Powder coating device

A powder coating and powder technology, which is applied in the direction of spraying device, spray discharge device, electrostatic spraying device, etc., can solve the problems of powder entering the atmosphere, air pollution, spraying amount and film thickness not up to standard, etc., to prevent powder Effects of deposition, continuous flow of process, and avoidance of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

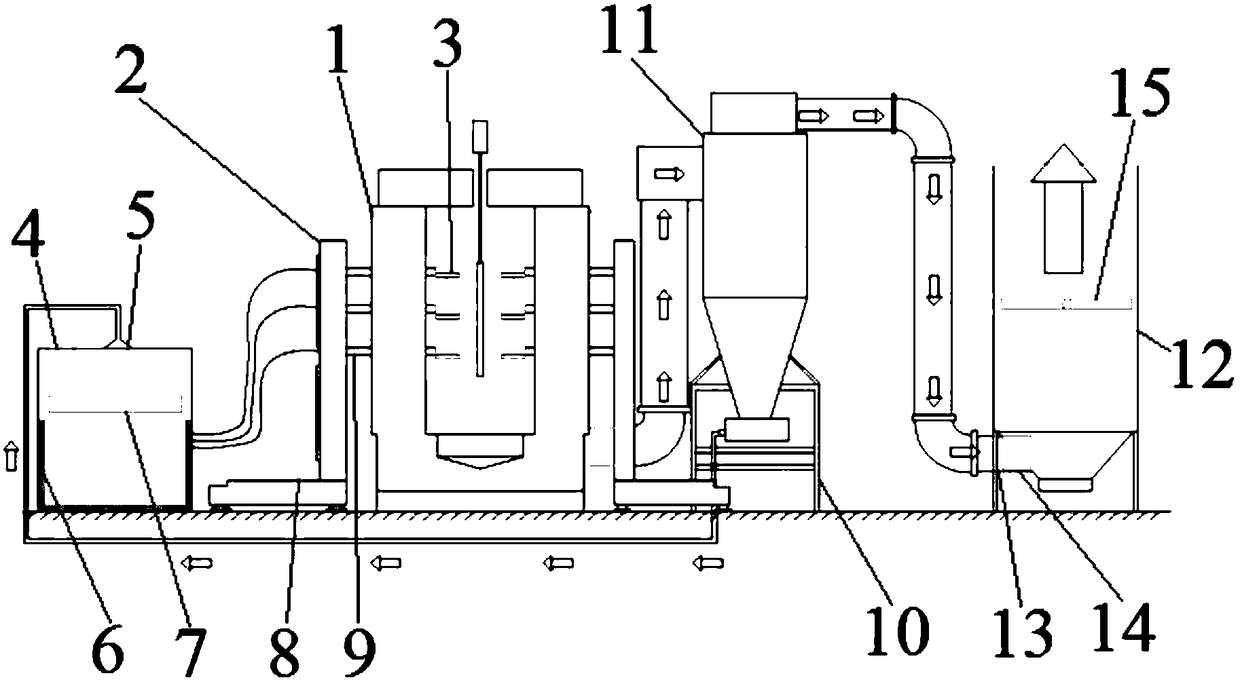

[0029] Such as figure 1 A powder coating device is shown, which includes a powder supply unit, a spray unit, and a powder recovery unit connected in series. The spray unit includes a spray booth 1 and a pair of lift-type spray booths that are respectively arranged on both sides of the spray booth 1. Mechanism, the lifting spraying mechanism includes an elevator 2 and a spray gun group 3 arranged on the elevator 2 and extending into the interior of the spraying room 1. The spraying gun group 3 communicates with the powder supply unit, and the powder recovery unit includes The cyclone separation and recovery mechanism and the second separation mechanism connected with the cyclone separation and recovery mechanism, the powder in the powder supply unit is sprayed on the surface of the workpiece in the spraying room 1 through the spray gun group 3, and the remaining powder in the spraying room 1 is passed through After being recovered by the powder recovery unit, it is sent to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com