High-precision 3D sand mold printing equipment

A printing equipment and high-precision technology, applied in the field of 3D printing, can solve problems such as the inability to comprehensively consider the uniformity of sand laying, the recovery of residual sand from sand surface settlement, affecting the preparation quality and efficiency of sand mold parts, and the complexity of the overall structure, and achieve automation. The effect of high degree, convenient collection and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

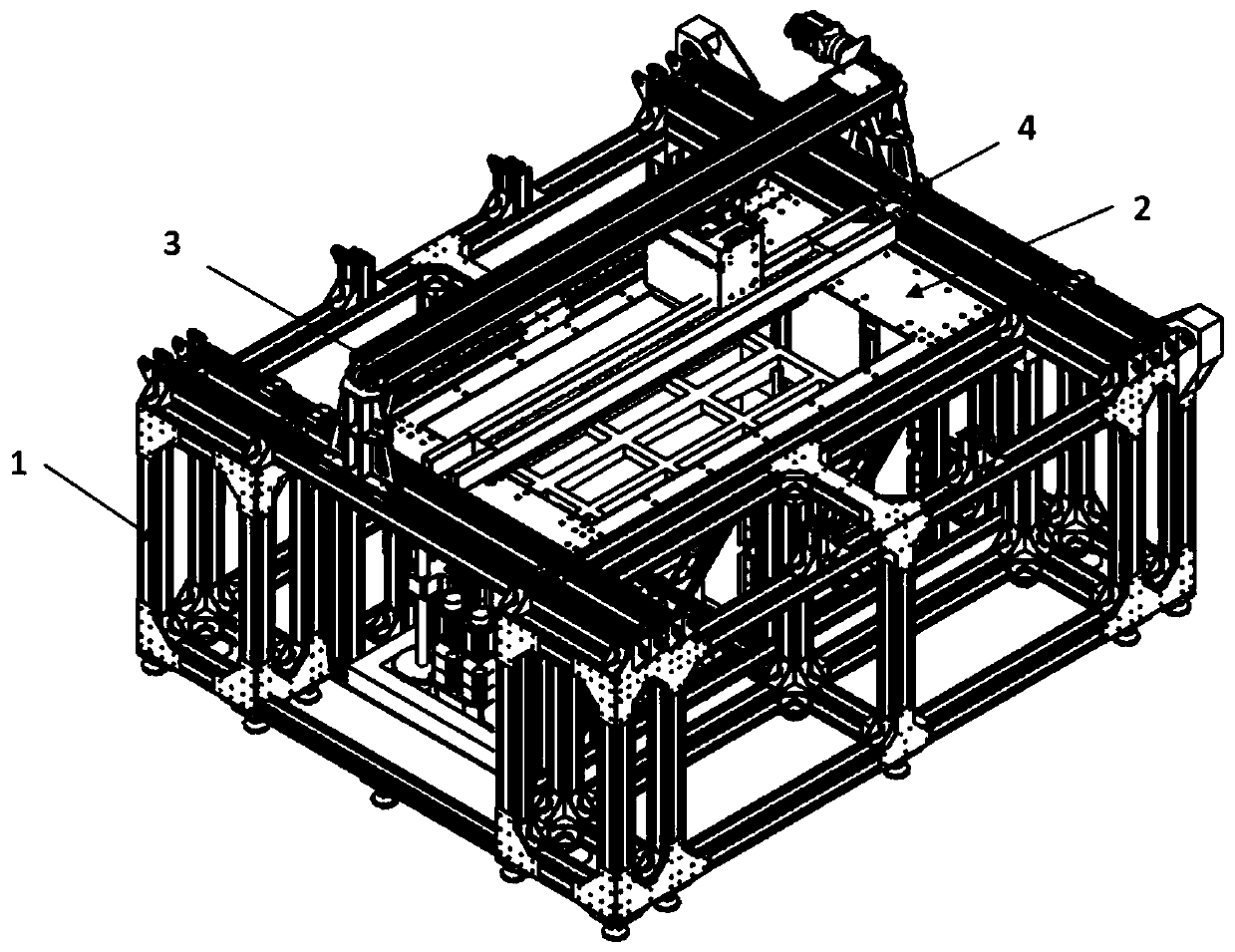

[0041] combine figure 1 and Figure 5 , a high-precision 3D sand printing device, including a support frame 1, a sand box 2, an inkjet assembly 3 and a sand delivery assembly 4, the sand box 2 is arranged inside the support frame 1, the inkjet assembly 3 and the sand delivery assembly The sand assembly 4 is arranged on the upper end of the support frame 1 , and the inkjet assembly 3 and the sand delivery assembly 4 correspond to the sand box 2 .

[0042]The inkjet assembly 3 includes an inkjet trolley 32, a first guide rail 31 and a second guide rail 33, the inkjet trolley 32 is slidably connected to the first guide rail 31, and the two ends of the first guide rail 31 are slidably connected to the second guide rail 31 through a bracket. The guide rail 33 , the first guide rail 31 is arranged perpendicular to the second guide rail 33 , and the second guide rail 33 is arranged on the upper end of the supporting frame 1 .

Embodiment 2

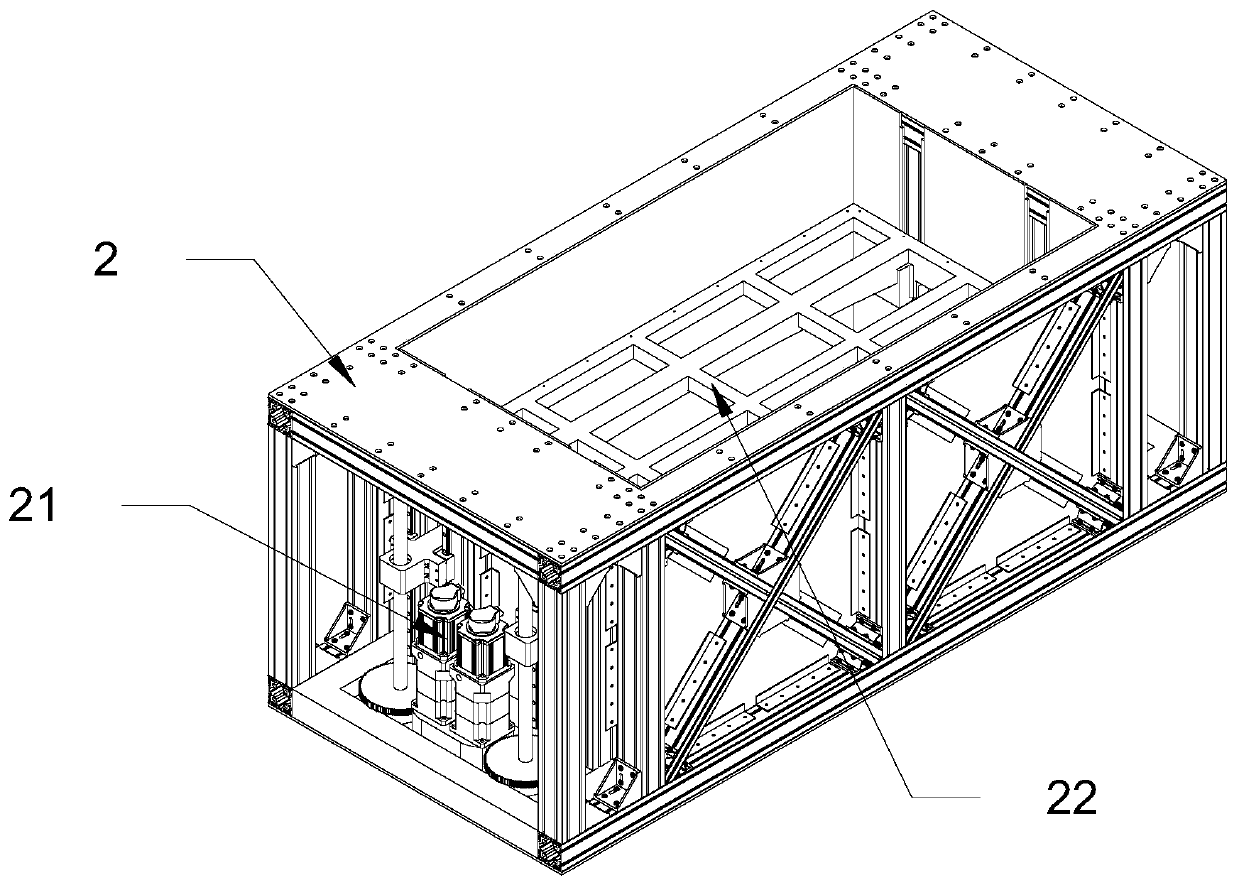

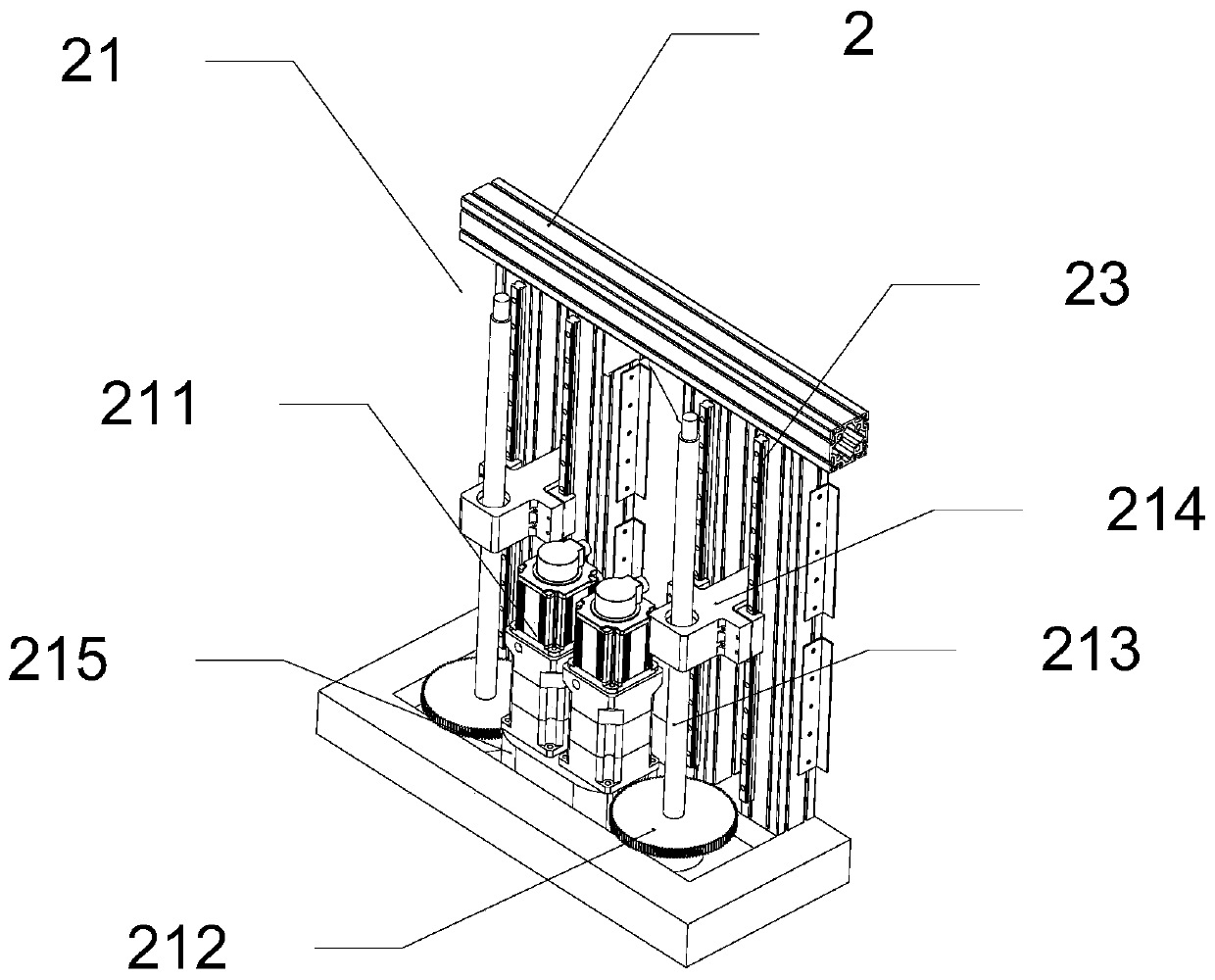

[0044] like Figure 2-4 As shown, the outer two ends of the sand box 2 are provided with slide rails 23 and a lifting mechanism 21, and the inside of the sand box 2 is provided with a lifter 22 connected with the lifting mechanism 21, and the lifting mechanism 21 is connected by the slide rail 23. Die frame 22, described elevating mechanism 21 comprises base 215, drive motor 211, ball screw pair 213 and sliding frame 214, and described base 215 is located at sandbox 2 bottom, and described drive motor 211 and ball screw pair 213 all Located on the upper end of the base 215, the output shaft of the drive motor 211 is connected to the bottom of the ball screw pair 213 through the sprocket 212, the sliding frame 214 is sleeved on the outside of the ball screw pair 213, and the ejector frame 22 The sliding frame 214 is slidably connected to the sliding rail 23, the sand box 2 is a box structure with an upper end open, and the ejector frame 22 is a square grid with several uniform ...

Embodiment 3

[0048] like Image 6 As shown, the inkjet assembly 3 includes an inkjet trolley 32, a first guide rail 31 and a second guide rail 33, the inkjet trolley 32 is slidably connected to the first guide rail 31, and the two ends of the first guide rail 31 slide through brackets Connected to the second guide rail 33 , the first guide rail 31 is arranged perpendicular to the second guide rail 33 , and the second guide rail 33 is arranged on the upper end of the supporting frame 1 .

[0049] The inkjet cart 32 includes a housing 321, an inkjet mechanism and a nozzle mechanism, the inkjet mechanism is arranged at the upper end of the housing 321, the nozzle mechanism is arranged at the lower end of the housing 321, and the inkjet mechanism Corresponding to the nozzle mechanism.

[0050] The inkjet mechanism includes a syringe pump 322, an ink cartridge 323 and an ink outlet hole 324. The output end of the syringe pump 322 is connected to the input end of the ink cartridge 323, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com