Spray gun for spraying painting at narrow slit

A spray gun and slit technology, applied in the field of atomizing spray devices, can solve problems such as the influence of spray painting operations and small range of activities, and achieve the effects of simple structure, easy implementation, and solution to paint quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

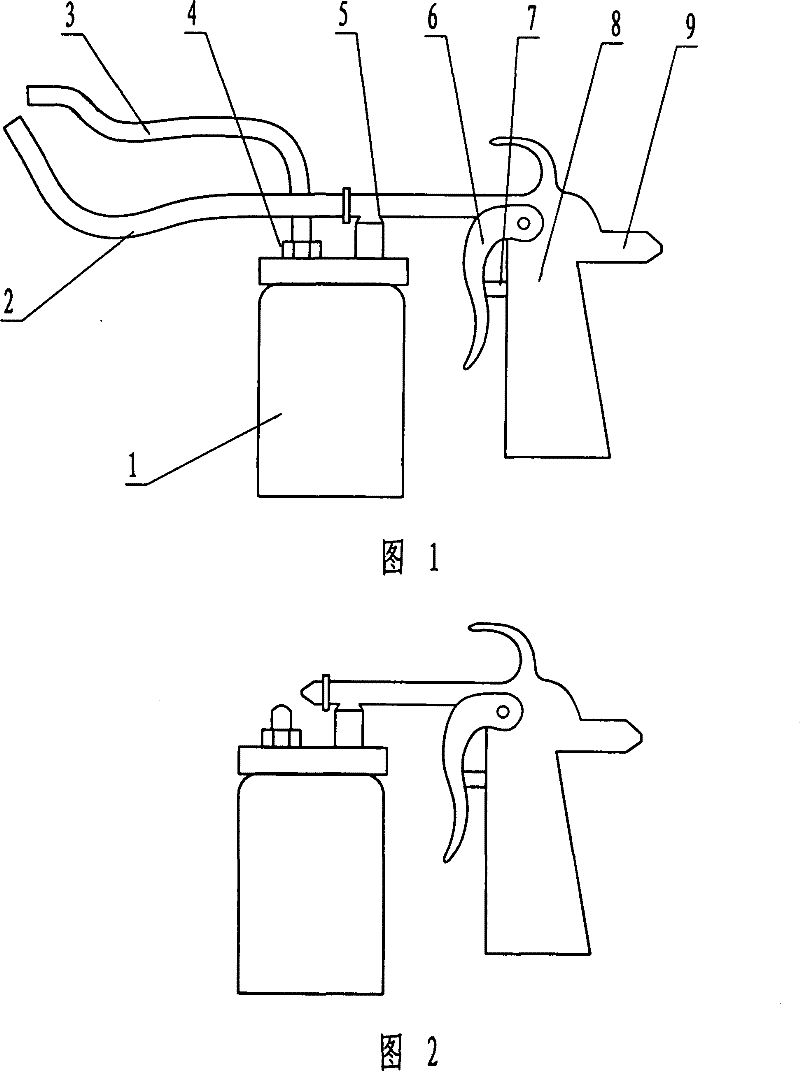

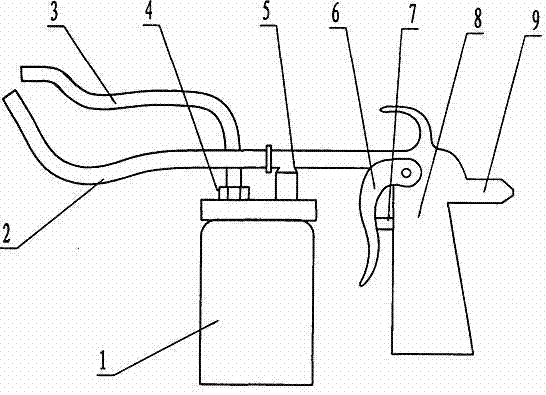

[0012] See figure 1 , The composition of the present invention includes a paint cylinder 1, a spray gun handle 8 and a trigger 6, and the upper part of the paint cylinder is provided with a paint nozzle 4 and an air nozzle 5. In order to solve the problem of spraying paint at the slit, the present invention adds a compressed air header 2 and a paint outlet header 3. The compressed air header communicates with the jet nozzle 5, the paint outlet header communicates with the paint outlet nozzle 4, the compressed air header and Corresponding to the port of the paint header. The length of the two additional pipes depends on the needs. The compressed air pipe and the air outlet can be connected by a fixed connection method such as welding, or a detachable connection method, such as a threaded connection, as is the connection between the paint outlet pipe and the paint outlet nozzle. The use of detachable threaded connection can obviously increase the flexibility of the spray gun, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com