High-hardness end-capped one-component baking type finishing coat resin and preparation method and application thereof

A technology of resin and end-capping agent, which is applied in the field of one-component color paint, can solve the problems of great difference in molecular weight, affecting the water resistance of the paint, unstable gloss of the paint film, etc., and achieve the effect of meeting the coating requirements and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

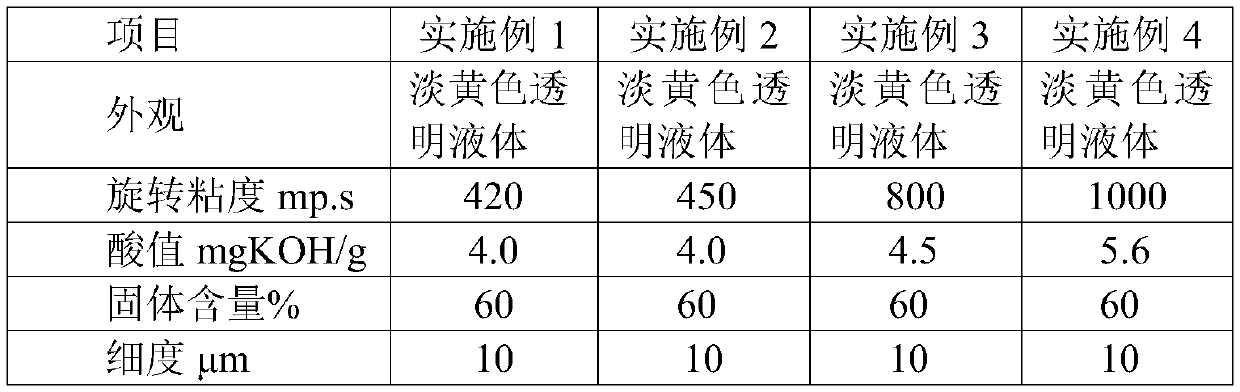

Embodiment 1

[0030] Weigh 66.5g isooctanoic acid, 77g trimethylolpropane, 112g neopentyl glycol, 171.5g phthalic anhydride, 105g isophthalic acid, 35g E-10P, 0.3g catalyst monobutyltin oxide, 0.3g Put the antioxidant and 60g xylene into a four-necked flask with nitrogen, and install a water separation and reflux device, heat up to 160-170°C for 1 to 2 hours to reflux, and keep warm at this temperature for 1 hour. , and then use 2 to 3 hours to heat up to 200°C to 210°C for reaction. During the reaction, the water in the water separator is properly released according to the heating rate, and the reaction is kept at 200-210°C until the acid value is 24mgKOH / g to 28mgKOH / g , Cone and plate viscosity 520CP.s~600CP.s (150℃, No. 3 rotor), cool down to below 135℃, slowly add 28g end-capping agent epoxycyclohexane dropwise to keep it from reflux, heat up to 160℃~190℃ and keep warm React until the acid value is 8mgKOH / g-10mgKOH / g, and the cone-plate viscosity is 480CP.s-560CP.s (150°C, No. 3 ro...

Embodiment 2

[0032] Weigh 31.5g trimethylolpropane, 147g neopentyl glycol, 31.5g BEPD, 157.5g phthalic anhydride, 87.5g isophthalic acid, 63g adipic acid, 17.5g E-10P, catalyst 0.3g mono Put butyl tin oxide, 0.3g antioxidant and 60g xylene into a four-necked flask with nitrogen, and install a water separation and reflux device, heat up to 160-170°C for 1 hour to 2 hours and reflux, and The temperature is kept for 1 hour. After the heat preservation is over, it takes 2-3 hours to raise the temperature to 200°C~210°C for reflux reaction, and keep the temperature at 200°C~210°C until the acid value is 24mgKOH / g~28mgKOH / g. The heating rate is appropriate to release the water in the water separator, and reflux reaction at 200℃~210℃ until the acid value is 24mgKOH / g~28mgKOH / g, and the cone and plate viscosity is 520CP.s~600CP.s (150℃, No. 3 rotor) , lower the temperature to below 135°C, slowly add 28g of capping agent epoxycyclohexane dropwise to keep it from reflux, raise the temperature to 1...

Embodiment 3

[0034]Weigh 45.5g of methylpropanediol, 25.2g of trimethylolpropane, 119g of neopentyl glycol, 14g of BEPD, 171.5g of phthalic anhydride, 120.4g of isophthalic acid, 35g of adipic acid, 56g of E-10P, Put 0.5g of monobutyltin oxide catalyst, 0.3g of antioxidant and 60g of xylene into a four-necked flask with nitrogen, and install a water separation and reflux device, and heat up to 160-170°C for 1-2 hours to reflux. And keep it at this temperature for 1 hour. After the heat preservation is over, heat it up to 200°C-210°C for 2-3 hours to react. During the reaction, release the water in the water separator according to the heating rate, and keep it warm at 200°C-210°C. React until the acid value is 24mgKOH / g-28mgKOH / g, the cone-plate viscosity is 520CP.s-600CP.s (150°C, No. 3 rotor), cool down to below 135°C, and slowly add 28g of end-capping agent cyclohexane epoxy Maintain no reflux, raise the temperature to 160°C~190°C and keep it warm until the acid value is 8mgKOH / g~10mgK...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com