Water-proof additive speically for pulp moulding and its producing method

A technology of pulp molding and additives, applied in the direction of non-fiber pulp addition, papermaking, textiles and papermaking, etc., can solve the problems of high price, no waterproof effect, harsh use conditions, etc., and achieve high economic value and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

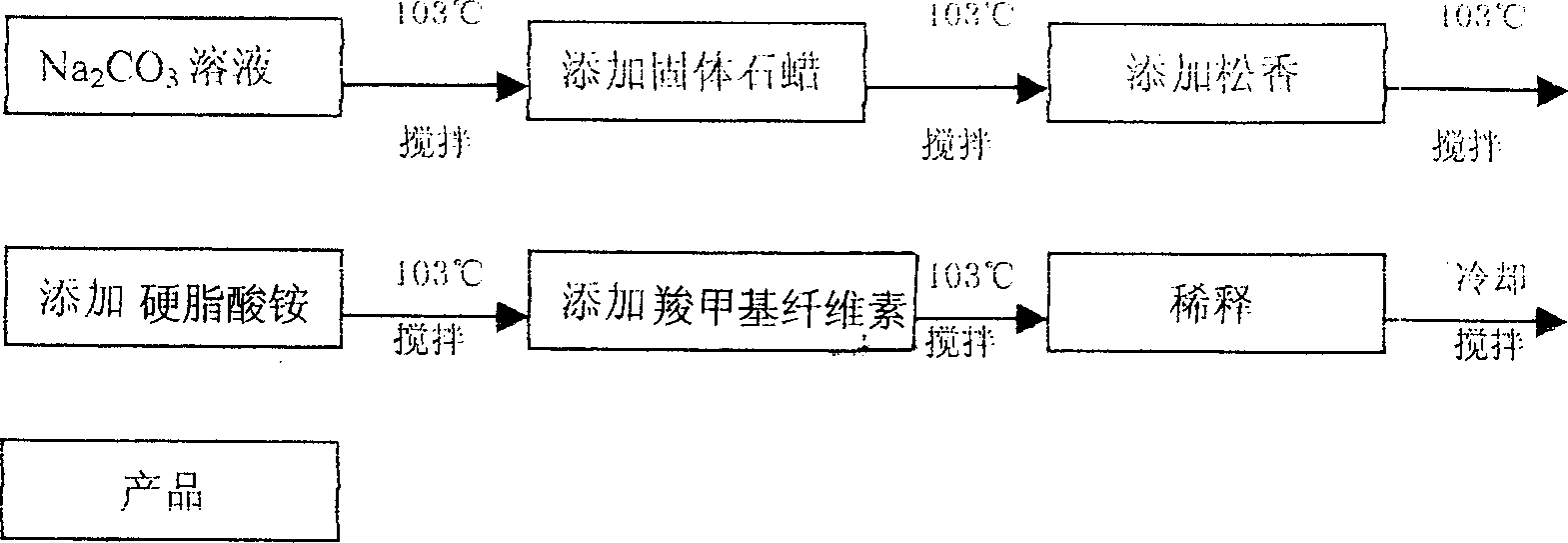

[0021] Example 1 Preparation of a liquid waterproof additive, the formula ratio used: anhydrous sodium carbonate 2.3, paraffin 8.2, rosin 13, ammonium stearate 1, carboxymethyl cellulose 0.8, water 75. Its procedure is:

[0022] (1) Inject 80-100 kg of clean water into the reactor, turn on the mixer and heat it to 100°C with steam

[0023] about;

[0024] (2) add the anhydrous sodium carbonate of 2 / 3rds of adding alkali amount by hopper, make it all dissolve;

[0025] (3) Add nuclear quantitative paraffin to make it dissolve completely;

[0026] (4) Slowly add the rosin block that has been smashed into the size of a walnut into the reactor;

[0027] (5) Regulate the steam pressure, control the temperature of the reactor to be 102-106°C, and the speed of the mixer to be 240 rpm

[0028] / min, the reaction time is 3 hours;

[0029] (6) add the anhydrous sodium carbonate of other 1 / 3rd addition amount of alkali by hopper, continue reaction one hour;

[0030] (7) Check...

Embodiment 2

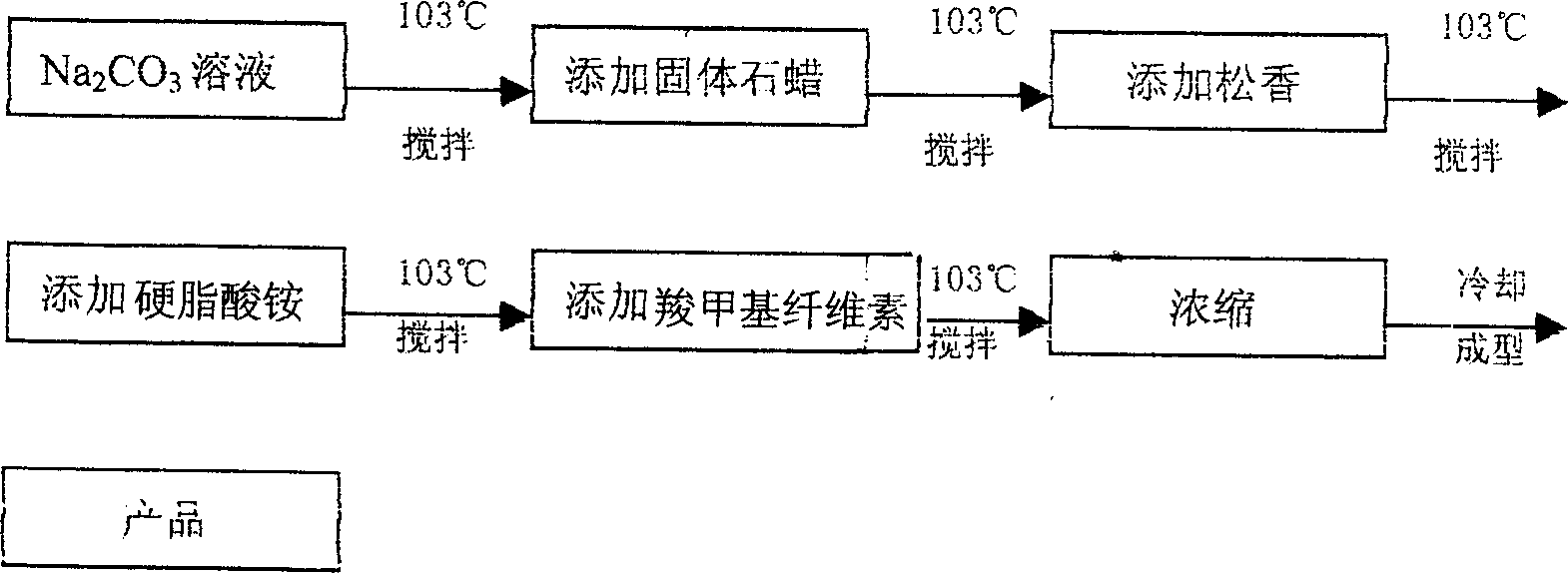

[0051] Liquid waterproof additive formulation ratio: anhydrous sodium carbonate 2.2, paraffin 8.4, rosin 13.5, ammonium stearate 1.1, carboxymethyl cellulose 0.8, water 74;

[0052] The solid waterproof additive formula ratio adopts: anhydrous sodium carbonate 12, paraffin wax 33, rosin 46, ammonium stearate 4, carboxymethyl cellulose 4, water<1; its procedure is the same as embodiment 1

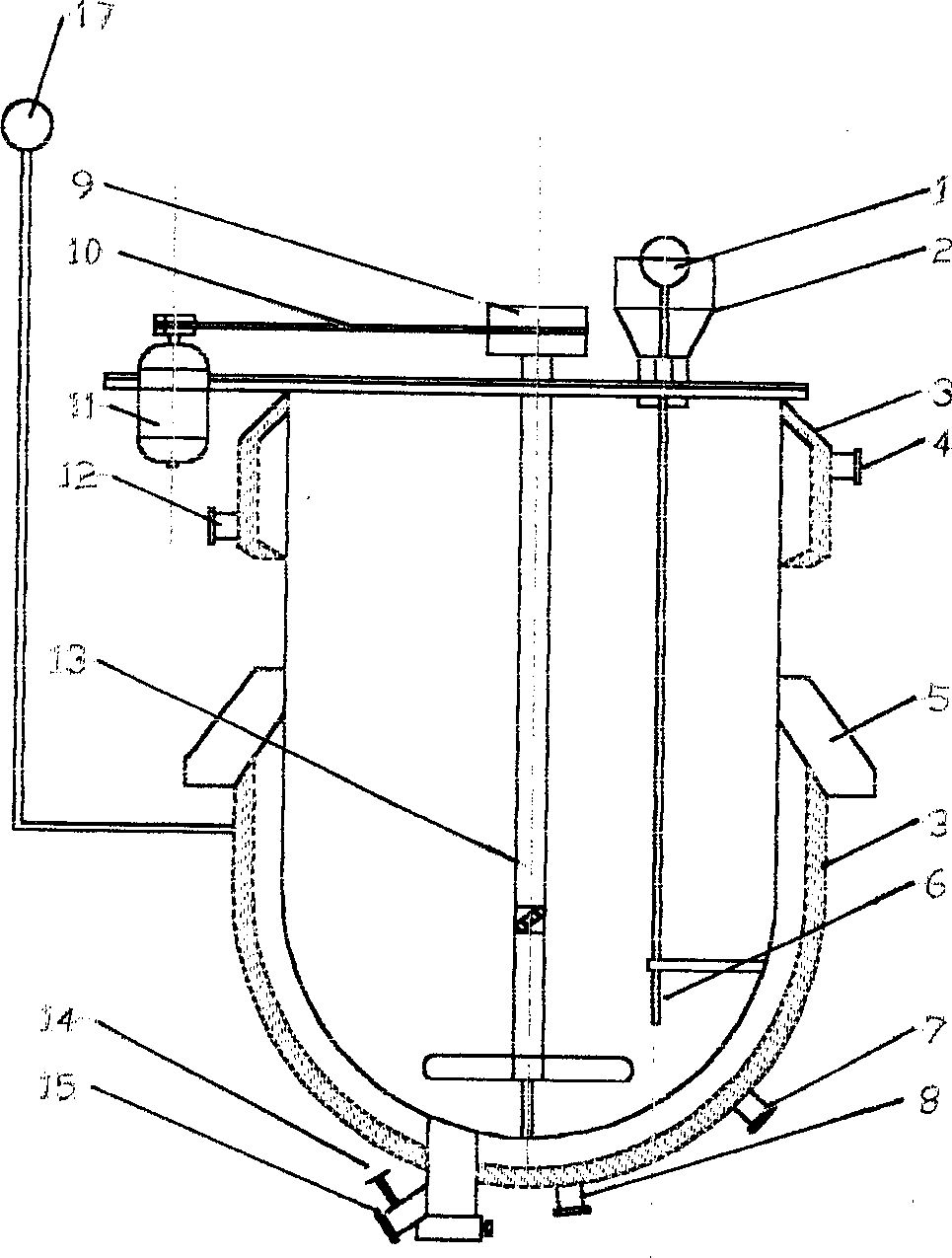

[0053] attached image 3 , 4 It is a special reaction kettle for the preparation method of the present invention, and its structure includes a bracket 5 supporting the cylinder body of the reaction kettle, a hopper 2, a discharge port 15, a discharge port valve 14, a motor 11, a transmission belt 10, a stirrer flywheel 9, and a stirring shaft 13. Reaction thermometer 1, thermometer probe 6, reaction kettle cover 16, characterized in that it also includes a jacket 3 surrounding the lower half of the cylinder body, a steam pipe inlet 7 connected to the jacket, a steam pressure gauge 17, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com