A kind of preparation method of fireproof cable

A technology of fireproof cable and waterproof layer, applied in cable/conductor manufacture, insulation of conductor/cable, circuit, etc., can solve the problems of destructive discharge of cable insulation, unstable current, damage of cable insulation structure, etc., to reduce fire The probability of resistance, the effect of preventing the increase of resistance and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

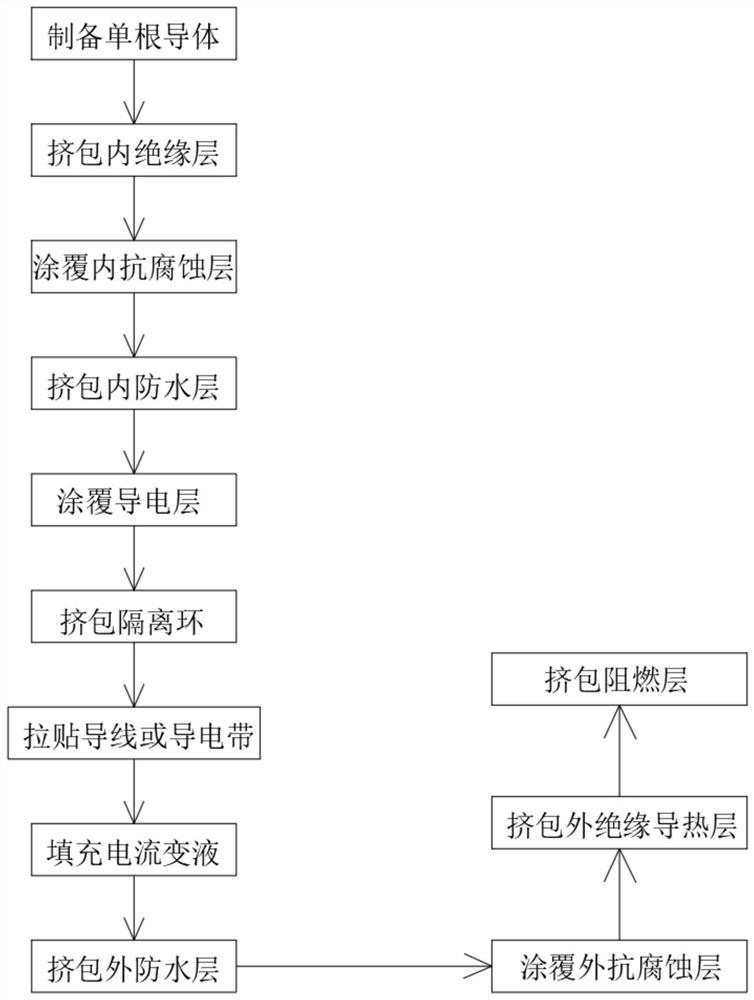

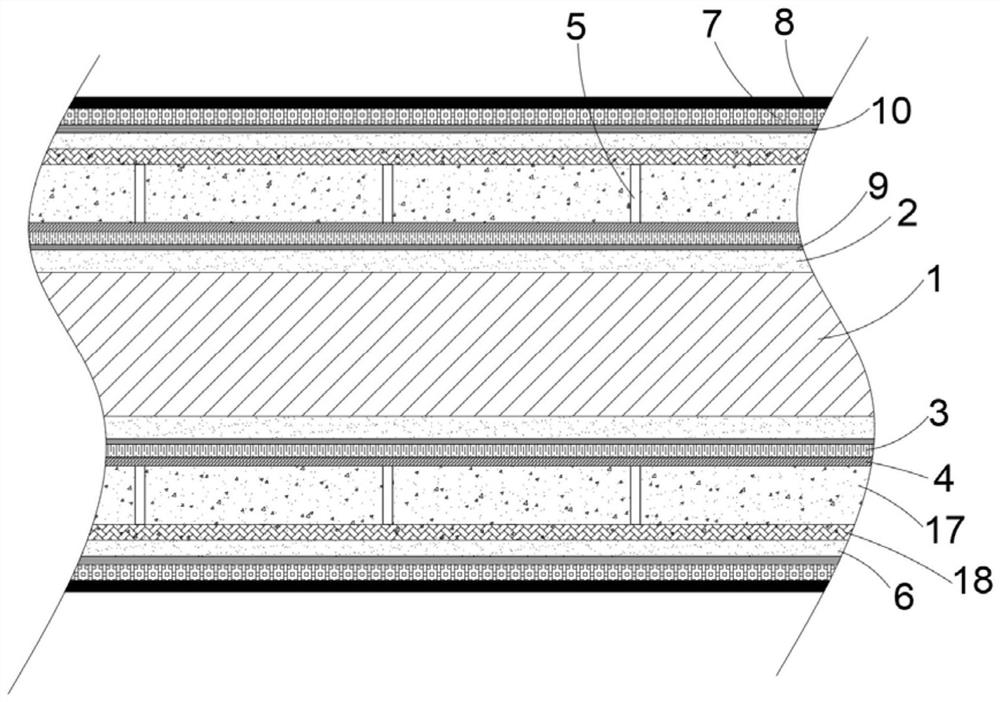

[0034] see figure 1 and figure 2 As shown, a preparation method of a fireproof cable includes a single conductor 1 formed by drawing a single wire, annealing the single wire, and forming it, and at least includes the following steps:

[0035] ①Extrude the inner insulating layer 2, and coat the inner insulating layer 2 on the conductor 1;

[0036] ②Extrude the inner waterproof layer 3, and cover the inner waterproof layer 3 on the insulating layer 2;

[0037] 3. Coating the conductive layer 4, coating the conductive layer 4 outside the inner waterproof layer 3 and drying;

[0038] ④Extrude the isolation ring 5, extrude the package outside the conductive layer 4 at a certain time interval, and extrude the package for a short time each time, so that the isolation ring 5 is covered on the outer surface of the conductive layer 4, and the adjacent isolation rings 5 are separated by a certain distance to form a groove, During or after the extrusion process, one or more thin wir...

Embodiment 1

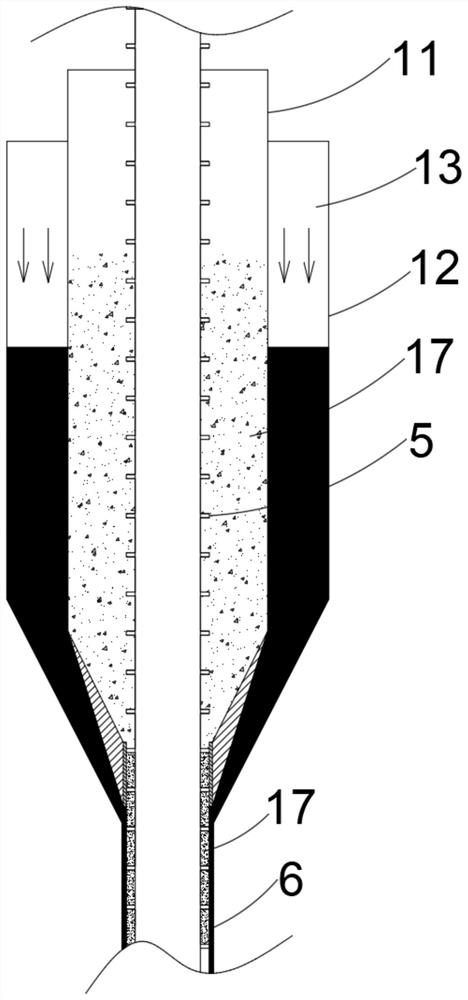

[0048] see image 3 , the extruder used in step 5. comprises an upright inner cylinder 11 and an outer cylinder 12 sleeved outside the inner cylinder 11; the inner cylinder 11 and the outer cylinder 12 are both bullet-shaped with a diameter gradually reduced from top to bottom, and the The outlet at the lower end of the inner cylinder 11 is slightly larger than the diameter of the isolation ring 5; the inner cylinder 11 and the outer cylinder 12 enclose an extrusion cavity 13 whose diameter is gradually reduced from top to bottom; the cable passes through the inner cylinder 11 from top to bottom , and the lower end of the extrusion cavity 13 is covered by the outer waterproof layer 6 extruded under pressure in the extrusion cavity 13; The electrorheological fluid 17 filled in the groove is also encapsulated therein.

Embodiment 2

[0050] see Figure 4 , the device for filling the electrorheological fluid 17 in step ⑤ comprises a vertical bullet-shaped cylinder 14; the lower end of the cylinder 14 is connected to an upright thermally conductive connecting pipe 15; the inner diameter of the thermally conductive connecting pipe 15 is separated from the isolation The diameter of the ring 5 is the same or slightly larger than the diameter of the isolation ring 5; the cable passes through the cylinder 14 and the heat conducting connecting pipe 15 from top to bottom; The heat exchange tube 16 circulates the refrigerant to freeze the electrorheological fluid 17 filled in the groove of the cable passing through the heat conduction connecting tube 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com