Hob type film cutting device

A hob, film technology, applied in the direction of metal processing, etc., can solve the problem of manual auxiliary feeding, accumulation and silt above the feeding port, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

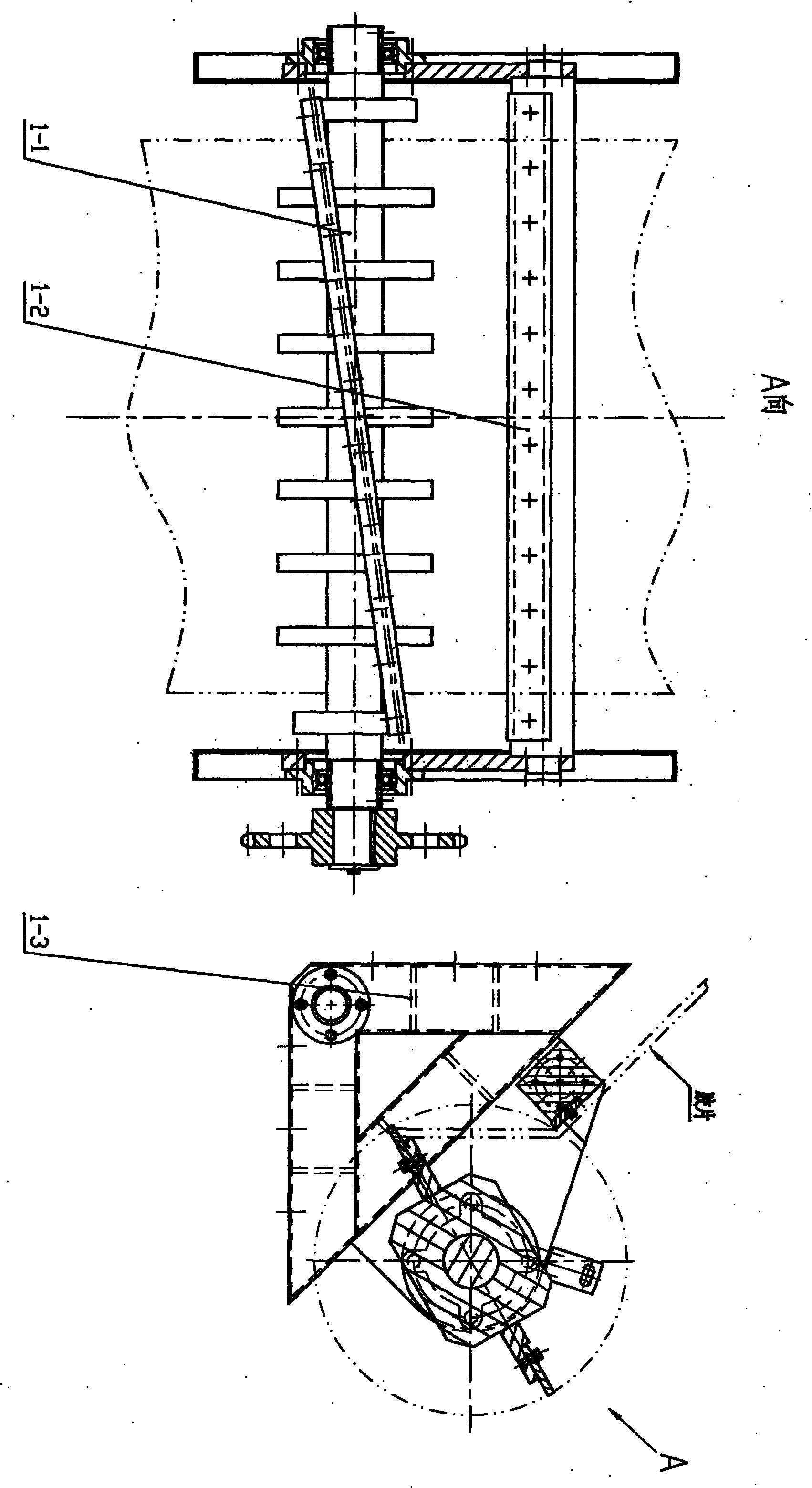

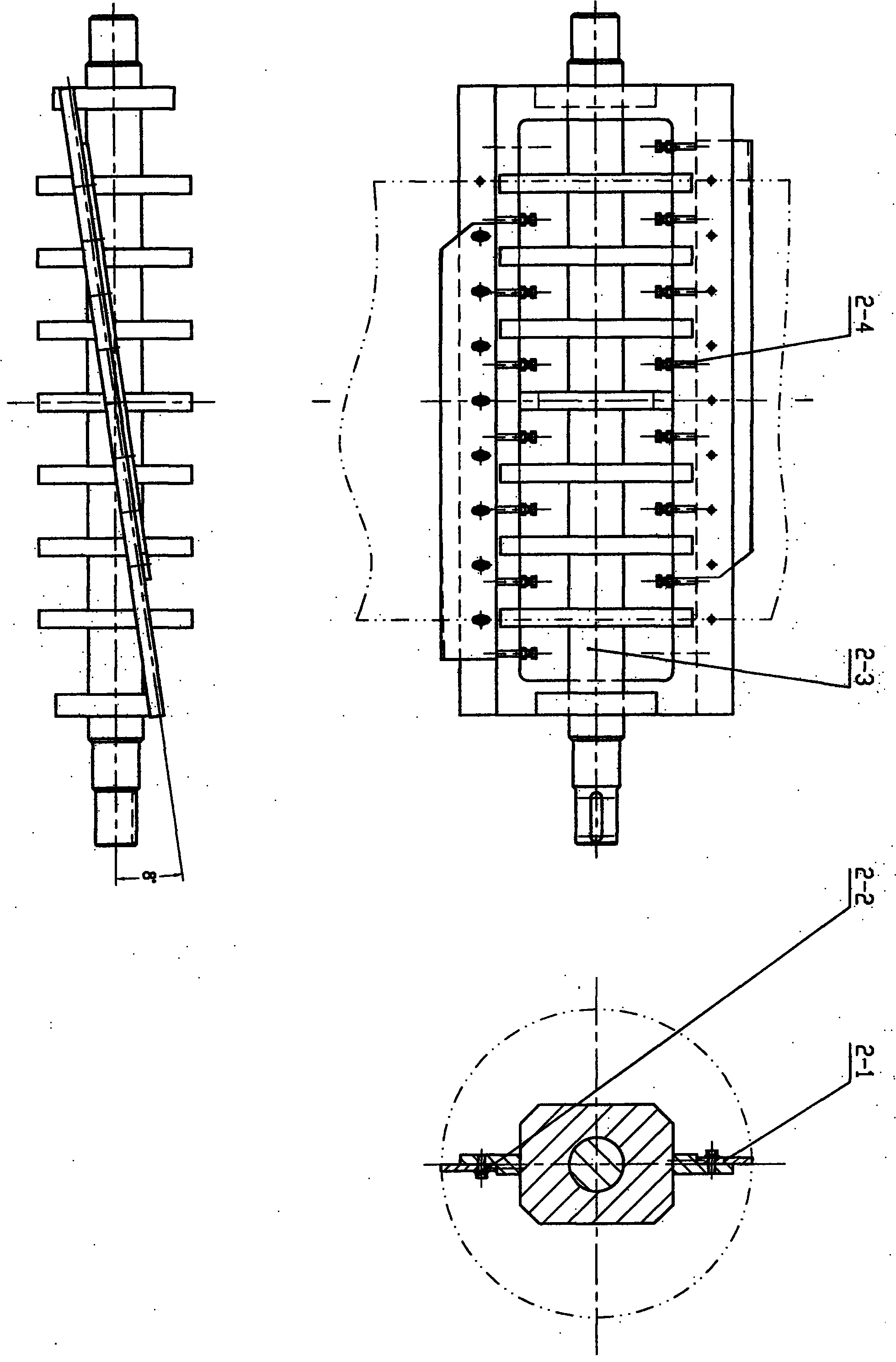

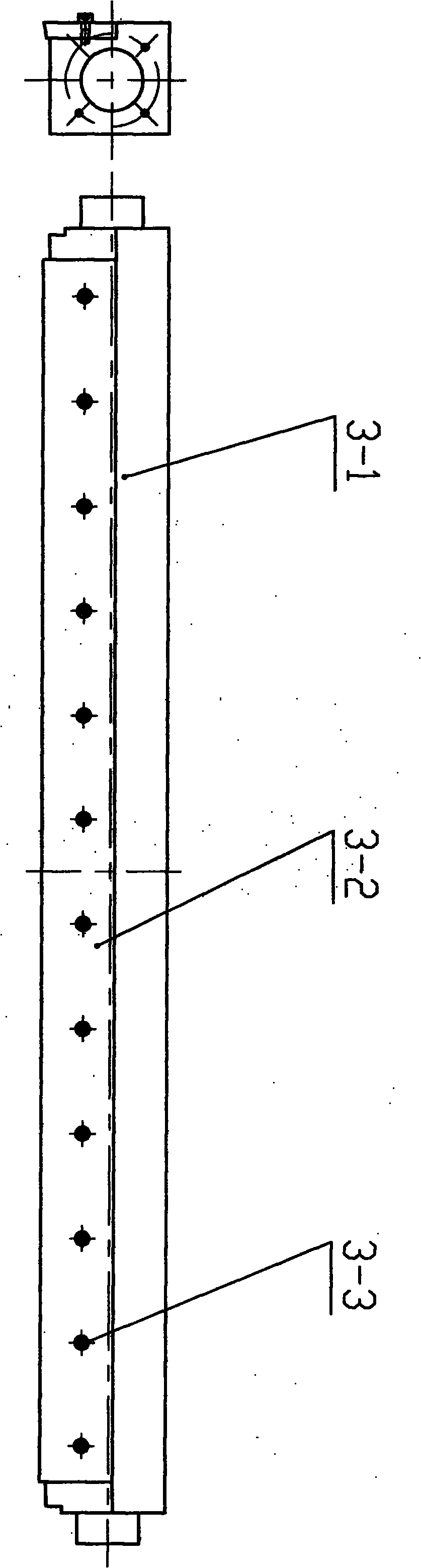

[0018] Embodiment: the hob type film cutting device of the present invention (see attached figure 1 ) is composed of a rolling knife assembly (1-1), a fixed knife assembly (1-2) and a supporting knife rest (1-3) connecting the two. The cut film continuously passes through the gap between the hob and the fixed knife at a certain speed, and the hob assembly driven by the transmission device also rotates continuously at a certain speed, so that the two hobs installed on the hob shaft frame Staggered and fixed knives are tangent, because the two hobs are installed opposite to each other on the frame plane, and their positions are staggered in the direction of the long side of the frame (see attached figure 2 ), the length of each hob is shorter than the width of the film, the superimposed length of the installed two hobs is greater than the width of the film, and the length of the fixed knife is greater than the installed superimposed length of the two hobs, so that each knife in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com