High-flame-retarding low-smoke modified polyvinyl ethylene cable material and preparation method thereof

A polyvinyl chloride cable and polyvinyl chloride resin technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problem of large amount of PVC wire and cable, and achieve increased flexibility, enhanced flame retardancy, and enhanced physical and chemical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A high flame-retardant and low-smoke modified polyvinyl chloride cable material, which is characterized in that it is prepared from the following parts by weight (kg): polyvinyl chloride resin 100, polyethylene adipate glycol 8, Antimony trioxide 3, chlorinated paraffin 4, aluminum hydroxide 8, dioctyl terephthalate 30, tricresyl phosphate 10, organotin stabilizer 5, antioxidant TPP 4, nano kaolin 6, epoxy resin Soybean oil 7, tetrabromophthalic anhydride ester 9, UV absorber 7, pentaerythritol amine stearate 4, white oil 5, mica powder 6, calcium ricinoleate 7, conductive carbon black 5, nano silica 10.

[0016] The method for preparing a high flame-retardant and low-smoke modified polyvinyl chloride cable material is characterized in that it comprises the following steps:

[0017] (1) Add antimony trioxide, chlorinated paraffin, tricresyl phosphate, organotin stabilizer, antioxidant TPP, and nano-kaolin into an appropriate amount of dioctyl terephthalate, stir to form a pa...

Embodiment 2

[0021] A high flame-retardant and low-smoke modified polyvinyl chloride cable material, characterized in that it is prepared from the following parts by weight (kg) of raw materials: polyvinyl chloride resin 110, polyethylene adipate glycol 10, Antimony trioxide 4.5, chlorinated paraffin 4.5, aluminum hydroxide 9, dioctyl terephthalate 35, tricresyl phosphate 12, organotin stabilizer 6, antioxidant TPP 6, nano kaolin 7.5, epoxy resin Soybean oil 8.5, tetrabromophthalic anhydride ester 11, ultraviolet absorber 7.5, pentaerythritol amine stearate 4.5, white oil 5.5, mica powder 7, calcium ricinoleate 8, conductive carbon black 7, nano silica 11.

[0022] The preparation method is the same as in Example 1.

Embodiment 3

[0024] A high flame-retardant and low-smoke modified polyvinyl chloride cable material, characterized in that it is prepared from the following parts by weight (kg) of raw materials: polyvinyl chloride resin 120, polyethylene adipate glycol 12, Antimony trioxide 6, chlorinated paraffin 5, aluminum hydroxide 10, dioctyl terephthalate 40, tricresyl phosphate 14, organotin stabilizer 7, antioxidant TPP 8, nano kaolin 9, epoxy resin Soybean oil 10, tetrabromophthalic anhydride ester 13, ultraviolet absorber 8, pentaerythritol amine stearate 5, white oil 6, mica powder 8, calcium ricinoleate 9, conductive carbon black 9, and nano silica 12.

[0025] The preparation method is the same as in Example 1.

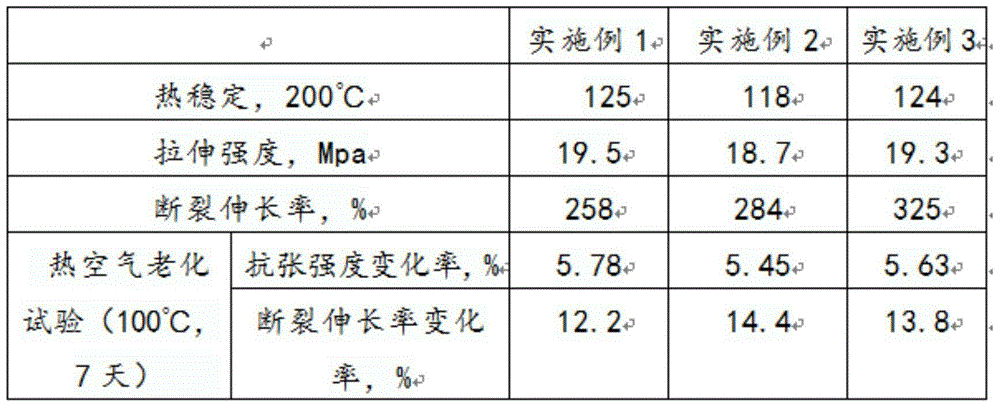

[0026] The performance test results of the high flame-retardant and low-smoke modified polyvinyl chloride cable materials prepared in the foregoing Examples 1-3 are shown in the following table:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com