Novel injection device for injection molding machine

An injection device and injection molding machine technology, applied in the field of injection molding machines, can solve problems such as low production efficiency, slow molding speed, and low injection accuracy, and achieve the effects of improving quality, shortening the plasticizing cycle, and ensuring injection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

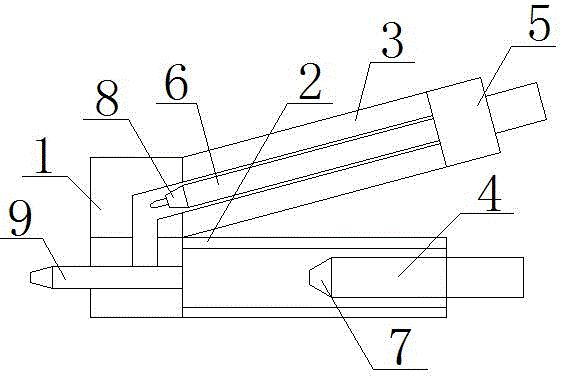

[0012] like figure 1 It is a structural schematic diagram of the present invention, a new injection molding machine injection device, including a connecting body 1, a material storage cylinder 2, an injection cylinder 3, a push plug 4, an injection cylinder 5, an injection screw 6, a material feeding device 7, Gluing device 8 and nozzle 9, connecting body 1 is connected with storage cylinder 2, injection cylinder 3 is provided above storage cylinder 2, push plug 4 is provided in storage cylinder 2, and one end of injection cylinder 3 is provided with Injection cylinder 5, injection barrel 3 is provided with injection screw 6, the front end of push plug 4 is provided with feeding glue device 7, the front end of injection screw 6 is provided with glue passing device 8, and connecting body 1 is provided with nozzle 9.

[0013] When in use, the injection device and the discharge device are separated but work synchronously. The injection barrel 3 is equipped with an injection screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com