Low-water-absorption flame-retardant glass fiber reinforced PA6 (polyamide 6) composite and preparation method thereof

A low water absorption, composite material technology, applied in the field of polymer materials, can solve the problems of accelerating flame diffusion and spread, and achieve the effects of simple processing, low environmental protection and low energy consumption, and increased compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

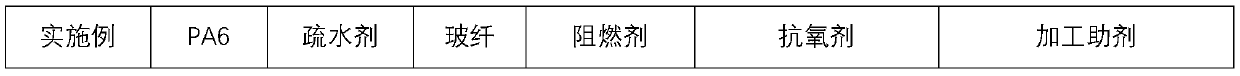

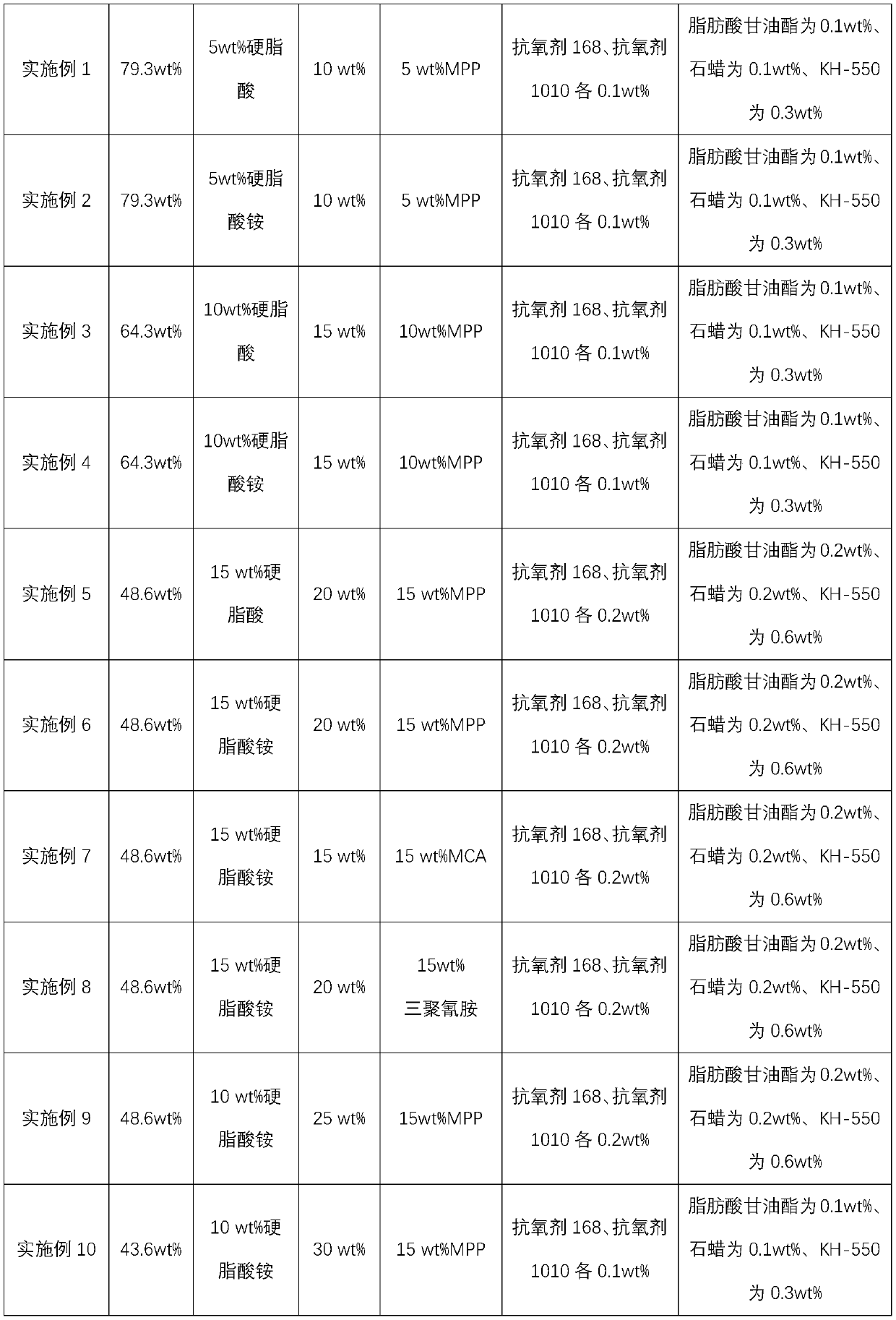

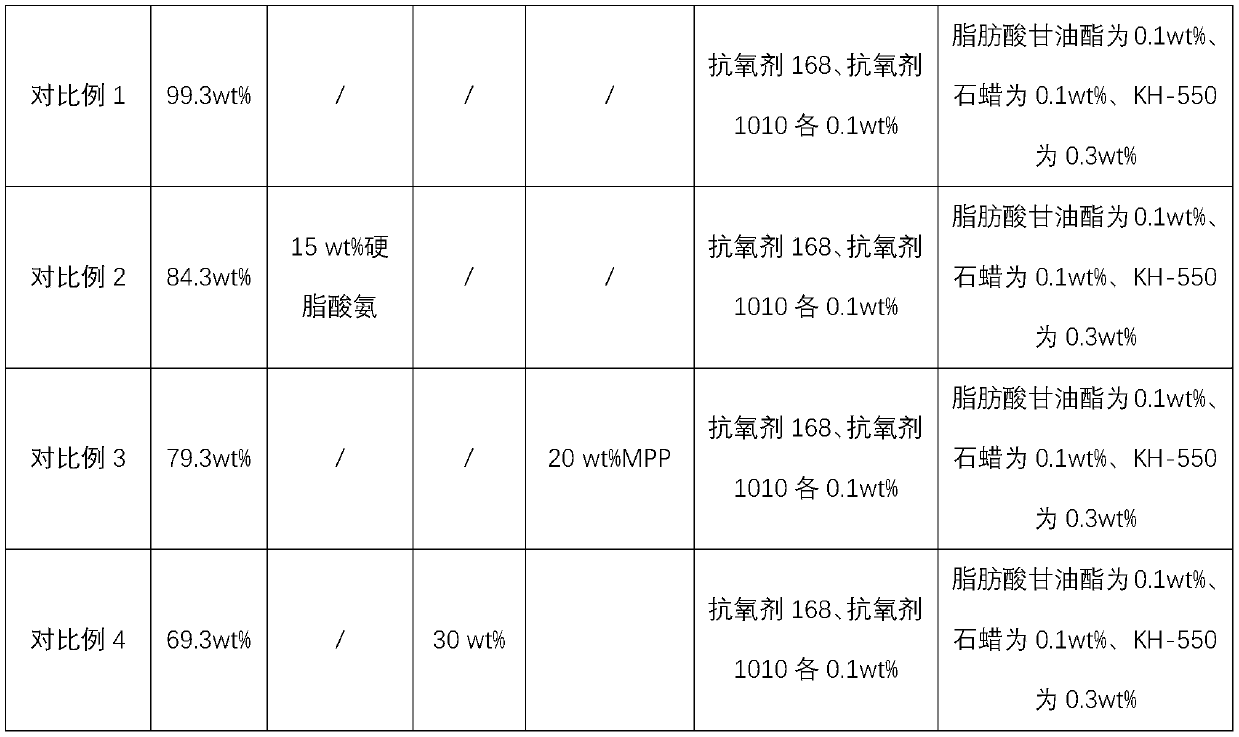

Examples

Embodiment 1

[0030] (1) 79.3wt% PA6 particles, 5wt% stearic acid, 5wt% MPP, 0.2wt% antioxidant (antioxidant 168, antioxidant 1010 are each 0.1wt%) and 0.5wt% processing aid ( Fatty acid glyceride is 0.1wt%, paraffin is 0.1wt%, KH-550 is 0.3wt%) stirring 10min in high-speed mixer, stirring speed 2500r / min;

[0031] (2) Put the mixture of PA6 particles, hydrophobic agent, flame retardant, antioxidant and processing aid in step (1) in a vacuum drying oven at 90°C for 24 hours;

[0032] (3) Add the PA6 particle after drying in step (2) and the hydrophobic agent, flame retardant, antioxidant and processing aid mixture from the main feeding port, add the glass fiber of 10wt% at the side feeding port, Extrude and granulate in a twin-screw extruder. The twin-screw parameters are 220±10°C for the first zone, 230±10°C for the second zone, 250±10°C for the third zone, and 250±10°C for the fourth zone. 10°C, the temperature in the fifth zone is 230±10°C, the temperature of the head is 220±10°C, the s...

Embodiment 2

[0035] (1) 79.3wt% PA6 particles, 5wt% ammonium stearate, 5wt% MPP, 0.2wt% antioxidant (antioxidant 168, antioxidant 1010 are each 0.1wt%) and 0.5wt% processing aid (fatty acid glyceride is 0.1wt%, paraffin is 0.1wt%, KH-550 is 0.3wt%) stir 10min in high-speed mixer, stirring speed 2500r / min;

[0036] (2) Put the mixture of PA6 particles, hydrophobic agent, flame retardant, antioxidant and processing aid in step (1) in a vacuum drying oven at 90°C for 24 hours;

[0037](3) Add the PA6 particle after drying in step (2) and the hydrophobic agent, flame retardant, antioxidant and processing aid mixture from the main feeding port, add the glass fiber of 10wt% at the side feeding port, Extrude and granulate in a twin-screw extruder. The twin-screw parameters are 220±10°C for the first zone, 230±10°C for the second zone, 250±10°C for the third zone, and 250±10°C for the fourth zone. 10°C, the temperature in the fifth zone is 230±10°C, the temperature of the head is 220±10°C, the sp...

Embodiment 3

[0040] (1) 64.3wt% PA6 particle, 10wt% stearic acid, 10wt% MPP, 0.2wt% antioxidant (antioxidant 168, antioxidant 1010 are each 0.1wt%) and 0.5wt% processing aid ( Fatty acid glyceride is 0.1wt%, paraffin is 0.1wt%, KH-550 is 0.3wt%) stirring 10min in high-speed mixer, stirring speed 2500r / min;

[0041] (2) Put the mixture of PA6 particles, hydrophobic agent, flame retardant, antioxidant and processing aid in step (1) in a vacuum drying oven at 90°C for 24 hours;

[0042] (3) PA6 particles after drying in step (2) and hydrophobic agent, flame retardant, antioxidant and processing aid mixture are added from the main feeding port, 15wt% is added at the side feeding port, Extrude and granulate in the screw extruder. The twin-screw parameters are 220±10℃ for the first zone, 230±10℃ for the second zone, 250±10℃ for the third zone, and 250±10℃ for the fourth zone. , the temperature in zone five is 230±10°C, the head temperature is 220±10°C, the twin-screw speed is 80r / min, the feede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com