Liquid crystal alignment agent and liquid crystal display element

A technology of liquid crystal aligning agent and liquid crystal aligning film, which is applied in the directions of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of poor display quality of liquid crystal display elements, long storage time, and damage to the uniformity of the coating film. Shows effects of suppression of quality deterioration, uniform film quality, excellent electrical properties and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

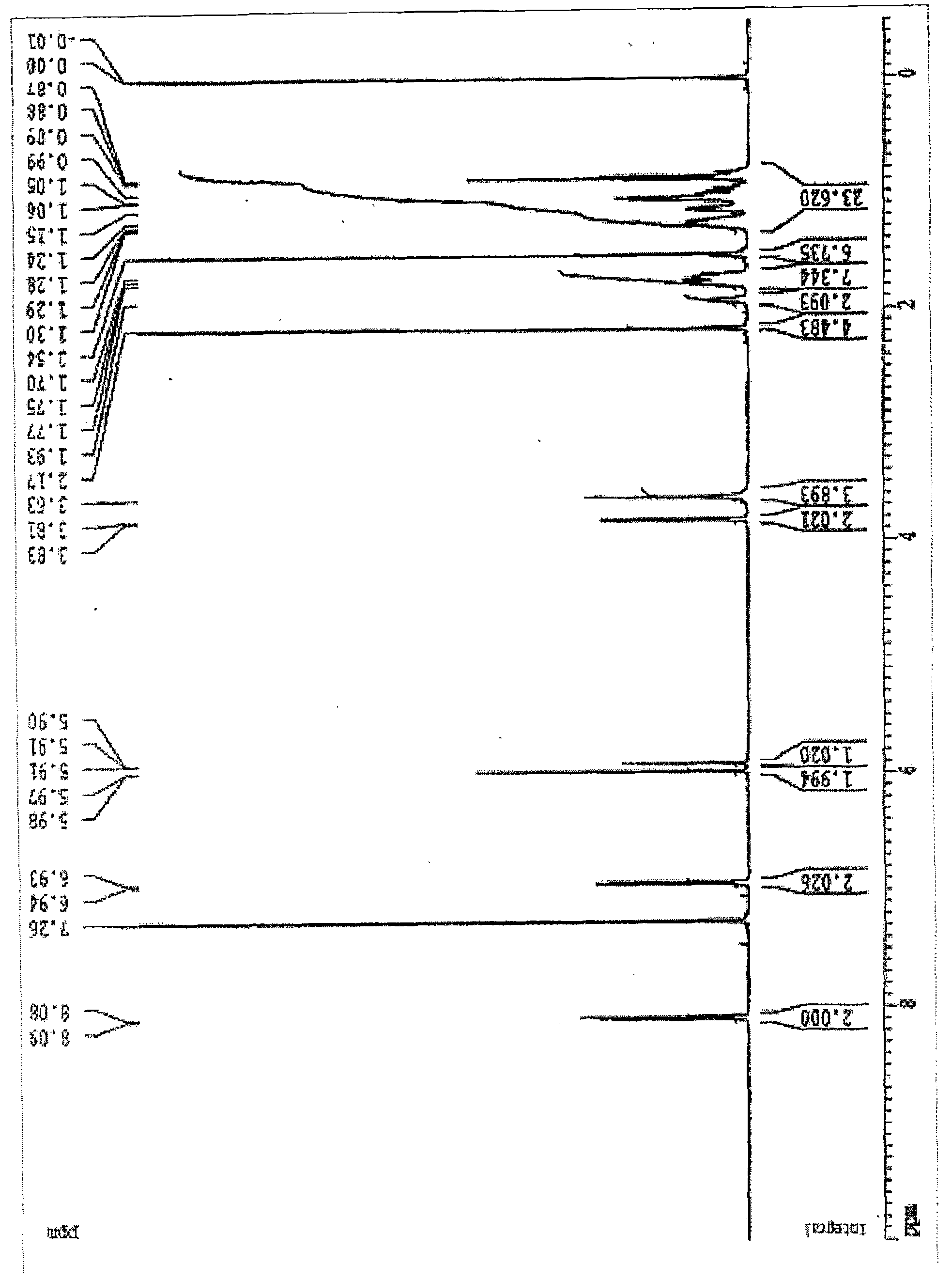

[0198] Synthesis Example A-1

[0199] According to the following synthetic route figure 1 To synthesize compound (A-1-1).

[0200]

[0201] synthetic route figure 1

[0202] Under a nitrogen atmosphere, in a 5000 mL three-necked flask, 266.5 g of compound (A-1-1a), 253.3 g of p-chlorobenzenesulfonyl chloride, and 1000 mL of dichloromethane were added, and the mixture was stirred at 0°C. Here, a solution in which 180 mL of triethylamine was dissolved in 200 mL of dichloromethane was added dropwise for 30 minutes, and stirred at room temperature (25°C) for 3 hours to perform the reaction. Next, 1000 mL of dichloromethane was added to the obtained reaction mixture, and the obtained organic layer was washed with distilled water. After the washed organic layer was dried with magnesium sulfate, the solvent was removed by a rotary evaporator to obtain a colorless viscous liquid. 3000 mL of ethanol was added to this colorless viscous liquid, and after fully stirring, the precipitated w...

Example Embodiment

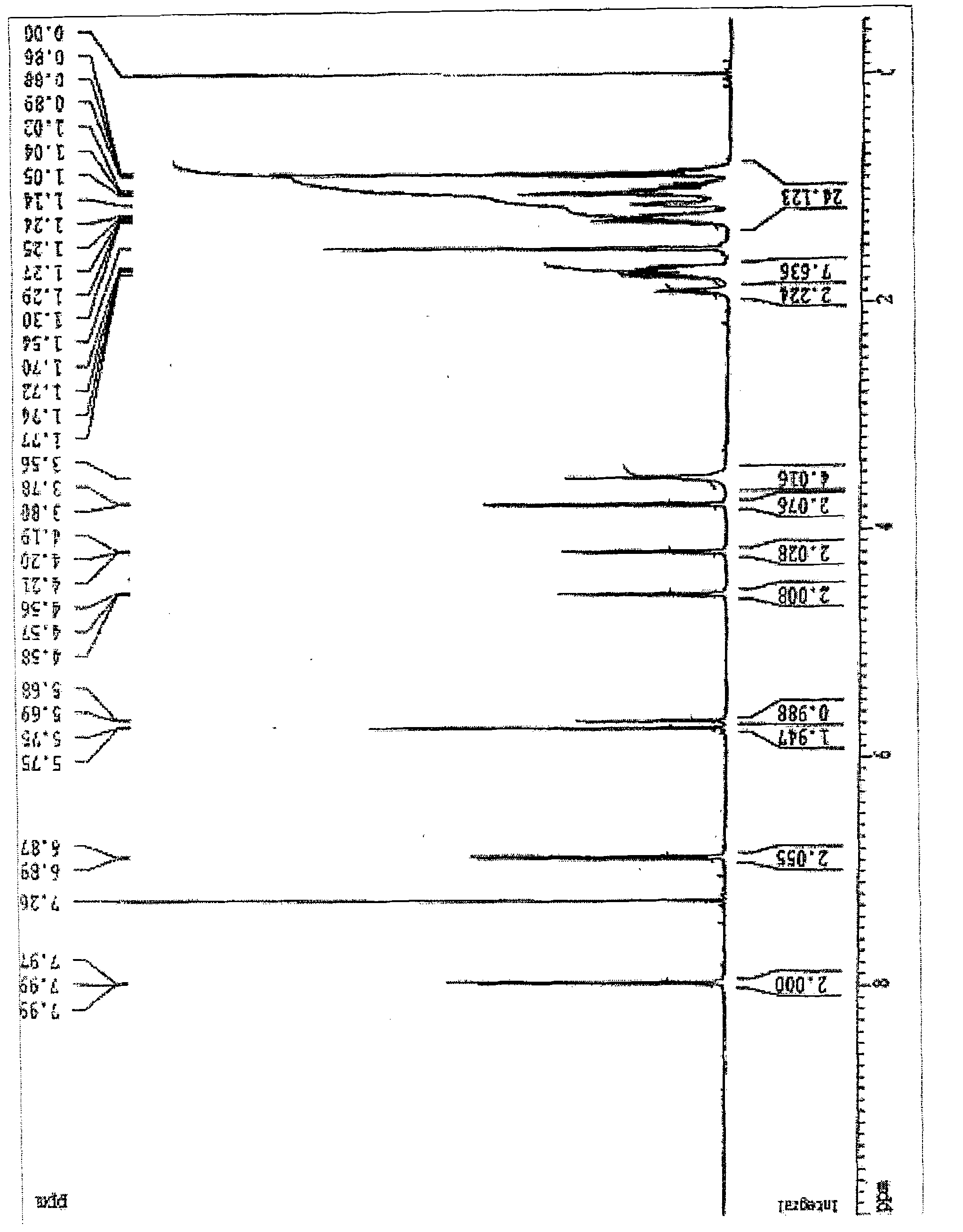

[0209] Synthesis Example A-2

[0210] According to the following synthetic route figure 2 Compound (A-2-1) was synthesized.

[0211]

[0212] In a nitrogen atmosphere, 142.2g of 3,5-bis(diallylamino)phenol (compound (B)), 220.2g of ethylene carbonate, 16.1g of tetrabutylammonium bromide and 1000 mL of N,N-dimethylformamide was stirred at 150°C for 6 hours to perform the reaction. 2000 mL ethyl acetate and 500 mL methanol were added to the obtained reaction mixture, and the obtained organic layer was washed with 1 equivalent sodium hydroxide aqueous solution and distilled water in sequence, dried with magnesium sulfate, and the solvent was removed by a rotary evaporator to obtain a crude product. The obtained composition was passed through a chromatographic column (filler: silica gel, developing solvent: hexane / ethyl acetate = 4 / 1 (weight ratio)), and the solvent was removed under reduced pressure to obtain a light orange viscous liquid. Compound (A-2-1a) 138.6g.

[0213] Next, un...

Example Embodiment

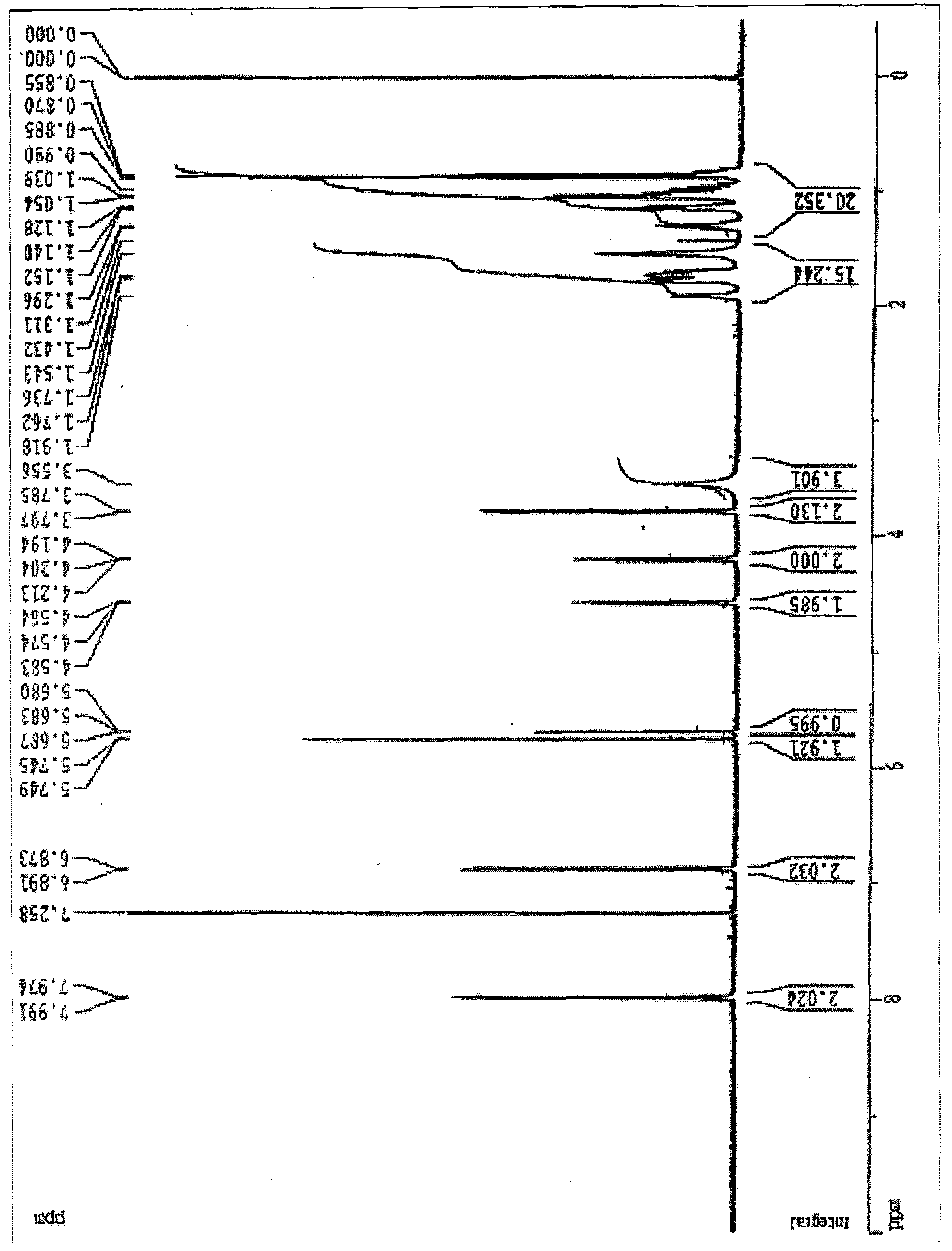

[0216] Synthesis Example A-3

[0217] According to the following synthetic route image 3 Compound (A-2-2) was synthesized.

[0218]

[0219] synthetic route image 3

[0220] Under a nitrogen atmosphere, 238.2 g of compound (A-2-2a), 253.3 g of p-chlorobenzenesulfonyl chloride, and 1000 mL of dichloromethane were added to a 5,000 mL three-necked flask, and the mixture was stirred at 0°C. Here, a solution in which 180 mL of triethylamine was dissolved in 200 mL of dichloromethane was added dropwise within 30 minutes, and then stirred at room temperature for 3 hours to perform the reaction. After the reaction was terminated, 1000 mL of dichloromethane was added to the obtained reaction mixture, and the obtained organic layer was washed with distilled water, and then dried with magnesium sulfate, and the solvent was removed by a rotary evaporator to obtain a colorless viscous liquid. 3000 mL of ethanol was added to the obtained colorless viscous liquid, and after thorough stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com