Sputtering device and sputtering method

A sputtering device and assembly technology, which is applied in the direction of sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problems of uneven film quality, non-promoting reaction, etc., and achieve the effect of uniform film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

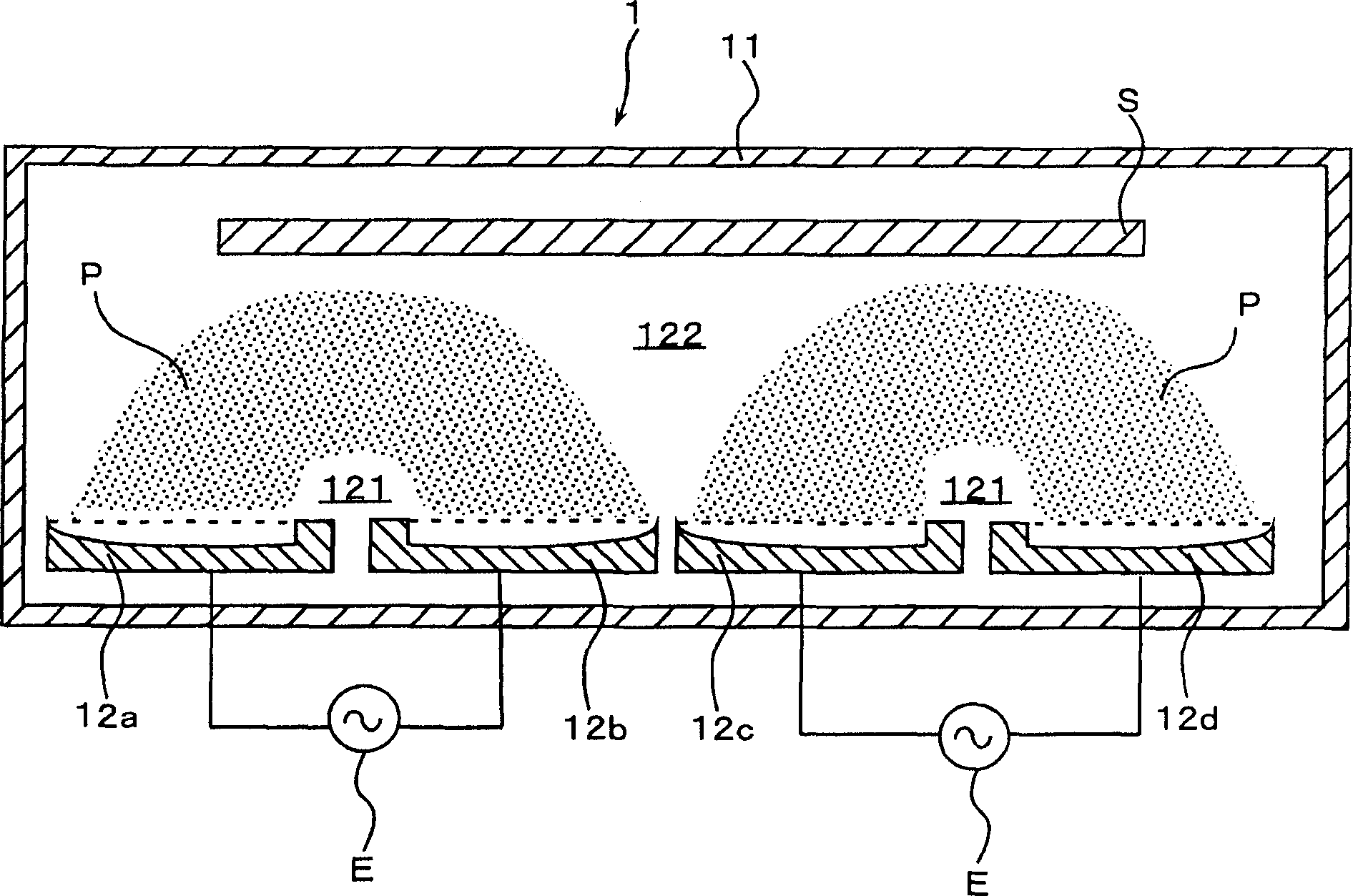

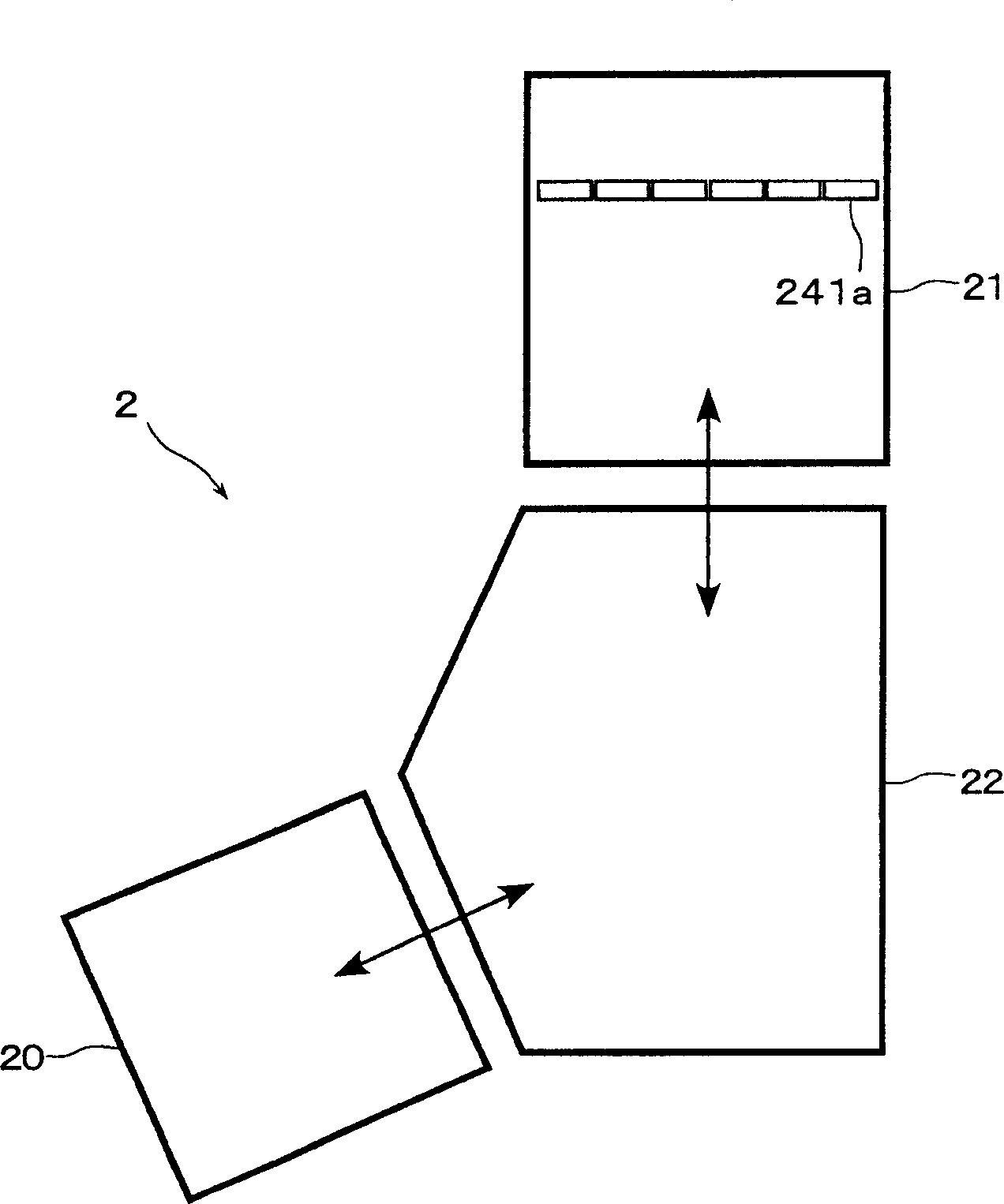

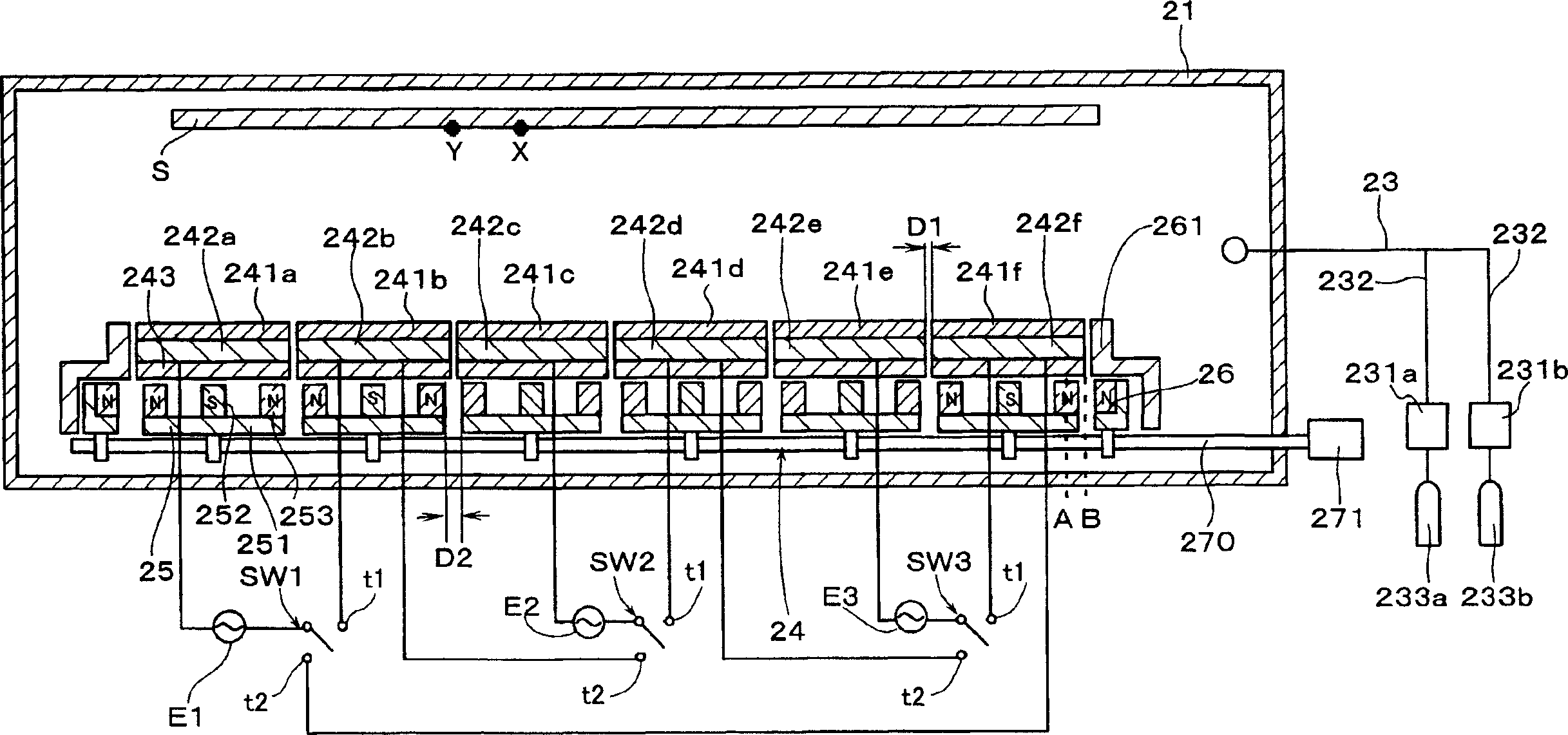

[0064] In Example 1, using figure 2 and image 3 Films were formed using the sputtering device shown in , and the number of occurrences of arc discharge during film formation was studied.

[0065] Will be composed of In 2 o 3 -10wt%SnO 2 A target made of (ITO) was installed parallel to the substrate at a position 150 mm away from the substrate. The target width was 2 mm, respectively. A magnet assembly with a width of 170 mm, a length of 1570 mm, and a thickness of 40 mm was installed behind each target so that the distance from each target was 47 mm, and the ball screw 271 was used to make the driving distance 50 mm. As a substrate, a glass substrate having a width of 1000 mm, a length of 1200 mm, and a thickness of 0.7 mm was prepared.

[0066] After the substrate was transported, evacuation was performed, and then argon gas was introduced from the gas introduction unit 23 at 240 sccm as a sputtering gas to form a film-forming atmosphere of 0.67 Pa. Additionally, H w...

Embodiment 2

[0071] In Example 2, using figure 2 and image 3 In the sputtering apparatus shown in , the in-plane uniformity of film quality was evaluated when reactive sputtering was performed.

[0072] The flow rate of the reaction gas during film formation was changed, and the flow rate at which the resistivity decreased the most at each point on the film was investigated, and the in-plane uniformity of film quality was evaluated using the difference in the flow rate.

[0073] Using the same sputtering apparatus as used in Example 1, a plurality of films were formed by changing the flow rate of the reaction gas in Example 1. As a reactive gas, H 2 The flow rate of O gas was set at 2.0 sccm, and O was introduced so that the flow rate was changed from 0.0 sccm to 4.0 sccm in increments of 0.2 sccm. 2 gas. The frequency of each AC power supply E was 25 kHz, and the power was gradually increased from 0 kW to 15 kW at last. The AC power supply was stopped 25 seconds after the AC power s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com