Foaming agent capable of reducing water absorption rate of foamed mixed light soil

A technology of foaming agent and light soil, which is applied in the field of foaming agent that can reduce the water absorption of air bubbles mixed with light soil, and can solve the problems that light soil is difficult to achieve the coordination of water absorption and use performance, and achieve good foaming , mild reaction conditions and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

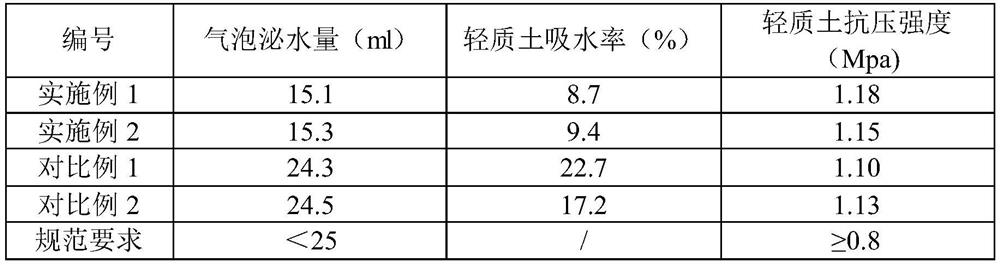

Examples

Embodiment 1

[0030] A kind of foaming agent that can reduce the water absorption rate of bubble-mixed light soil, its preparation method comprises the steps:

[0031] 1) Preparation of modified cardanol-based surfactant: cardanol and concentrated sulfuric acid (with introduced H 2 SO 4 Measure) according to the molar ratio of 1:0.2, weigh, put the cardanol that weighs into reaction kettle, add concentrated sulfuric acid (stirring speed 650r / min) while stirring, react 150min at 45 ℃, get intermediate product ( Sulfonated cardanol); Then under stirring (stirring speed 400r / min, temperature is 35 ℃) add N-methyldiethanolamine and sodium ethylate (the mol ratio of N-methyldiethanolamine and sodium ethylate is 1:1 ), reacted to the pH of the resulting solution system = 9; finally, under the conditions of nitrogen protection atmosphere and 0.3MPa, the temperature was raised to 130°C, and ethylene oxide (the molar ratio to cardanol was 20:1) was passed through to carry out polyether Chemical re...

Embodiment 2

[0035] A kind of foaming agent that can reduce the water absorption rate of bubble-mixed light soil, its preparation method comprises the steps:

[0036] 1) Preparation of modified cardanol-based surfactant: weigh cardanol and concentrated sulfuric acid at a molar ratio of 1:0.25, put the weighed cardanol into a reaction kettle, add concentrated sulfuric acid while stirring (stirring speed 650r / min), and reacted at 40°C for 160min to obtain an intermediate product (sulfonated cardanol); then add N-methyldiethanolamine and sodium ethylate under stirring conditions (stirring speed 450r / min, temperature 35°C) (The molar ratio of N-methyldiethanolamine and sodium ethoxide is 1:1), react until the pH of the obtained solution system=9.5; finally, under the condition of nitrogen protection atmosphere and 0.3MPa, heat up to 130°C, and pass into the ring Oxyethane (the molar ratio with cardanol is 10:1) carries out polyetherification reaction 4h, obtains modified cardanol-based surfact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com