Photodiffusion powder, preparation method of photodiffusion powder, quantum dot photoresist and quantum dot color film

A technology of light diffusion and quantum dots, which is applied in the direction of optomechanical equipment, chemical instruments and methods, photoplate making process coating equipment, etc. Light conversion efficiency and other issues to achieve the effect of improving brightness, good compatibility, and increasing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

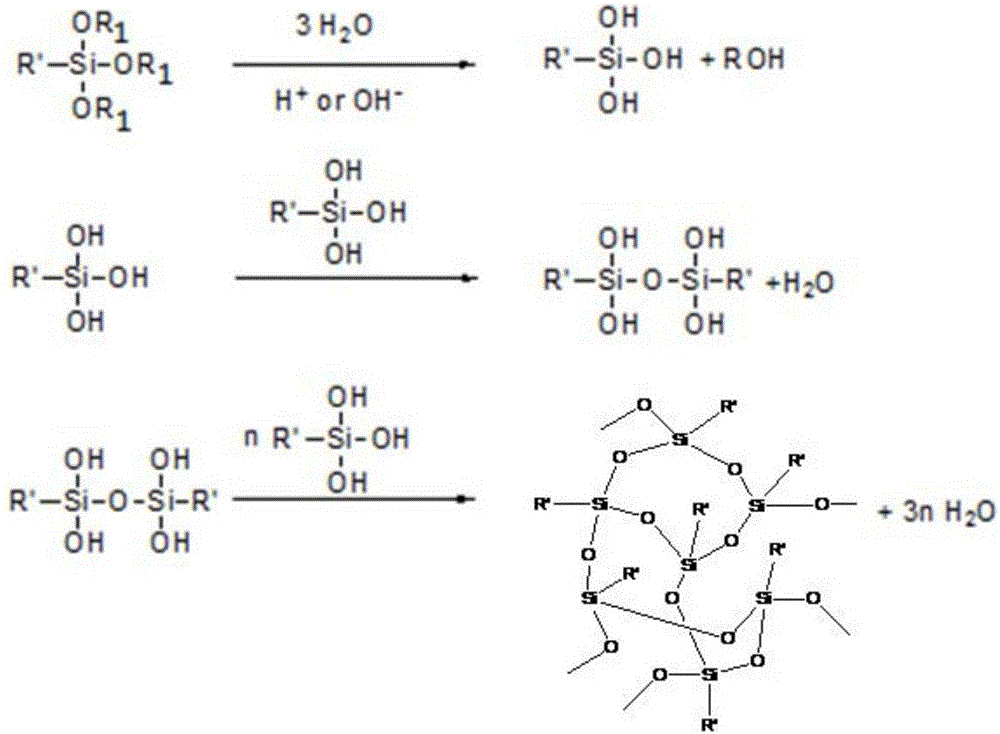

[0039] The invention discloses a preparation method of light diffusing powder, comprising the following steps:

[0040] The alkoxysilane is subjected to a co-hydrolysis condensation reaction under an acidic condition or an alkaline condition to obtain a light diffusing powder;

[0041] The alkoxysilane has the structure of formula I:

[0042]

[0043] Wherein, R1 is a C1-C50 alkyl group, preferably a C1-C20 alkyl group, more preferably a methyl group or an ethyl group;

[0044] Wherein, R' is an alkyl group or a substituted alkyl group, and the substituted alkyl group refers to a substituent such as halogen, amine group, hydroxyl group, and carboxyl group substituted for hydrogen in the alkyl chain, and the substituent group may also contain oxygen, nitrogen, sulfur, etc. Equiatomic carbon segments, such as alkoxy, epoxy, amide, ester, etc. Said R' is preferably as shown in the following structure:

[0045]

[0046] Wherein, A1, A2, A3, A4, B1, B2, B3, B4, and J are i...

Embodiment 1

[0104] Dissolve n-octyltriethoxysilane (13.8 mg, 0.05 mmol) in 20 ml of acetonitrile, then add 10 ml of 0.01 mol / L hydrochloric acid solution, stir, heat in an oil bath at 90 °C for 12 h, stop stirring, and continue in Heating and curing under reduced pressure for 5 hours, the obtained solid was washed with 1 mol / L hydrochloric acid solution, distilled water, acetonitrile solution, and finally with acetone, and vacuum dried at 60 °C to obtain light diffusing powder. The light diffusing powder has the structure of formula II, wherein R'=CH 3 (CH 2 ) 6 CH 2 -.

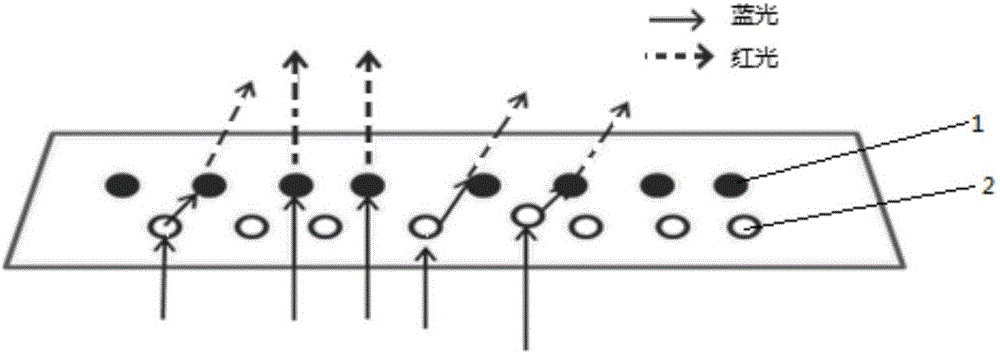

[0105] Disperse the red CdSe / ZnS core-shell quantum dots into the mass-produced photoresist mother solution (without pigment components), then add the above-mentioned light diffusing powder, and carry out ultrasonic dispersion for 1 h. The mixing ratio is: the content of quantum dots is 10wt% , the content of light diffusing powder is 20wt%, 20wt% acrylic resin, 10wt% 1,6-hexanediol diacrylate, 1.5wt% benzophenone co...

Embodiment 2

[0108] n-octadecyltriethoxysilane (20.9mg, 0.05mmol) was dissolved in 20ml of acetonitrile, then 10ml of 0.01mol / L hydrochloric acid solution was added, stirred, heated in an oil bath at 90°C for 12h, stopped stirring, and continued Heating and curing under reduced pressure for 3 hours, the obtained solid was washed with 1 mol / L hydrochloric acid solution, distilled water, acetonitrile solution, and finally with acetone, and vacuum dried at 60 °C to obtain light diffusing powder. The light diffusing powder has the structure of formula II, wherein R'=CH 3 (CH 2 ) 16 CH 2 -.

[0109] Disperse the red CdSe / ZnS core-shell quantum dots into a commercially available mass-produced photoresist mother solution (without pigment components), then add the above-mentioned light diffusing powder, and carry out ultrasonic dispersion for 1h. The mixing ratio is: the quantum dot content is: 10wt%, the content of light diffusing powder is 20wt%, 20wt% acrylic resin, 10wt% 1,6-hexanediol dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com