Coating and paint spraying system

A painting and spray booth technology, applied in the spray booth, spraying device, etc., can solve the problems of environmental pollution, personal health impact of spray workshop personnel, etc., and achieve the effect of meeting the painting requirements and facilitating later disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

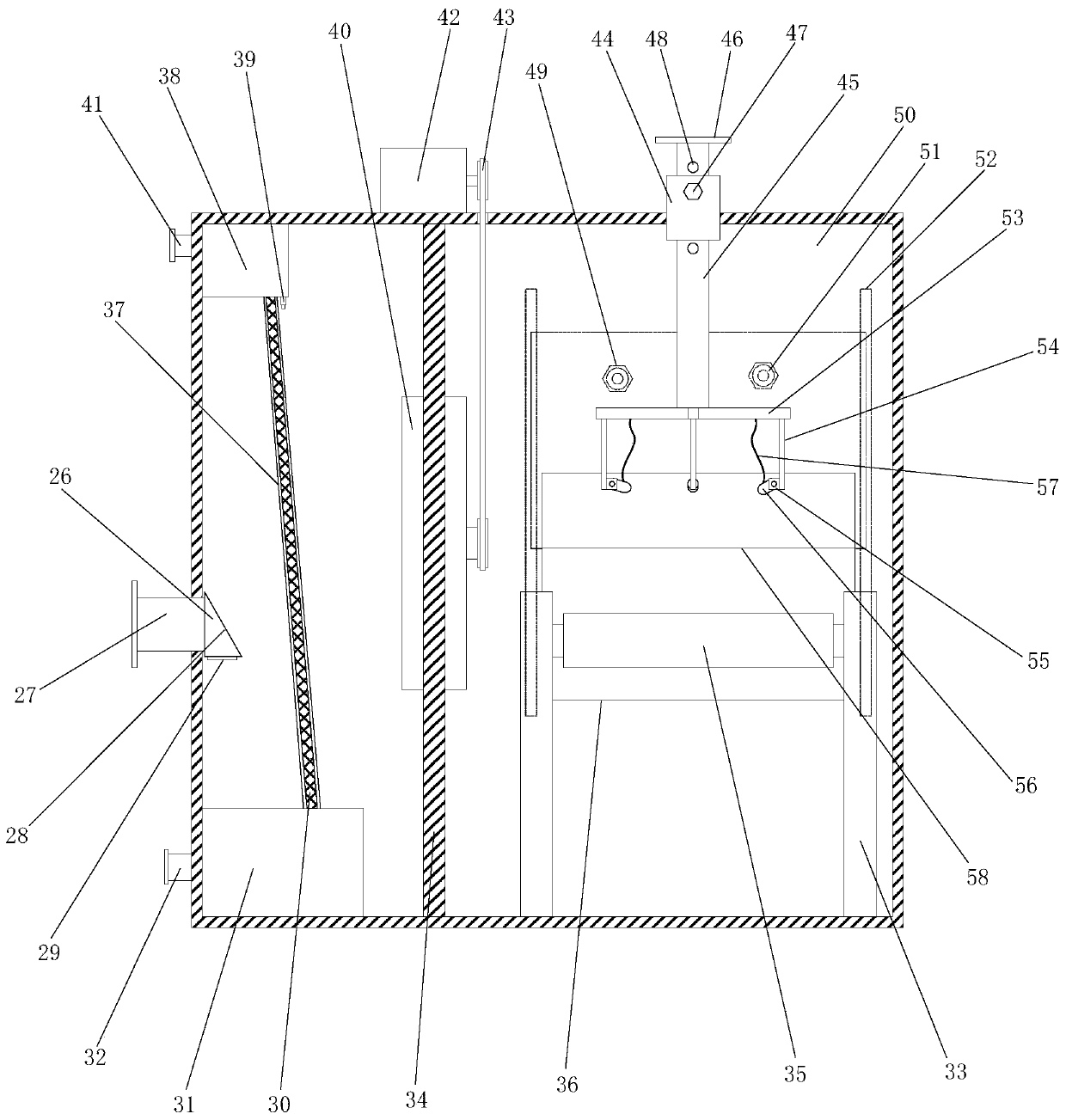

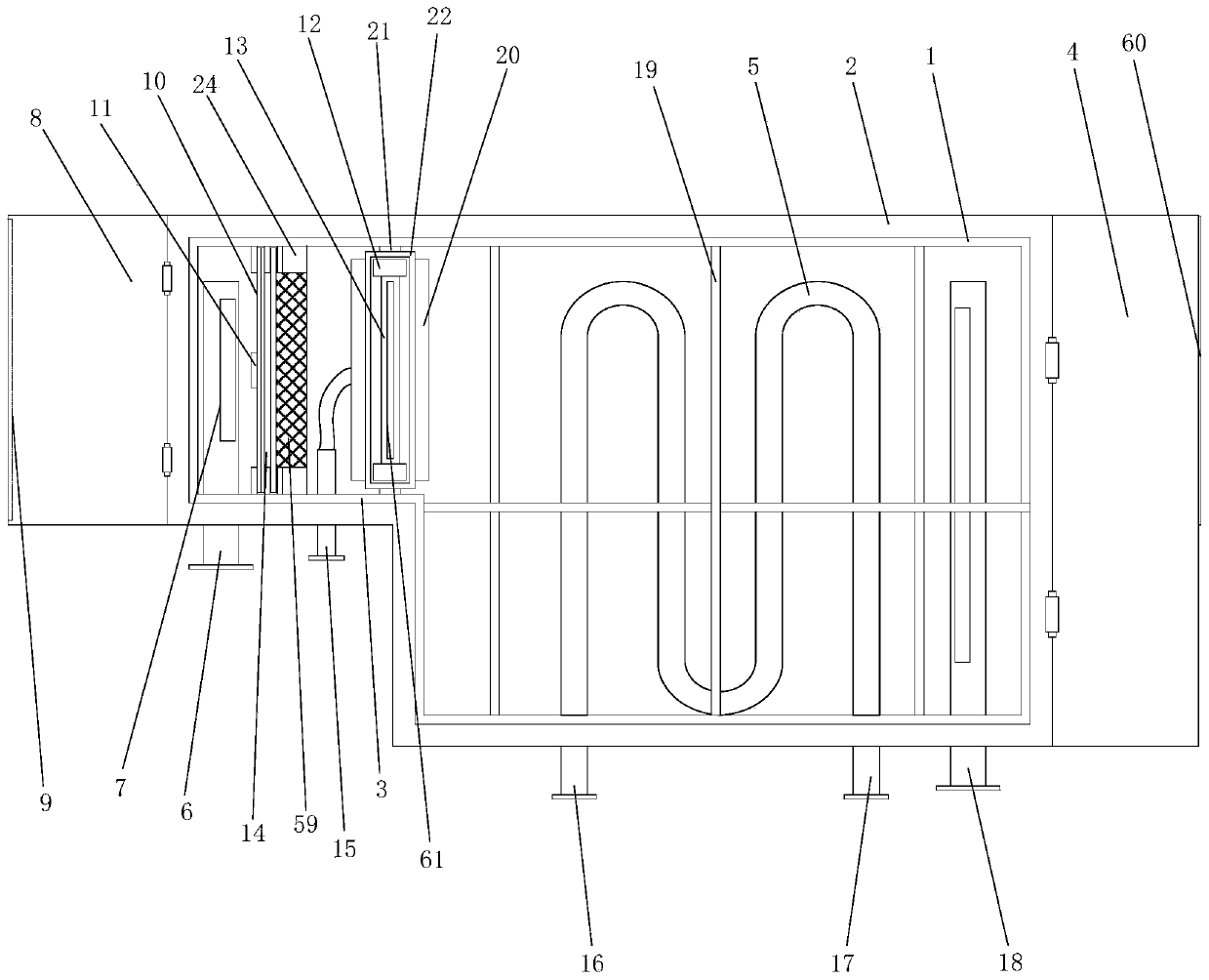

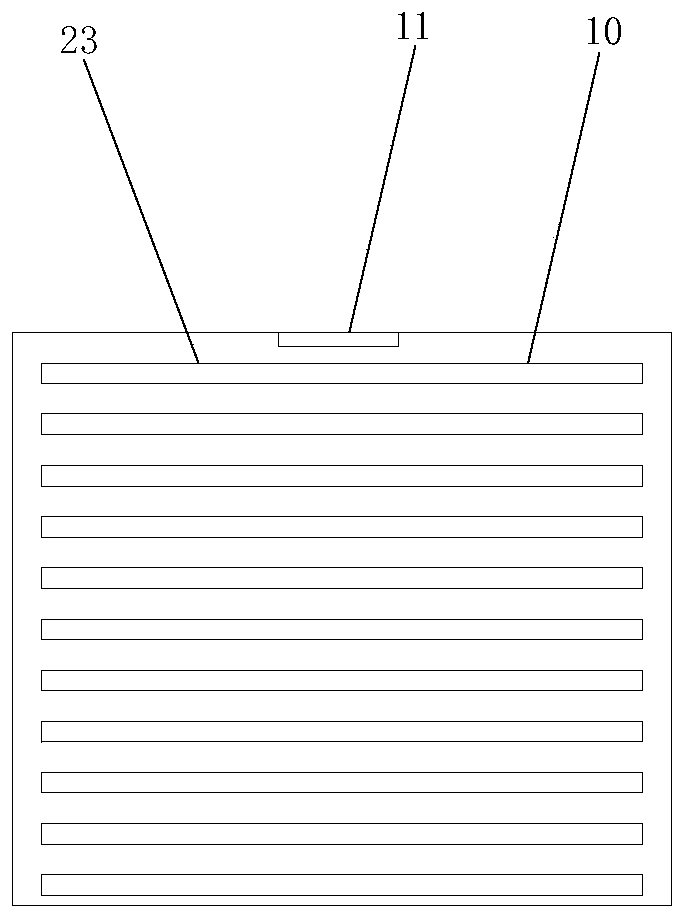

[0026] Such as Figure 1-3 As shown, the painting and spraying system disclosed by the present invention includes: comprising a spray booth and a water circulation device;

[0027] The paint spray booth includes a housing 50, an axial flow fan 40, a strip water storage tank 38, a steel mesh plate 30, a water collection tank 31, a conveyor belt 35 and a paint spray mechanism;

[0028] A partition plate 34 is vertically arranged inside the housing 50 to divide the interior of the housing 50 into a left cavity and a right cavity; the axial fan 40 is fixedly installed on the partition plate 34, and the air outlet is located on the left side. In the side cavity, the air inlet is located in the cavity on the right side; a driving motor 42 is installed on the outer top of the housing 50, and the driving motor 42 drives the axial flow fan 40 to rotate through the chain 43; the strip water storage tank 38 is fixed and installed vertically On the inner top of the cavity on the left sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com