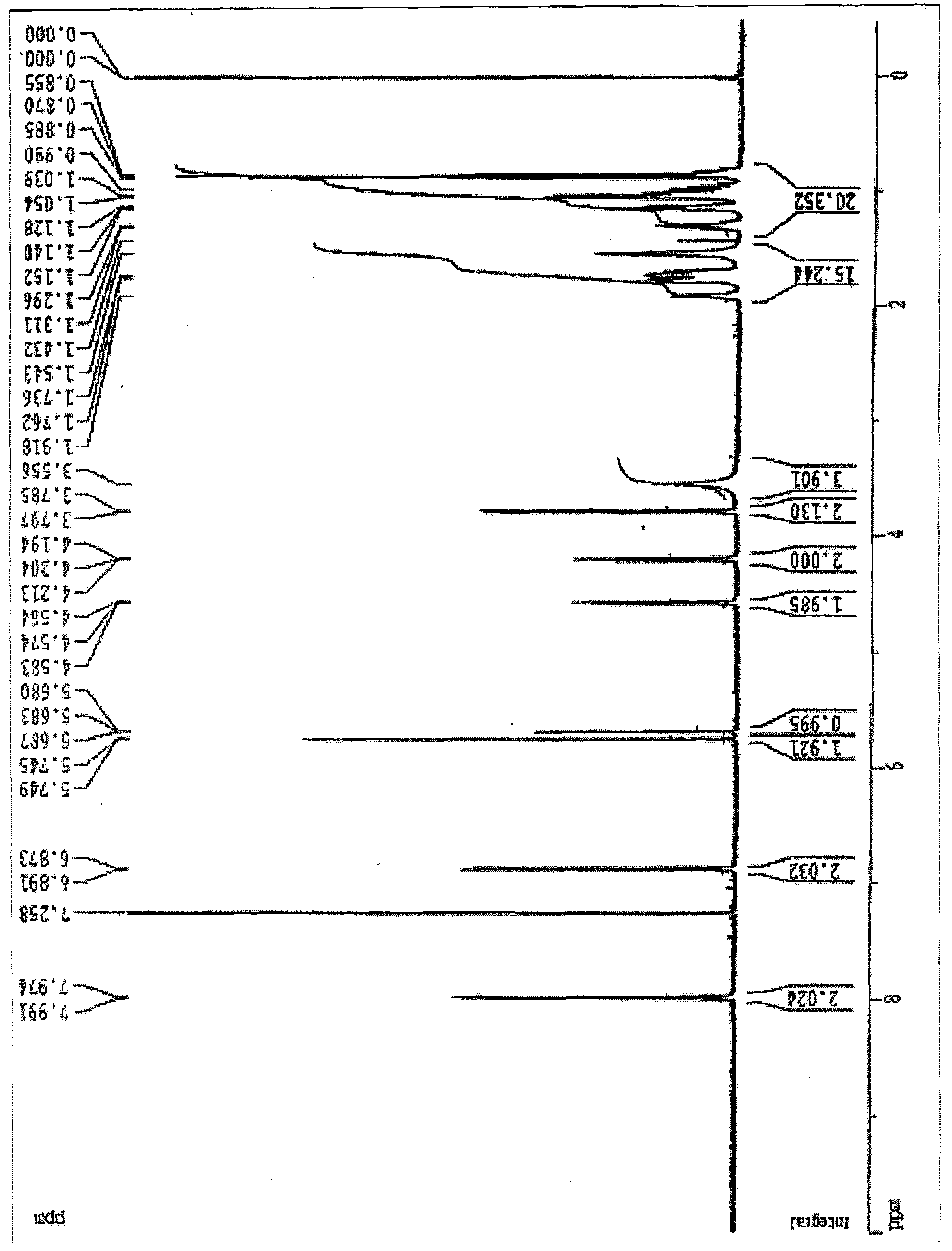

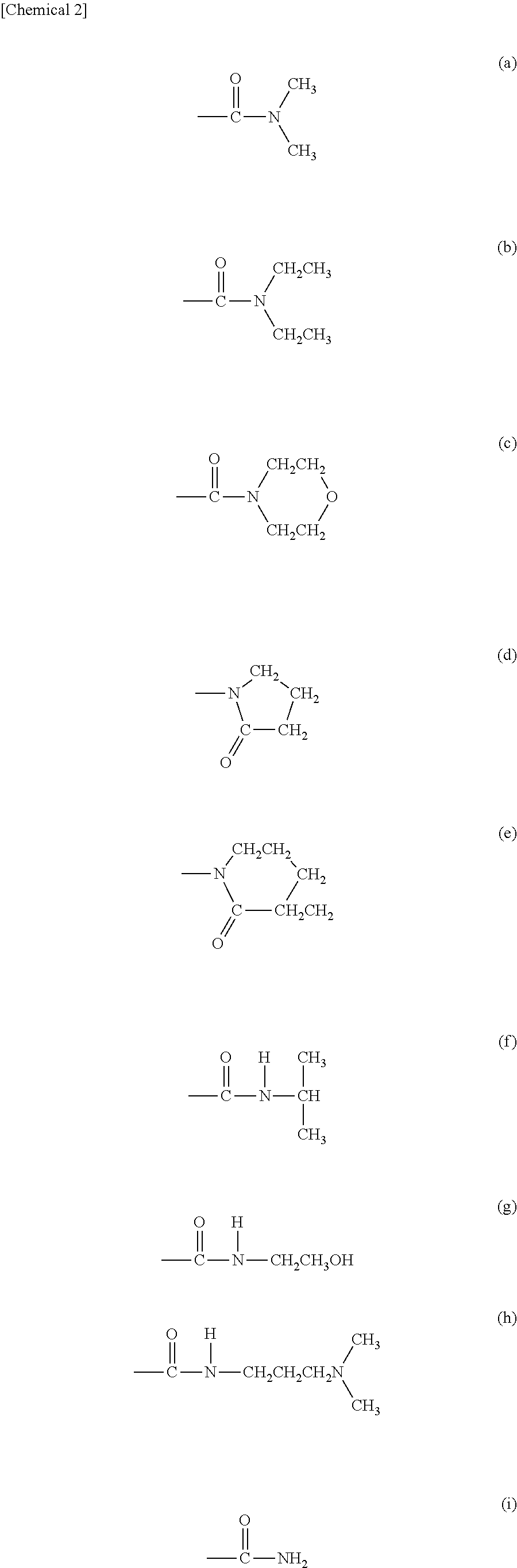

Polymerizable composition

ActiveUS20100090163A1Excellent solvent solubilityExcellent optical propertiesLiquid crystal compositionsPolarising elementsMeth-Stereochemistry

A polymerizable composition comprising a bifunctional (meth)acrylate compound represented by general formula (1) and a monofunctional (meth)acrylate compound having a nitrile group at the terminal thereof represented by general formula (2). The mass ratio of them (the former / the latter) is from 90 / 10 to 40 / 60.

Owner:ADEKA CORP +1

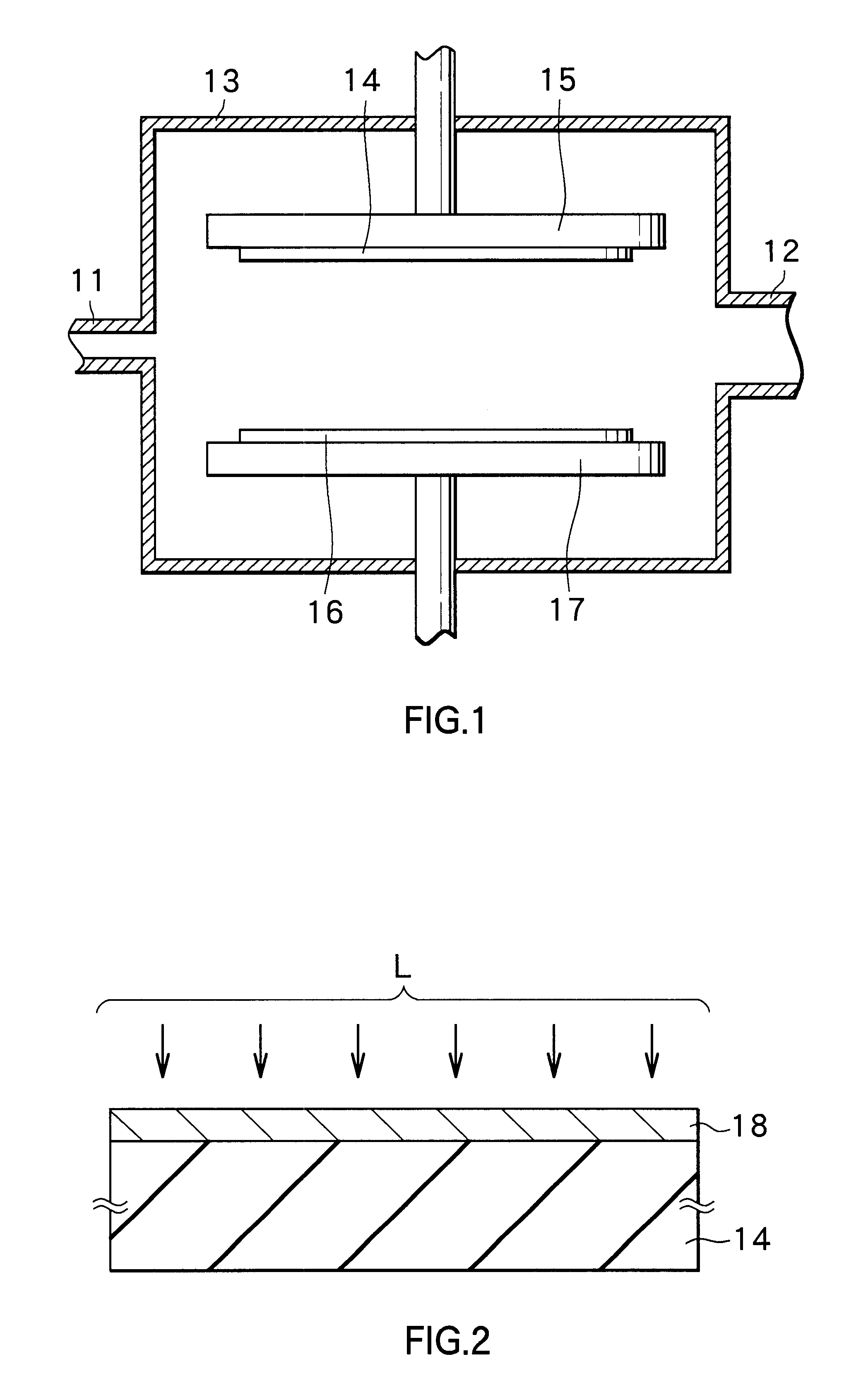

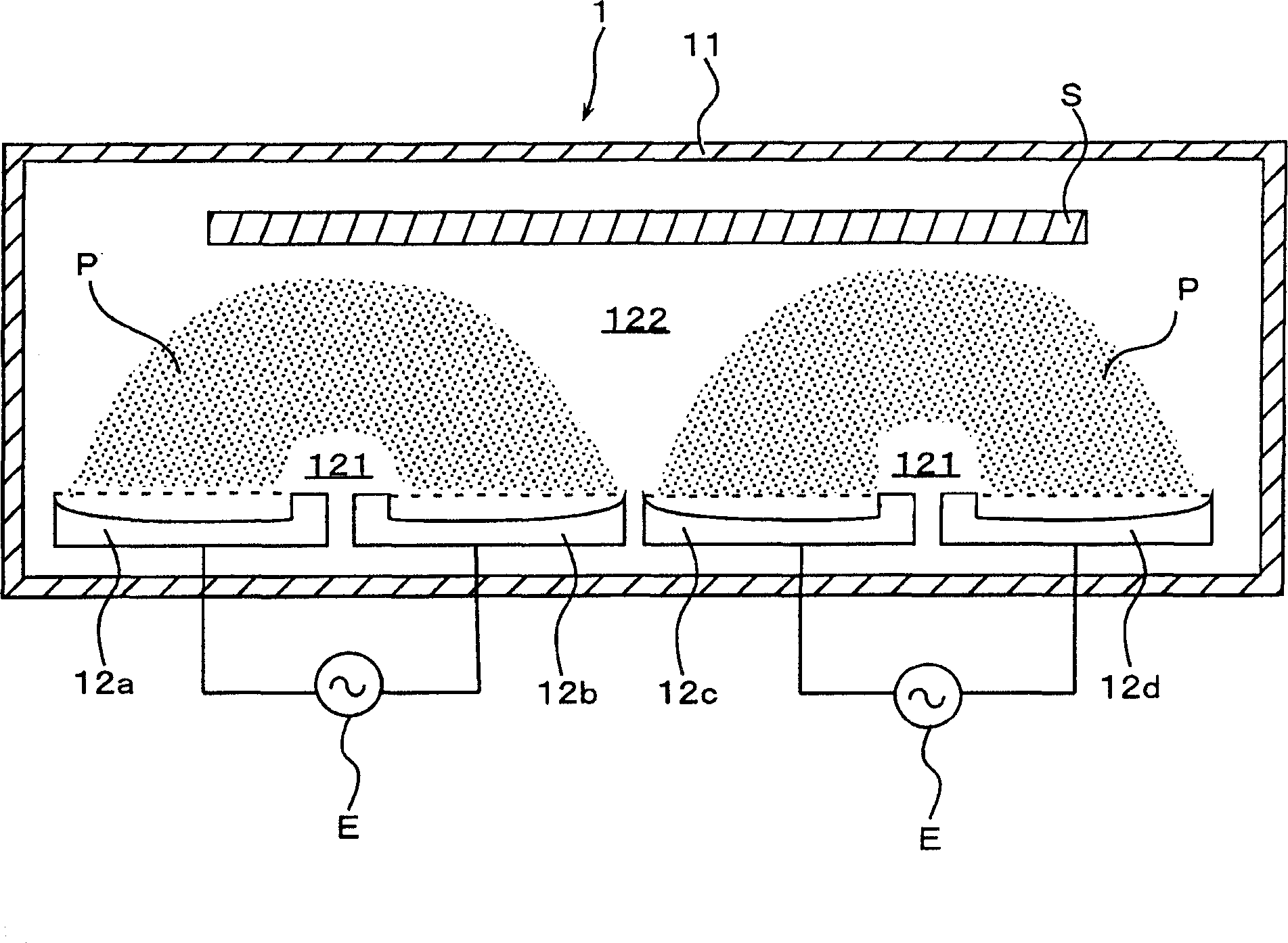

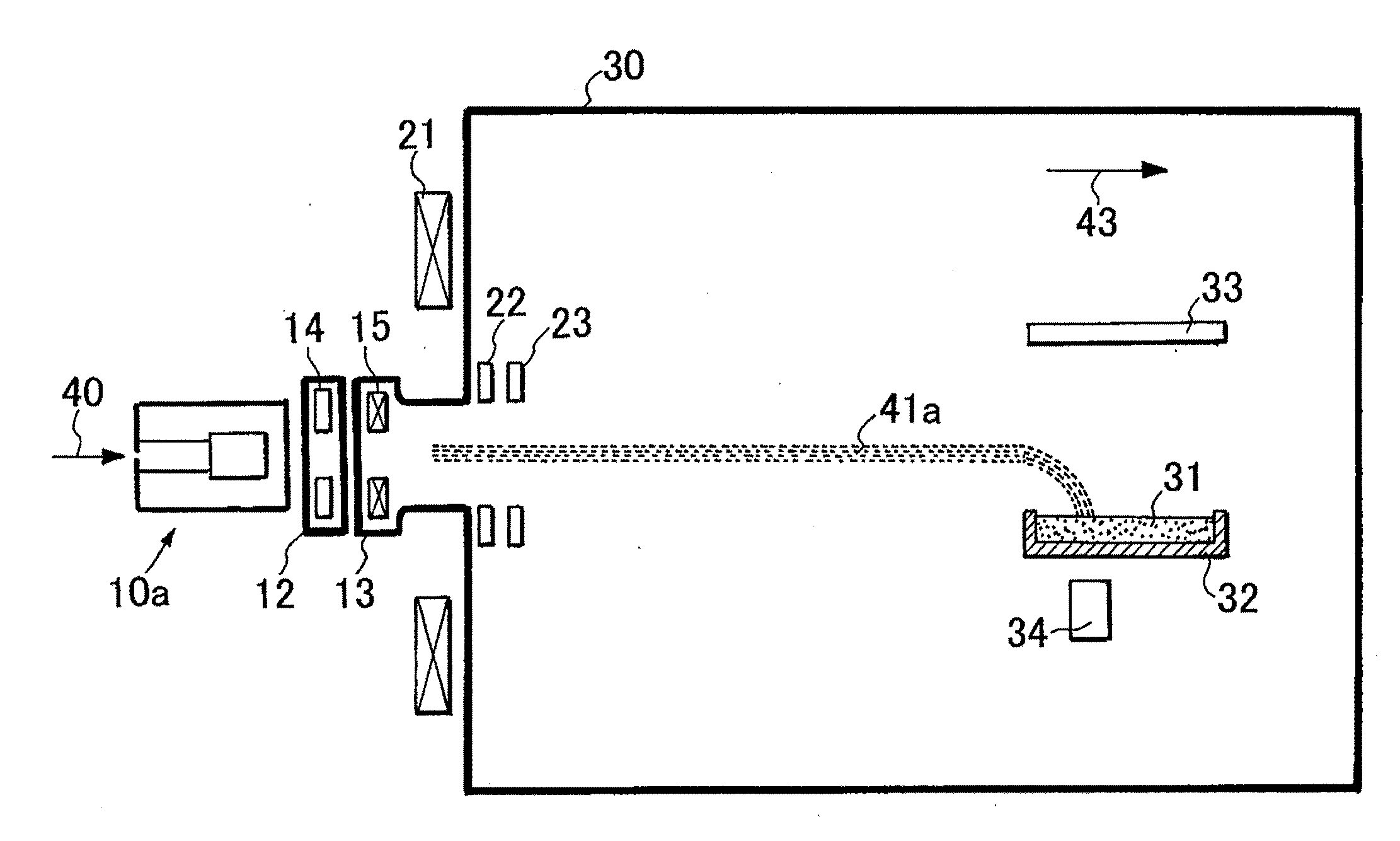

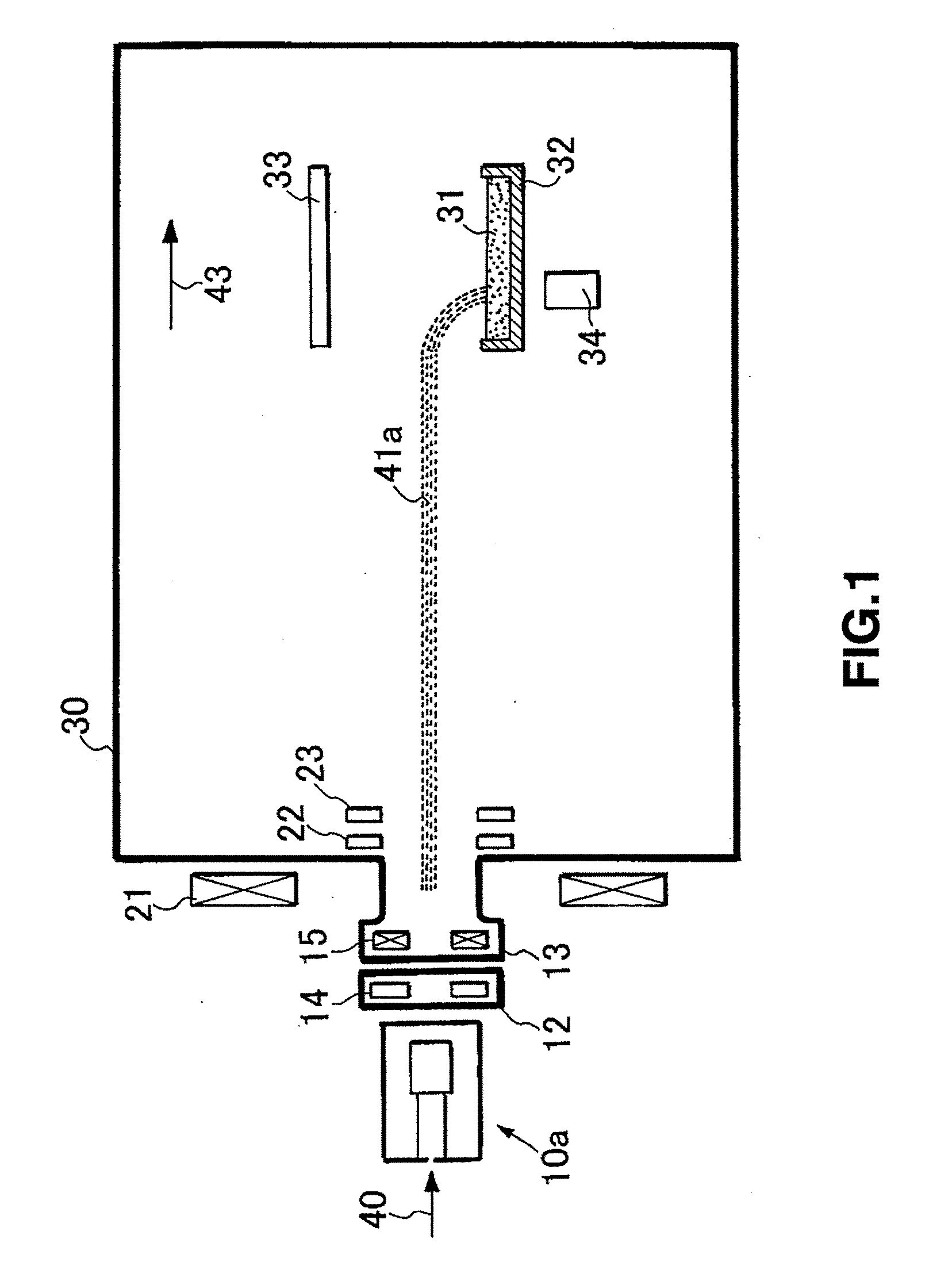

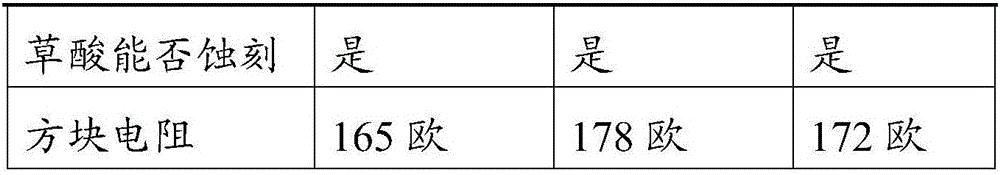

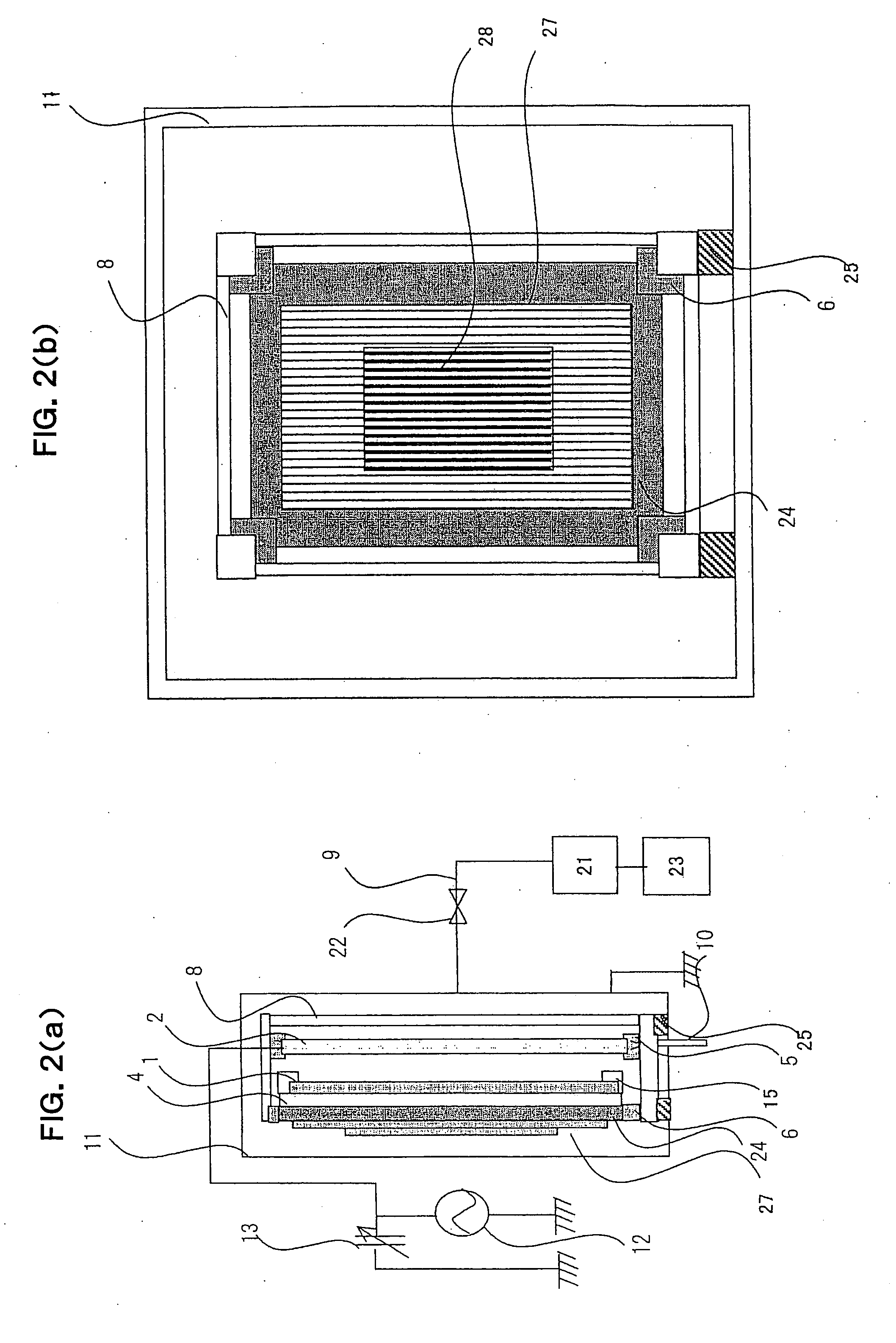

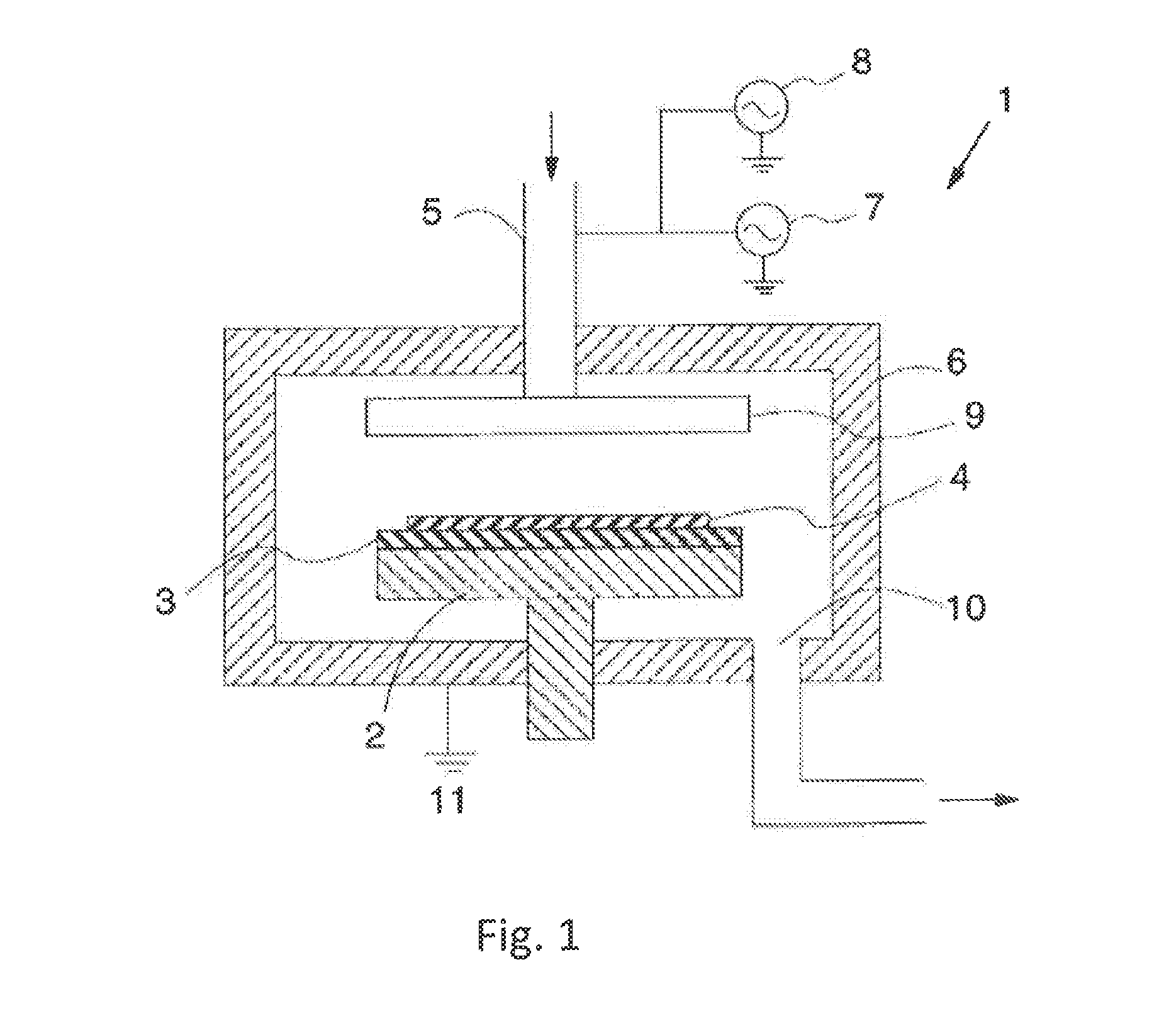

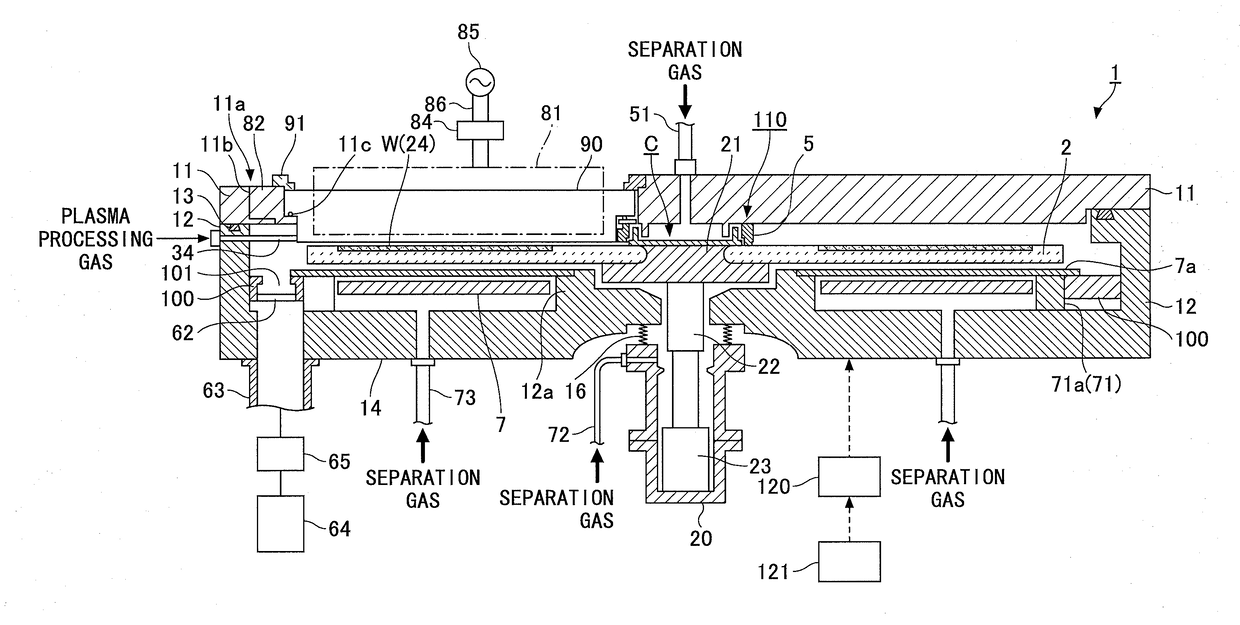

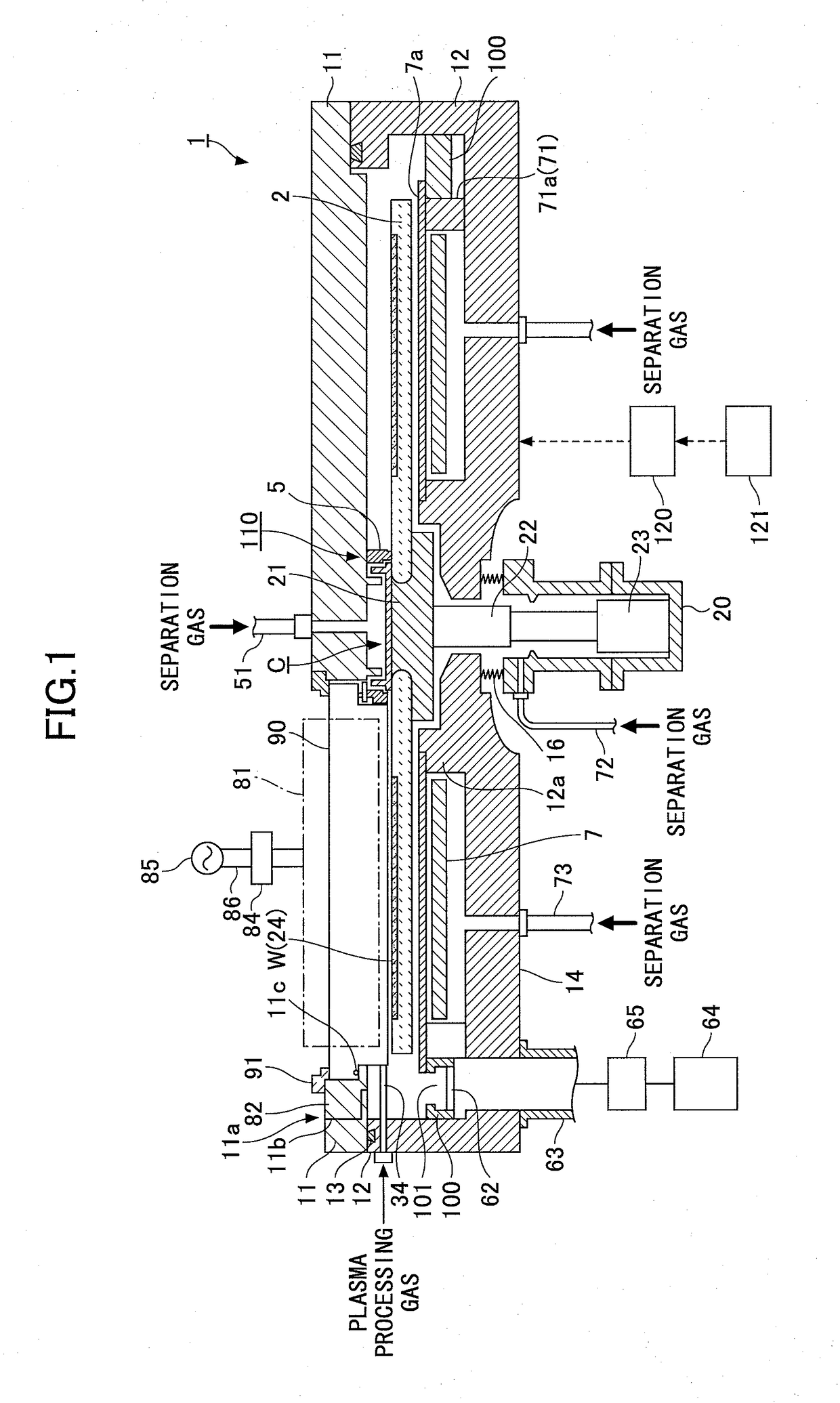

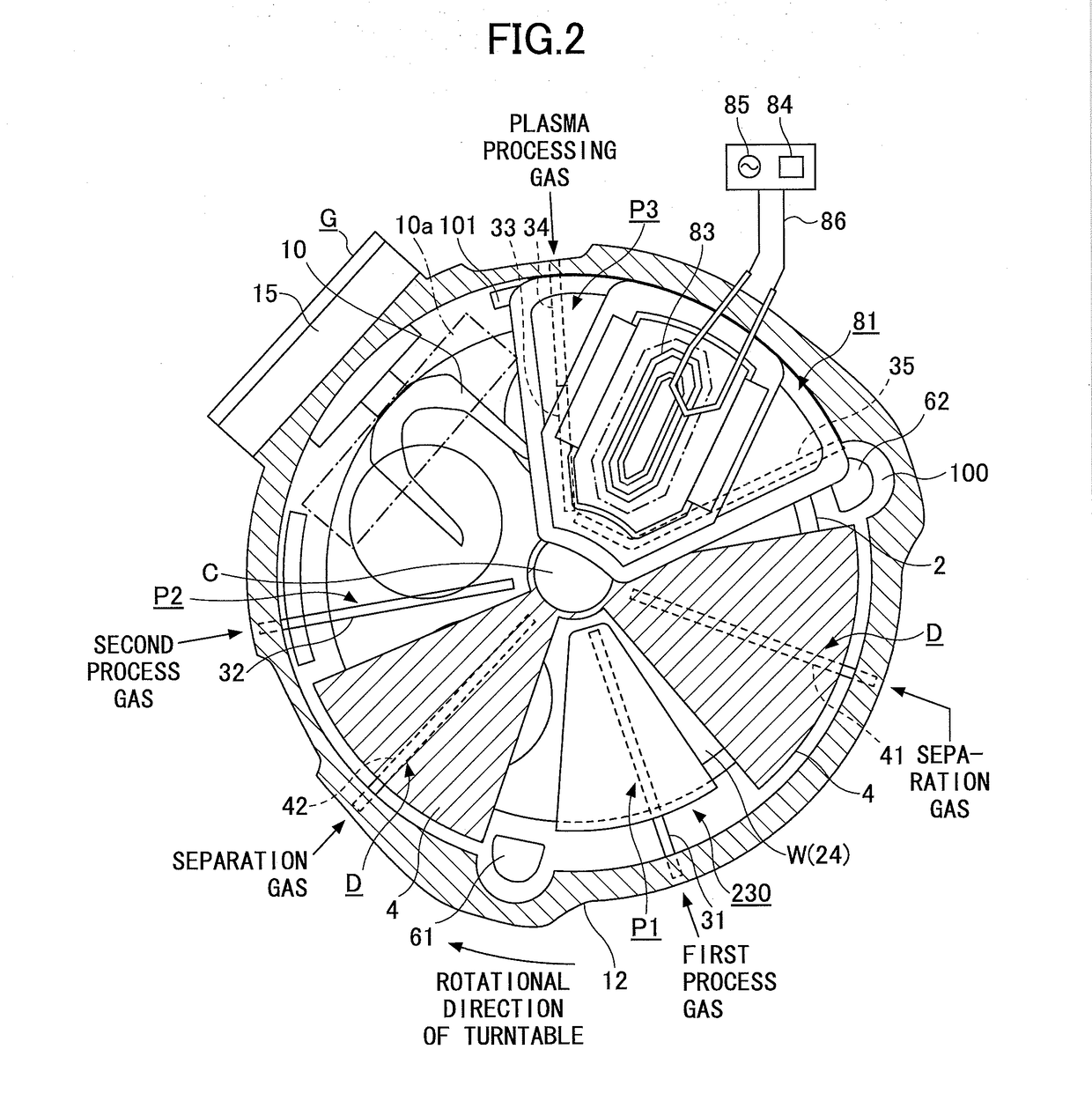

Plasma treatment apparatus

InactiveUS20090114154A1Uniform film qualityUniform film thicknessElectric discharge tubesVacuum evaporation coatingFloating potentialElectron

The present invention provides a plasma treatment apparatus which has a plurality of UR-type plasma guns including reflected electron return electrodes, and can stably form a film having uniform film thickness and film quality. A plasma treatment apparatus according to one embodiment of the present invention sets an electric potential of at least one UR-type plasma gun at a floating potential. In one embodiment of the present invention, all UR-type plasma guns may be set at floating potentials. In other embodiment of the present invention, only one UR-type plasma gun may be grounded, and the other UR-type plasma guns may be set at floating potentials.

Owner:CANON ANELVA CORP

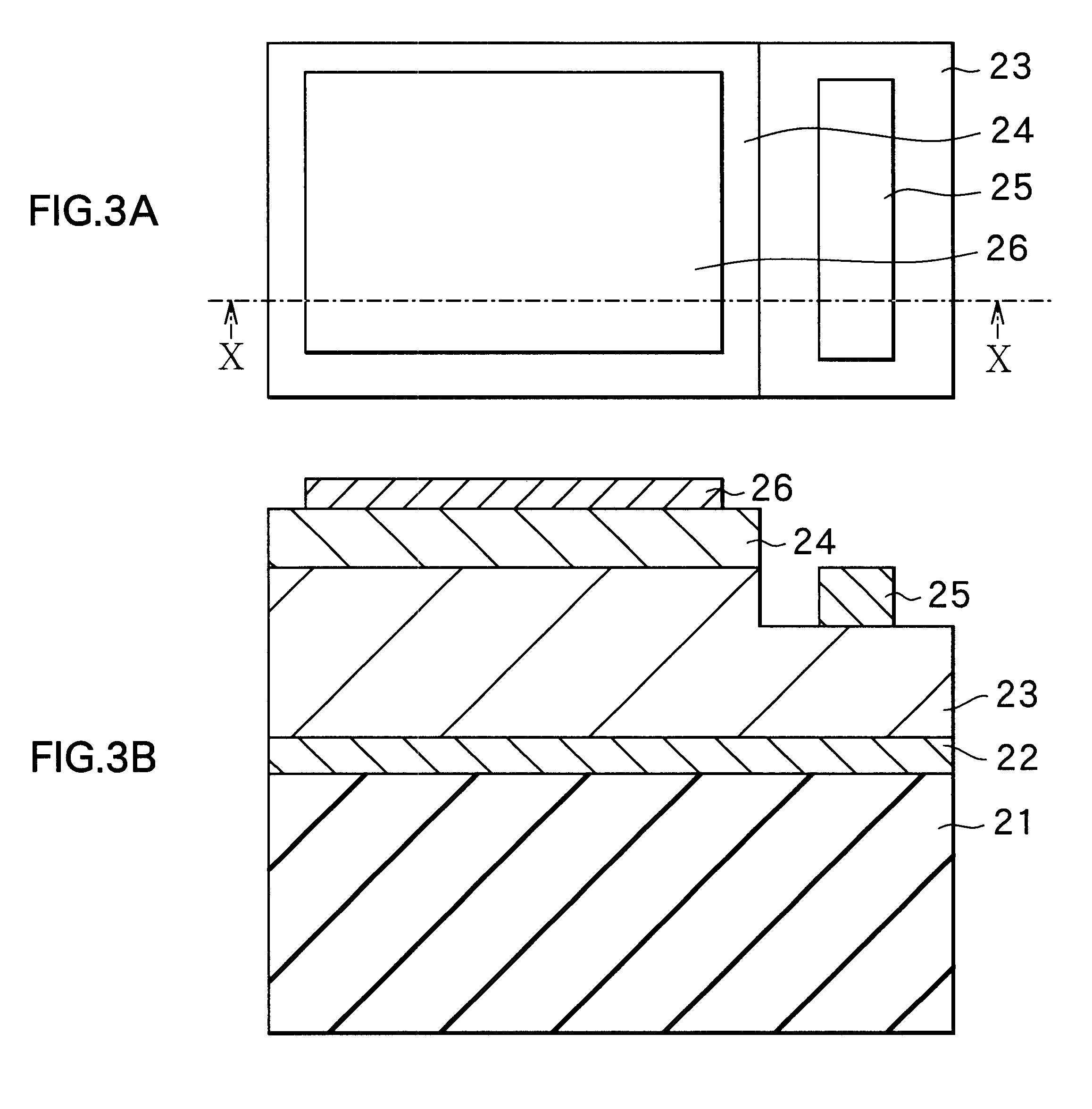

Method for manufacturing semiconductor device, substrate treater, and substrate treatment system

InactiveUS20070190802A1Eliminate the problemUniform thicknessElectric discharge tubesSemiconductor/solid-state device manufacturingPhysicsSubstrate surface

A radical source is movably provided in a processing vessel holding a substrate, and the location or driving energy of the radical source is set such that the film formed on the substrate has a uniform thickness. Further, a radical source is provided at a first side of the substrate and a radical flow is formed such that the radical flow flows from the first side of the substrate surface to the other side. By optimizing the condition of the radical flow, the film formed on the substrate has a uniform thickness.

Owner:TOKYO ELECTRON LTD

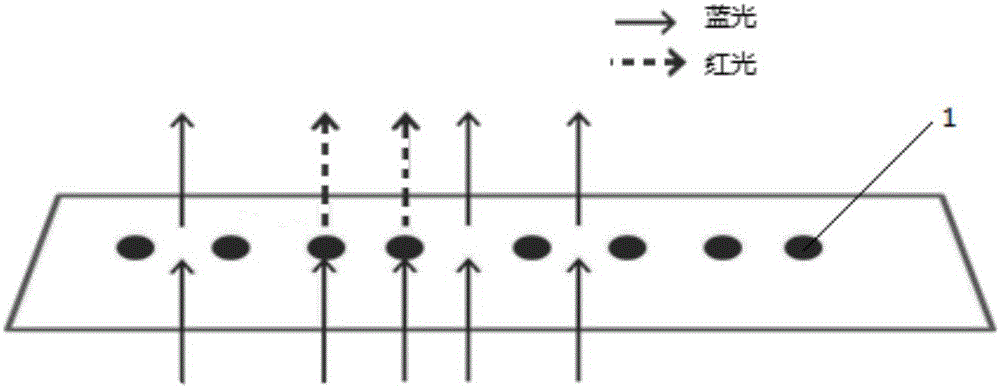

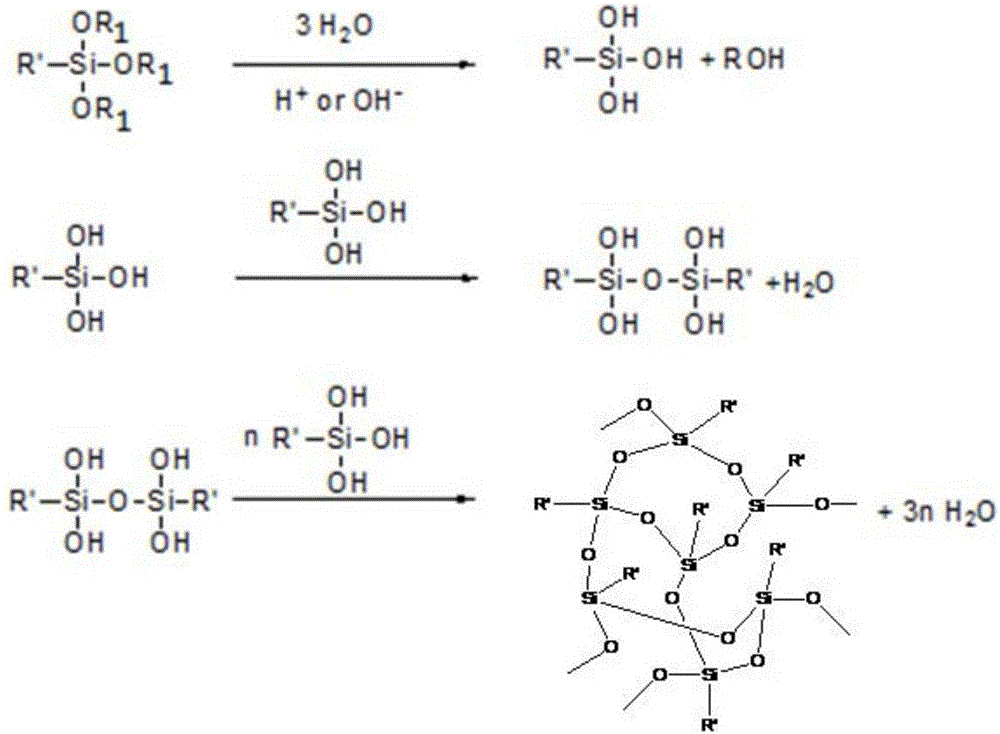

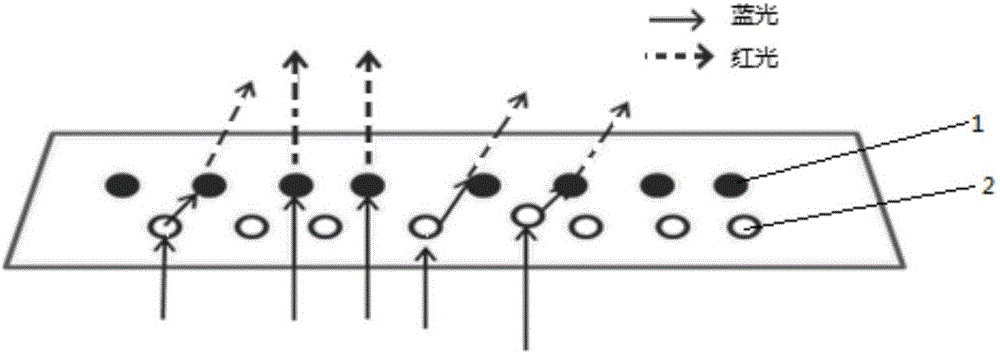

Photodiffusion powder, preparation method of photodiffusion powder, quantum dot photoresist and quantum dot color film

ActiveCN105694042AImprove uniformityUniform film qualityPhotomechanical coating apparatusPhotomechanical exposure apparatusSilanesColor film

The invention belongs to the technical field of display, and particularly relates to photodiffusion powder, a preparation method of the photodiffusion powder, quantum dot photoresist and a quantum dot color film.The preparation method of the photodiffusion powder comprises the steps that alkoxy silane is subjected to a cohydrolysis condensation reaction under the acidic condition or the alkaline condition, and the photodiffusion powder is obtained.The quantum dot photoresist made of the photodiffusion powder and the quantum dot color film are further disclosed.The photodiffusion powder has an organic chain segment structure and an inorganic structure, and is good in compatibility with all kinds of components in a quantum dot photoresist system, a good dispersion effect is achieved, and the uniformity of the photoresist is increased.The quantum dot color film made of the quantum dot photoresist is even in film quality and high in light utilization rate.

Owner:BOE TECH GRP CO LTD

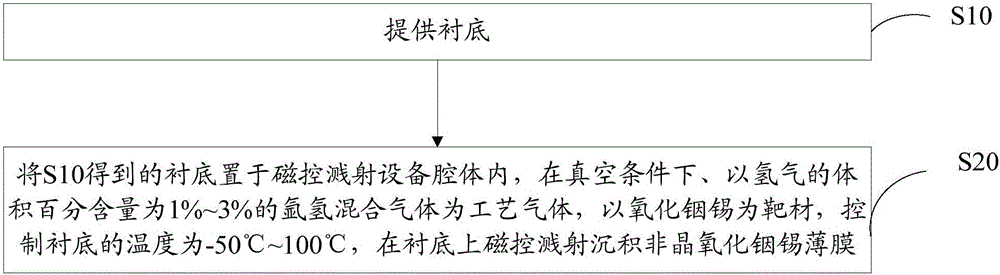

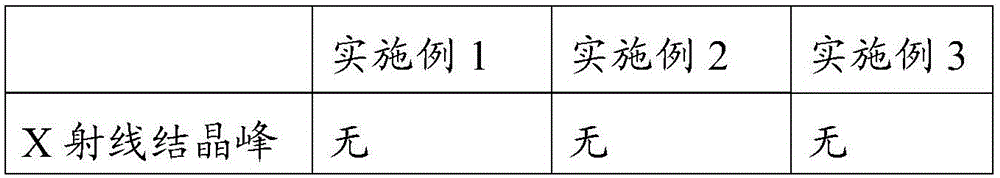

Preparation method of amorphous indium tin oxide thin film

InactiveCN105839064AImprove stabilityUniform film qualityVacuum evaporation coatingSputtering coatingIndiumHydrogen

The invention discloses a method for preparing an amorphous indium tin oxide thin film, which comprises the following steps: providing a substrate; and placing the substrate in a cavity of a magnetron sputtering device; Argon-hydrogen mixed gas with a content of 1% to 3% is used as the process gas, and indium tin oxide is used as the target material, the temperature of the substrate is controlled to be -50°C to 100°C, and magnetron sputtering is performed on the substrate An amorphous indium tin oxide film is deposited. The preparation method of this amorphous indium tin oxide thin film adopts the indium tin oxide target material (mass ratio of indium oxide is 85%~93%) used in the conventional crystalline indium tin oxide film, and the volume of hydrogen gas is used in the indium tin oxide coating process The argon-hydrogen mixed gas with a percentage content of 1% to 3% is the process gas. The hydrogen has good dispersibility and is conducive to uniform distribution. There is no need to add expensive testing equipment to monitor the water pressure. The prepared amorphous indium tin oxide film is excellent. stability.

Owner:YICHANG NANBO DISPLAY

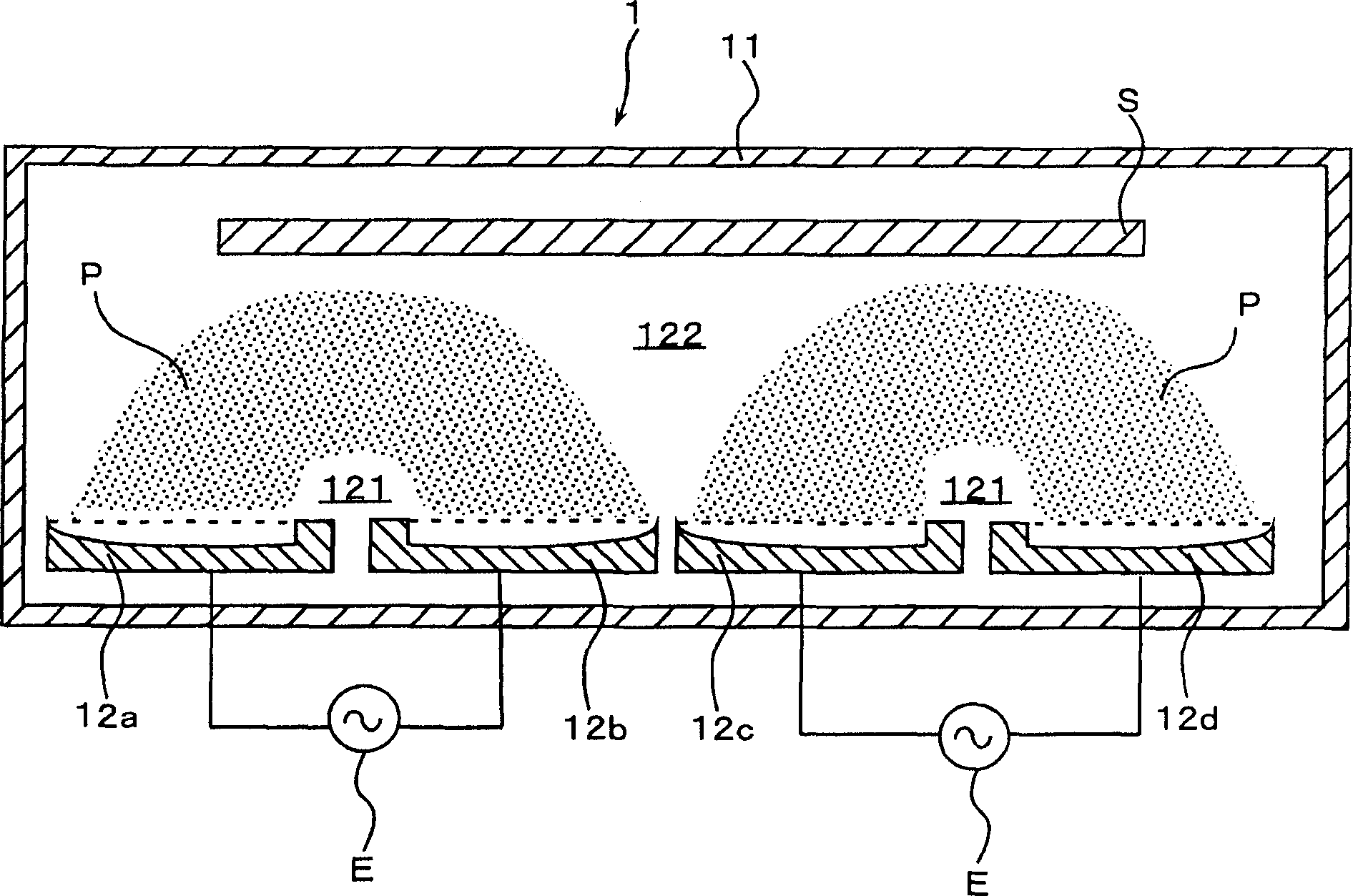

Plasma Processing Apparatus And Method Of Producing Semiconductor Thin Film Using The Same

InactiveUS20080164144A1Simple structureLow costCellsElectric discharge tubesInterior spaceReactive gas

A plasma processing apparatus characterized by comprising within a sealable chamber: an internal structural body that is disposed to be spaced apart from an inner wall surface of the chamber and that forms an inside space for housing a substrate serving as an object of processing; a substrate holding section that houses the substrate within the inside space; reactive gas supplying means for supplying a reactive gas to the inside space; a cathode and an anode that are supported by the internal structural body and disposed on both sides of the substrate within the inside space and that generate plasma discharge of the reactive gas; a heater that is supported by the internal structural body and that heats the substrate within the inside space; and heat-dissipating means capable of dissipating a Joule heat generated by the plasma discharge to outside of the inside space.

Owner:SHARP KK

Polymerizable composition

ActiveUS7931825B2Excellent solvent solubilityExcellent optical propertiesLiquid crystal compositionsPolarising elementsStereochemistryAcrylate

A polymerizable composition comprising a bifunctional (meth)acrylate compound represented by general formula (1) and a monofunctional (meth)acrylate compound having a nitrile group at the terminal thereof represented by general formula (2). The mass ratio of them (the former / the latter) is from 90 / 10 to 40 / 60.

Owner:ADEKA CORP +1

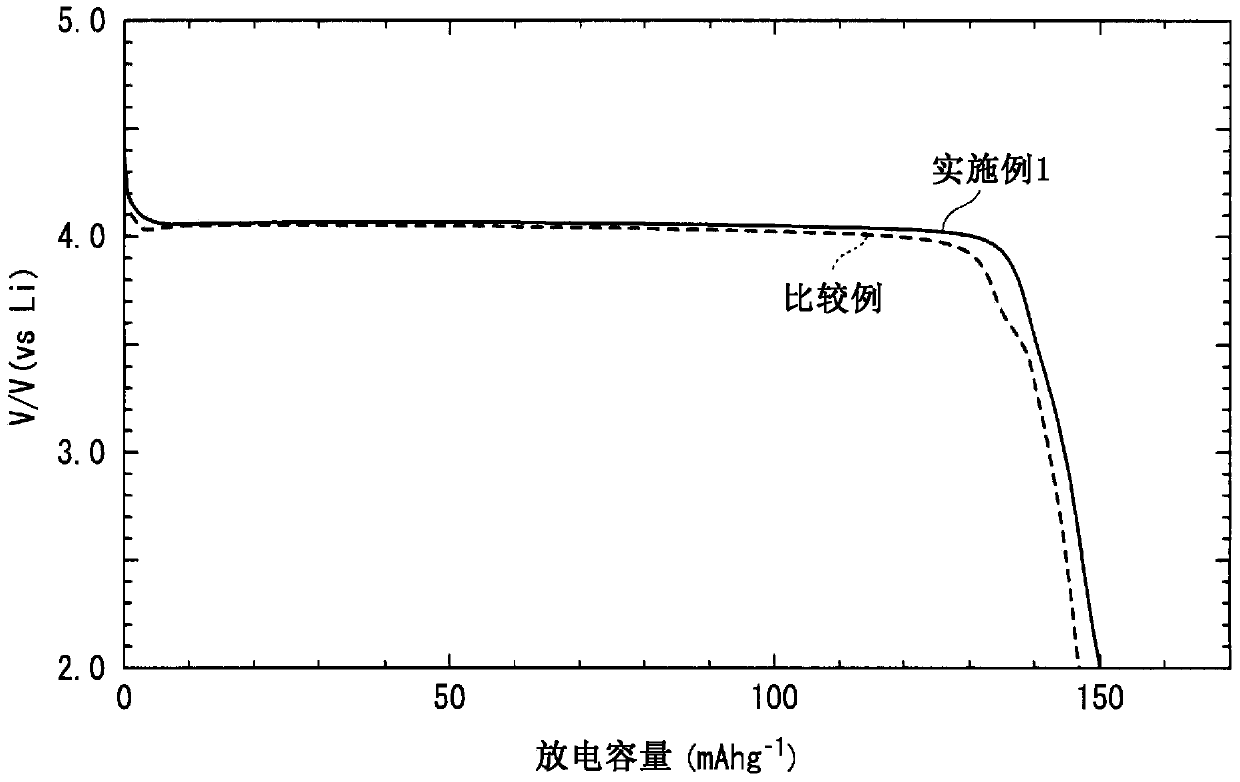

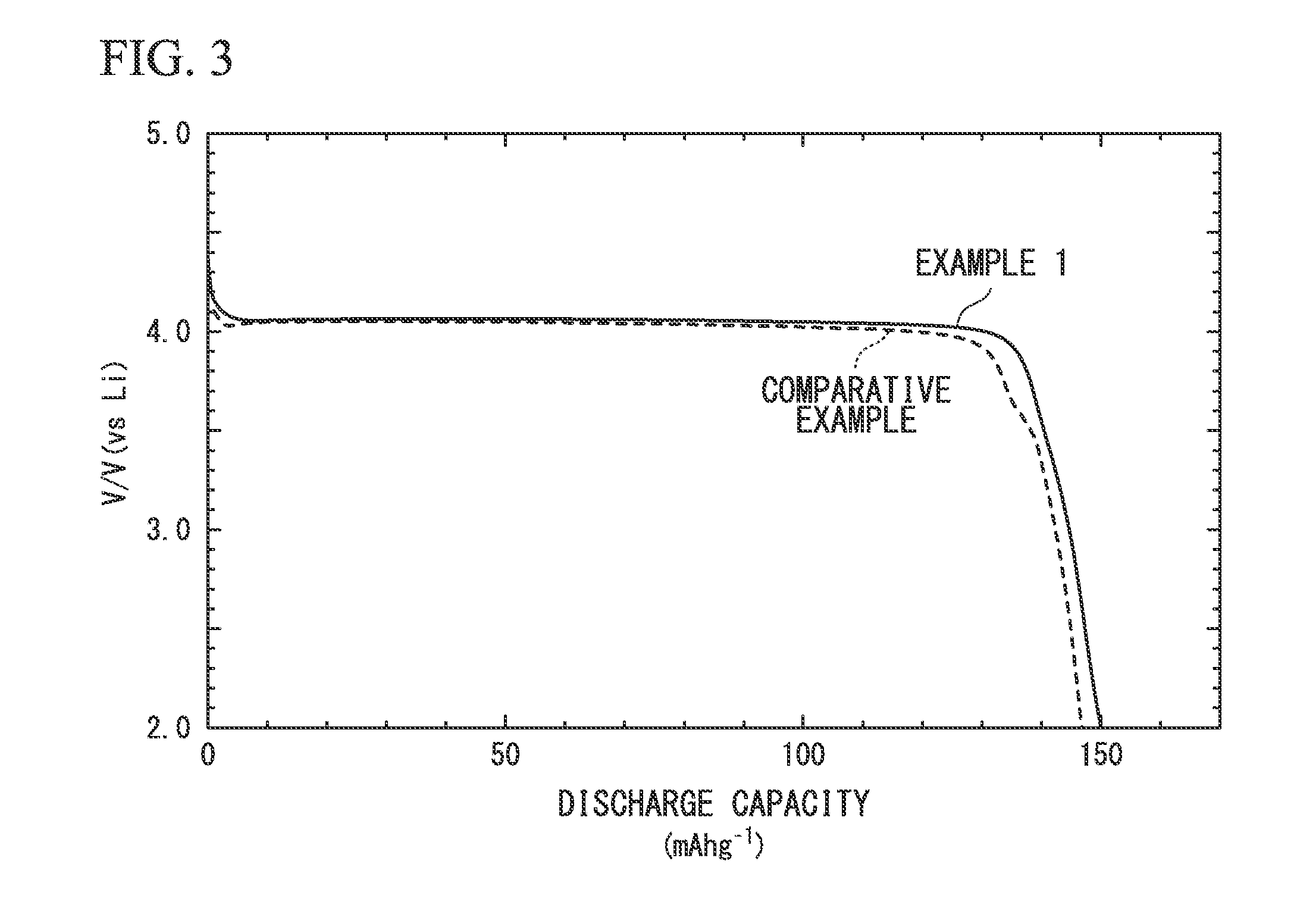

Electrode active substance and method for producing same

InactiveCN103403932AGood film quality and cheapImprove featuresCell electrodesPhosphorus compoundsSuspended particlesSlurry

Owner:SUMITOMO OSAKA CEMENT CO LTD

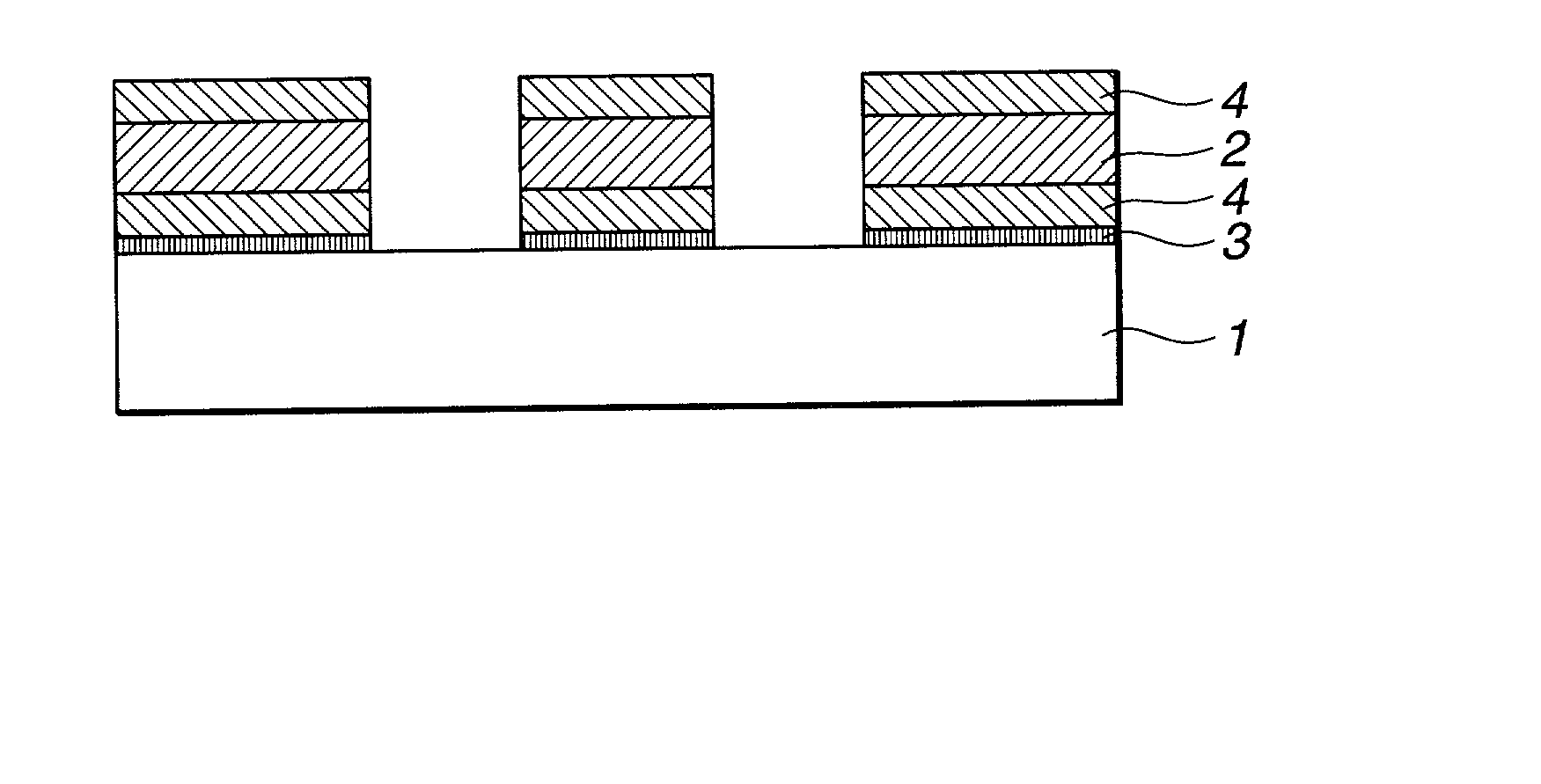

Method for Forming Layer Constituted by Repeated Stacked Layers

ActiveUS20140213065A1High wet etching selectivityUniform film qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSecondary layerEtching rate

A method for forming a layer constituted by repeated stacked layers includes: forming a first layer and a second layer on a substrate under different deposition conditions to form a stacked layer, wherein the film stresses of the first and second layers are tensile or compressive and opposite to each other, and the wet etch rates of the first and second layers are at least 50 times different from each other; and repeating the above step to form a layer constituted by repeated stacked layers, wherein the deposition conditions for forming at least one stacked layer are different from those for forming another stacked layer.

Owner:ASM IP HLDG BV

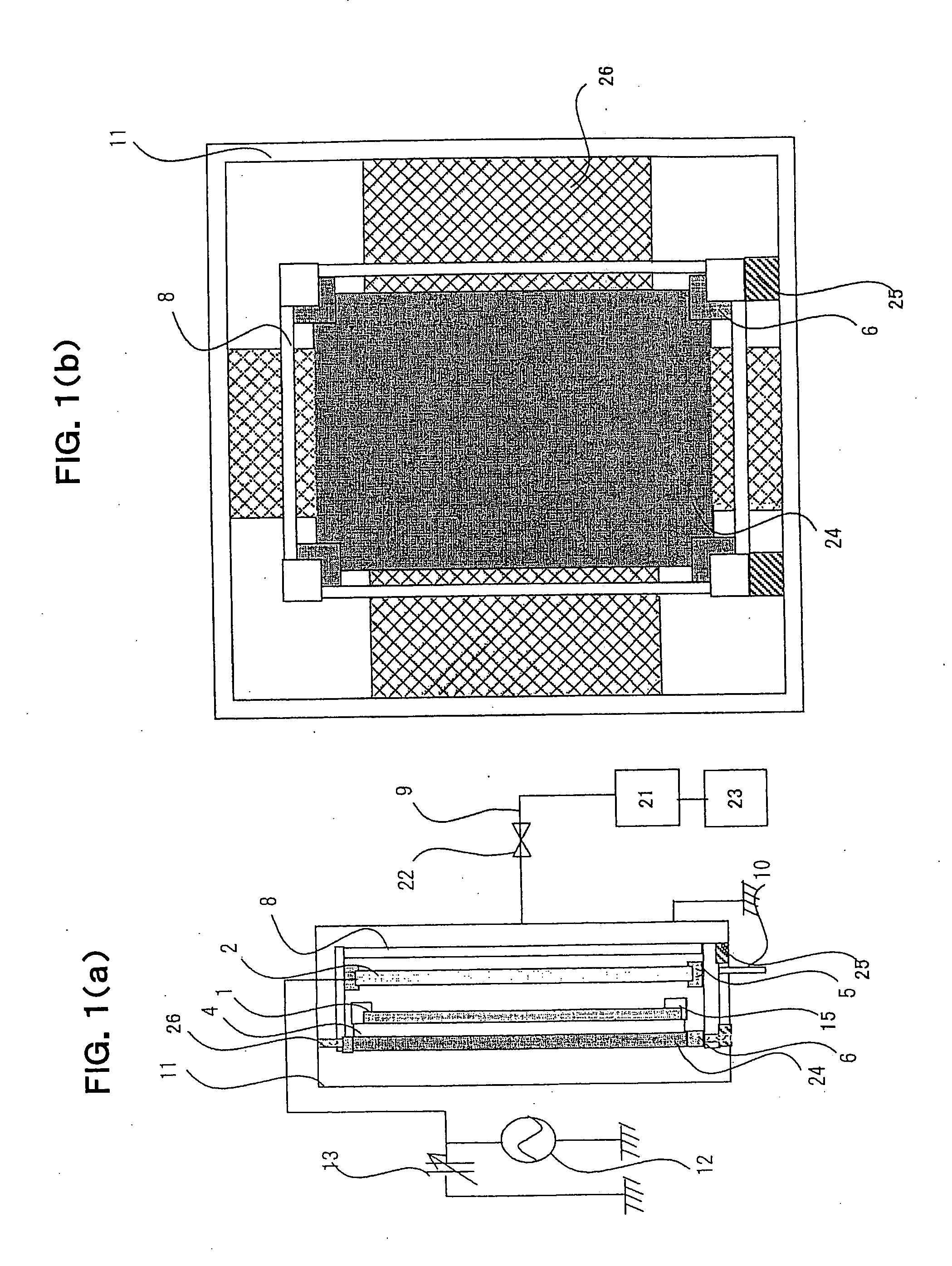

Sputtering device and sputtering method

ActiveCN1904133AUniform film qualityUniform sputteringVacuum evaporation coatingSputtering coatingNegative potentialEngineering

A sputtering apparatus which does not spoil the non-corrosive area on the target and gives uniform film during the reactive sputtering process is disclosed. The sputtering apparatus 2 comprises:(a) supplying a space to set more than three targets 241 in the vacuum chamber 21. (b)using alternating current power supply E1~E3 to alternatively charge each target 241 with negative potential and positive potential or with the ground potential, which is characterized by using at least one of branched outputs of the alternating current power supply E1~ E3 to connect more than two of targets 241, and placing the switches SW1~ SW3 which are the switches to control charging potential to targets from alternating current supply between targets 241 connected by branched outputs.

Owner:ULVAC INC

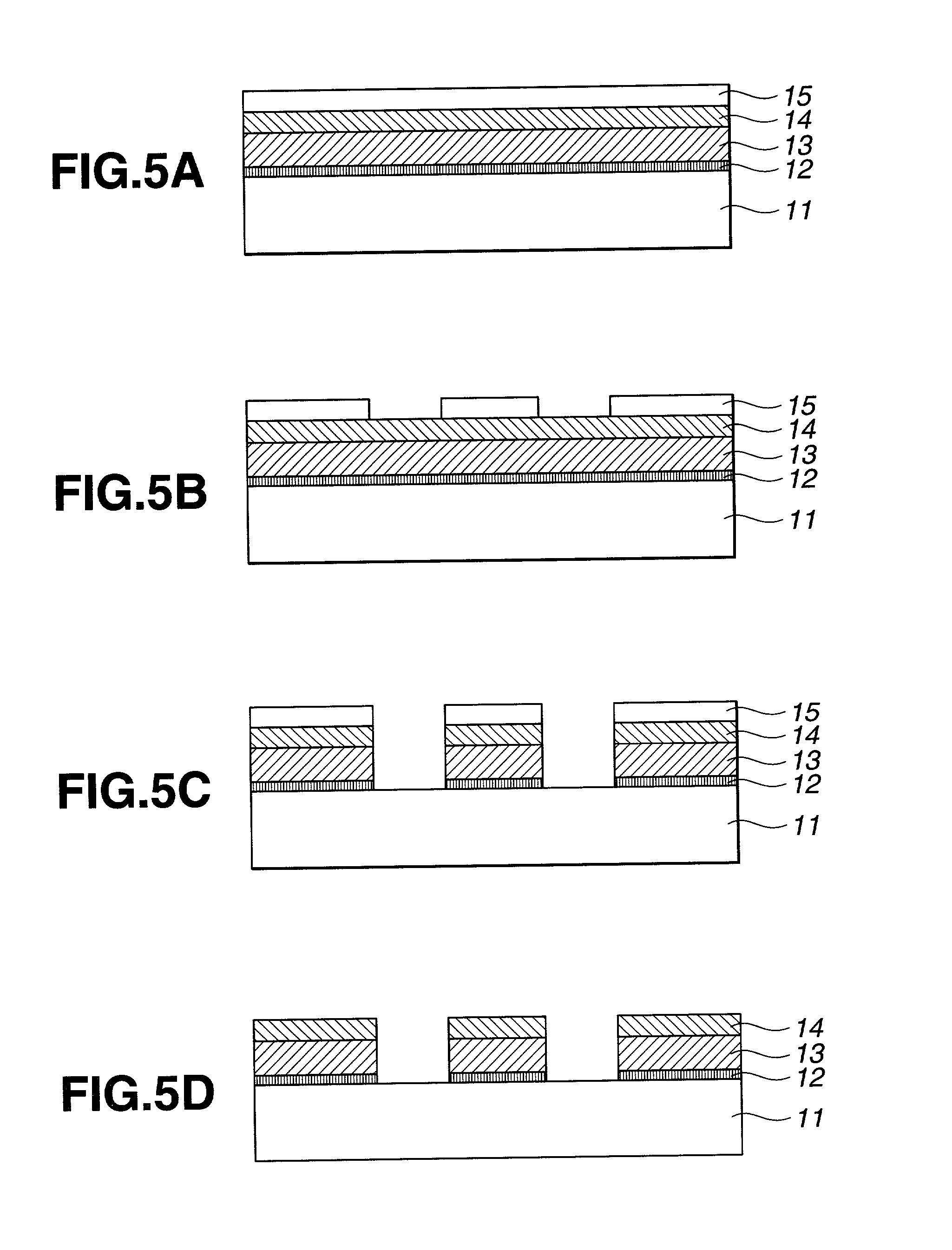

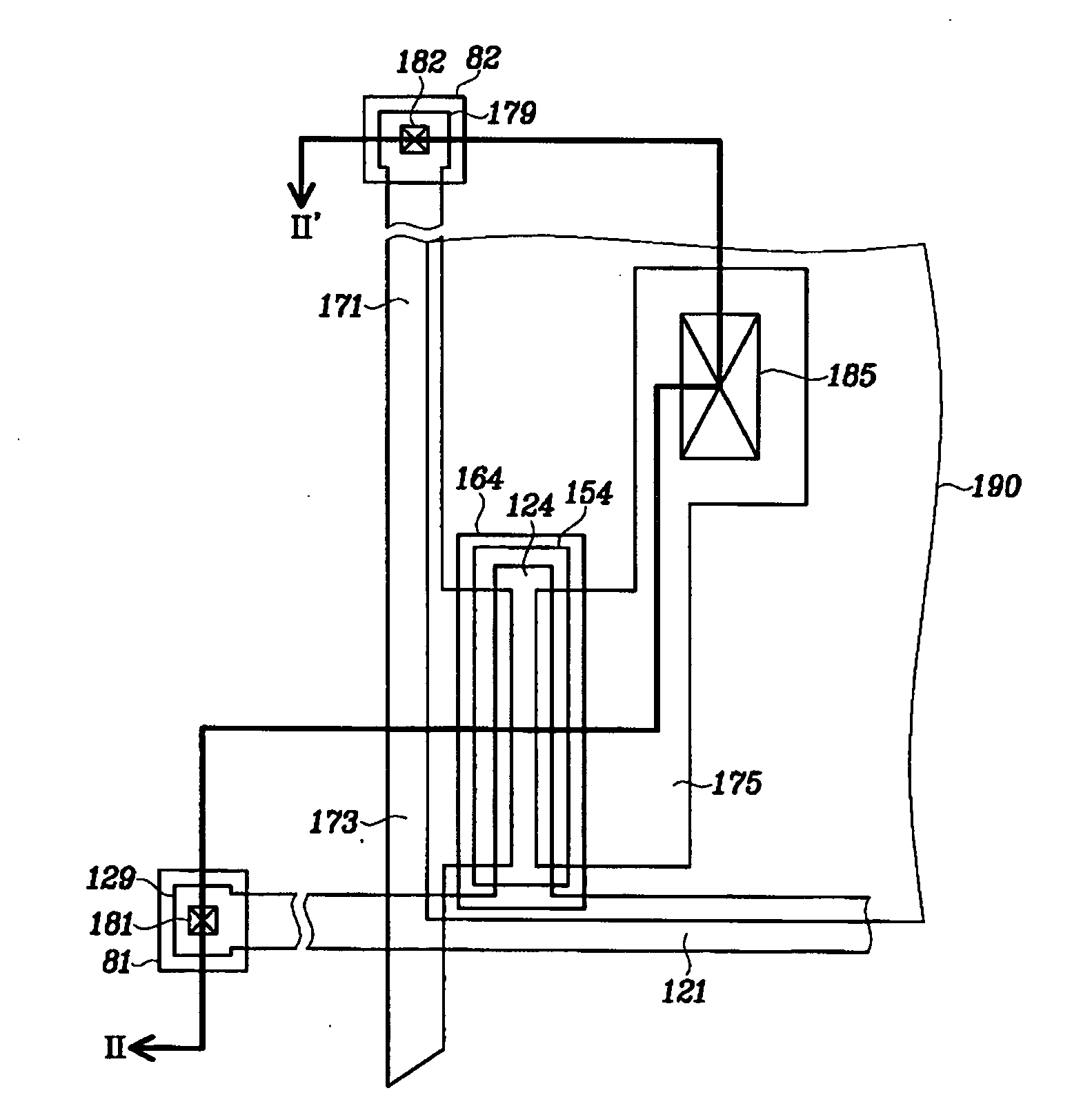

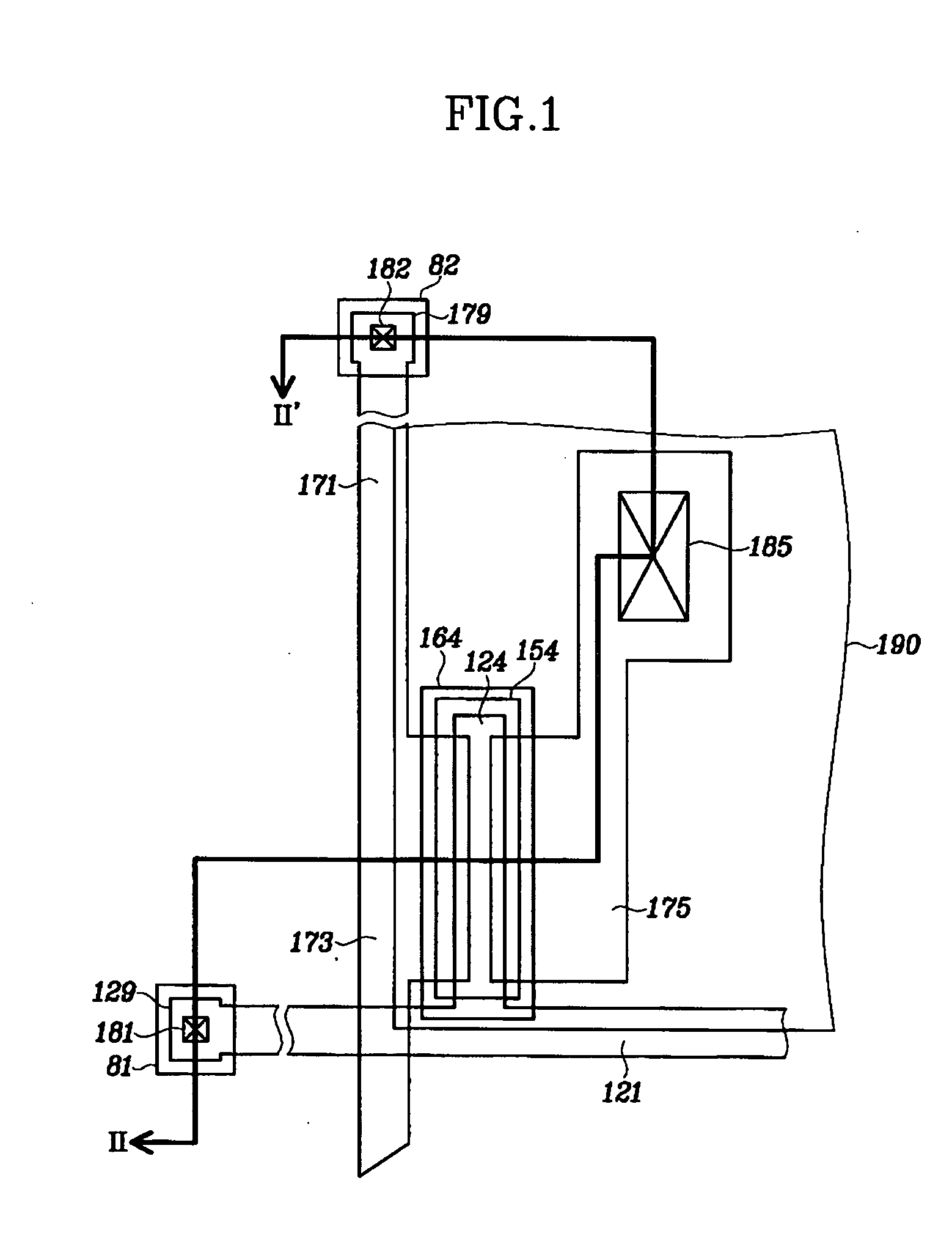

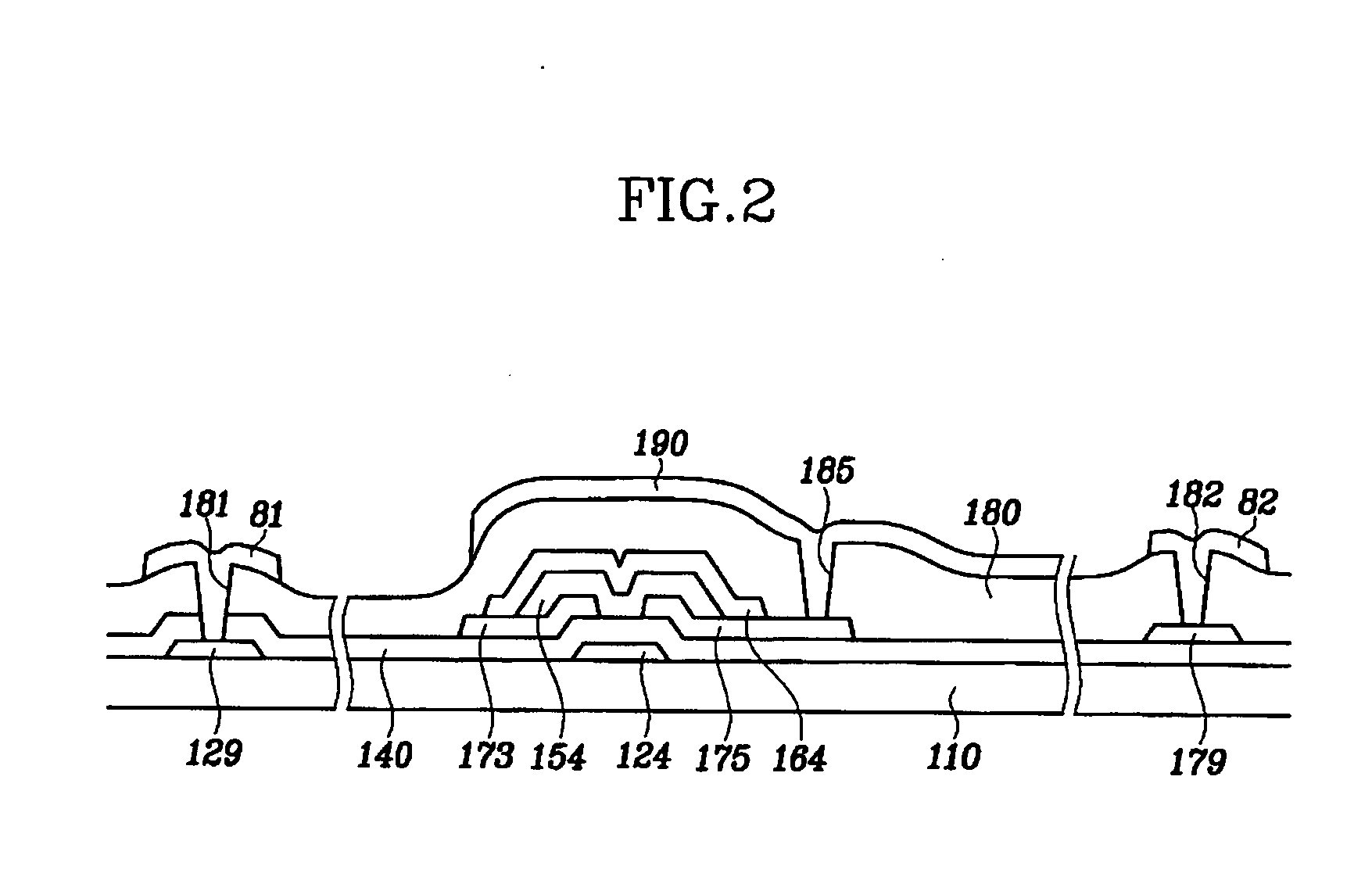

Organic thin film transistor array panel and manufacturing method thereof

InactiveUS20060102954A1Uniform film qualityElectroluminescent light sourcesSolid-state devicesOrganic filmEngineering

A method of manufacturing a thin film transistor array panel is provided, the method includes: forming a gate line on a substrate; forming a gate insulating layer on the gate line; depositing an ITO layer at a temperature of about 20-35° C.; etching the ITO layer to form a data line and a drain electrode on the gate insulating layer; and forming an organic semiconductor on the data line, the drain electrode, and the gate insulating layer.

Owner:SAMSUNG DISPLAY CO LTD

Electrode active material and method of producing the same

InactiveUS20130337329A1Satisfactory characteristicUniform film qualityNon-aqueous electrolyte accumulator electrodesCoatingsSuspended particlesSlurry

Provided is an electrode active material that is obtained by coating a surface of each particle of LiwAxDO4 (provided that, A represents at least one selected from the group consisting of Mn and Co, D represents one or more selected from the group consisting of P, Si, and S, 0<w≦4, and 0<x≦1.5) with a coating layer containing LiyE2PO4 (provided that, E represents at least one selected from the group consisting of Fe and Ni, 0<y≦2, and 0<z≦1.5) and a carbonaceous electron conductive material. The electrode active material of the invention may be obtained by drying slurry obtained by suspending particles of LiwAxDO4 in an aqueous solution containing a Li source, an E source, a PO4 source, and a carbon source, and by subjecting the resultant dried product to a heat treatment under a non-oxidizing atmosphere.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Die, manufacturing method of a laser disk, and a laser disk

InactiveUS20070125302A1Uniform thickness distributionReduce manufacturing costLiquid surface applicatorsRecord information storageMaterials scienceLaser

The die as provided is a die in which an upper block is placed on an upper surface of a lower block with a lower surface of the upper block in contact with the upper surface, wherein the lower block includes a manifold and a slit serving as a path for discharging paint from the manifold to the outside, constituted respectively from between the lower block and the lower surface of the upper block by forming a cavity and a space which communicates with the outside from this cavity along a columnar direction, respectively, from one end face of a columnar body with a trapezoidal shape of cross section to the other end face, a paint supply path which communicates with the manifold is formed from an outer side located between the one end face and the other end face of the lower block, a slit space dimension of the slit between front end portions in a paint discharge direction of the lower block and the upper block in a discharge port serving as an open end to the outside is smallest on the one end face side and increases toward the other end face side, and a slit length which is a dimension along the paint discharge direction of a space forming surface of the lower block constituting the slit is largest on at least one of the one end face side and the other end face side and is smallest in a position between both the end faces.

Owner:PANASONIC CORP

Plasma processing method and plasma processing apparatus

ActiveUS20170130333A1High plasma controllabilityPreferable uniformity of film thicknessChemical vapor deposition coatingNoble gasEngineering

A plasma processing method is provided. In the plasma processing method, a plurality of types of mixed gases is supplied to a plurality of areas on a film deposited on a surface of a substrate. The plurality of types of mixed gases contains a plurality types of noble gases. The plurality of types of mixed gases has different mix proportions of the plurality types of noble gases from each other. The plurality of types of mixed gases is converted to plasma. A plasma process is performed by using the mixed gases converted to the plasma on the film.

Owner:TOKYO ELECTRON LTD

Preparation method of biferroelectric bismuth ferrite/bismuth vanadatephotoelectrochemical film

ActiveCN111003948ASmall size and shape requirementsUniform film qualityElectrolytic inorganic material coatingEnergy inputPara-BenzoquinoneTube furnace

The invention discloses a preparation method of a biferroelectric bismuth ferrite / bismuth vanadatephotoelectrochemical film. The method comprises the following steps: 1) performing FTO pretreatment; 2) dissolving bismuth nitrate pentahydrate and potassium iodide in water, and adding metal salt ions and nitric acid to adjust the pH value; 3) dissolving p-benzoquinone in ethanol; 4) mixing the two,and performing electrochemical deposition to obtain a film electrode; and 5) dropwise adding dimethyl sulfoxide in which ferrous acetylacetonate and vanadylacetylacetonate are dissolved into the filmelectrode obtained in the step 4), and carrying out high-temperature heat treatment in a tubular furnace to obtain the biferroelectric doped bismuth ferrite / bismuth vanadatefilm. According to the preparation method of the biferroelectric bismuth ferrite / bismuth vanadatephotoelectrochemical film, the preparation method is simple and easy to implement, the requirement for the size and shape of a bottom electrode is low, the film is uniform in quality, large in specific surface area, accurate in stoichiometric ratio, excellent in photocatalytic performance and high in water photolysis efficiency,and doping modification research is easy to carry out.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Liquid crystal alignment agent and liquid crystal display element

ActiveCN101921598AUniform film qualityExcellent electrical characteristics and heat resistanceLiquid crystal compositionsOrganic chemistryPolyamideChemistry

Owner:JSR CORPORATIOON

Semiconductor device and method of manufacturing the same

InactiveUS8026184B2Uniform film qualityGood step coverageTransistorSolid-state devicesCapacitanceMetal electrodes

Disclosed is a method of manufacturing a semiconductor device formed by laminating a capacitor including a bottom metal electrode, a capacitive insulating film, and an upper metal electrode. When the capacitive insulating film is formed by performing a first step of forming a first dielectric layer on the bottom metal electrode by a vapor phase film forming method using a precursor gas that contains constituent elements of a dielectric; and a second step of forming a second dielectric layer on the first dielectric layer by a vapor phase film forming method using a precursor gas that contains constituent elements of a dielectric, a film forming temperature in the first step is set so as to be lower than a film forming temperature in the second step.

Owner:PS4 LUXCO SARL

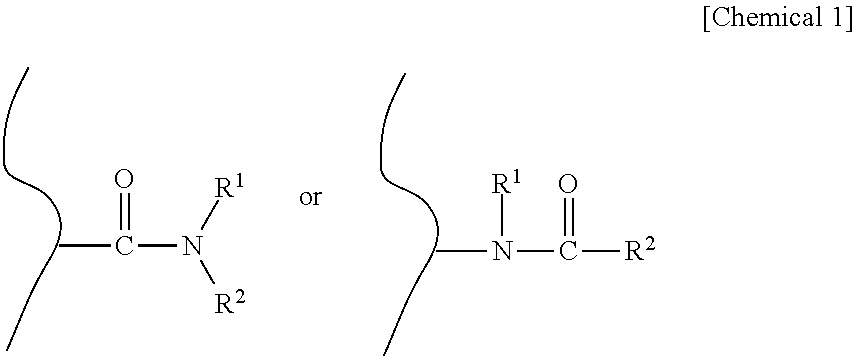

Electroconductive composition, composite material and production methods thereof

ActiveUS9589697B2High bonding strengthEffectively prevent the amide group from being hydrolyzedConductive materialOrganic conductorsOrganic solventSide chain

An electroconductive composition including polystyrene sulfonic acid, poly(3,4-ethylenedioxythiophene), water, an organic solvent having an affinity to water and a polymer having an amide group as a side chain.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com