A kind of polymer denitration agent and preparation method thereof

A polymer and denitration agent technology, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

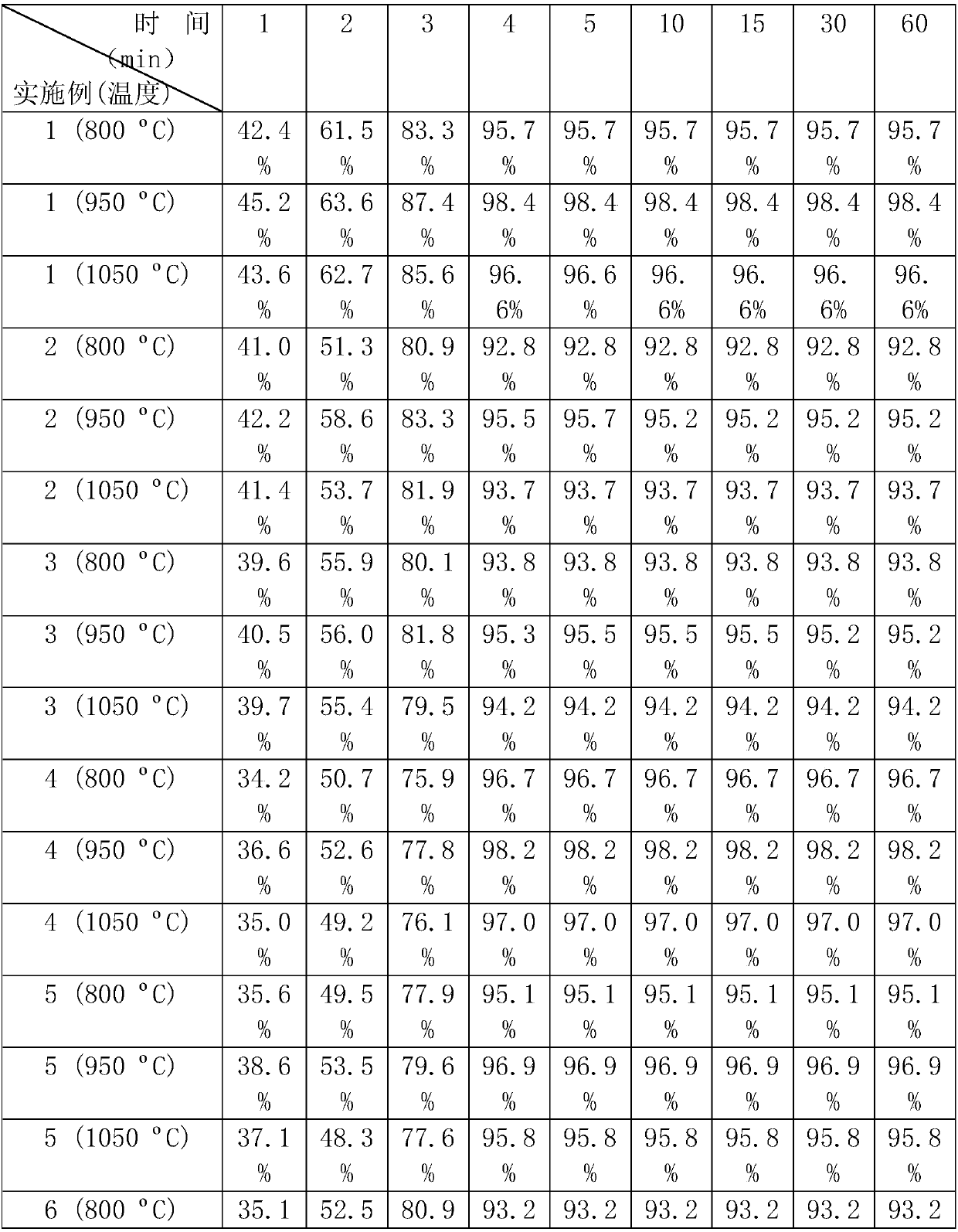

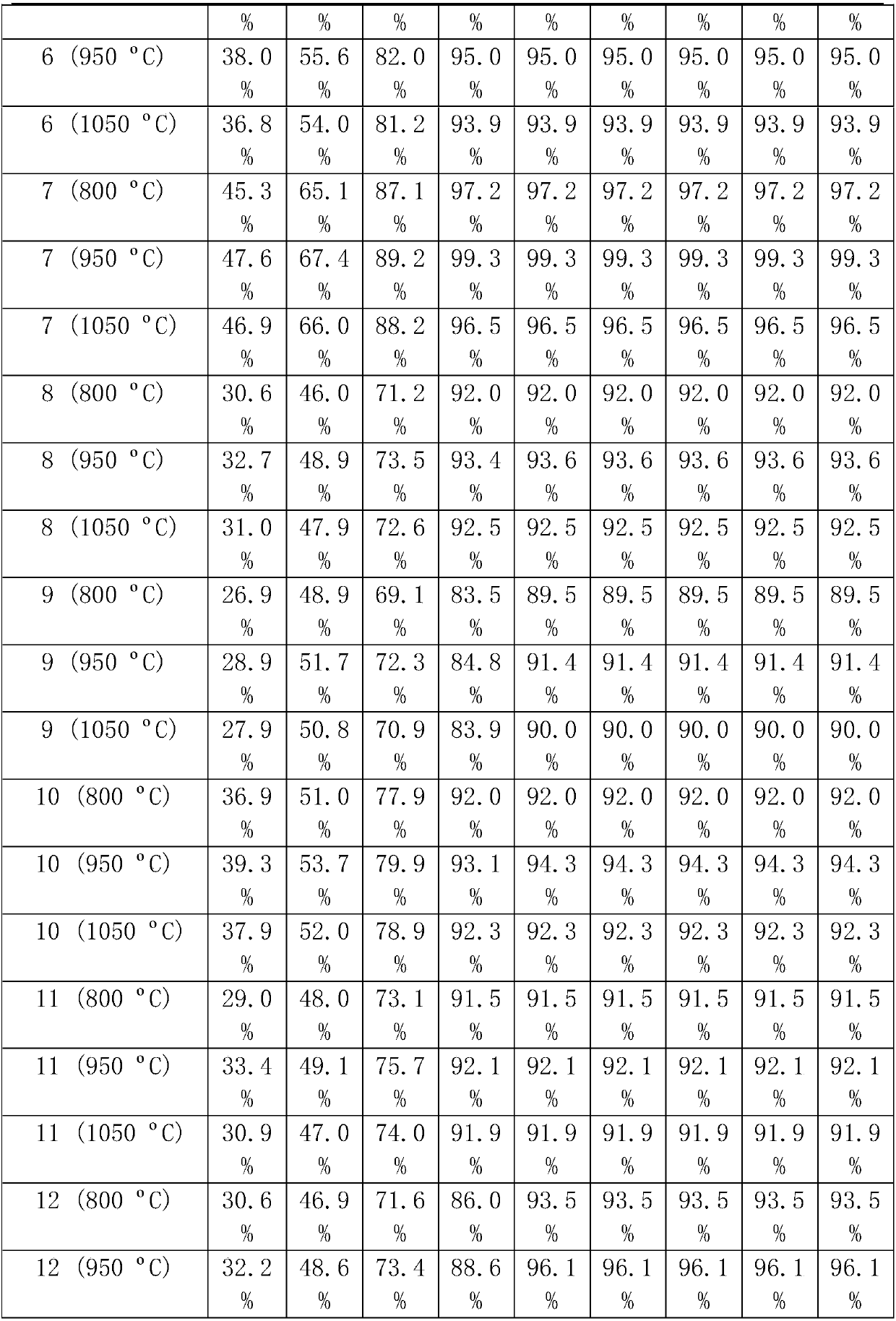

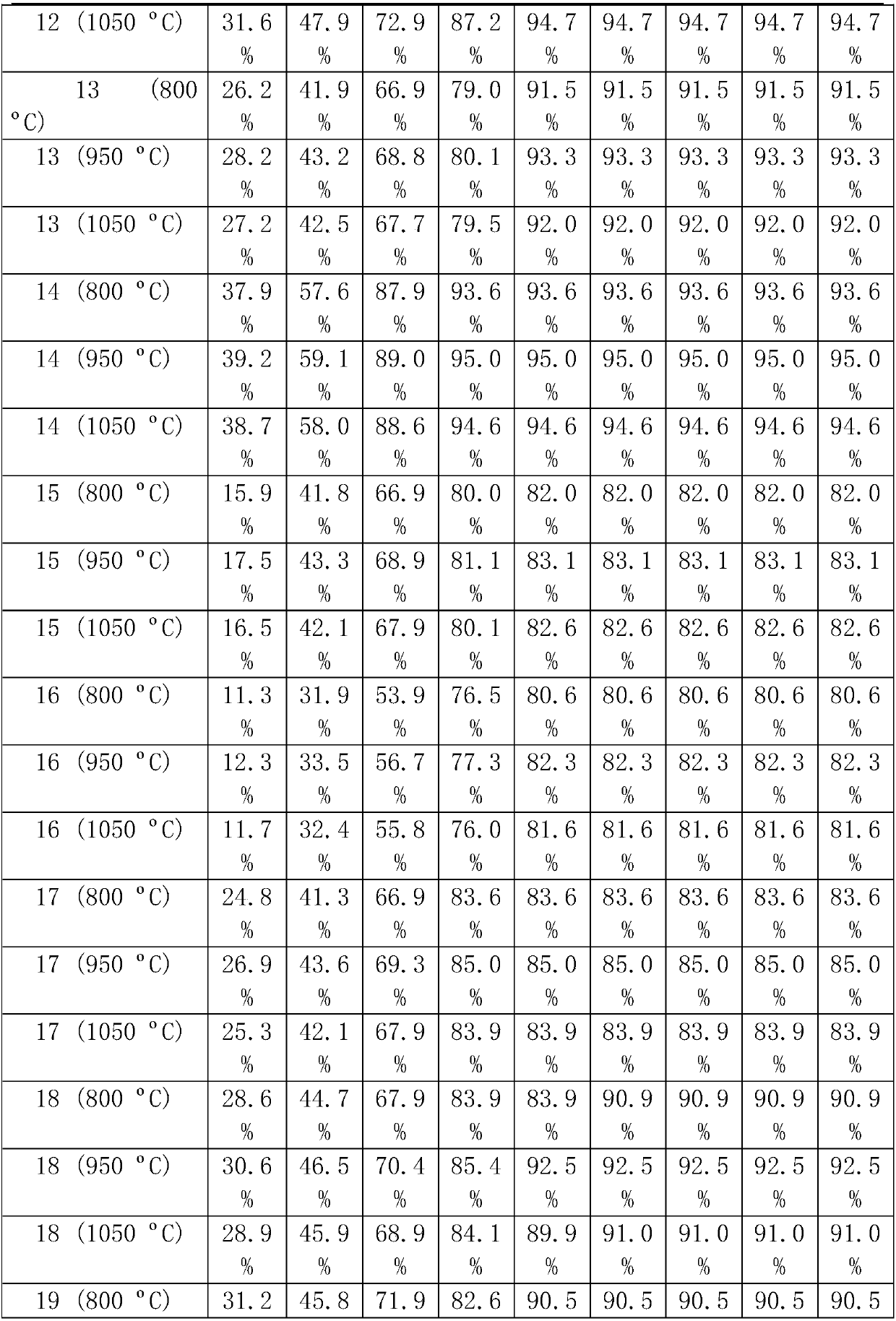

Examples

Embodiment 1

[0029] 1) Preparation of polymer denitration agent:

[0030] Weigh 33.1 parts by mass of sodium hydroxide and 238.1 parts by mass of distilled water into the reaction kettle to form a sodium hydroxide solution; and keep the reaction kettle in an ice bath and stirring state at 0 ° C ~ 4 ° C and slowly dissolve the mass parts of 100.0 Add acrylic acid to the above sodium hydroxide solution, then add 0.043 parts by mass of potassium persulfate and 0.029 parts by mass of N,N'-methylenebisacrylamide, continue stirring for 30 minutes, then heat up to 75 degrees Celsius for 90 minutes until the mixture polymerizes. Then the polymer was dried at 70 degrees Celsius for 5 hours, and pulverized into particles by a pulverizer to obtain synergistic polymer A.

[0031] 44.0 parts by mass of urea, 55.0 parts by mass of benzomelamine and 1.0 parts by mass of the aforementioned synergistic polymer A were compounded, and mixed by a high-speed mixer. The reaction conditions are as follows: the...

Embodiment 2

[0036] 1) Preparation of polymer denitration agent:

[0037] Weigh 42.9 parts by mass of potassium hydroxide and 228.3 parts by mass of distilled water into the reaction kettle to form a potassium hydroxide solution; and keep the reaction kettle at 0 ° C ~ 4 ° C under ice bath and stirring state to slowly dissolve the mass parts of 45.7 Acrylic acid and 54.3% methacrylic acid were added to the above potassium hydroxide solution, and then 0.041 parts by mass of potassium persulfate and 0.027 parts by mass of N,N'-methylenebisacrylamide were added, and after stirring for 30 minutes, the temperature was raised to Heat at 75°C for 90 minutes until the mixture polymerizes. Then the polymer was dried at 70°C for 5 hours, and pulverized into particles by a pulverizer to obtain synergistic polymer B.

[0038]Mix 5.0 parts by mass of ammonium bicarbonate, 5.0 parts by mass of ammonium carbonate, 38.3 parts by mass of urea, 45.0 parts by mass of melamine, and 6.7 parts by mass of the s...

Embodiment 3

[0041] 1) Preparation of polymer denitration agent:

[0042] Weigh 31.6 parts by mass of sodium acrylate, 36.8 parts by mass of potassium acrylate, and 31.6 parts by mass of acrylic acid dissolved in 200.0 parts by mass of distilled water, then add 0.036 parts by mass of potassium persulfate, 0.024 parts by mass of For N,N'-methylenebisacrylamide, continue to stir for 30 minutes, then raise the temperature to 90 degrees Celsius and heat for 30 minutes until the mixture is polymerized. Then the polymer was dried at 70 degrees Celsius for 5 hours, and pulverized into particles by a pulverizer to obtain synergistic polymer C.

[0043] 15.0 parts by mass of ammonium acetate, 5.0 parts by mass of urea, 40.0 parts by mass of melamine and 40.0 parts by mass of the above synergistic polymer C were compounded, and mixed by a high-speed mixer. The reaction conditions are as follows: the linear velocity of the high-speed stirring paddle is 40 m / s-80 m / s, the stirring time is 5-10 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com