Pine water-based grain-protruding-prevention white primer and preparing method thereof

A water-based, anti-swelling technology, applied in the direction of coating, etc., can solve the problems of pine wood tending to swell, and achieve the effects of saving processes, improving leveling wettability, and excellent film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

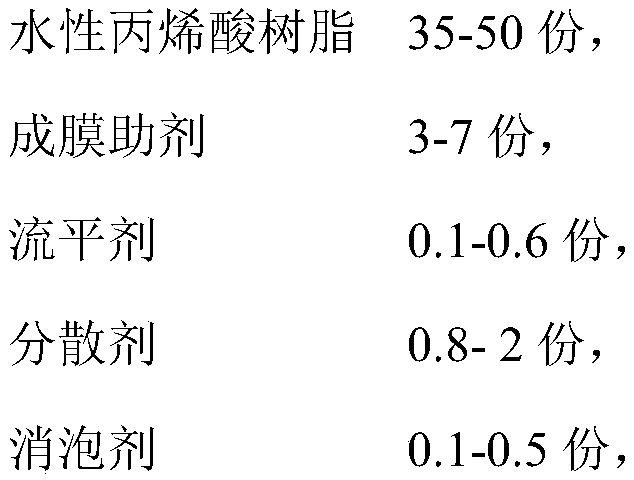

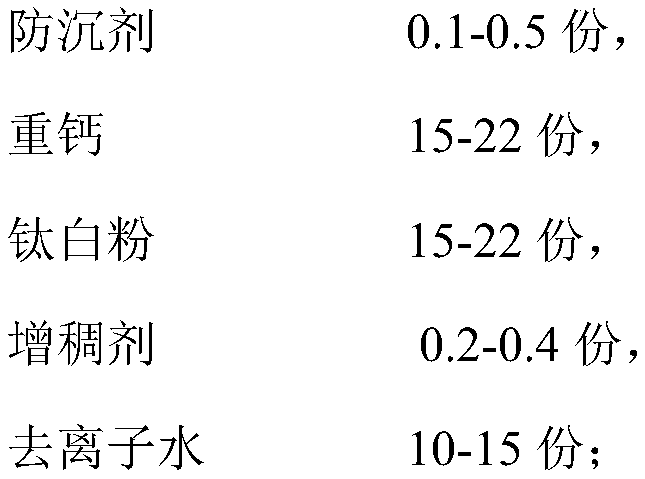

Method used

Image

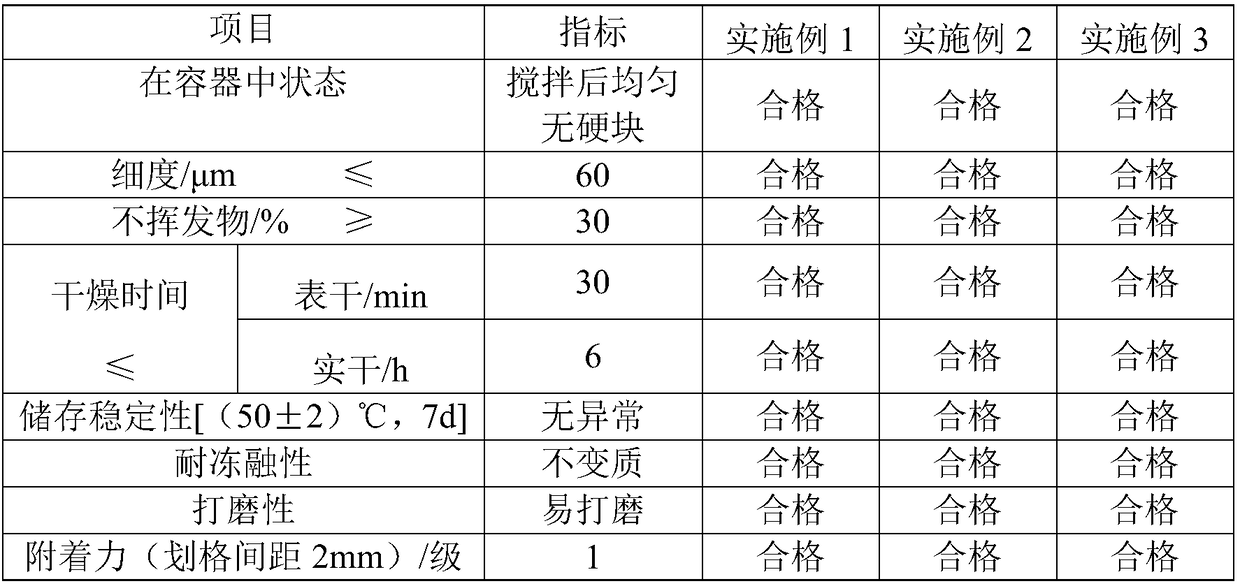

Examples

Embodiment 1

[0041] A preparation method for pine water-based anti-expansion tendon white primer, comprising the following steps:

[0042] (1) Add 10 parts of deionized water into the material preparation tank, add 0.3 parts of TEGO 825, 1.1 parts of TEGO755W and 0.1 part of BYK420 at 500r / min, stir for 15-20min at 1000r / min; add 18 parts of 800 mesh heavy calcium and 18 parts of rutile titanium dioxide, stirred at 1000r / min for 15-20min, added 0.1 part of RM-8W under stirring at 1000r / min, stirred for 10-15min, passed through a grinder, and ground to a fineness of ≤15μm to obtain a white slurry for later use.

[0043] (2) At 500r / min, add 10 parts of 4298 emulsion and 37.7 parts of 4088 emulsion, 0.1 part of TEGO 825, 0.5 part of BYK346, stir at 1000r / min for 15-20min, add 1 part of dipropylene glycol methyl ether, 1 part of Dipropylene glycol butyl ether, 1 part of alcohol ester-12 and 1 part of deionized water, stirred at 1000r / min for 15-20min, added the white slurry ground in step (1)...

Embodiment 2

[0047] A preparation method for pine water-based anti-expansion tendon white primer, comprising the following steps:

[0048] (1) Add 10 parts of deionized water into the material preparation tank, add 0.2 parts of TEGO 825, 1.1 parts of TEGO755W and 0.1 part of BYK420 at 500r / min, stir for 15-20min at 1000r / min; add 15 parts of 800 mesh heavy calcium and 21 parts of rutile titanium dioxide, stirred at 1000r / min for 15-20min, added 0.1 part of RM-8W under stirring at 1000r / min, stirred for 10-15min, passed through a grinder, and ground to a fineness of ≤15μm to obtain a white slurry for later use.

[0049] (2) At 500r / min, add 20 parts of 4298 emulsion and 23.1 parts of 4088 emulsion, 0.2 parts of TEGO 825, 0.4 parts of BYK346, stir at 1000r / min for 15-20min, add 1.5 parts of dipropylene glycol methyl ether, 2 parts of Dipropylene glycol butyl ether, 2 parts of alcohol ester-12 and 3 parts of deionized water, stirred at 1000r / min for 15-20min, added the white slurry ground in ...

Embodiment 3

[0053] A preparation method for pine water-based anti-expansion tendon white primer, comprising the following steps:

[0054] (1) Add 9.9 parts of deionized water into the material preparation tank, add 0.3 parts of TEGO 825, 1 part of TEGO 755W and 0.2 parts of BYK420 at 500r / min, stir for 15-20min at 1000r / min; add 21 parts of 800 mesh heavy calcium at 500r / min With 15 parts of rutile titanium dioxide, stir at 1000r / min for 15-20min, add 0.1 part of RM-8W under stirring at 1000r / min, stir for 10-15min, pass through a grinder, and grind to a fineness of ≤15μm to obtain a white slurry for later use.

[0055] (2) At 500r / min, add 30 parts of 4298 emulsion and 15 parts of 4088 emulsion, 0.1 part of TEGO 825, 0.4 part of BYK346, stir at 1000r / min for 15-20min, add 2 parts of dipropylene glycol methyl ether, 1.5 parts of Dipropylene glycol butyl ether, 1.5 parts of alcohol ester-12 and 3 parts of deionized water, stirred at 1000r / min for 15-20min, added the white slurry ground in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com