Special high-permeability moisture-curing seal primer for concrete as well as preparation method and application thereof

A technology for sealing primer and concrete, applied in climate change adaptation, coating, anti-corrosion coatings, etc., can solve the problems of single performance, high VOC content of coatings, unable to form dense coatings, etc., to reduce the difficulty of surface treatment, reduce Corrosive medium penetration, low surface treatment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

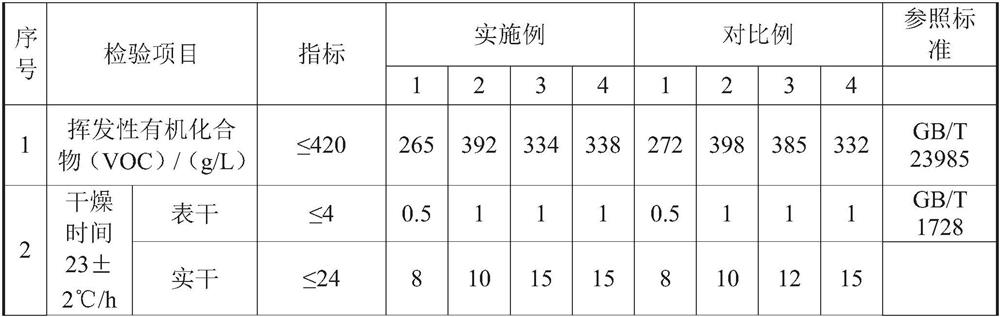

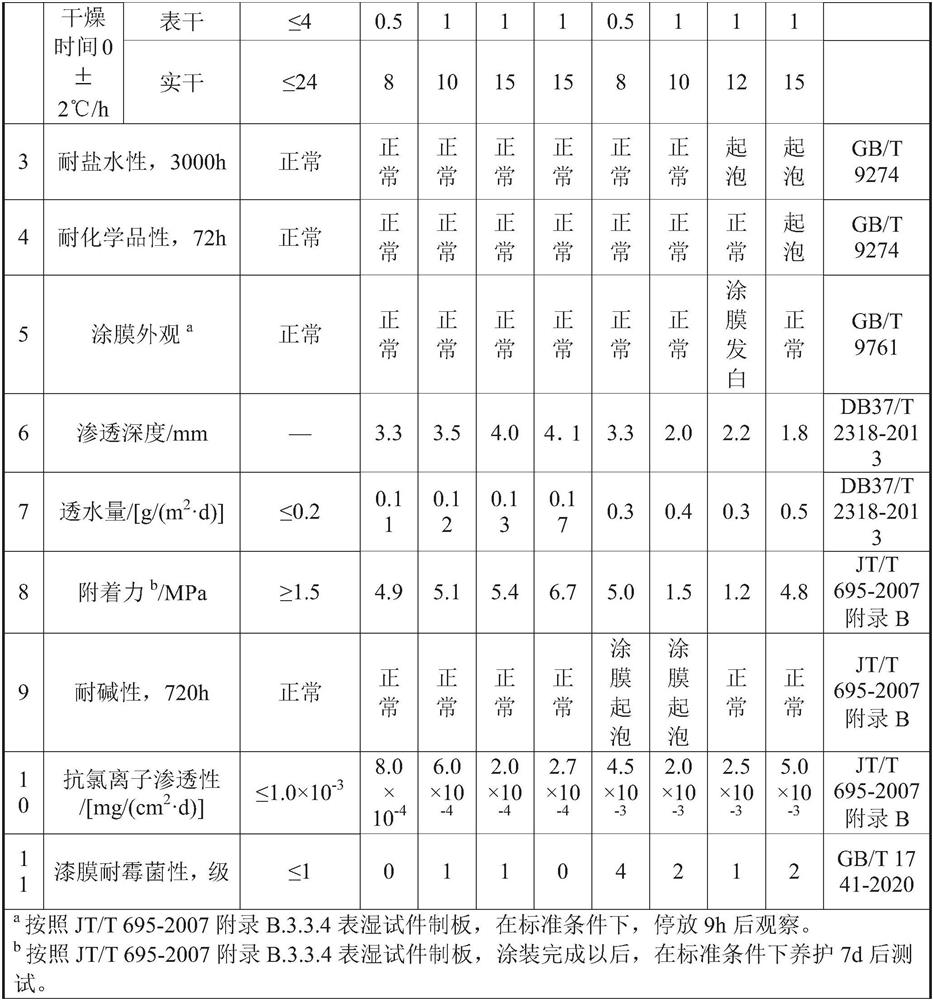

Examples

preparation example Construction

[0038]Another aspect of the embodiments of the present invention also provides a method for preparing the aforementioned high-penetration moisture-curing sealing primer for concrete, comprising:

[0039] Mix quaternary ammonium salt-modified epoxy resin, butanol and xylene, then add wetting and dispersing agent, graft coupling agent, anti-settling agent, reactive diluent, graphene, silver-loaded zirconium phosphate, and basalt flakes in turn. Stir and disperse, then add pigments and fillers to mix and adjust the viscosity of the obtained mixture to form the A component;

[0040] Mix phenalkamine, phenalkamide curing agent, butanol and xylene, then add wetting and dispersing agent, anti-settling agent, graphene, basalt flakes, mix, stir and disperse, then add pigment and filler to mix and adjust the viscosity of the obtained mixture, forming the B component;

[0041] And, the A component and the B component are mixed and cured to obtain a high-penetration moisture-curing seali...

Embodiment 1

[0079] In this embodiment, the special high-penetration moisture-curing sealing primer for concrete includes A component and B component, and A component is made of the following components according to the total weight of 100 parts: 30.0 parts of quaternary ammonium salt modified epoxy resin, Add 6.0 parts of alcohol and 5.0 parts of xylene to the mixing pot and stir at a speed of 3000r / min for 5 minutes. While stirring, add 1.5 parts of ANTI-TERRA-U dispersant, 0.5 part of KH560 coupling agent, and polyamide wax anti-settling agent in turn. 2.0 parts, 5.0 parts of NC-513 active diluent, 2.0 parts of silver-loaded zirconium phosphate, 1.0 parts of graphene, 12.0 parts of basalt flakes. 9.0 parts of mica powder and 8.0 parts of zinc phosphate, continue to stir at the same speed for 15 minutes, grind to a fineness of ≤80 μm by a sand mill, adjust the viscosity with xylene to a viscosity of -4 cups for 60s, cool to room temperature, filter and pack to obtain A components.

[00...

Embodiment 2

[0083] In this embodiment, the high-penetration moisture-curing sealing primer for concrete includes A component and B component, and A component is made of the following components according to the total weight of 100 parts: 39.7 parts of quaternary ammonium salt-modified epoxy resin, 10.0 parts of alcohol and 25.0 parts of xylene were added to the mixing pot and stirred at a speed of 3000r / min for 5 minutes. While stirring, 0.8 parts of ANTI-TERRA-U dispersant, 3.5 parts of KH560 coupling agent, and polyamide wax anti-settling agent were added in turn. 1.0 parts, 3.0 parts of NC-513 active diluent, 1.0 parts of silver-loaded zirconium phosphate, 1.5 parts of graphene, 4.5 parts of basalt flakes. 3.0 parts of mica powder and 2.0 parts of zinc phosphate, continue to stir at the same speed for 15min, grind to a fineness of ≤80μm by a sand mill, adjust the viscosity with xylene to a viscosity of -4 cups for 30s, cool to room temperature, filter and pack to obtain A components. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com