Patents

Literature

32results about How to "Meet painting requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing magnesium alloy chemical conversion coating

ActiveCN1880503AEliminate hazardsImprove corrosion resistanceMetallic material coating processesSodium iodideFluohydric acid

The invention discloses a chemical transmission film preparing technology of magnesium alloy, which comprises the following steps: a. proceeding degreasing disposal for magnesium or magnesium alloy through sodium hydroxide or one or multiple hybrid solutions of sodium phosphate with sodium hydroxide, sodium carbonate and sodium silicate solution; b. proceeding acid cleaning disposal for degreased magnesium or magnesium alloy through hybrid solution of phosphoric acid and sodium phosphate; c. proceeding activating disposal for acid cleaned magnesium or magnesium alloy through hybrid solution of fluohydric acid and sodium phosphate; d proceeding chemical synthesizing disposal for activated magnesium or magnesium alloy through composite solution of calcium nitrate hydrate, sodium nitrite, sodium iodide and hydrogen dioxide solution; e. packing hole of synthetic magnesium or magnesium alloy through deionized water. The invention doesn't utilize chromic composition, which eliminates danger for environment.

Owner:靖江市华信科技创业园有限公司

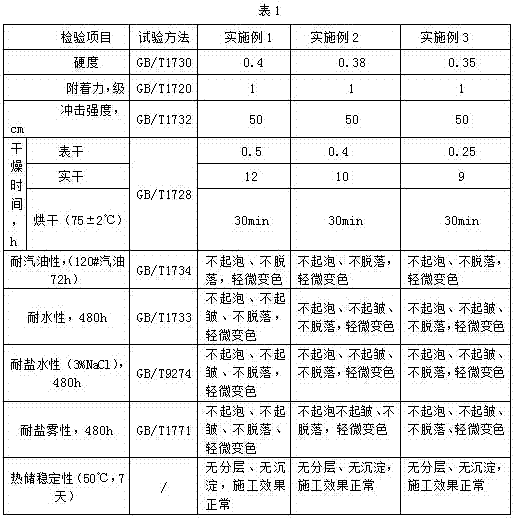

Water-based metal antirust paint and preparation method thereof

InactiveCN105602382AImprove densification performanceImprove shielding effectAnti-corrosive paintsWater basedEmulsion

The invention discloses water-based metal antirust paint. The water-based metal antirust paint is prepared from, by mass, 35-45 parts of pigment, 8-15 parts of filler, 8-15 parts of corrosion inhibitors, 10-20 parts of deionized water, 15-25 parts of silicone acrylic emulsion, 0.1-0.2 part of a dispersing agent, 0.1-0.2 part of a flatting agent, 2-5 parts of an adhesive force promoting agent, 1-3 parts of film-forming aiding agent, 0.1-0.3 part of surfactant OP-10, 0.1-0.2 part of a defoaming agent and 0.05-0.1 part of bacteriacide. The invention further discloses a preparation method of the water-based metal antirust paint. The water-based metal antirust paint solves the problems that water-based metal antirust paint used in the current market is poor in corrosion resistance and adhesive force, slow in drying, poor in early-stage water resistance and high in cost.

Owner:JINAN GUANGDA CASTING MATERIAL CO LTD

Coating method for water-based paint for engineering machines

PendingCN107234047AMeet painting requirementsImprove physicsPretreated surfacesAnti-corrosive paintsEpoxyWater based

The invention provides a coating method for water-based paint for engineering machines. The method comprises the following steps that a base material is pretreated; primer is sprayed, and baking is conducted after leveling; and finishing coat is sprayed, and baking is conducted after leveling, wherein the primer is water-based epoxy corrosion resisting primer, and the finishing coat is water-based crylic acid polyurethane finishing coat. By adoption of the coating method and in cooperation with the specific water-based paint for coating of the engineering machine base material, the defect of a paint film can be effectively avoided, and the flexibility, corrosion resistance and durability of the paint film are greatly improved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

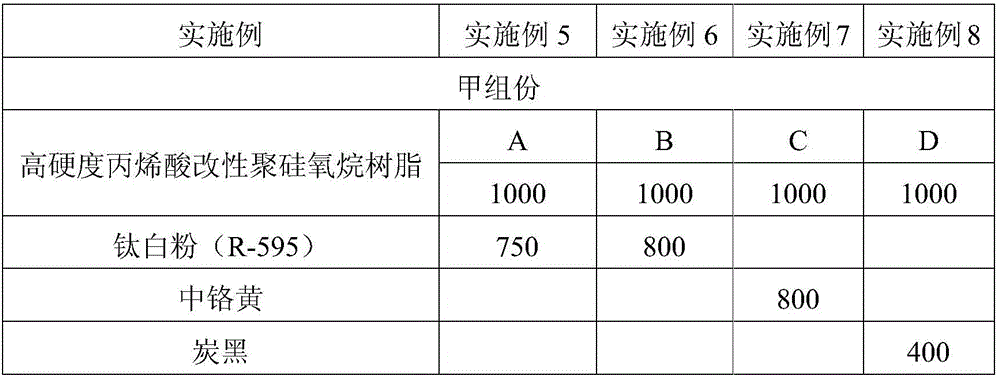

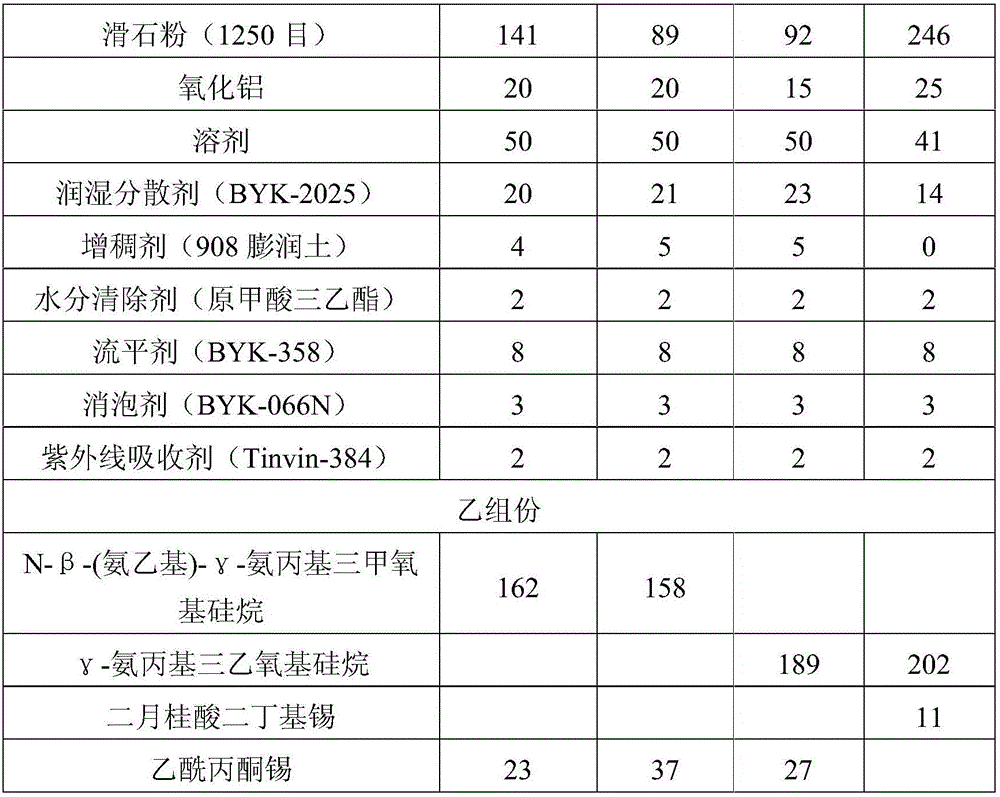

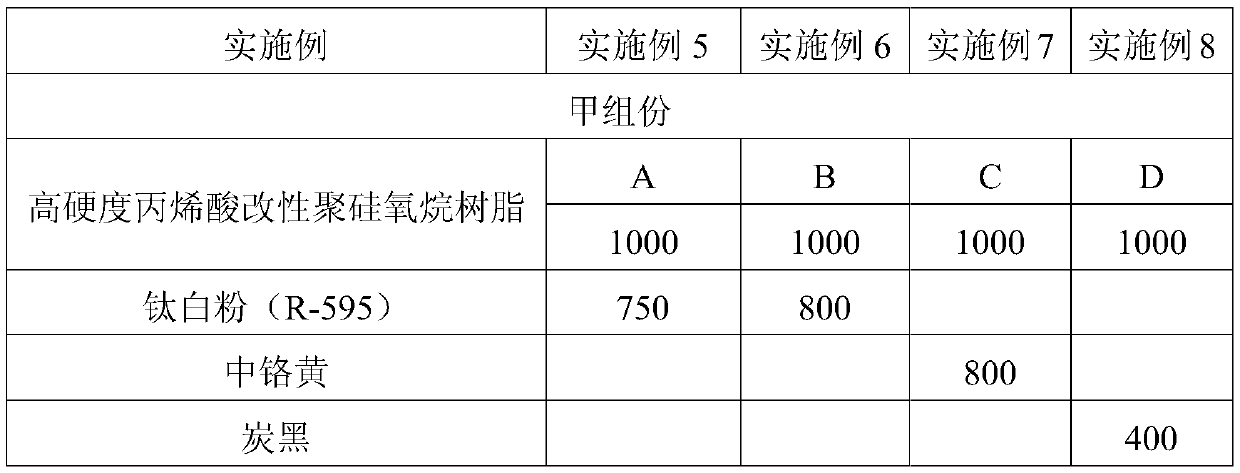

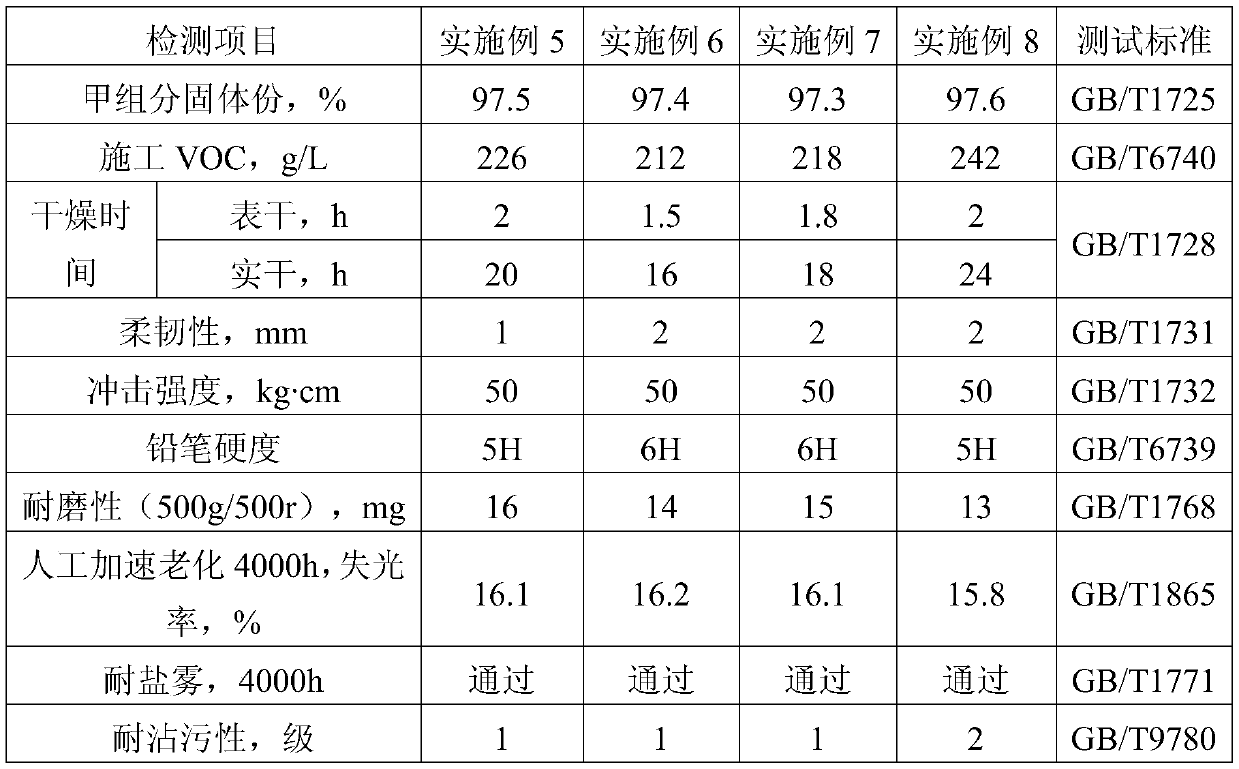

High-hardness acrylate-modified polysiloxane resin and coating employing high-hardness acrylate-modified polysiloxane resin as base material

ActiveCN106675133ALow viscosityLow VOCAntifouling/underwater paintsPaints with biocidesWeather resistanceRoom temperature

The invention discloses high-hardness acrylate-modified polysiloxane resin and a coating employing the high-hardness acrylate-modified polysiloxane resin as a base material. The resin is mainly prepared by compounding 41-65wt% of active polysiloxane intermediate, 15-36wt% of cyclohexyl-containing acrylic ester, 5-15wt% of polyfunctional acrylate monomer and 10-20wt% of amino-hydrocarbon alkoxy silane. The harness of a pencil solidified by a two-component coating prepared from the acrylate-modified polysiloxane resin as the base material is greater than or equal to 5H, and meanwhile, the acrylate-modified polysiloxane resin can meet high solid content, low viscosity, room-temperature fast curing performance, overlong weather resistance and anticorrosion performance, and can be widely applied to surface coating of rail vehicles of subways and high-speed rails.

Owner:中昊北方涂料工业研究设计院有限公司

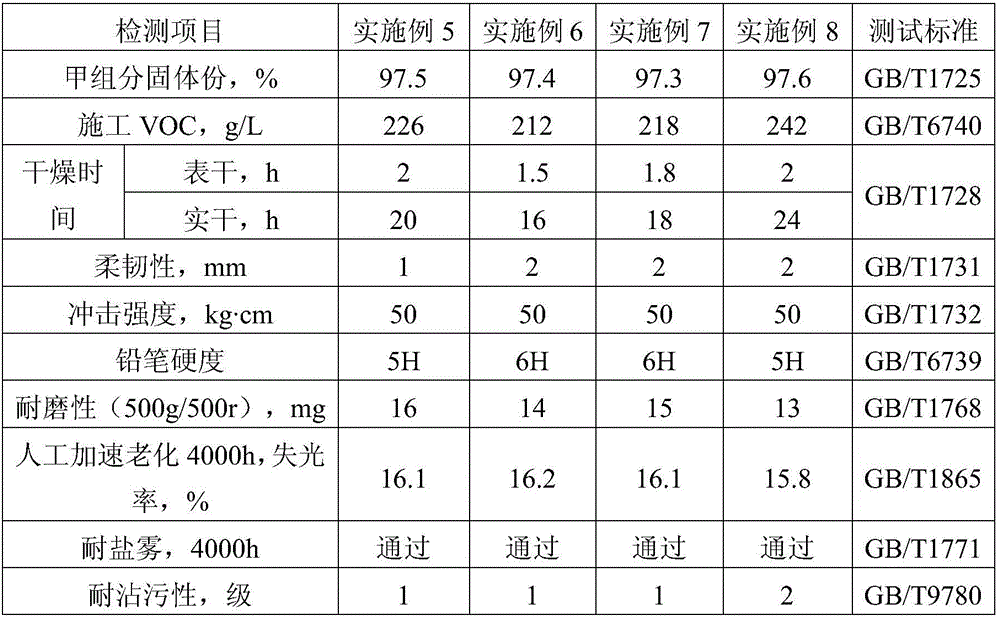

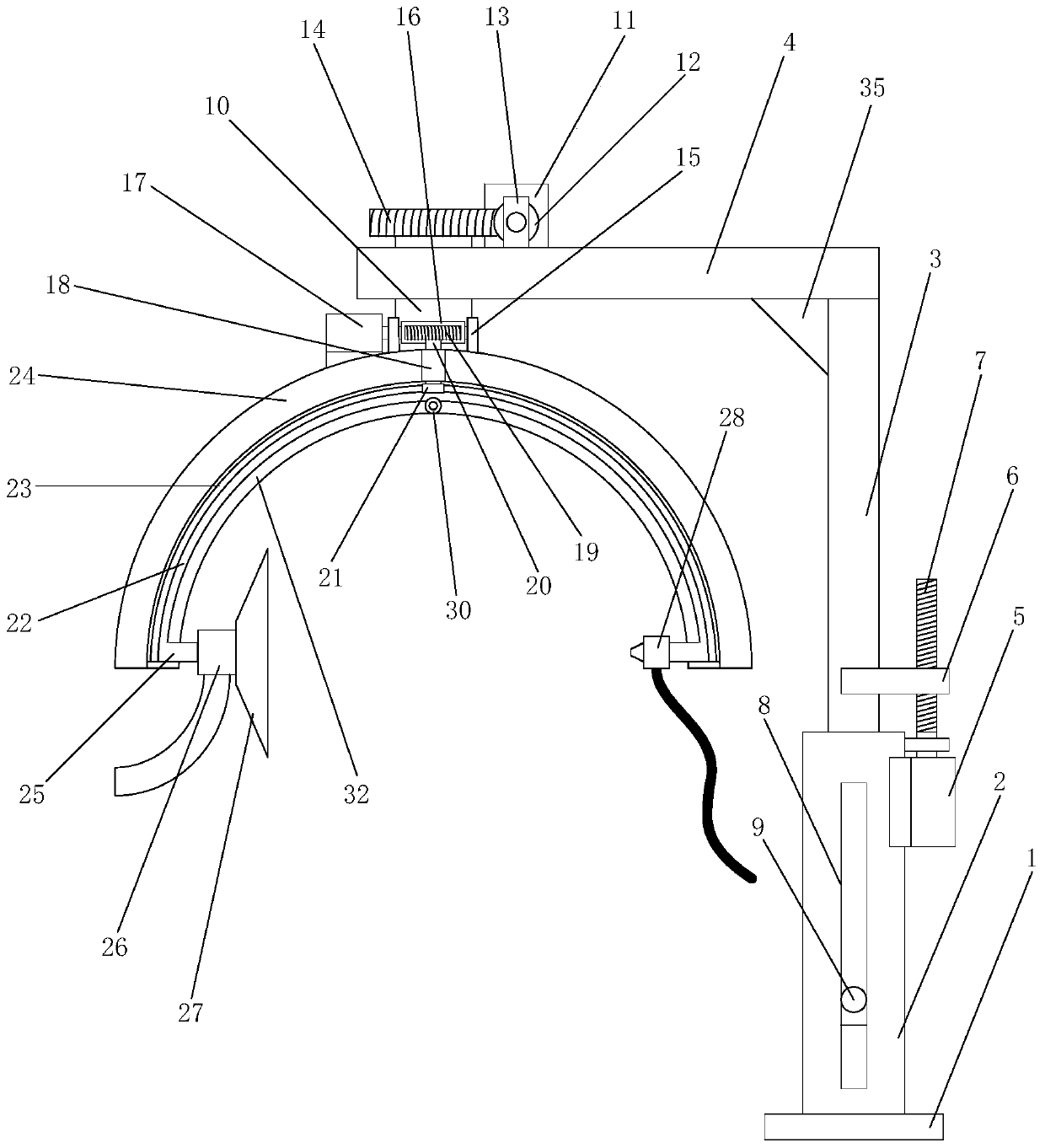

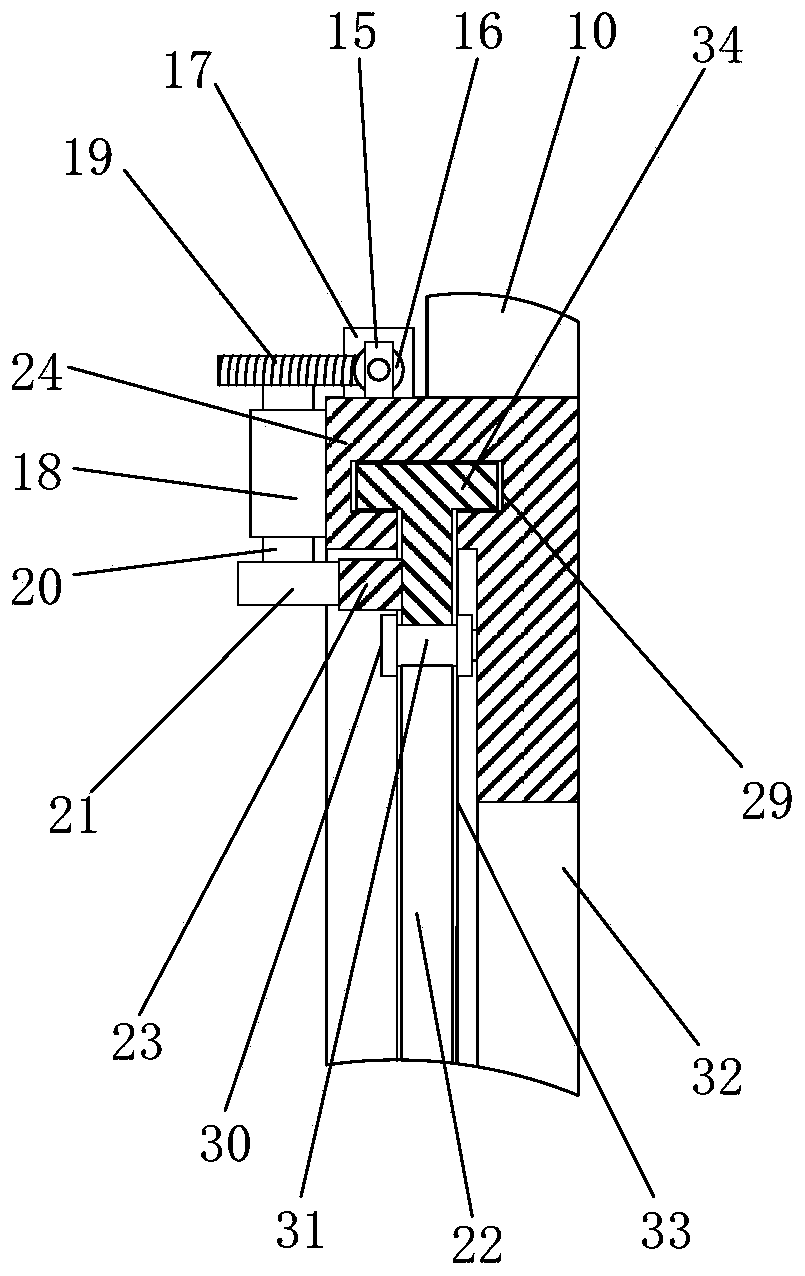

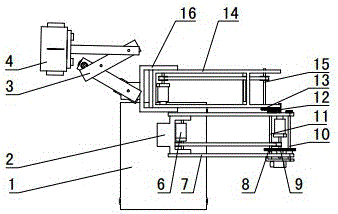

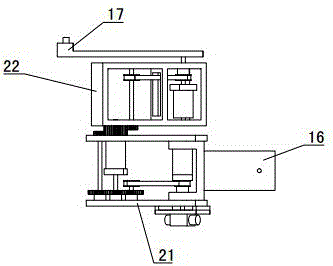

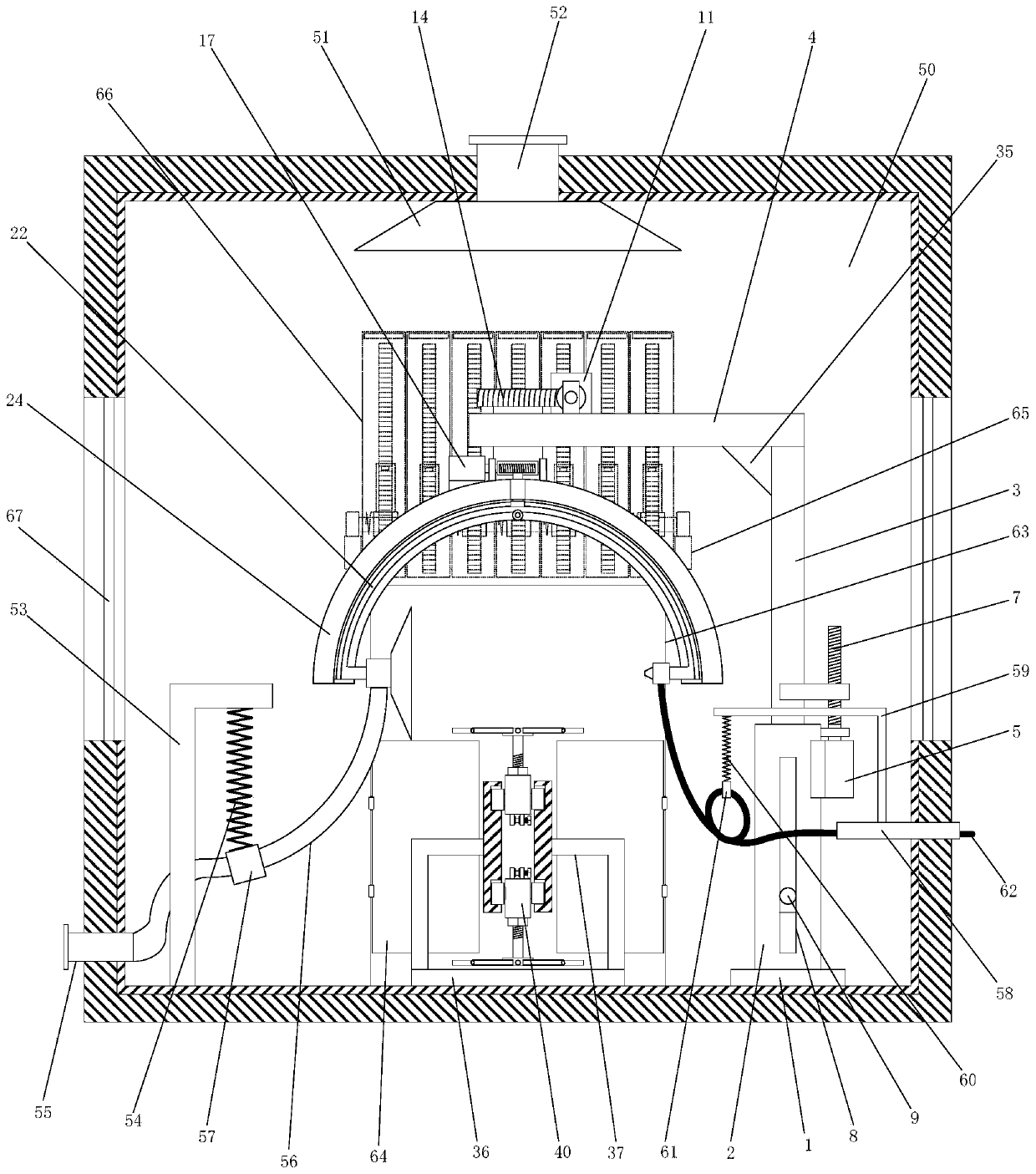

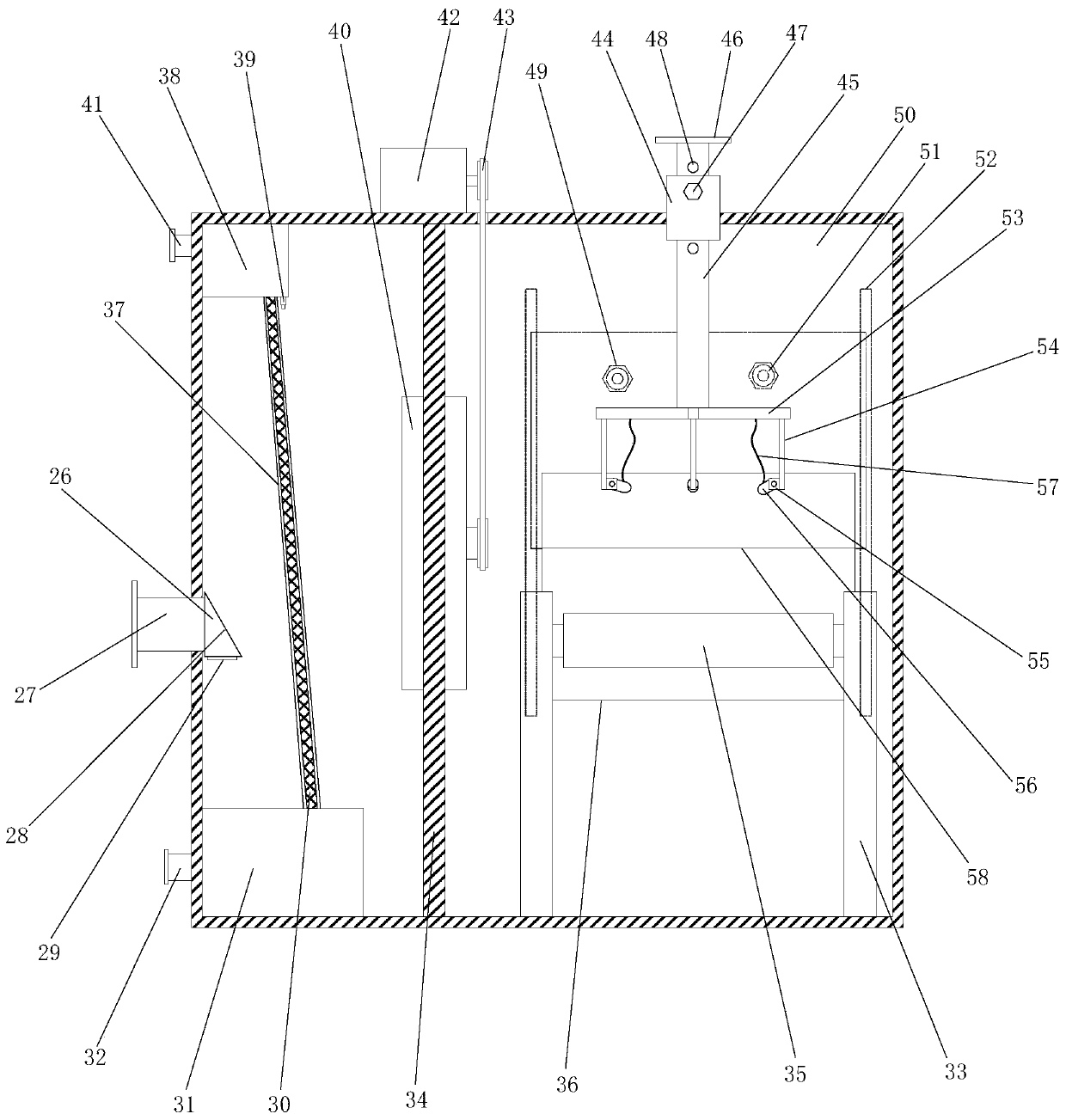

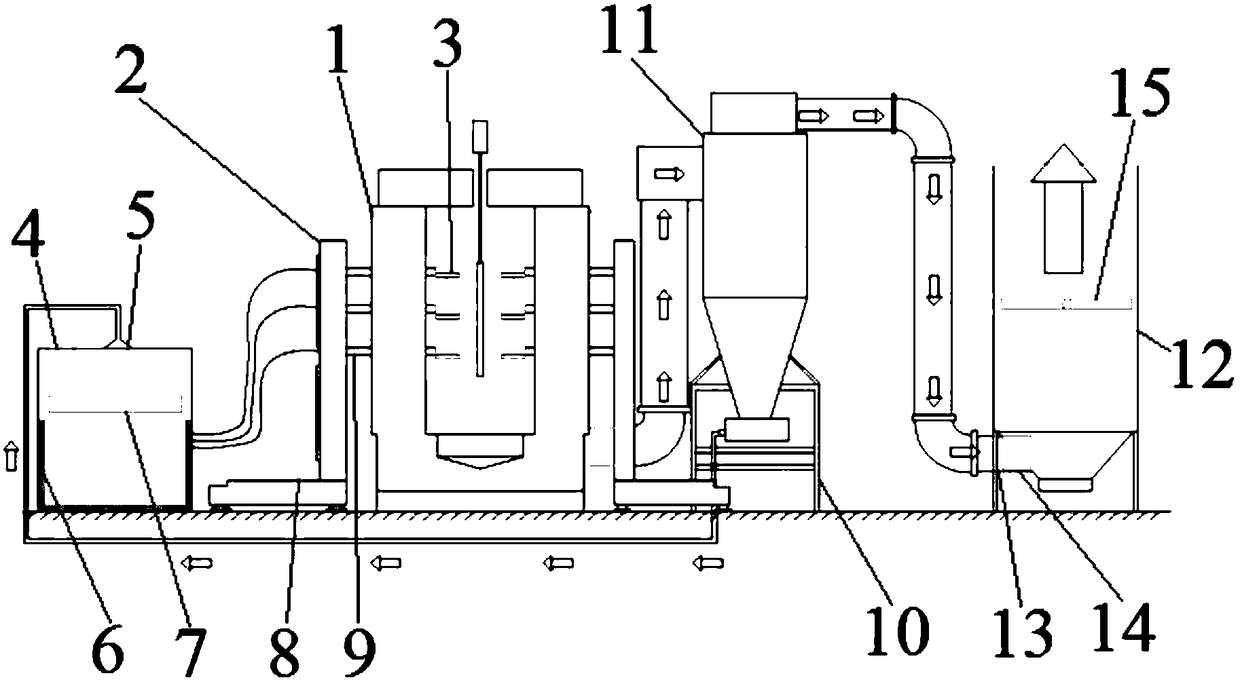

Environmental-protection paint spraying chamber

PendingCN110694848AEasy to adjust the inclination orientationMeet painting requirementsSpray boothsElectric machineEngineering

The invention discloses an environmental-protection paint spraying chamber. The environmental-protection paint spraying chamber comprises a rotary paint spraying mechanism, a workpiece conveying mechanism and a cuboid shell; the rotary paint spraying mechanism comprises a lifting bracket, a transverse beam, a rotary driving motor, an angle adjusting motor, a suction conical cover, a paint nozzle,a semi-arc plate and a semicircular plate; and the workpiece conveying mechanism is longitudinally mounted and used for conveying workpieces to the paint spraying mechanism. The environmental-protection paint spraying chamber uses the paint spraying mechanism for spraying paint to the workpieces on the workpiece conveying mechanism one by one; when the paint nozzle sprays the paint, a paint mist recovery cover and a paint mist recovery pipe opposite to the paint nozzle can be used for outwards quick suction and recovery of redundant paint mist; and the workpiece conveying mechanism can be usedfor intermittent paint spraying and drying of the workpieces conveyed into the shell according to process demands.

Owner:JIANGSU SULI MACHINERY SHARES CO LTD

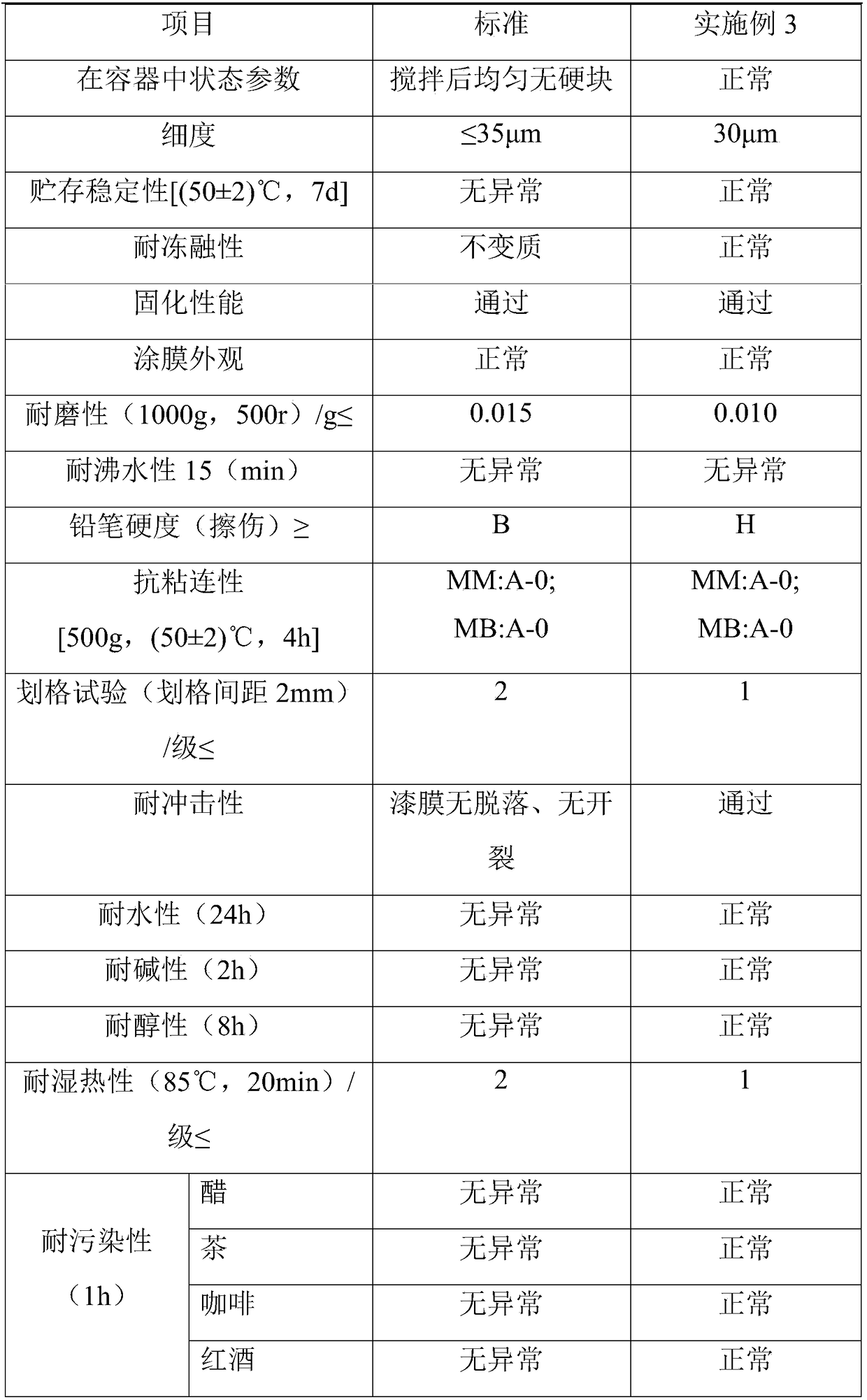

High-wear-resistance waterborne UV (ultraviolet) floor paint and preparation method thereof

InactiveCN109486394AMeet painting requirementsPerformance is not affectedPolyurea/polyurethane coatingsPolyurethane dispersionEmulsion

The invention relates to the technical field of paints, particularly to a high-wear-resistance waterborne UV floor paint and a preparation method thereof. The high-wear-resistance waterborne UV floorpaint is composed of, by weight part, 67-80 parts of waterborne UV polyurethane dispersion, 3-5 parts of waterborne alkali-soluble acrylic emulsion, 0.4-0.8 parts of defoamer, 0.3-0.6 part of wettingagent, 0-2 parts of solubilizer, 0.1-0.2 part of neutralizer, 0.1-0.5 part of in-tank bactericide, 0.2-1 part of rheologic additives, 0.5-2 parts of matting powder, 9-22 parts of deionized water and 1-3 parts of photoinitiator. Compared with the prior art, the h high-wear-resistance waterborne UV floor paint can meet floor painting requirements and achieve high wearing resistance, specifically, can firstly meet the requirements on floor painting roller construction and UV curing, and above all, by matching different types of resins, improves product viscosity without affecting paint film performance and increases single-roller coating capacity to achieve final painting effects.

Owner:上海展辰涂料有限公司 +3

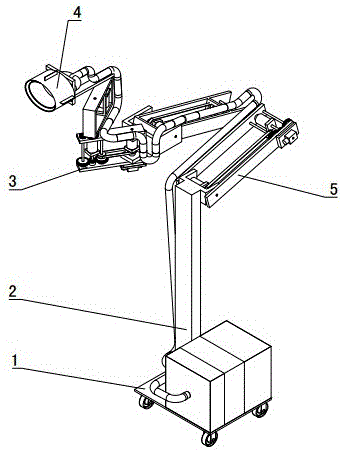

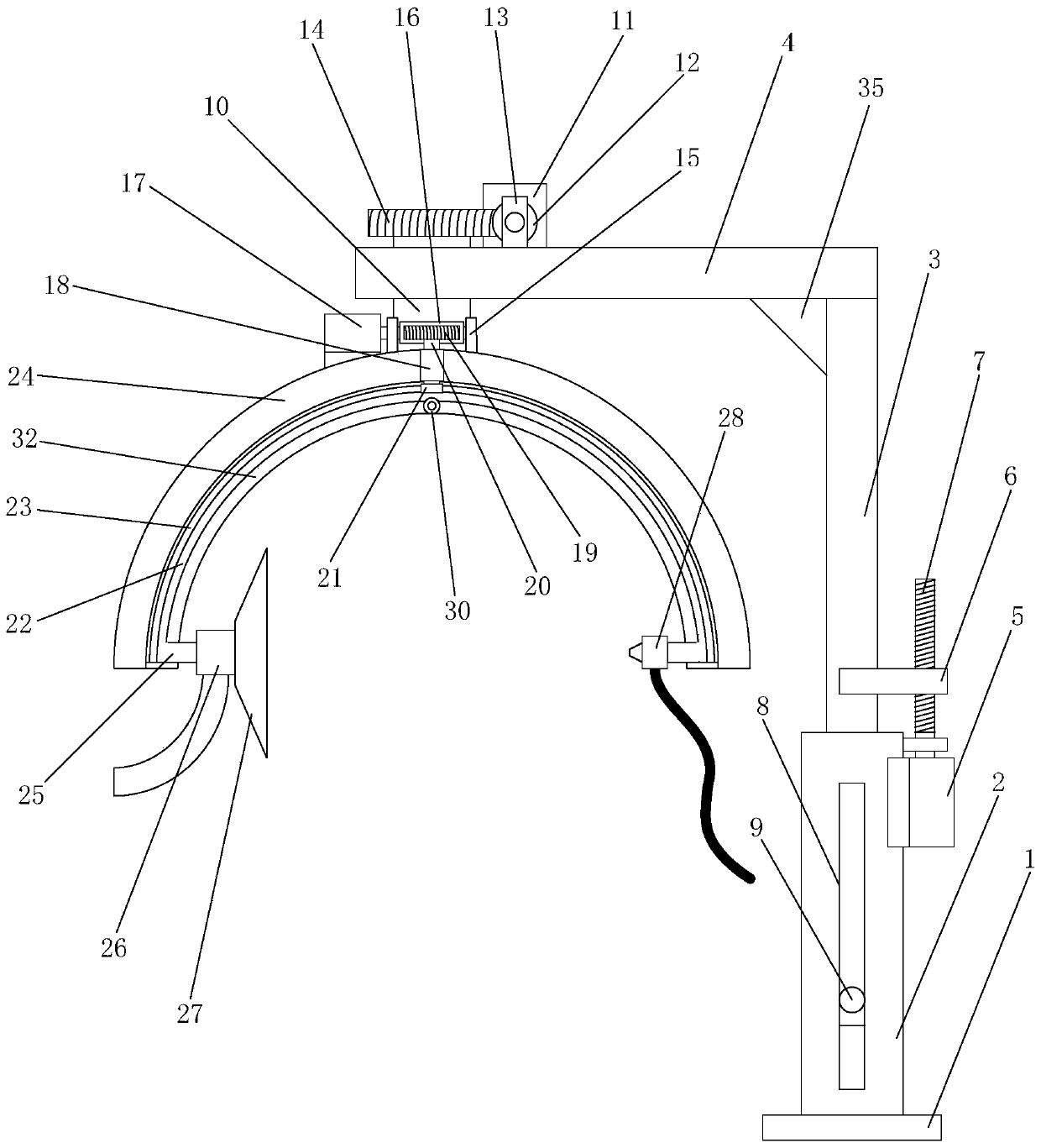

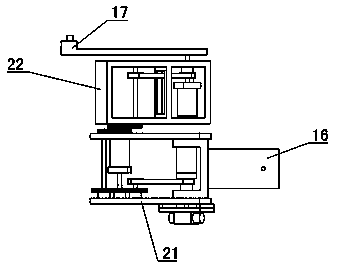

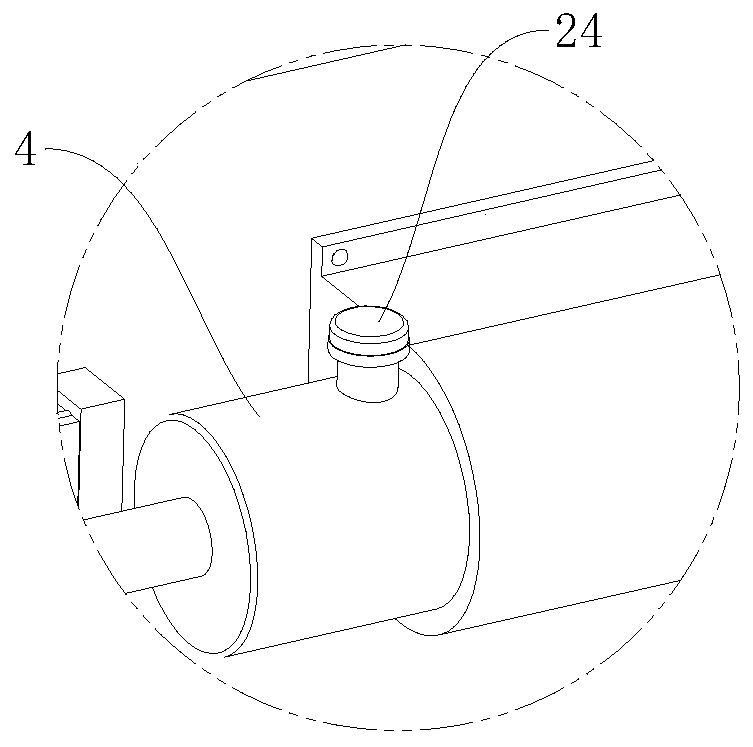

Automatic paint spraying device

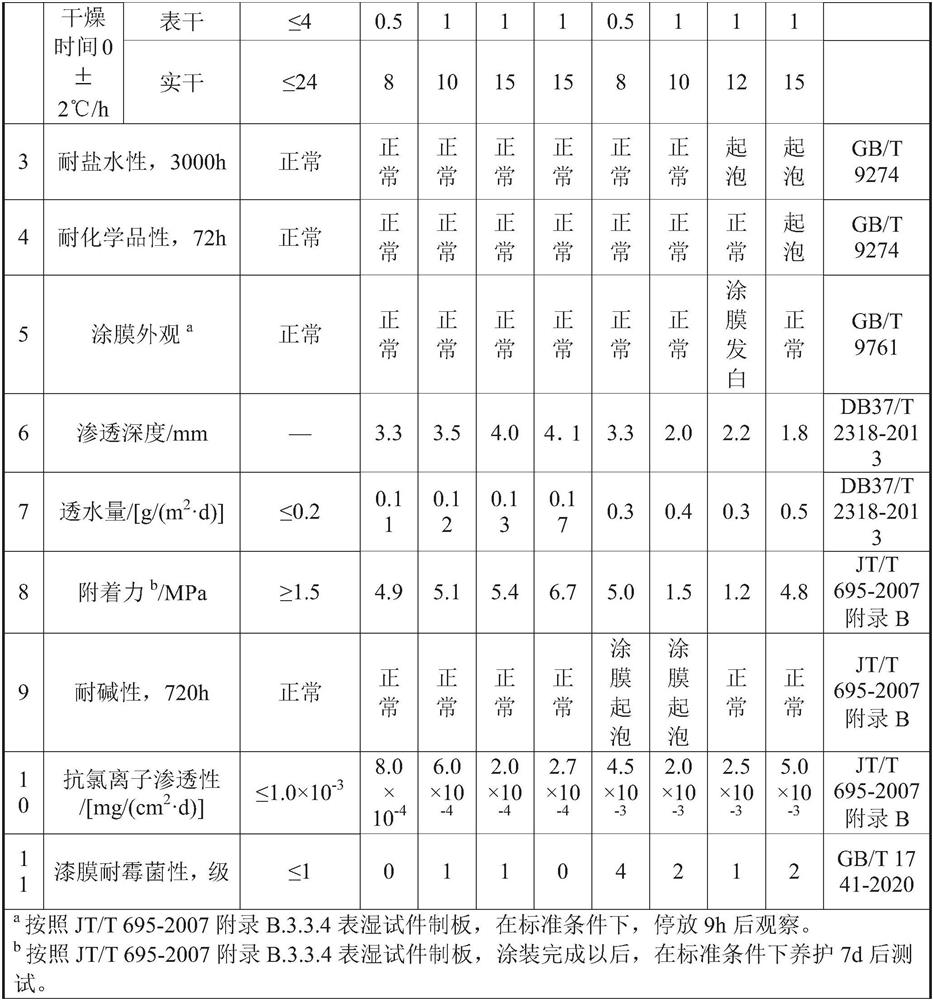

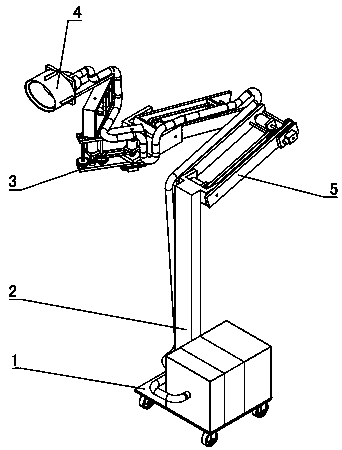

ActiveCN105772299AGuaranteed paint effectExtended range of movementSpraying apparatusEngineeringMechanical engineering

Owner:淄博奧冠交通科技有限公司

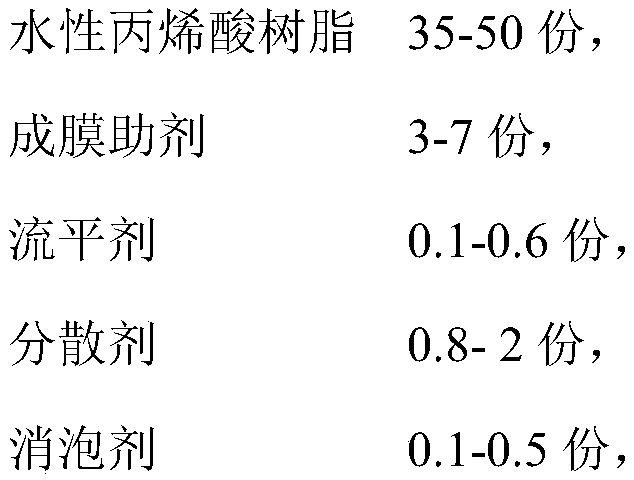

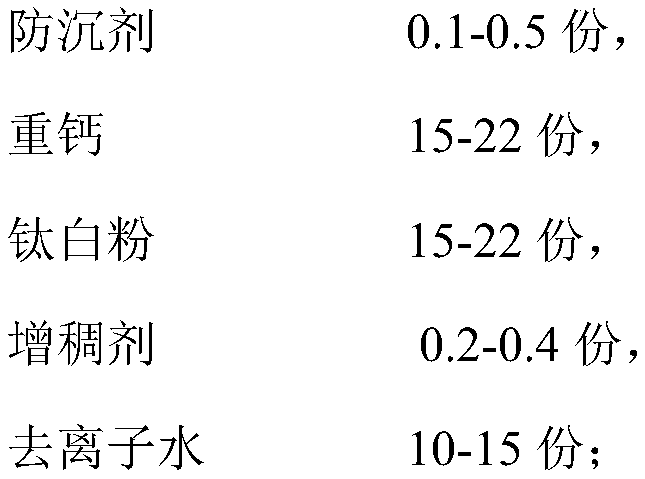

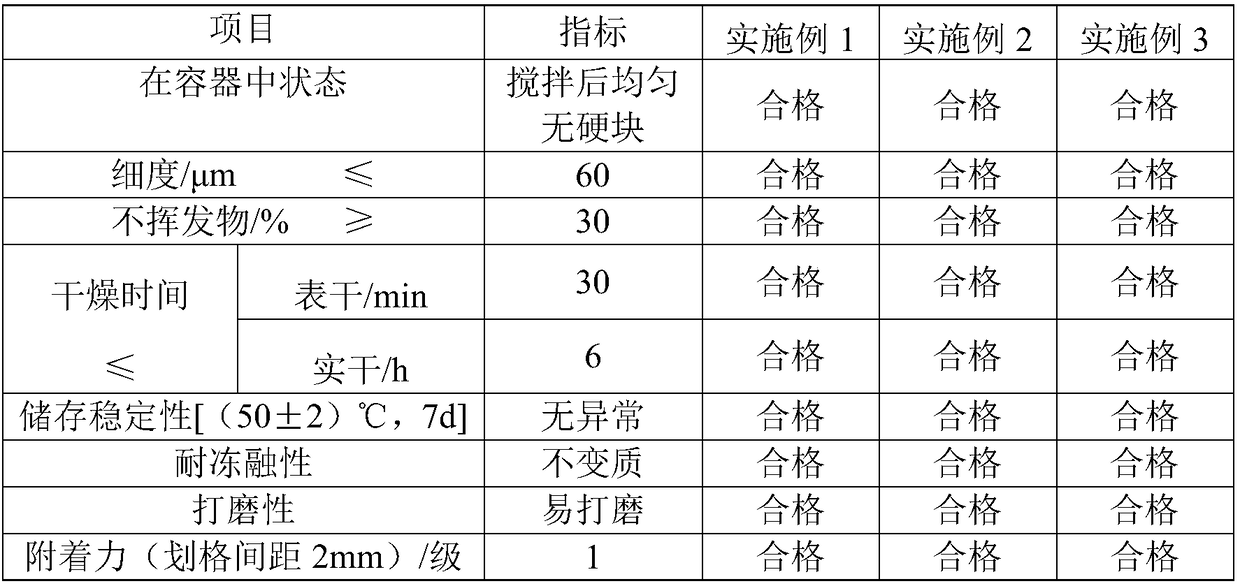

Pine water-based grain-protruding-prevention white primer and preparing method thereof

The invention discloses a pine water-based grain-protruding-prevention white primer and a preparing method thereof, and relates to the field of water-based paint. The water-based grain-protruding-prevention white primer is prepared from, by weight, 35-50 parts of water-based acrylic resin, 3-7 parts of coalescing agent, 0.1-0.6 part of flatting agent, 0.8-2 parts of dispersing agent, 0.1-0.5 partof defoaming agent, 0.1-0.5 part of anti-settling agent, 15-22 parts of ground calcium carbonate, 15-22 parts of titanium dioxide, 0.2-0.4 part of thickening agent and 10-15 parts of deionized water.The primer has good permeability and sealing performance, can be quickly combined with wood fiber components, and is then quickly cured, so that when pine is subjected to white process coating, the occurrence of grain protruding can be avoided.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

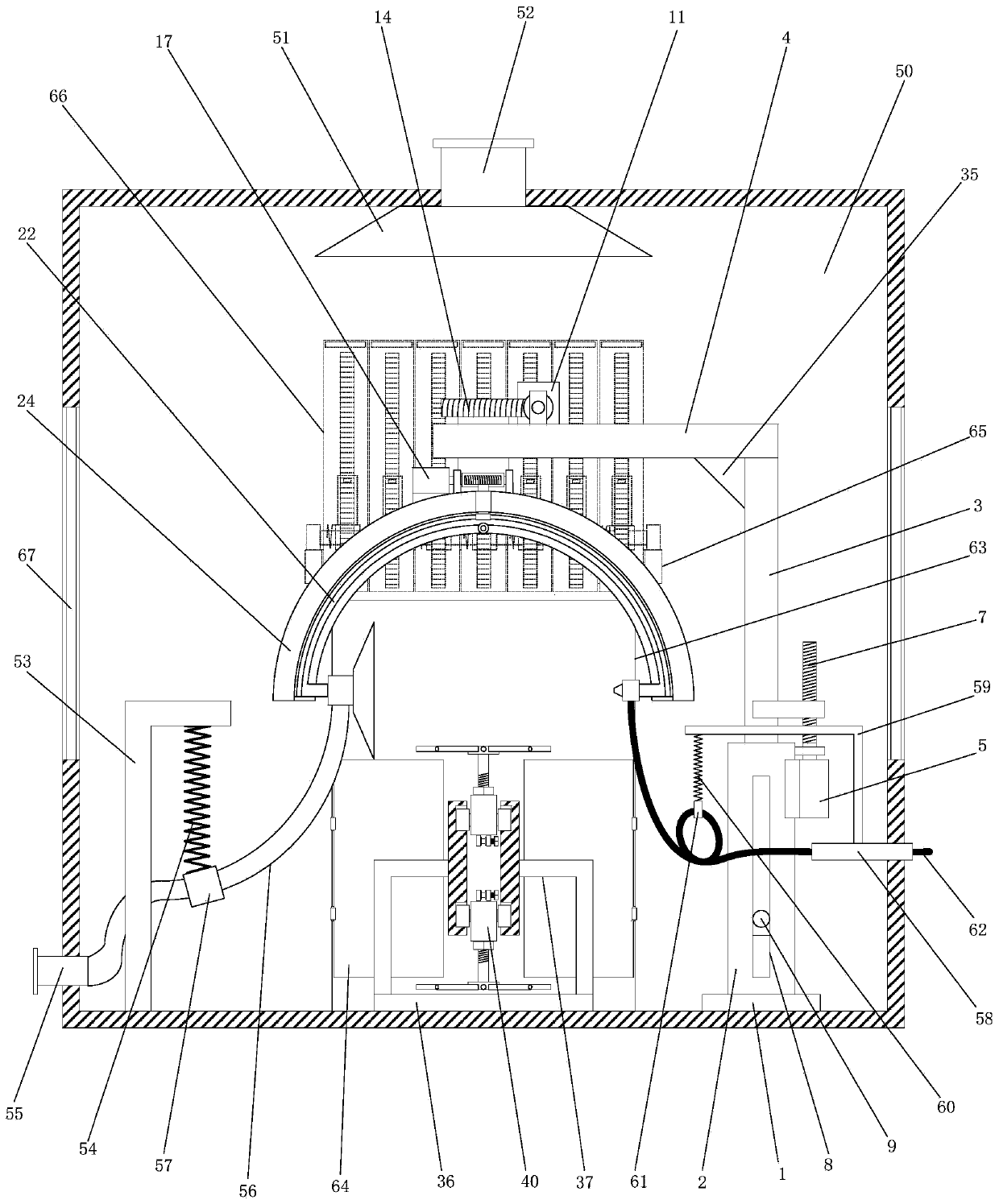

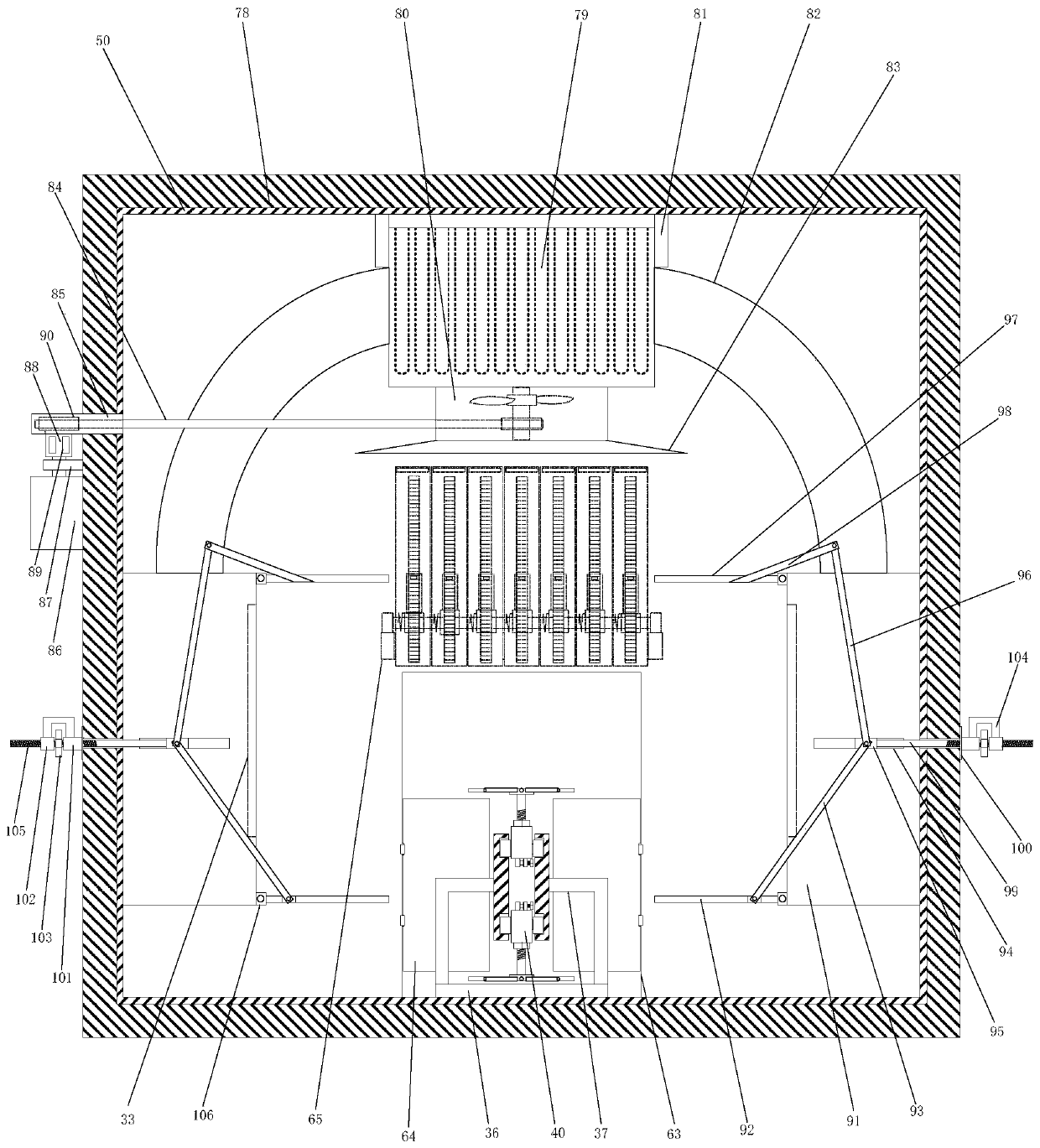

Paint spraying and drying integrated system

PendingCN110694847AMeet painting requirementsPretreated surfacesCoatingsElectric machineStructural engineering

The invention discloses a paint spraying and drying integrated system which comprises a paint spraying mechanism, a workpiece conveying mechanism, a convection drying mechanism and a cuboid-shaped shell. The paint spraying mechanism comprises a lifting support, a transverse beam, a rotating drive motor, an angle adjusting motor, a suction conical cover, a paint nozzle, a semi-arc-shaped plate anda semicircular-ring-shaped plate. The convection drying mechanism comprises an electric heating bellow, an axial flow draught fan, an air extracting motor, an air return bar-shaped cover and two air discharging bar-shaped boxes. The workpiece conveying mechanism is used for conveying workpieces. By means of the paint spraying and drying integrated system, the paint spraying mechanism is used for conducting paint spraying on the workpieces one by one, in addition, when the paint nozzle is used for conducting paint spraying, a paint mist recycling cover and a paint mist recycling pipe are used for conducting outward fast suction recycling of redundant paint mist; and the convection drying mechanism can dry the workpieces from the left side and the right side, in addition, after hot airflow ascends, an air return bar-shaped cover collects the hot airflow and then conducts cyclic heating, and therefore cyclic heating airflow can be formed on the left side and the right side of the interiorof a shell to dry the workpiece continuously.

Owner:JIANGSU SULI MACHINERY SHARES CO LTD

Production method for treating weathering steel for containers without sand blasting or shot blasting

The invention provides a production method for treating weathering steel for containers without sand blasting or shot blasting. The production method adopts the following hot rolling process flow: heating with a heating furnace, rough rolling, finish rolling, laminar cooling, coiling, air blast cooling, insulating with an insulation cover and finishing. The production method is characterized in that the initial rolling temperature of a finishing mill is controlled between 950 DEG C and 1020 DEG C, the finishing rolling temperature is controlled between 850 DEC C and 900 DEC C, the rolling speed is more than 5.5m / s and each finish rolling stand adopts lubricating rolling; the surface roughness Ra of the roller of the stand at the tail of the finishing mill is controlled between 0.8mu m and 2.4mu m; front-section rapid cooling is adopted on the laminar cooling stage, the cooling water is controlled to be alkalescent and the PH value is 7.0-10; the coiling temperature is controlled between 550 DEG C and 620 DEG C; the steel coil after coiling is put in the ventilative and convective place or a fan is adopted to improve ventilation and convection to cool the steel coil to 460-500 DEG C at a speed of 2-5 DEG C / min; then the steel coil is put into the insulation cover to be insulated, is taken out after the temperature drops to 200+ / -20 DEG C and is naturally cooled to the room temperature; and the chemical component Si of the adopted slab is controlled between 0.20% and 0.25%.

Owner:武汉钢铁有限公司

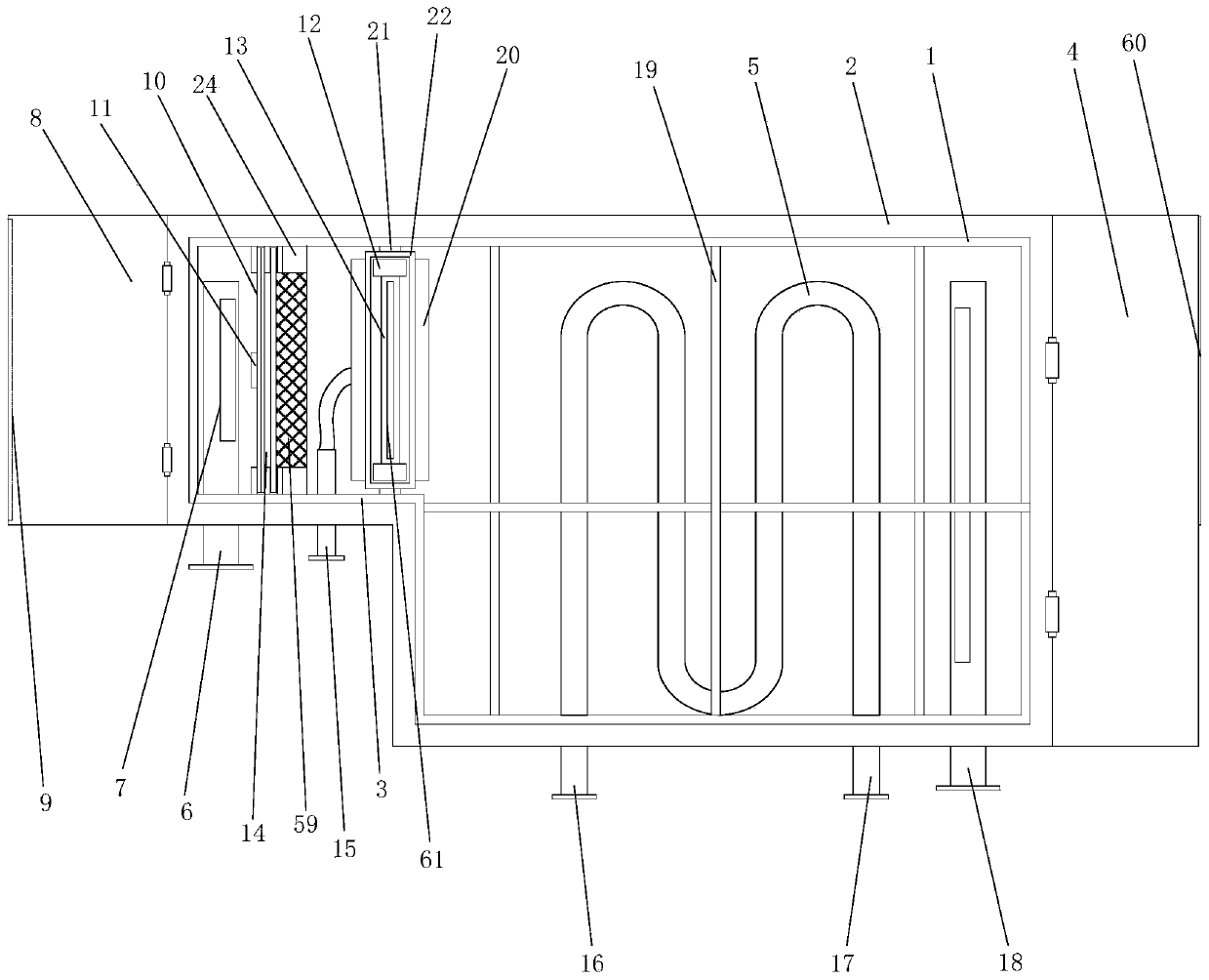

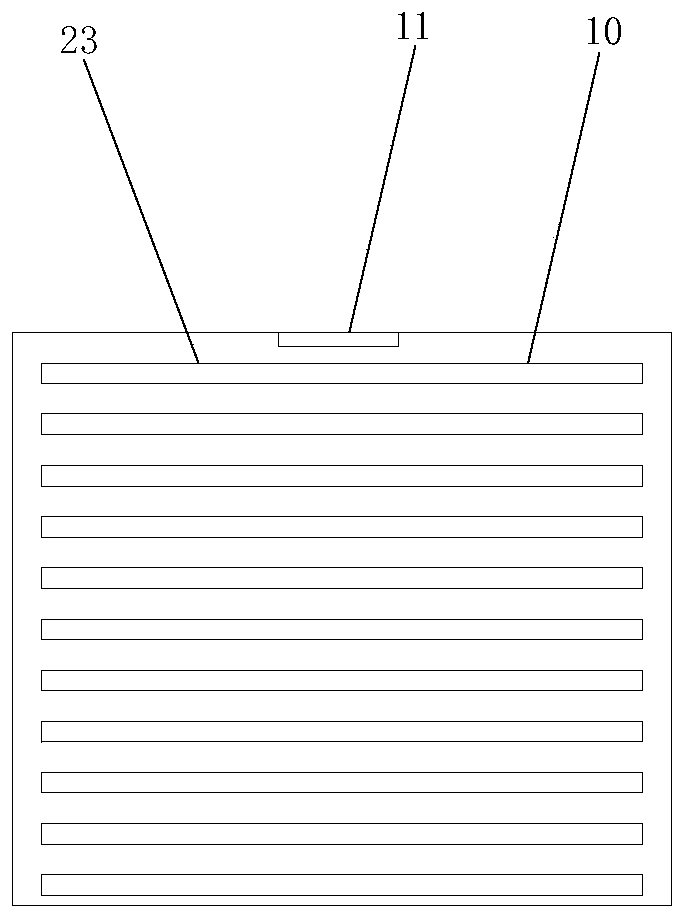

Coating and paint spraying system

PendingCN111068966AFully adsorbedAdjust the spray angleSpray boothsWater storage tankWater resources

The invention discloses a coating and paint spraying system. The coating and paint spraying system comprises a paint spraying chamber and a water circulating device; the paint spraying chamber comprises a shell, an axial flow fan, a strip-shaped water storage tank, a steel mesh plate, a water collecting tank, a conveying belt and a paint spraying mechanism; and the water circulating device comprises a recycling tank, a right side cover plate, a left side cover plate, a liquid inlet pipe, a recycling pipe, a filtering membrane plate, a rectangular frame plate, a suspended foam plate and an oilrecycling pipe. The coating and paint spraying system facilitates post-disassembly and maintenance by mounting the filtering membrane plate in a plugging manner; manual isolation is realized through an arranged fixed baffle plate and an unplugging-plugging baffle plate, so that the filtering membrane plate can be replaced and maintained without shutdown; water mist is sprayed on the steel mesh plate by utilizing a water mist spraying head, so that a flowing air flow is subjected to water curtain adsorption, and oil paint in paint mist can be fully adsorbed; a uniform water curtain can be formed on the steel mesh plate by utilizing the strip-shaped water storage tank, the steel mesh plate, the water collecting tank and the water mist spraying head; and water resources can be collected for recycling.

Owner:江苏欧迈机械工程有限公司

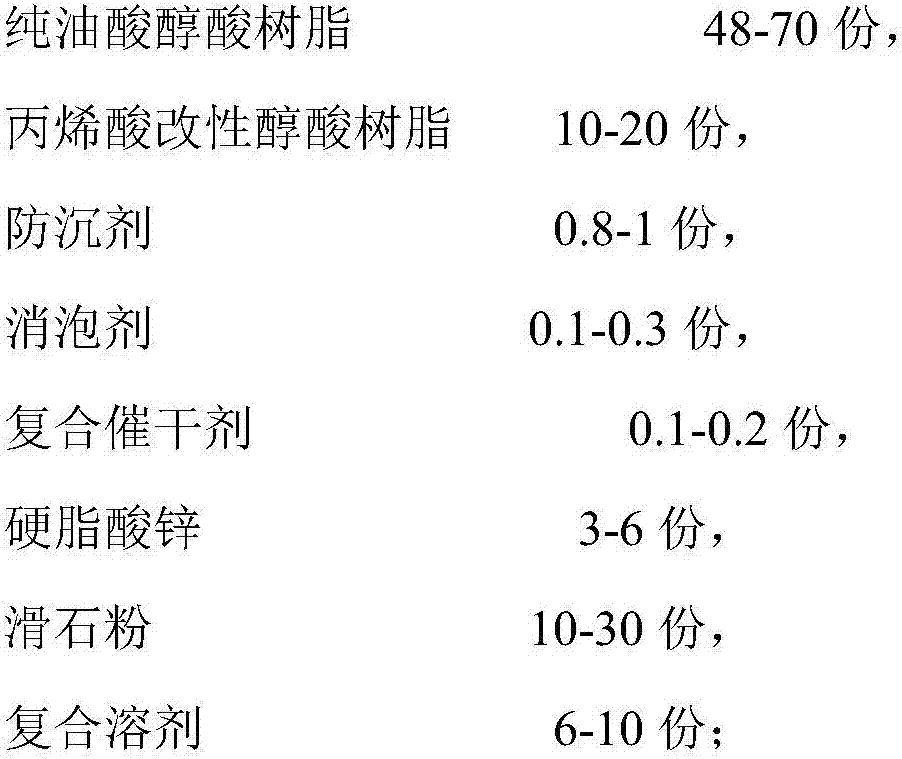

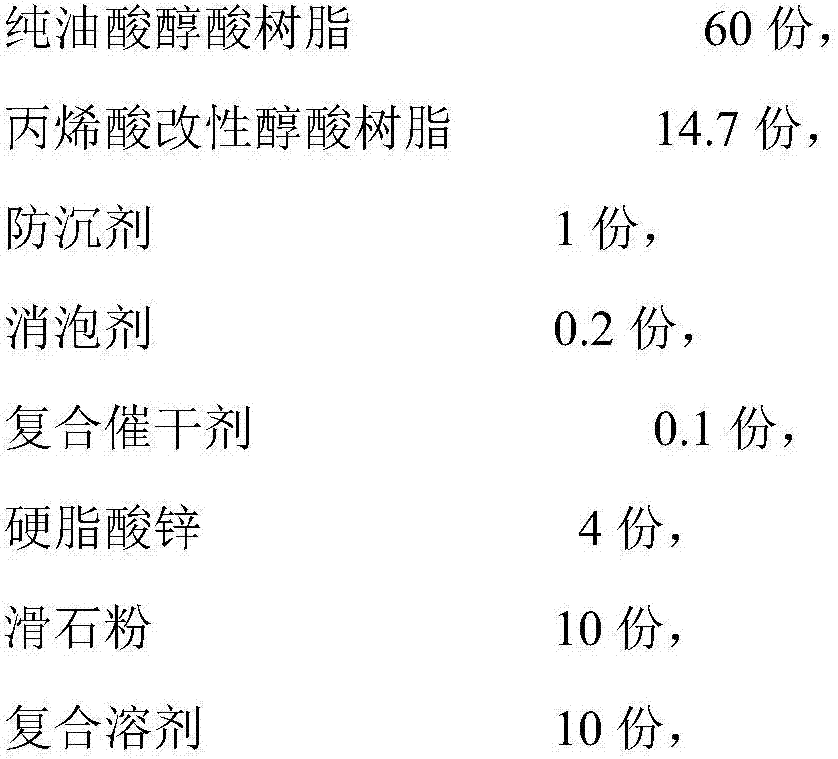

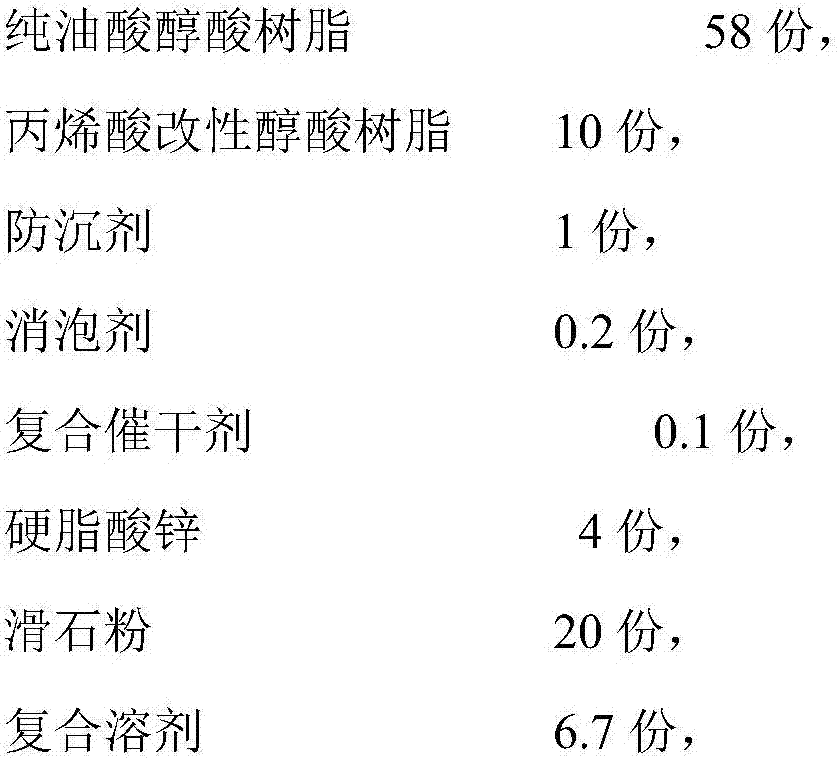

Transparent primer easy to apply and preparation method of transparent primer

InactiveCN107502178AFast dryingImprove drying effectPolyurea/polyurethane coatingsPriming paintsHigh surfaceDipropylene glycol monomethyl ether acetate

The invention provides transparent primer easy to apply. The transparent primer is prepared from main paint, a curing agent and a diluting agent, wherein a ratio of the three components is 1 to (0.3 to 0.5) to (0.5 to 0.7), the main paint is prepared from alkyd resin, acrylic modified alkyd resin, an anti-settling agent, a defoaming agent, a composite drying agent, zinc stearate, talcum powder and a composite solvent, the curing agent is prepared from a TDI addition product curing agent, a TDI trimer and butyl acetate, and the diluting agent is prepared from dimethylbenzene, butyl acetate and propylene glycol methyl ether acetate. The primer easy to apply has the characteristics of convenience in construction, high surface compactness and smoothness, good toughness, excellent grinding performance and prinkly heat prevention and also meets the environment-friendly and energy-saving requirements at the same time.

Owner:HUILON COATING IND

Automobile transmission shaft sliding spline surface coating process

The invention relates to an automobile transmission shaft sliding spline surface coating process. The process comprises the following steps: (1) performing cleaning and sandblasting pretreatment on a spline; (2) immerging the pretreated spline into a mixed solution of phenolic resin epoxy resin modified paint, draining the residual mixed solution and drying; (3) heating the dried spline to 220-300 DEG C; (4) performing nylon 11 coating on the surface of the spline by use of a fluidized bed spraying method; (5) after curing, cooling, thereby obtaining the automobile transmission shaft sliding spline. According to the automobile transmission shaft sliding spline surface coating process, the high-temperature-resistant phenolic resin and epoxy resin modified paint with good adhesive force are selected as intermediate substances, and are high-temperature resistant, and the adhesive forces between the phenolic resin and epoxy resin modified paint and the surfaces of metal parts are high, so that the automobile transmission shaft sliding spline surface coating process completely conforms to the coating requirements.

Owner:WUXI CHENGBO SCI & TECH DEV

Powder coating device

PendingCN108372063APrevent powder depositionThe process is continuous and smoothSpray boothsSpray discharge apparatusPowder coatingMechanical engineering

The invention relates to a powder coating device. The device comprises a powder supplying unit, a spraying unit and a powder recycling unit which are connected in series; the spraying unit comprises aspraying chamber and a pair of lifting spraying mechanisms which is separately arranged on two sides of the spraying chamber; each lifting spraying mechanism comprises a lifter and a spraying gun group which is arranged on the lifter and extends into the spraying chamber; each spraying gun group communicates with the powder supplying unit; the powder recycling unit comprises a cyclone separationrecycling mechanism which communicates with the bottom of the spraying chamber and a second separation mechanism which communicates with the cyclone separation recycling mechanism; powder in the powder supplying unit is sprayed on the surface of a workpiece in the spraying chamber through the spraying gun groups; and residual powder in the spraying chamber is recycled by the powder recycling unitand is conveyed to the powder supplying unit. Compared with the prior art, the powder coating device has the advantages that the powder can be uniformly sprayed on the surface of the workpiece; thickness of a coating film is convenient to control; the powder can be recycled effectively; and pollution to the environment is reduced.

Owner:AURORA CHINA

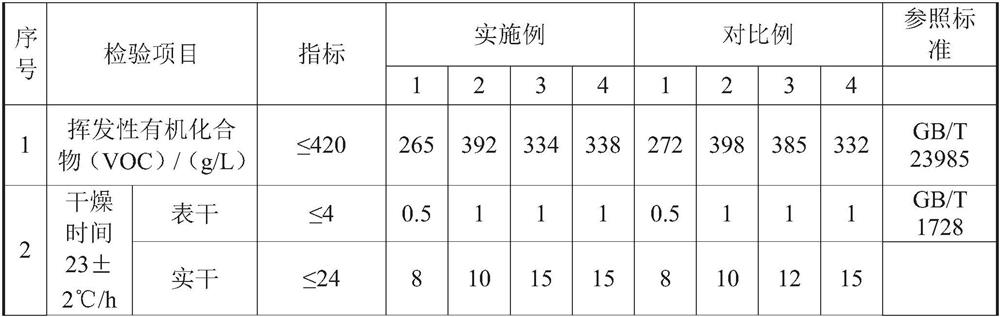

Special high-permeability moisture-curing seal primer for concrete as well as preparation method and application thereof

ActiveCN114539885ALow surface treatment requirementsReduce penetrationClimate change adaptationAnti-corrosive paintsXylylenePhosphoric acid

The invention discloses a special high-permeability moisture-curing seal primer for concrete as well as a preparation method and application of the special high-permeability moisture-curing seal primer. The special high-permeation type moist curing seal primer for the concrete comprises a component A and a component B, the component A comprises quaternary ammonium salt modified epoxy resin, graphene, basalt scales, silver-loaded zirconium phosphate, a wetting dispersant, a grafting coupling agent, an anti-settling agent, a reactive diluent, a pigment filler, butanol and xylene; the component B comprises phenolic aldehyde amine, phenolic aldehyde amide, graphene, basalt scales, a wetting dispersant, an anti-settling agent, a pigment filler, butanol and xylene. The special high-permeation type moist curing seal primer for the concrete, provided by the invention, is green and environment-friendly, has low surface treatment requirements on a matrix, can be moist and cured, and can realize single-time coating thick film, and meanwhile, a prepared coating can be used for surface protection of a concrete matrix in severe environments such as a marine environment and the like.

Owner:ZHEJIANG YUXI CORROSION CONTROL CORP

An automatic painting device

ActiveCN105772299BExtended range of movementReduce volumeSpraying apparatusEngineeringMechanical engineering

Owner:淄博奧冠交通科技有限公司

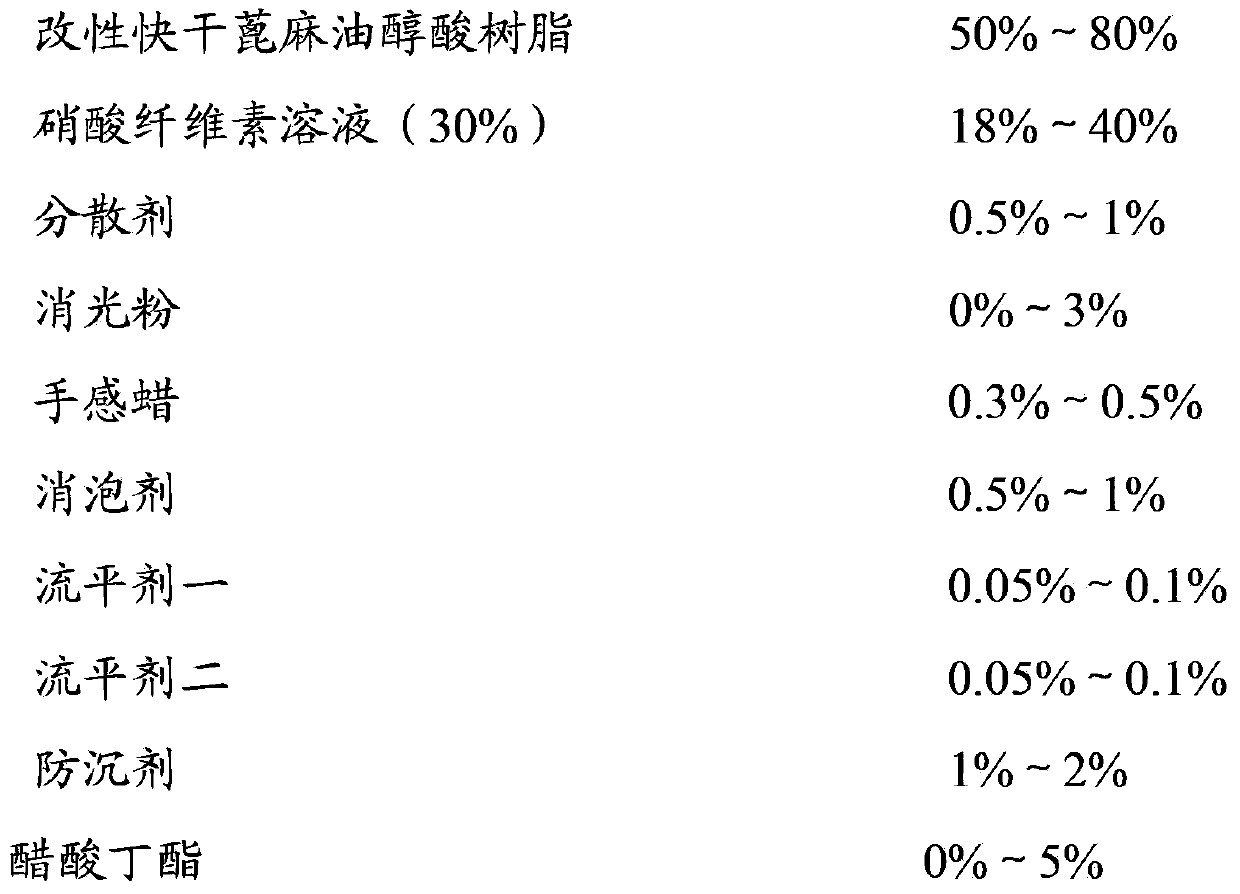

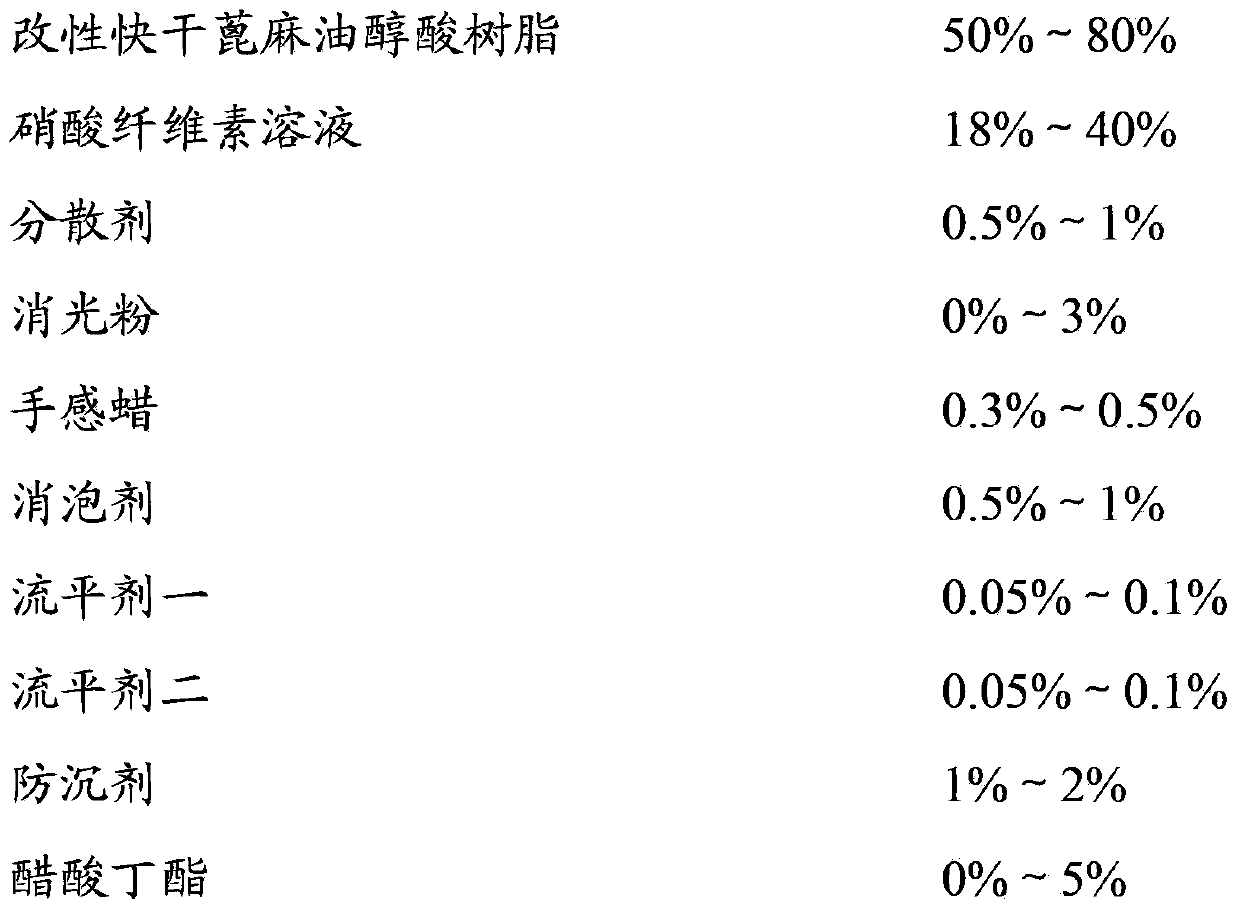

Polyurethane transparent top-coat for coating assembly line in three-dimensional effect and preparation method thereof

ActiveCN102559036BImprove toughnessHigh transparencyPolyurea/polyurethane coatingsNitrocelluloseAssembly line

The invention relates to the technical field of coatings and in particular relates to a polyurethane transparent top-coat for coating an assembly line in a three-dimensional effect and a preparation method thereof. The polyurethane transparent top-coat comprises a component A and a component B, wherein the weight ratio of the component A to the component B is 4:1, the solid content of the component A is 42-48%, the component A comprises modified quick-drying castor oil alkyd resin, a nitrocellulose solution, a dispersing agent, extinction powder, handfeel wax, a defoaming agent, a flatting agent I, a flatting agent II and an anti-settling agent; and the solid content of the component B is 40-45%, and the component B comprises a TDI (toluene diisocynate) tripolymer, a TDI addition product, an HDI (hexamethylene diisocyanate) tripolymer and butyl acetate. The component A and the component B are respectively mixed, dispersed at a high speed, inspected, filtered and packaged to prepare the polyurethane transparent top-coat. The polyurethane transparent top-coat can achieve the coating effect and drying speed of an NC (nitrocellulose) coating, and has the advantages of short polishing time, environment friendliness and excellent physical and chemical properties of common polyurethane coats, and wide application range.

Owner:东莞大宝化工制品有限公司 +1

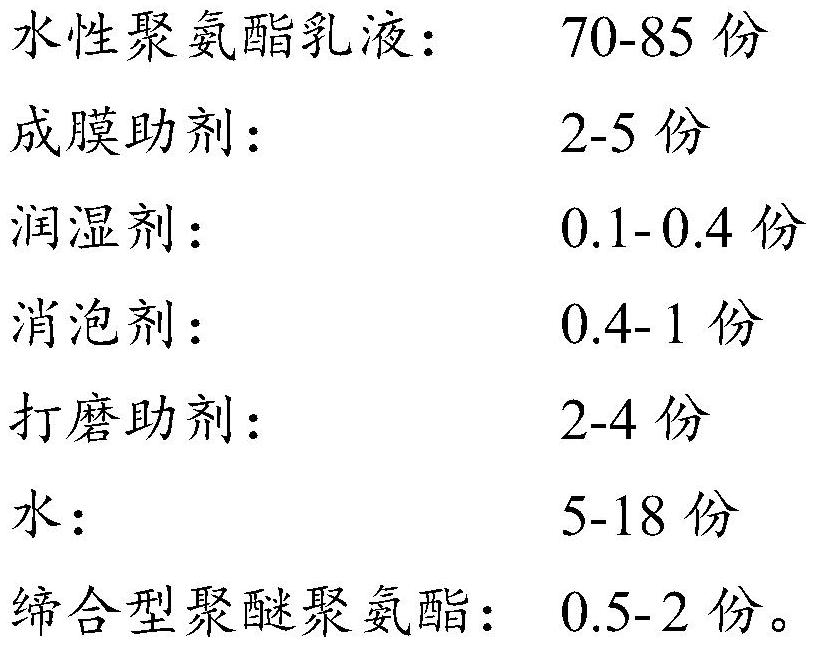

Water-based anti-sagging clear primer and preparation method thereof

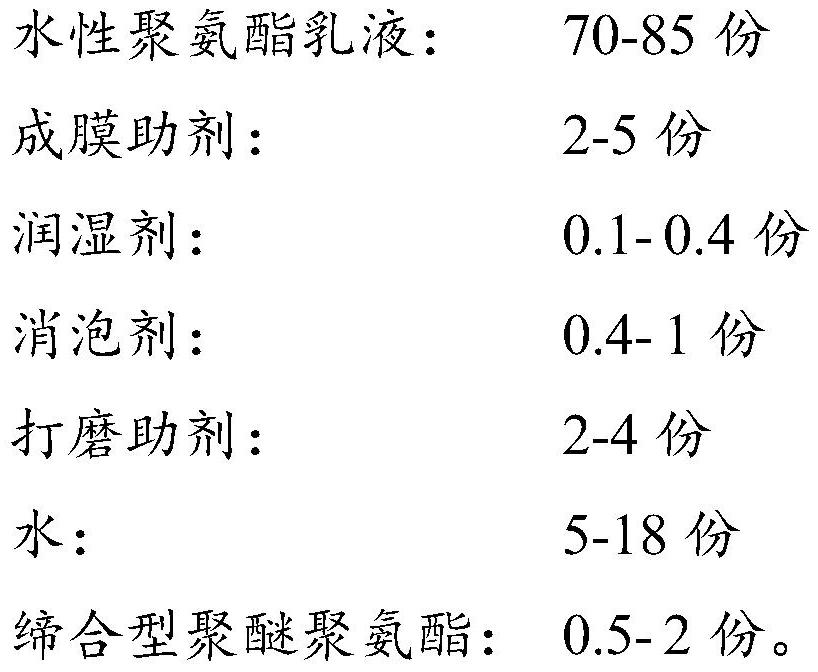

PendingCN113444431ADry fastGood anti-sag performancePolyurea/polyurethane coatingsPriming paintsDefoaming AgentsEmulsion

The invention discloses a water-based anti-sagging clear primer and a preparation method thereof, and the water-based anti-sagging clear primer comprises the following components in parts by weight: 70 to 85 parts of a water-based polyurethane emulsion, 2 to 5 parts of a coalescing agent, 0.1 to 0.4 part of a wetting agent, 0.4 to 1 part of a defoaming agent, 2 to 4 parts of a polishing aid, 5 to 18 parts of water and 0.5 to 2 parts of associated polyether polyurethane. The preparation method is simple and feasible, and the prepared clear primer does not generate a rib expansion phenomenon when being coated on a wood board, is safe and environment-friendly, has efficient sealing performance and can solve the problem of spraying sagging of a vertical surface.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

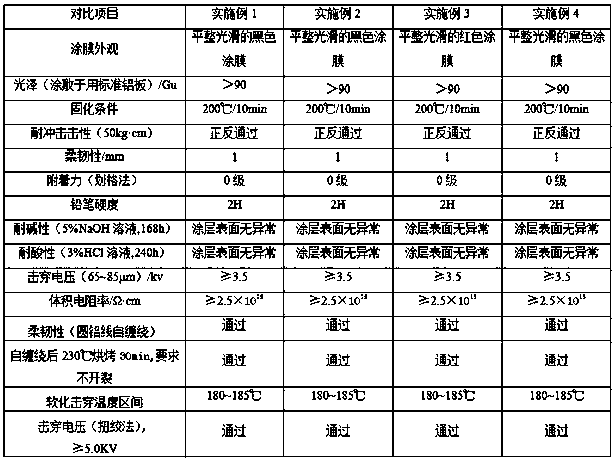

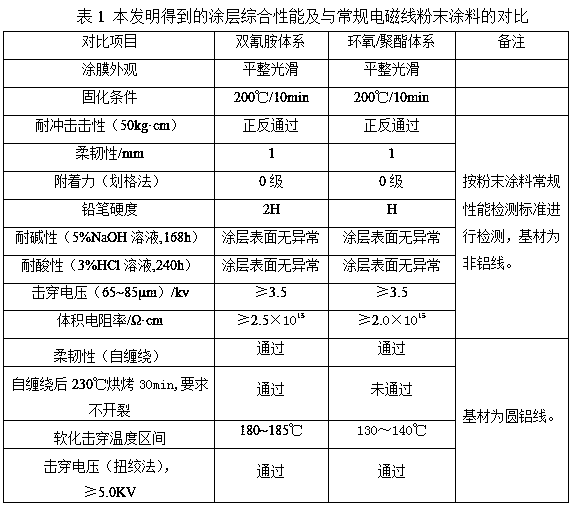

A kind of pure epoxy powder coating for electromagnetic wire coating and preparation method thereof

ActiveCN105199535BImprove flexibility and heat resistanceGood leveling performancePowdery paintsEpoxy resin coatingsAdjuvantOxide coating

The invention discloses a pure epoxy powder coating for electromagnetic wire coating, which comprises the following components in proportion by weight: 200 parts of epoxy resin, 3-6 parts of curing agent, 1-5 parts of auxiliary agent, 0-0 parts of filler 20 parts, 0‑10 parts of pigment. The invention also discloses a preparation method of the powder coating. The cured coating of the powder coating has good flexibility and electrical properties, and also has good insulation properties.

Owner:GUANGZHOU KINTE IND

Process for preparing magnesium alloy chemical conversion coating

ActiveCN100532642CEliminate hazardsImprove corrosion resistanceMetallic material coating processesChromium CompoundsSodium phosphates

Owner:靖江市华信科技创业园有限公司

Water-based antirust paint and preparation method thereof

ActiveCN105238232BImprove densification performanceImprove shielding effectAntifouling/underwater paintsPaints with biocidesEpoxyDefoaming Agents

The invention discloses waterborne antirust paint and a preparation method thereof. The waterborne antirust paint is prepared from, by mass, 10-25 parts of waterborne acrylic acid modified epoxy ester, 0.6-1.2 parts of neutralizer, 20-30 parts of deionized water, 0.5-1.5 parts of dispersing agents, 0.2-0.5 part of defoaming agent, 14-18 parts of iron oxide red, 2-4 parts of mica powder, 6-10 parts of modified zinc phosphate, 10-14 parts of precipitated barium sulphate, 1-2 parts of propylene glycol, 10-15 parts of styrene-acrylic emulsion, 0.5-1.0 part of coalescing agent, 0.5-1.0 part of waterborne flush rust prevention agent, 0.5-1.5 parts of thickening agents and 0.2-0.5 part of mildew prevention agent. The waterborne antirust paint is high in film hardness, good in adhesive force and excellent in corrosion-resistant performance and mechanical performance, dryness and initial water resistance of paint films are remarkably improved due to the addition of styrene-acrylic emulsion, and the flush rust restraining performance of paint films is improved due to the addition of the waterborne flush rust prevention agent. Water serves as the diluent for the waterborne antirust paint, VOC emission in production and construction projects is greatly reduced, and the waterborne antirust paint is safe, environmentally friendly and capable of being widely used for paint coating on the aspects of steel structures, pipelines, automobile parts and the like.

Owner:西北永新涂料有限公司

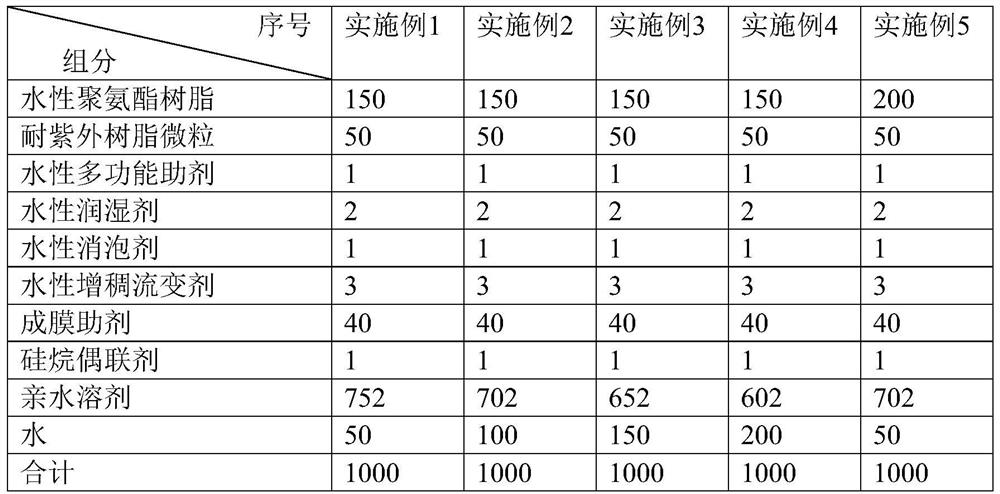

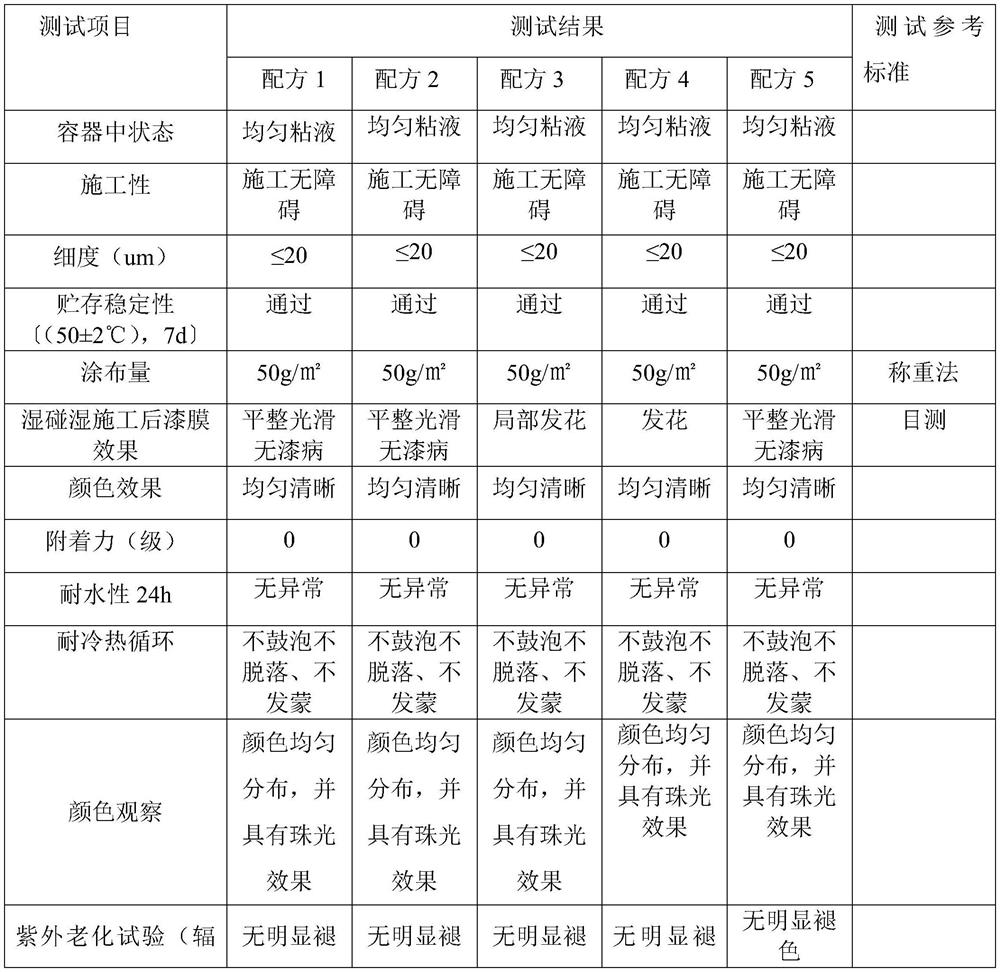

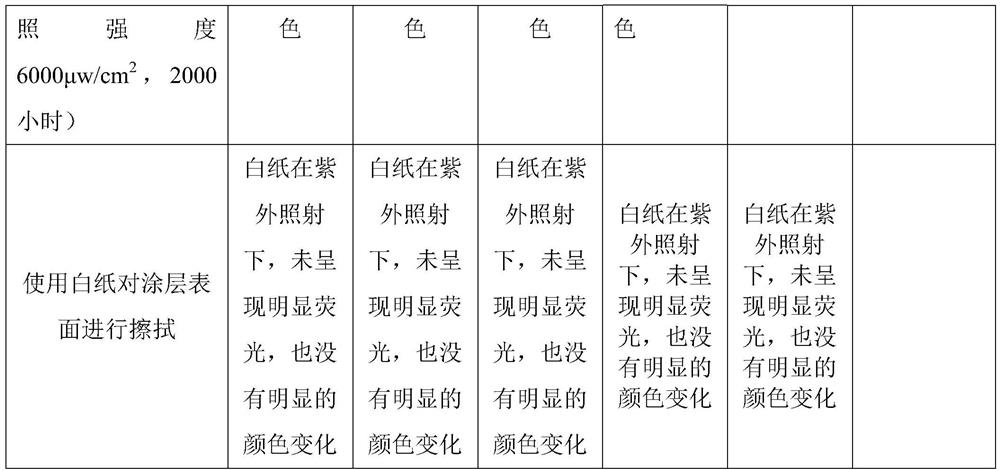

A kind of anti-ultraviolet color repairing agent and preparation method thereof

ActiveCN112251123BMeet painting requirementsAvoid the problem of standing and easy delaminationPolyurea/polyurethane coatingsRadiation-absorbing paintsUv absorbancePolymer science

The invention discloses an ultraviolet-resistant color repairing agent, which is composed of the following raw materials in parts by weight: 15-20 parts by weight of water-based polyurethane resin, 1-10 parts by weight of ultraviolet-resistant resin particles, 0.1-0.5 parts by weight of PH regulator, water-based moisturizer 0.1-0.3 parts by weight of wet agent, 0.1-0.3 parts by weight of water-based defoamer, 0.1-0.3 parts by weight of water-based thickening rheological agent, 3.0-5.0 parts by weight of co-solvent, 0.1-0.2 parts by weight of silane coupling agent, hydrophilic 70-80 parts by weight of solvent, 1-10 parts by weight of water, base material, pigment and ultraviolet absorber are wrapped in the UV-resistant resin particles, and the resin particles are selected from polypropylene resin, polycarbonate resin, nylon resin, One or more of polyetheretherketone resin and polyethersulfone resin, the base material is nano-inorganic particles, and the particle size of the nano-inorganic particles is 1-100nm. The invention does not need to add or change the original production equipment, has fast drying, good adhesion, meets the requirements of assembly line coating, and the ultraviolet absorber can be evenly mixed with the pigment, avoiding the problem of easy separation after standing for a long time, and is suitable for industrialized large-scale production.

Owner:GUANGDONG MAYDOS BUILDING MATERIALS LTD CO

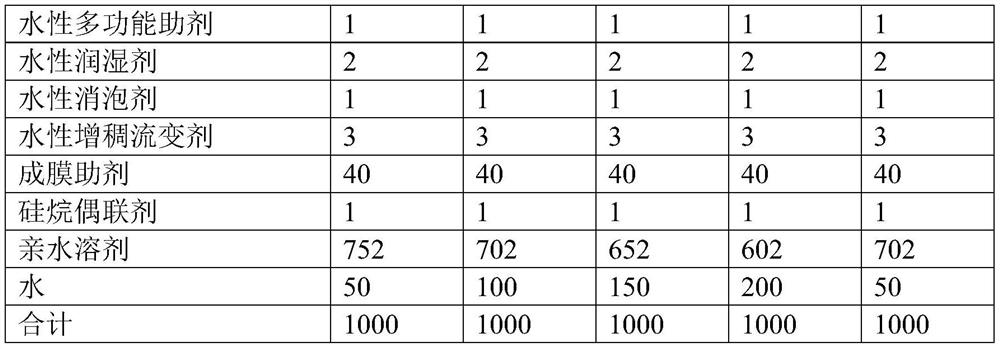

A kind of water-based color correction agent and preparation method thereof

ActiveCN112341923BSolve the problem of having to dry before applying a topcoatSolve the problem of waiting to dry before applying topcoatPolyurea/polyurethane coatingsColor correctionAssembly line

The invention discloses a water-based color repairing agent used in furniture and woodware production industries. The water-based color repairing agent is composed of the following raw materials in parts by weight: 15-20 parts by weight of water-based polyurethane resin, 0.1-0.5 parts by weight of pH regulator, 0.1-0.3 parts by weight of water-based wetting agent, 0.1-0.3 parts by weight of water-based defoamer, 0.1-0.3 parts by weight of water-based thickening rheological agent, 3.0-5.0 parts by weight of co-solvent, 0.1-0.2 parts by weight of silane coupling agent, 70-80 parts by weight of hydrophilic solvent, 1-10 parts by weight of water. The invention has simple formula composition, simple production process, low economic cost, no need to add or change the original production equipment, and the invented product has quick drying, good adhesion, good color matching, can be "wet on wet" construction, and has a wide range of applications, etc. Features, meet the assembly line coating requirements, suitable for industrialized mass production.

Owner:GUANGDONG MAYDOS BUILDING MATERIALS LTD CO

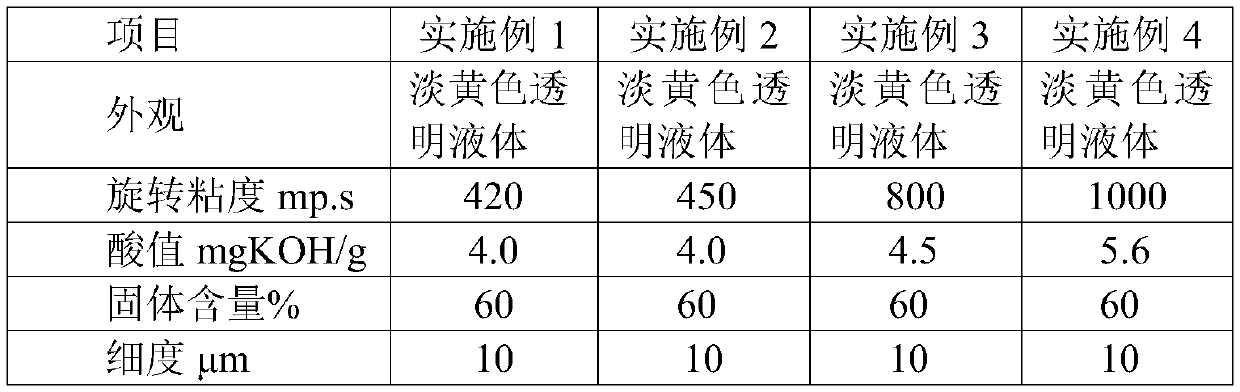

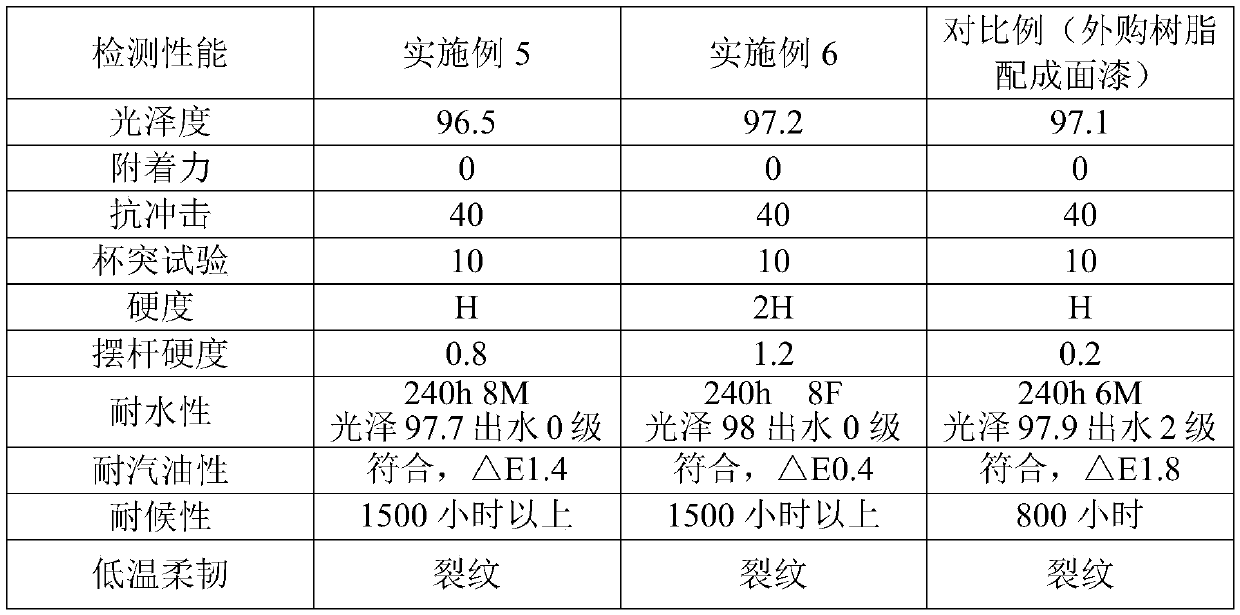

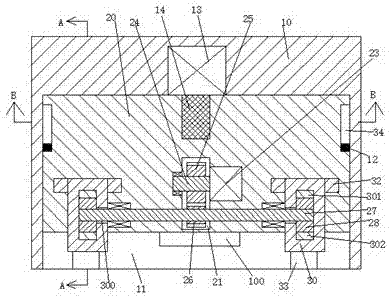

High-hardness end-capped one-component baking type finishing coat resin and preparation method and application thereof

The invention relates to a resin. The resin is prepared by esterifying and copolymerizing 12-22 w / w% of diol, 1-9 w / w% of ternary alcohol or higher alcohol, 32-37 w / w% of acid or anhydride, 1-6 w / w% of E10P and 2-4 w / w% of an end-capping gent and then adding 36-39 w / w% of a solvent for dilution, wherein the sum of the components is 100%. The provided resin is compounded with auxiliaries, pigmentsand solvents to prepare one-component paint, and the paint is used as a finishing coat to be applied in automotive coating with three coatings, namely the primer, the finishing coat and the varnish; the hardness of an automotive paint surface is improved, and the occurrence of scratching of the paint surface is effectively avoided.

Owner:江苏柏鹤涂料有限公司 +1

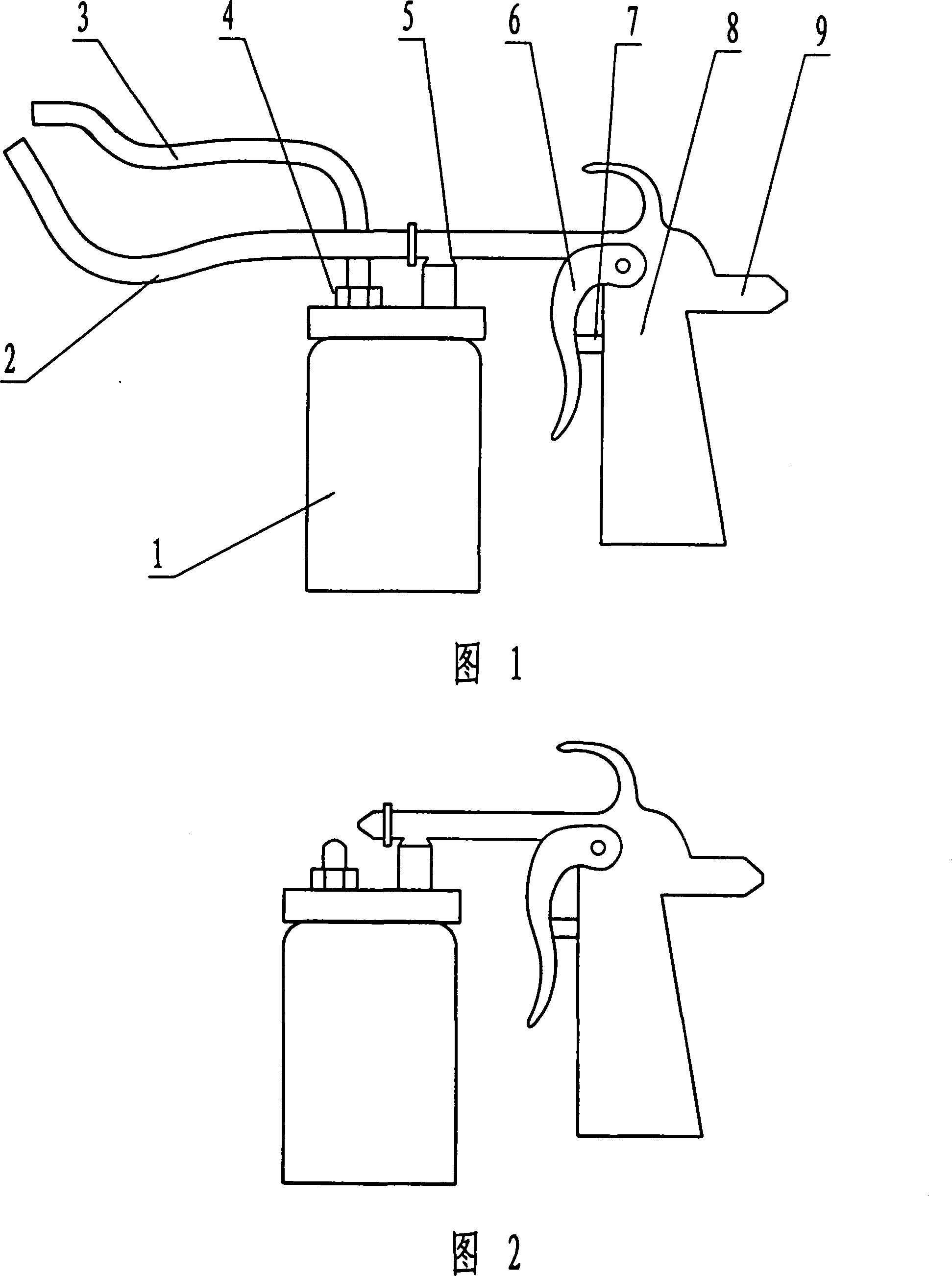

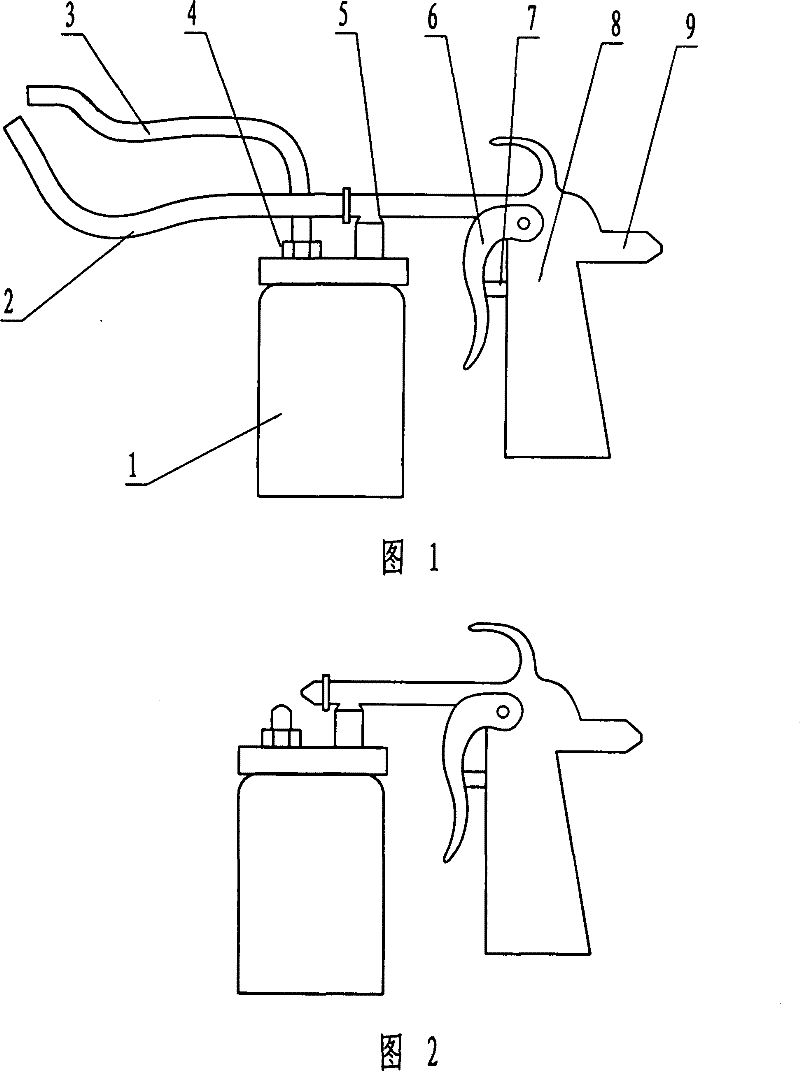

Spray gun for spraying painting at narrow slit

ActiveCN101214474AMeet painting requirementsSolve paint quality problemsLiquid spraying apparatusLacquerEngineering

A spray guy used for spraying paint on a slit belongs to the technology field of blast atomizer, which is used for overcoming the difficulty in paint-spraying on the slit. The spray guy consists of a paint cylinder and a handle. The upper part of the paint cylinder is provided with a painting nozzle and an air nozzle. Particularly, the spray guy is provided with an additional compressed air connecting pipe and an additional paint outlet pipe. The compressed air connecting pipe is communicated with the nozzle. The paint outlet pipe is communicated with the painting nozzle. The compressed air connecting pipe and the paint outlet pipe are extensional flexible pipes, the end positions of which correspond to each other. The compressed air nozzle and the compressed painting nozzle are respectively provided with an additional pipe that has some rigidity and produces plastic deformation easily. When the invention is used, the terminal parts of two pipes can be placed into the slit to spray the paint on the slit of an object. So the slit can be painted evenly. The invention has simple structure and is easy to be implemented. Trial results show that the invention has a good spray-paint effect and overcoming the difficulty in spraying the paint on the slit.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

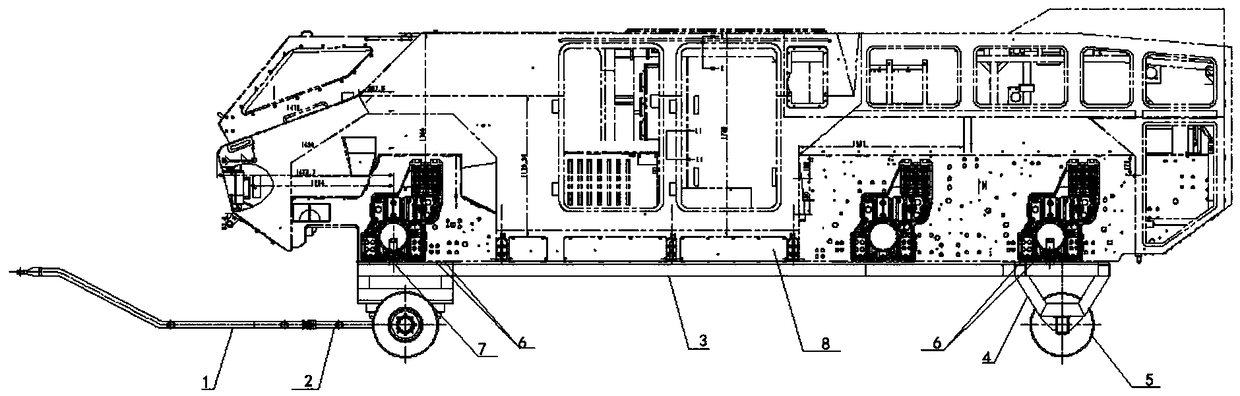

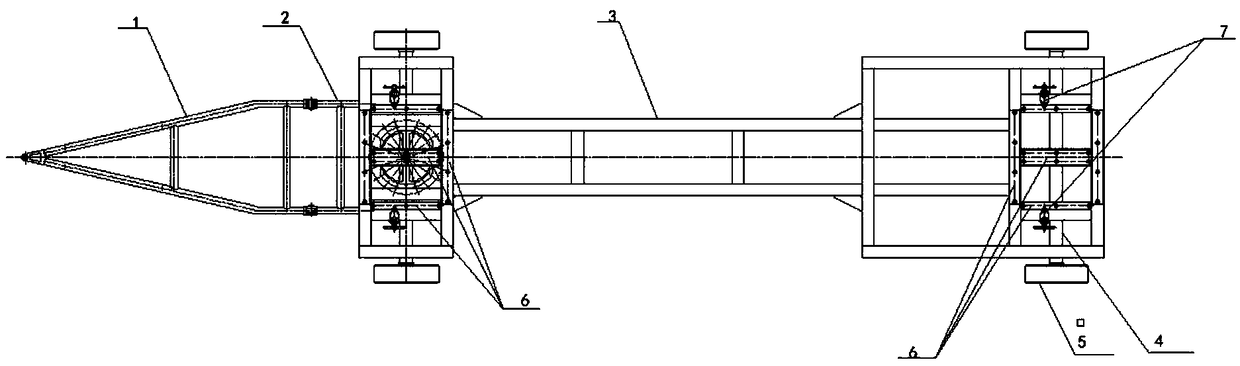

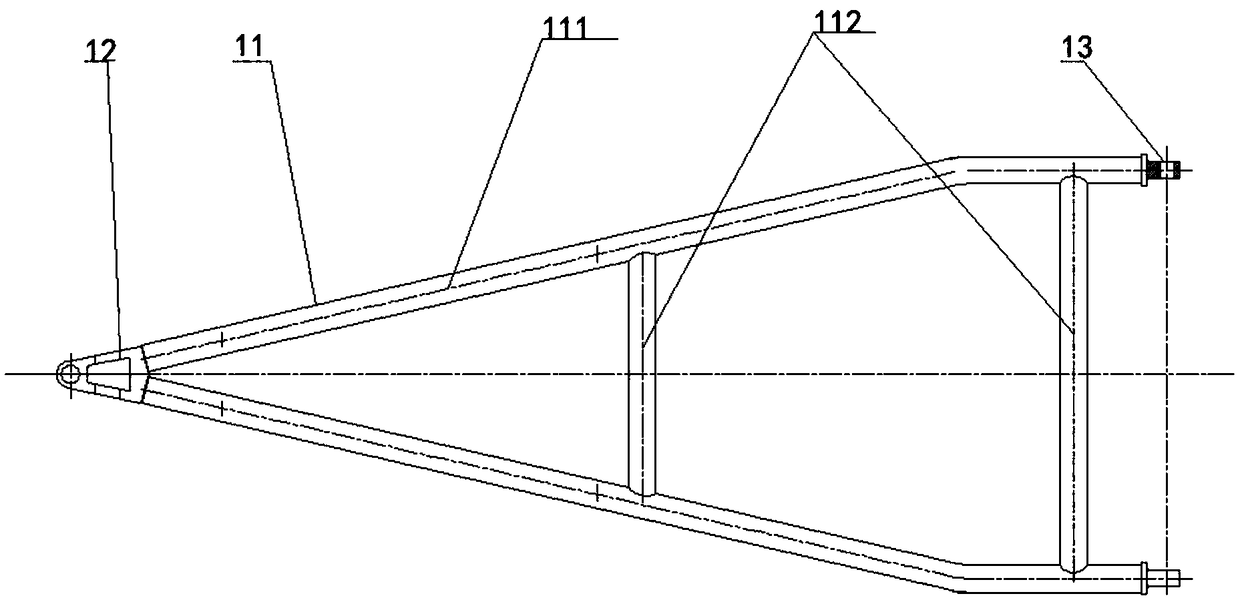

Turnover trolley for vehicle body and frame integrated structure

The invention discloses a turnover trolley for a vehicle body and frame integrated structure. The turnover trolley comprises a traction assembly, a front vehicle axle assembly, a frame assembly, a rear vehicle axle assembly, a base plate and a tire assembly, wherein the traction assembly is hinged to the front vehicle axle assembly; one end of the frame assembly is in rotary connection with the front vehicle axle assembly and the other end of the frame assembly is fixedly connected with the rear vehicle axle assembly; the tire assembly is connected with the frame assembly through the front vehicle axle assembly and the rear vehicle axle assembly respectively; the base plate is arranged on the frame assembly. By adopting the turnover trolley disclosed by the invention, the turnover requirements of the vehicle body and frame integrated structure are met and coating work is also convenient to arrange, so that the turnover efficiency is extremely improved; meanwhile, a product also can beprotected very well in a turnover process.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

A kind of high-hardness acrylate-modified polysiloxane resin and coating based on it

ActiveCN106675133BLow viscosityLow VOCAntifouling/underwater paintsPaints with biocidesWeather resistanceSilanes

The invention discloses high-hardness acrylate-modified polysiloxane resin and a coating employing the high-hardness acrylate-modified polysiloxane resin as a base material. The resin is mainly prepared by compounding 41-65wt% of active polysiloxane intermediate, 15-36wt% of cyclohexyl-containing acrylic ester, 5-15wt% of polyfunctional acrylate monomer and 10-20wt% of amino-hydrocarbon alkoxy silane. The harness of a pencil solidified by a two-component coating prepared from the acrylate-modified polysiloxane resin as the base material is greater than or equal to 5H, and meanwhile, the acrylate-modified polysiloxane resin can meet high solid content, low viscosity, room-temperature fast curing performance, overlong weather resistance and anticorrosion performance, and can be widely applied to surface coating of rail vehicles of subways and high-speed rails.

Owner:中昊北方涂料工业研究设计院有限公司

Spray gun for spraying painting at narrow slit

ActiveCN101214474BMeet painting requirementsSolve paint quality problemsLiquid spraying apparatusEngineeringSpray painting

A spray guy used for spraying paint on a slit belongs to the technology field of blast atomizer, which is used for overcoming the difficulty in paint-spraying on the slit. The spray guy consists of a paint cylinder and a handle. The upper part of the paint cylinder is provided with a painting nozzle and an air nozzle. Particularly, the spray guy is provided with an additional compressed air connecting pipe and an additional paint outlet pipe. The compressed air connecting pipe is communicated with the nozzle. The paint outlet pipe is communicated with the painting nozzle. The compressed air connecting pipe and the paint outlet pipe are extensional flexible pipes, the end positions of which correspond to each other. The compressed air nozzle and the compressed painting nozzle are respectively provided with an additional pipe that has some rigidity and produces plastic deformation easily. When the invention is used, the terminal parts of two pipes can be placed into the slit to spray the paint on the slit of an object. So the slit can be painted evenly. The invention has simple structure and is easy to be implemented. Trial results show that the invention has a good spray-paint effect and overcoming the difficulty in spraying the paint on the slit.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

Paint spraying device

InactiveCN107413562AReduce wasteIncrease the thickness of the attachmentSpraying apparatusSpray nozzleMechanical engineering

Owner:YIWU MOYA OPTOELECTRONICS TECH CO LTD

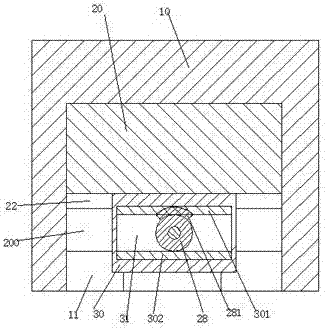

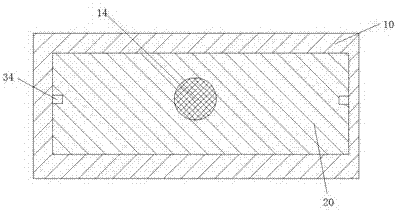

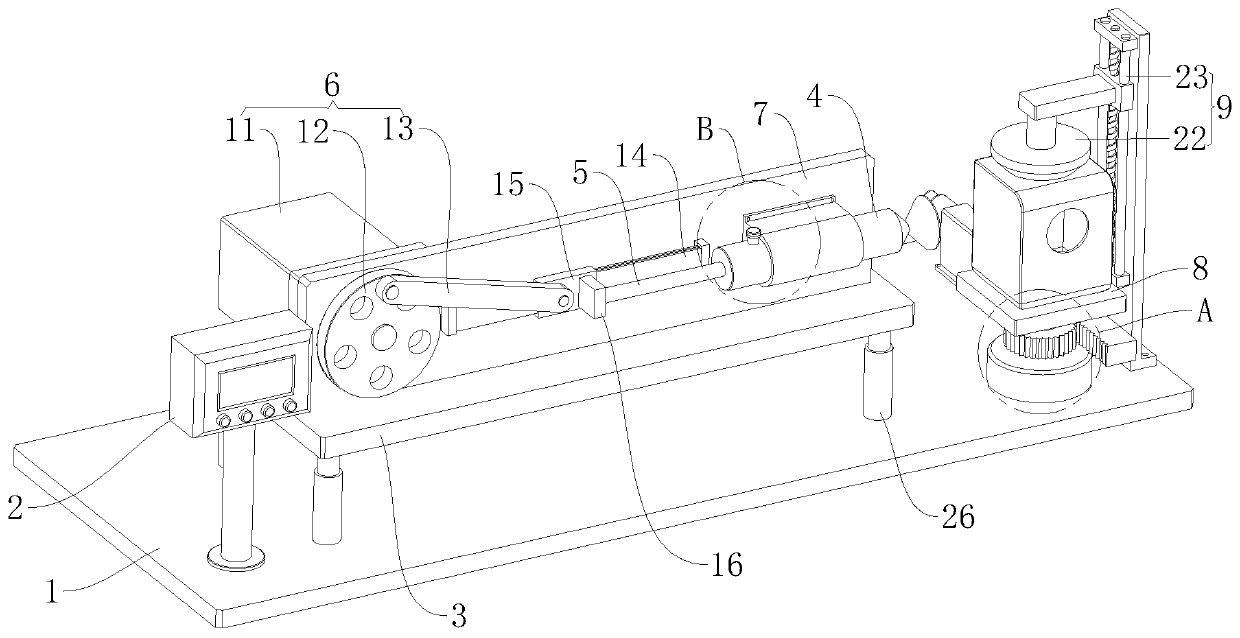

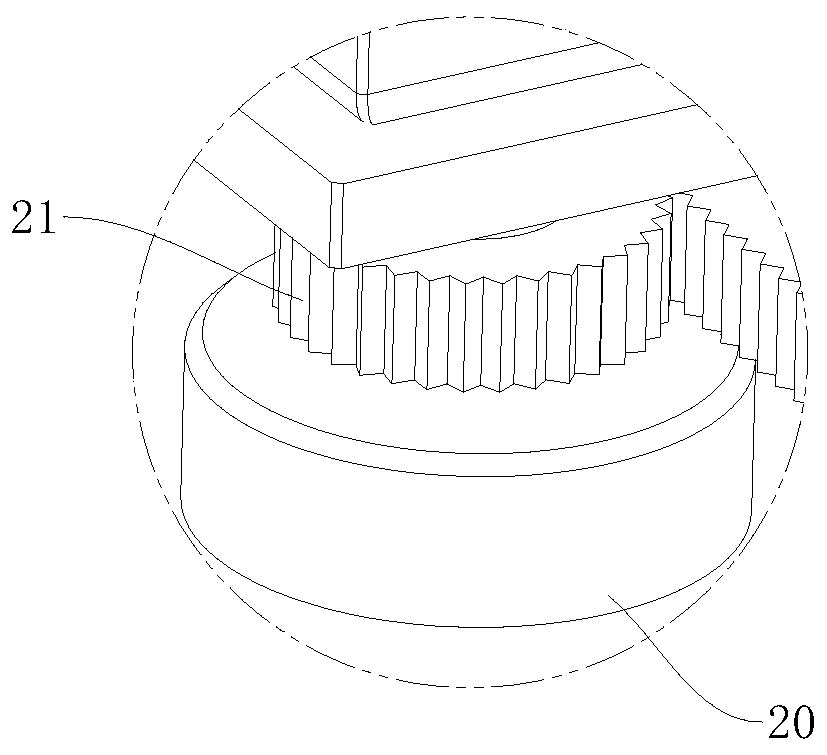

Sound equipment shell paint spraying equipment

InactiveCN111013898AEasy to adjustSimplify operation stepsLiquid spraying apparatusPhysicsSpray painting

The invention relates to the field of sound equipment processing and particularly relates to sound equipment shell paint spraying equipment. The equipment includes a base, the device further comprisesa controller, a lifting table, a fixing mechanism and a paint spraying mechanism, wherein the paint spraying mechanism is arranged on the lifting table to spray paint to a sound equipment shell, thepaint spraying mechanism comprises a storage barrel, a piston rod and a driving assembly, the fixing mechanism comprises a machining table, a pressing assembly and a rotating assembly, and the drivingassembly and the rotating assembly are both electrically connected with the controller. The equipment is advantaged in that multi-directional paint spraying of the sound equipment shell can be realized, the paint spraying requirements of all angles are met, moreover, adjustment is convenient, operation steps are simple, the paint spraying requirements of sound equipment shells of different sizescan be met, paint spraying efficiency is effectively improved, that paint spraying is uniform during paint spraying can be guaranteed, waste is not likely to occur, that paint spraying thickness of surfaces of the sound equipment shells is consistent can be guaranteed, product appearance and quality are improved, and enterprise income is increased.

Owner:嘉善金嘉塑业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com