Solid-liquid mixed type foam stabilizer and preparation method thereof

A technology of solid-liquid mixing and foam stabilizer, which is applied in the direction of textiles and papermaking, can solve the problem of no significant improvement in pore dispersion, achieve the effects of eliminating irritating odor, improving the working environment, and improving foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

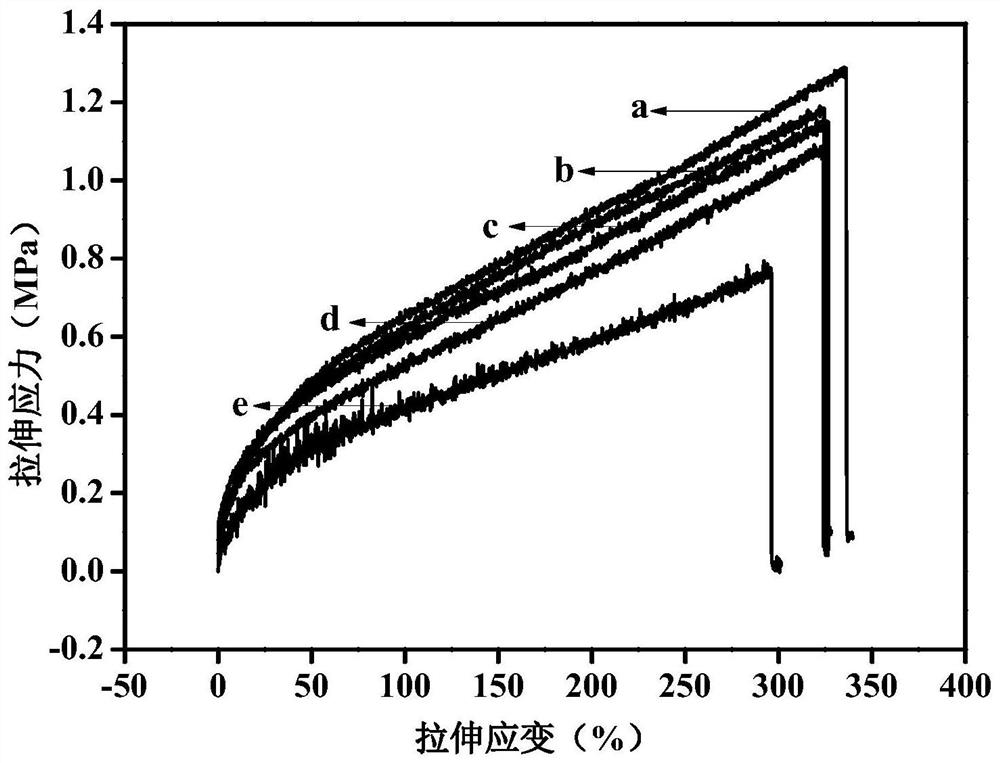

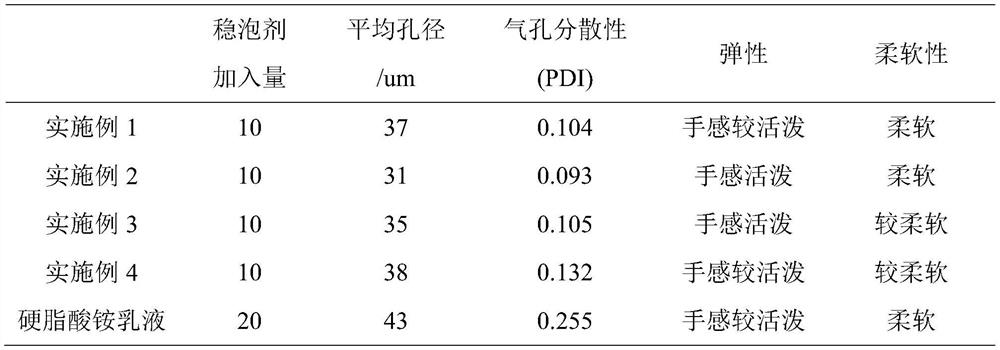

Examples

Embodiment 1

[0023] 1) Weigh 20 parts of propylene glycol, 20 parts of stearic acid and 10 parts of calcium carbonate (particle size 2 microns) particles in a reaction kettle, control the temperature at 50°C, mix and stir to form a suspension;

[0024] 2) adding dropwise 20 parts of mass fraction again is 20% potassium hydroxide solution (n 氢氧化钾 :n 硬脂酸 =1:1), and continued to stir for 3 hours at 50°C;

[0025] 3) After the reaction is over, continue to add water to the reactor until the total mass of the product is 100 parts, and mix and stir for 10 minutes;

[0026] 4) The product is emulsified (shear rate 10000r / min, emulsification time 60min) to obtain the final product.

Embodiment 2

[0028] 1) Weigh 10 parts of ethylene glycol, 10 parts of stearic acid and 20 parts of calcium carbonate (particle size 0.5 micron) particles in a reaction kettle, control the temperature at 40°C, mix and stir to form a suspension;

[0029] 2) 20 parts of mass fractions are 10% potassium hydroxide solution (n 氢氧化钾 :n 硬脂酸 =1:1), and continued to stir for 4 hours at 40°C;

[0030] 3) After the reaction is over, continue to add water to the reactor until the total mass of the product is 100 parts, and mix and stir for 10 minutes;

[0031] 4) The product is emulsified (shear rate 15000r / min, emulsification time 45min) to obtain the final product.

Embodiment 3

[0033] 1) Weigh 20 parts of propylene glycol, 10 parts of stearic acid and 20 parts of calcium carbonate (5 microns in particle size) particles in a reaction kettle, control the temperature at 65°C, mix and stir to form a suspension;

[0034] 2) 20 parts of mass fractions are 20% potassium hydroxide solution (n 氢氧化钾 :n 硬脂酸 =2:1), continued to stir for 2 hours at 65°C;

[0035] 3) After the reaction is over, continue to add water to the reactor until the total mass of the product is 100 parts, and mix and stir for 10 minutes;

[0036] 4) The product is emulsified (shear rate 20000r / min, emulsification time 30min) to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com