A kind of anti-ultraviolet color repairing agent and preparation method thereof

A UV-resistant and color-repairing technology, applied in radiation-absorbing coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of different UV-resistant properties of coatings, avoid easy delamination after standing, and meet the needs of assembly lines. Effect of coating requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than Full examples.

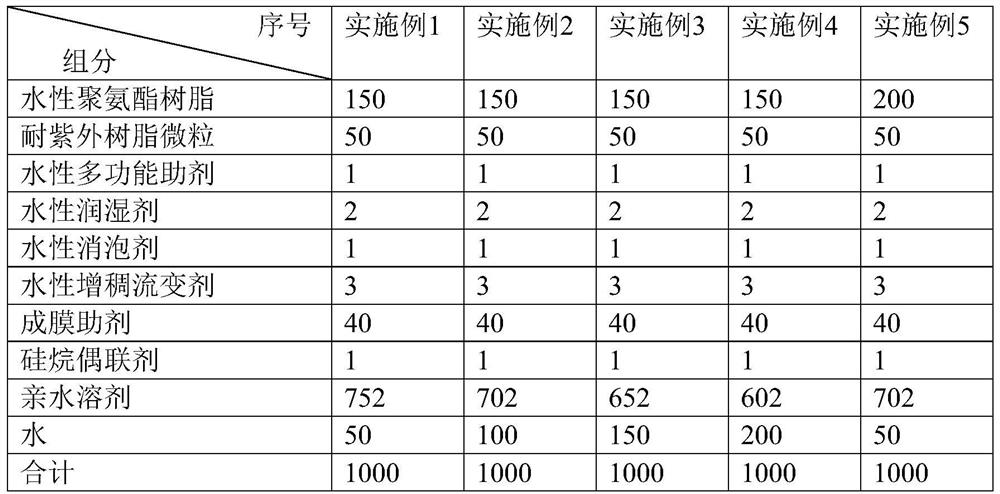

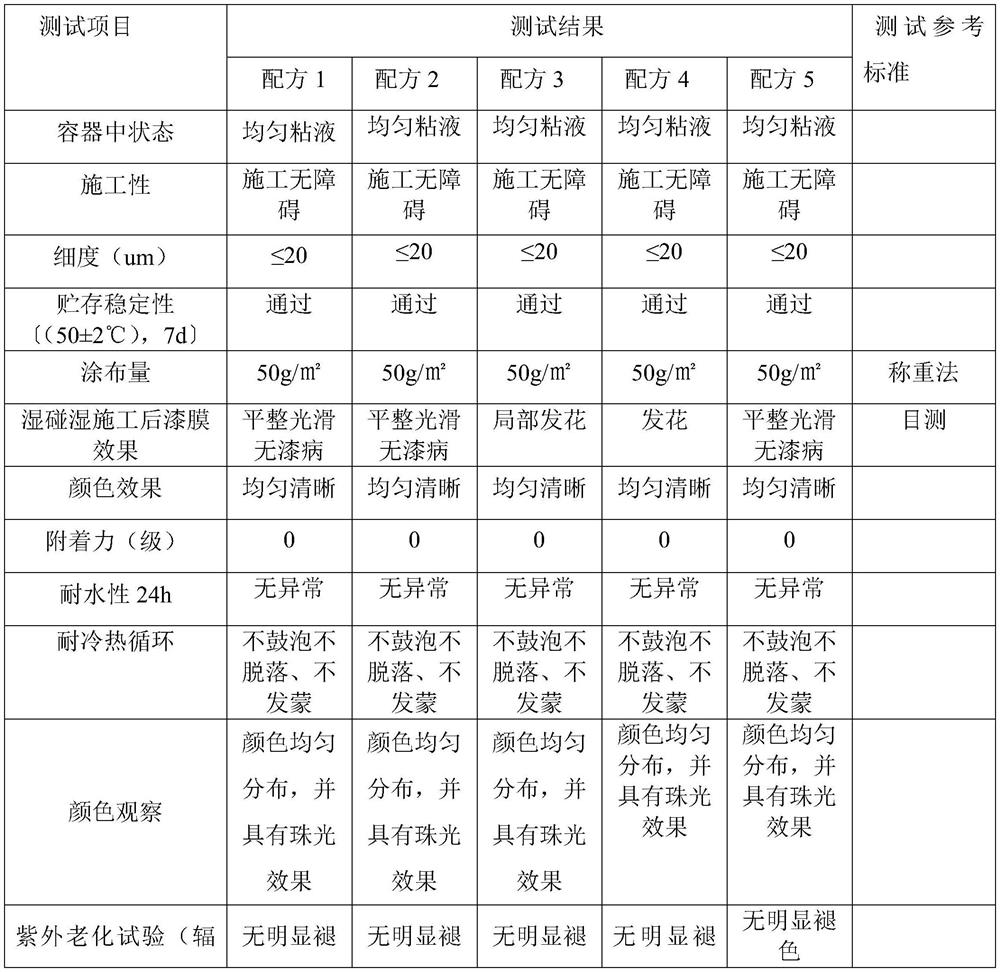

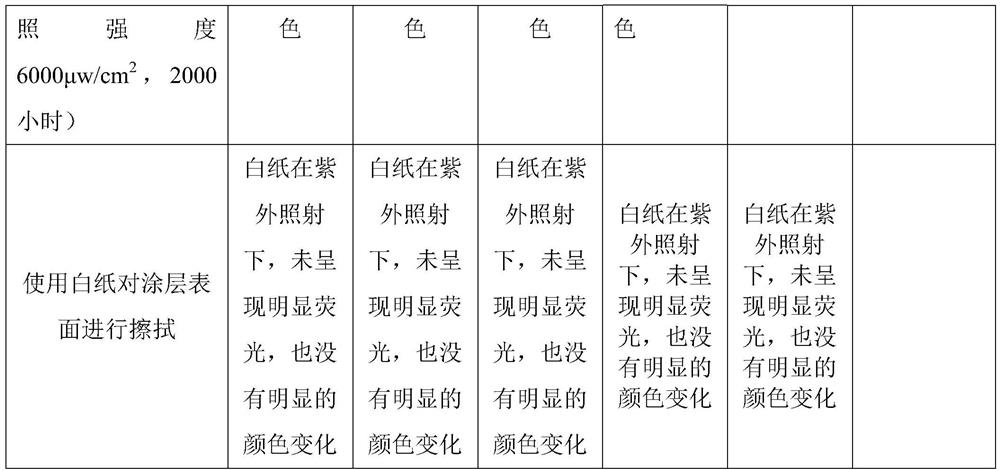

[0036] The components of Embodiment 1-5 of the present invention are as follows:

[0037] The water-based polyurethane resin is an anionic aliphatic polyester polycarbonate water-based polyurethane that does not contain solvent-free, low-viscosity, and free isocyanate groups. The solid content is 35 parts by weight, the pH is 7.5-8.5, and the MFFT is 5. ℃, density 1.05g / cm3, can choose the water-based polyurethane resin of U9150 brand of Oubaodi company; the water-based multi-functional auxiliary agent adopts AMP-95 multi-functional auxiliary agent, which can adjust the pH value, synergistically strengthen the dispersant, defoaming agent, leveling agent, etc....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com