Waterborne wood coating and preparation method thereof

A wood coating, water-based technology, applied in the field of coatings, can solve problems such as human harm and environmental pollution, and achieve the effects of preventing penetration, increasing solid content and improving filling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A water-based wood coating, the formula includes: polyurethane dispersion, hydroxyacrylic acid emulsion, filler, film-forming aid, nano-alumina, wetting agent, thickening agent, dispersing agent and defoaming agent, the weight percentage of each raw material They are: 50% polyurethane dispersion, 40% hydroxy acrylic emulsion, 0.1% filler, 0.1% film-forming aid, 8.5% nano-alumina, 0.1% wetting agent, 0.1% thickener, 0.1% dispersant, Defoamer 1%.

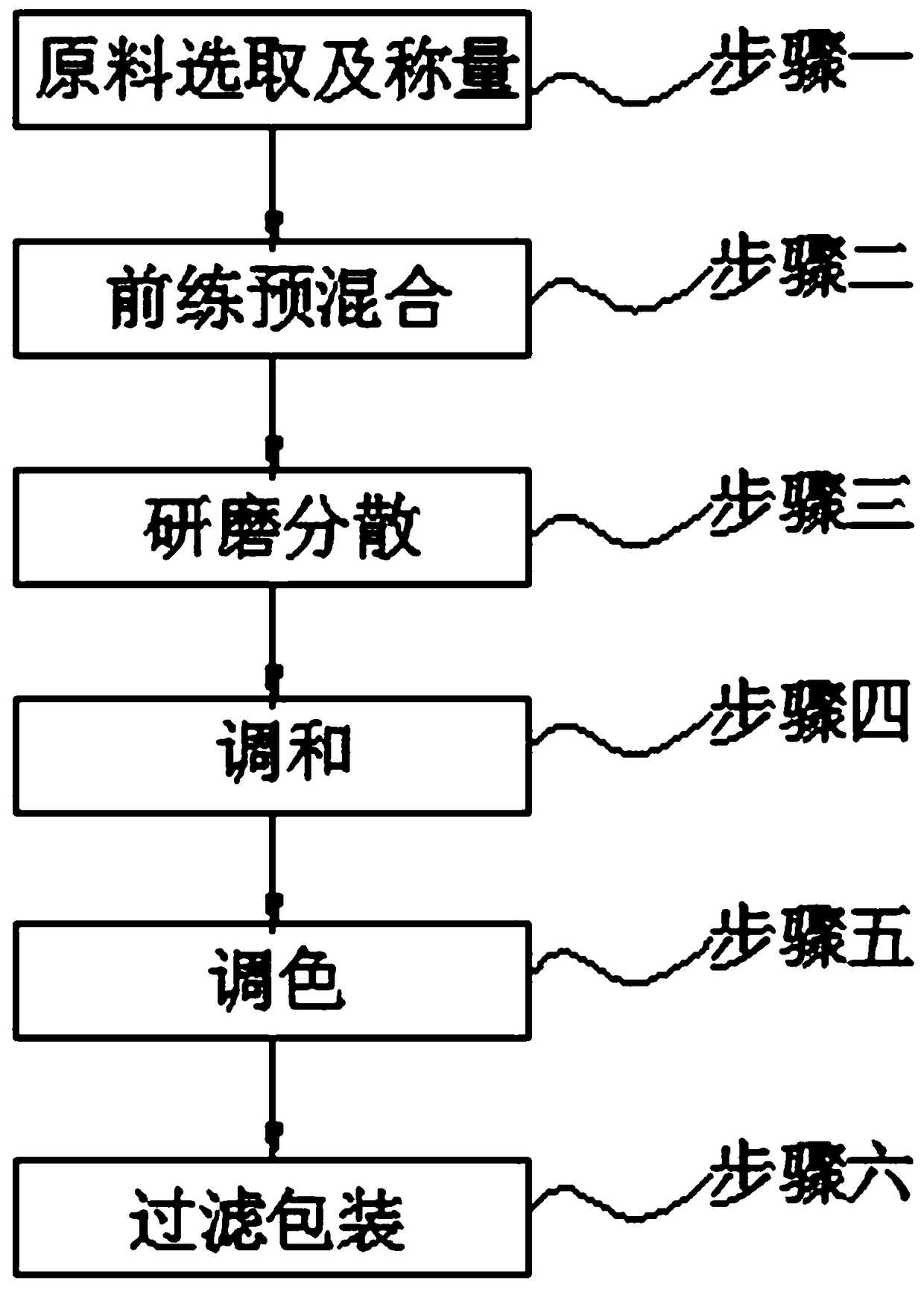

[0026] A method for preparing water-based wood coatings, comprising the following steps: step 1, raw material selection and weighing; step 2, pre-training and premixing; step 3, grinding and dispersing; step 4, blending; step 5, toning; step 6, filtering Package;

[0027] Wherein in the above-mentioned step 1, according to the weight percentages, they are: polyurethane dispersion 50%, hydroxyacrylic acid emulsion 40%, filler 0.1%, film-forming aid 0.1%, nano-alumina 8.5%, wetting agent 0.1%, Thickener 0.1%, dispersant 0.1%, d...

Embodiment 2

[0035] A water-based wood coating, the formula includes: polyurethane dispersion, hydroxyacrylic acid emulsion, filler, film-forming aid, nano-alumina, wetting agent, thickening agent, dispersing agent and defoaming agent, the weight percentage of each raw material They are: polyurethane dispersion 45%, hydroxy acrylic emulsion 45%, filler 0.5%, film-forming aid 0.5%, nano-alumina 7%, wetting agent 0.5%, thickener 0.5%, dispersant 0.5%, Defoamer 0.5%.

[0036] A method for preparing water-based wood coatings, comprising the following steps: step 1, raw material selection and weighing; step 2, pre-training and premixing; step 3, grinding and dispersing; step 4, blending; step 5, toning; step 6, filtering Package;

[0037] Wherein in the above-mentioned step 1, according to the weight percentages, they are: polyurethane dispersion 45%, hydroxyacrylic acid emulsion 45%, filler 0.5%, film-forming aid 0.5%, nano-alumina 7%, wetting agent 0.5%, Thickener 0.5%, dispersant 0.5%, def...

Embodiment 3

[0045] A water-based wood coating, the formula includes: polyurethane dispersion, hydroxyacrylic acid emulsion, filler, film-forming aid, nano-alumina, wetting agent, thickening agent, dispersing agent and defoaming agent, the weight percentage of each raw material They are: 40% polyurethane dispersion, 50% hydroxy acrylic emulsion, 0.1% filler, 0.1% film-forming aid, 8.5% nano alumina, 0.1% wetting agent, 1% thickener, 0.1% dispersant, Defoamer 0.1%.

[0046] A method for preparing water-based wood coatings, comprising the following steps: step 1, raw material selection and weighing; step 2, pre-training and premixing; step 3, grinding and dispersing; step 4, blending; step 5, toning; step 6, filtering Package;

[0047] Wherein in the above-mentioned step 1, according to the weight percentages, they are: polyurethane dispersion 40%, hydroxyacrylic acid emulsion 50%, filler 0.1%, film-forming aid 0.1%, nano-alumina 8.5%, wetting agent 0.1%, Thickener 1%, dispersant 0.1%, def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com