High-wear-resistance waterborne UV (ultraviolet) floor paint and preparation method thereof

A floor paint, high wear-resistant technology, applied in the field of coatings, can solve the problems of poor construction, affecting the coating effect and wear resistance, affecting the leveling of the paint film, and circulating defoaming, so as to improve the wear resistance and take into account the protection. and decorative effect, the effect of improving the coating amount of a single roll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of high wear-resistant water-based UV floor paint includes the following steps:

[0038] (1) Add 67 kg of water-based UV polyurethane dispersion, 0.1 kg of neutralizer, 3 kg of aqueous alkali swelling acrylic emulsion and 0.8 kg of defoamer to the reactor;

[0039] (2) Mix 0.1 kg of the sterilant in the tank with water in equal proportions, then slowly drop it into the reactor and continue to stir at medium speed;

[0040] (3) After mixing 2 kg of co-solvent and 2 kg of photoinitiator until completely dissolved, slowly add dropwise to the reactor, and continue to stir at medium speed;

[0041] (4) Add 0.5 kg of wetting agent and 2 kg of matting powder in sequence, and stir at high speed until the fineness is ≤30μm;

[0042] (5) Add 21.5 kilograms of deionized water, adjust the viscosity to 25°C DIN6 cup 40" with 0.9 kilograms of rheological additives, stir at medium speed for 10 minutes, then filter and pack with 200 mesh filter cloth.

[0043] The water-based...

Embodiment 2

[0054] A preparation method of high wear-resistant water-based UV floor paint includes the following steps:

[0055] (1) Add 76 kg of aqueous UV polyurethane dispersion, 0.1 kg of neutralizer, 4 kg of aqueous alkali swelling acrylic emulsion and 0.6 kg of defoamer to the reactor;

[0056] (2) Mix 0.1 kg of the sterilant in the tank with water in equal proportions, then slowly drop it into the reactor and continue to stir at medium speed;

[0057] (3) After mixing 2 kg of co-solvent and 1.5 kg of photoinitiator until completely dissolved, slowly add dropwise to the reaction kettle, and continue stirring at medium speed;

[0058] (4) Add 0.5 kg of wetting agent and 1.4 kg of matting powder in sequence, and stir at high speed until the fineness is ≤30μm;

[0059] (5) Add 13 kilograms of deionized water, adjust the viscosity to 25°C DIN6 cup 40" with 0.7 kilograms of rheological additives, stir at medium speed for 10 minutes, then filter and pack with 200 mesh filter cloth.

[0060] The wate...

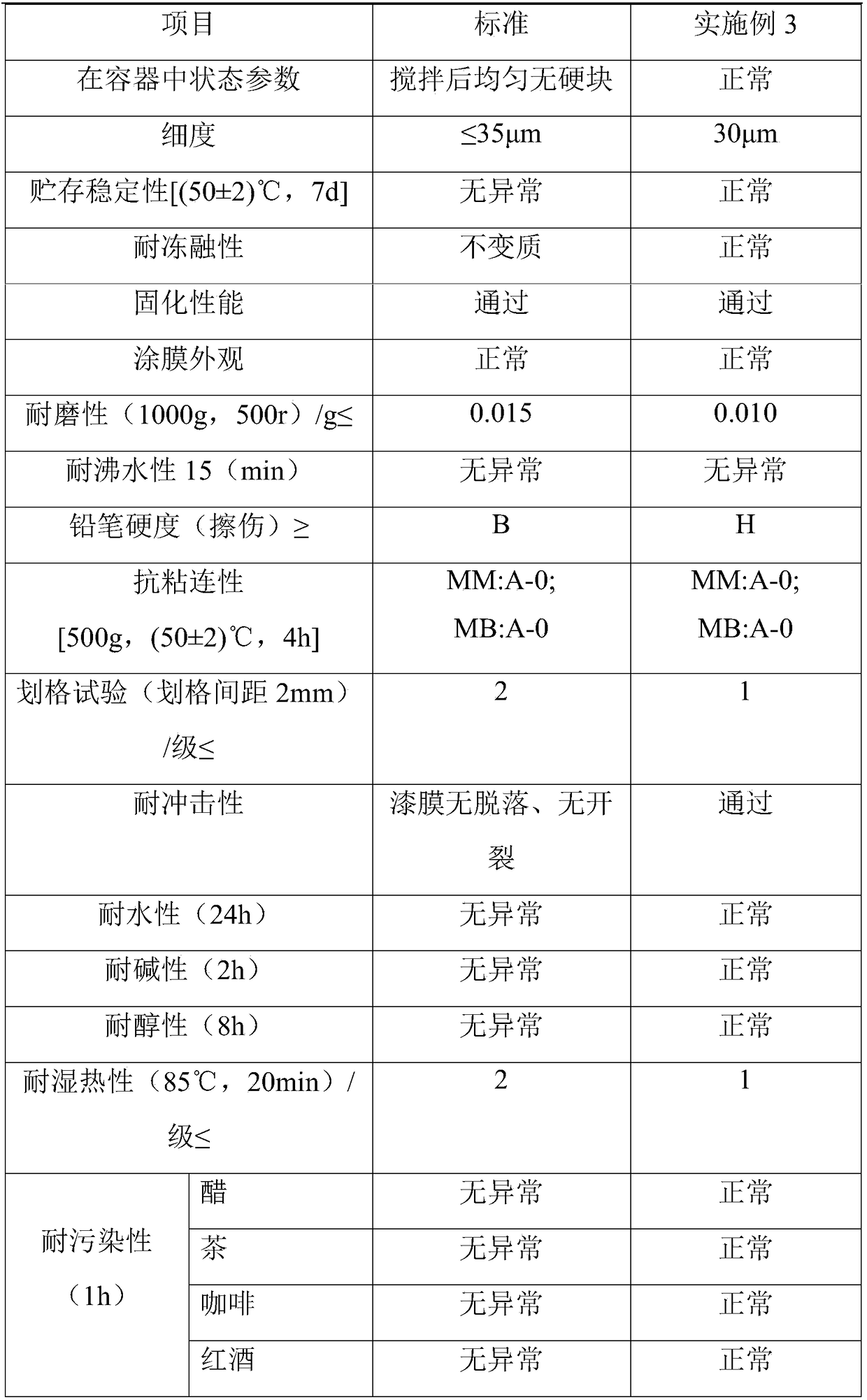

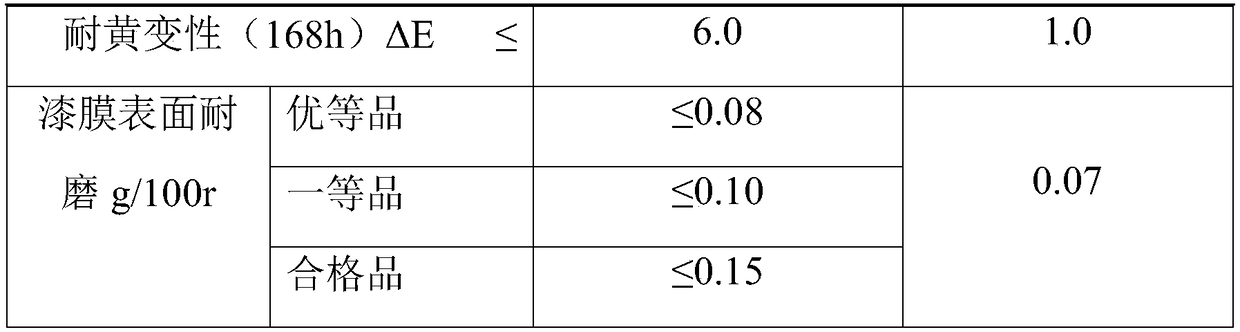

Embodiment 3

[0071] A preparation method of high wear-resistant water-based UV floor paint includes the following steps:

[0072] (1) Add 80 kg of aqueous UV polyurethane dispersion, 0.2 kg of neutralizer, 5 kg of aqueous alkali swelling acrylic emulsion and 0.4 kg of defoamer to the reactor;

[0073] (2) Mix 0.1 kg of the sterilant in the tank with water in equal proportions, then slowly drop it into the reactor and continue to stir at medium speed;

[0074] (3) After mixing 3 kg of photoinitiator, heat it in a water bath to 50°C, slowly add it dropwise to the reactor after it is completely melted, and continue stirring at a medium speed;

[0075] (4) Add 0.5 kg of wetting agent and 1.4 kg of matting powder in sequence, and stir at high speed until the fineness is ≤30μm;

[0076] (5) Add 8.9 kilograms of deionized water, adjust the viscosity to 25°C DIN6 cup 40" with 0.4 kilograms of rheological additives, stir at medium speed for 10 minutes, then filter and pack with 200 mesh filter cloth.

[0077]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com