Central pipe film-falling drying pot reboiling device for vacuum water distilling and generating oxygen-18

A central tube and reboiler technology, applied in fractionation, boiling equipment, oxygen preparation, etc., can solve the problems of high operating costs, investment costs and increased operating costs, and achieve low operating costs, low cost, continuous and stable process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

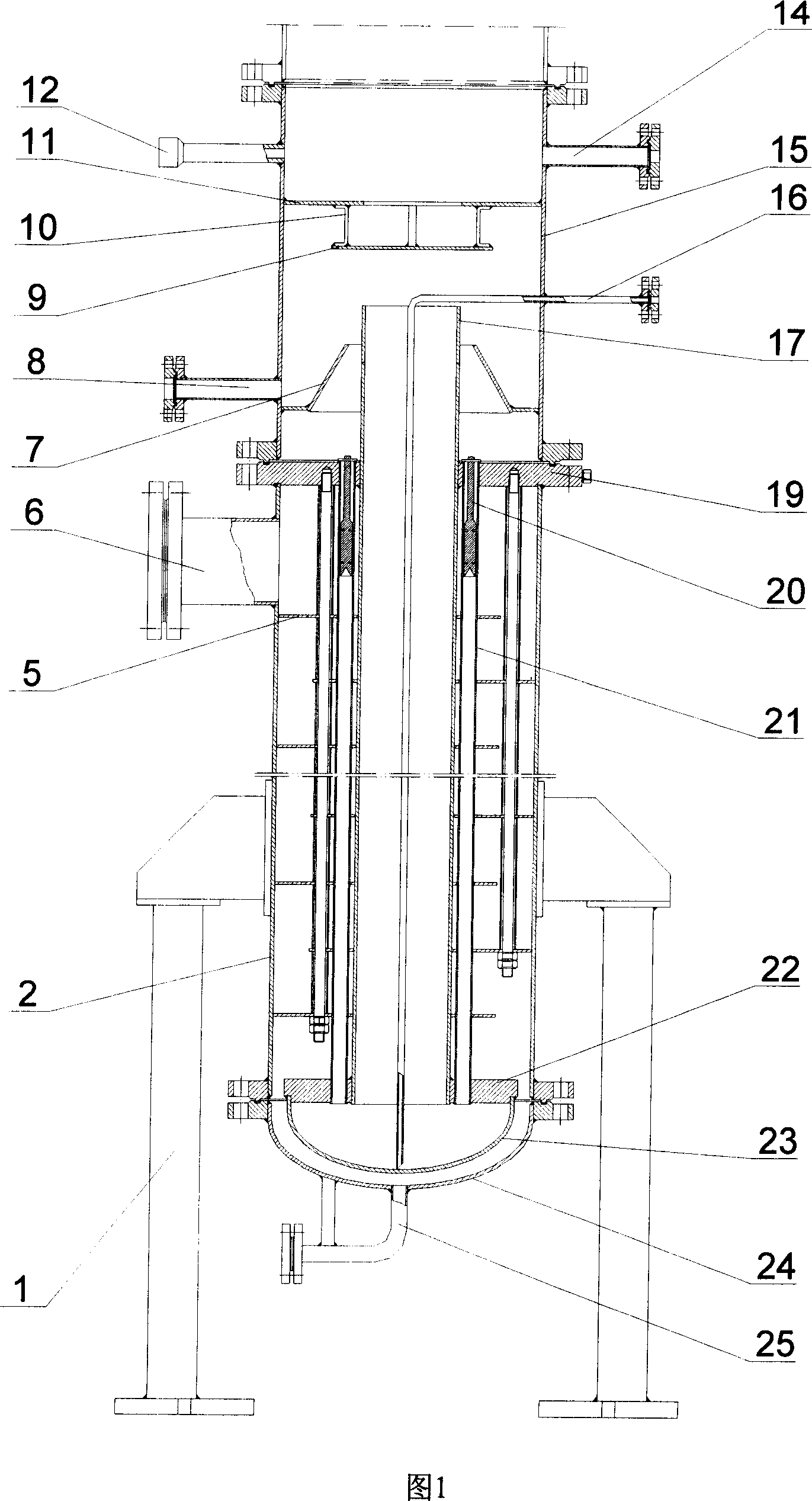

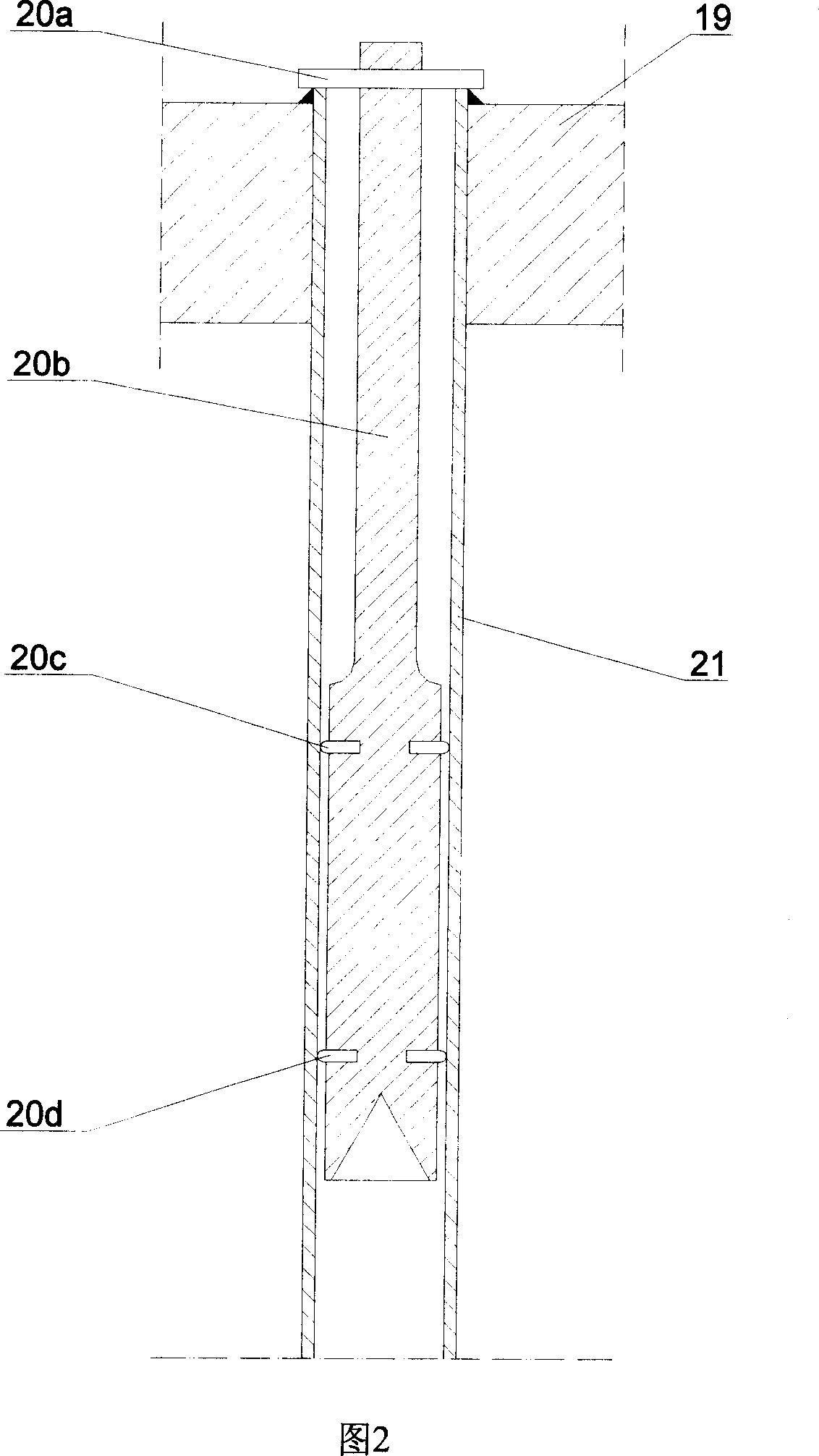

[0040] As shown in Figure 1, in a typical embodiment of the present invention, the central tube falling film dry kettle reboiler for producing oxygen-18 by vacuum water rectification includes: an upper body connected in sequence from top to bottom 15. The lower body 2 and the bottom head 24, the partition ring 11 arranged in the middle of the upper body 15, the U-shaped hangers 10 distributed around the inner circular hole of the partition ring 11, and the round ring welded to the lower end of the U-shaped hanger 10. shaped baffle plate 9, the liquid collection weir 7 located below the circular baffle plate 9, the liquid outlet connecting pipe 8 located at the bottom of the upper body 15, the tube plate 19 welded to the upper port of the lower body 2, which runs through the lower body 2 And stretch out the central tube 17 of liquid collection weir 7 upwards, be locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com