Anticorrosive viscoelastic body rubber belt and preparation method thereof

A viscoelastic body and adhesive tape technology, applied in chemical instruments and methods, adhesives, film/sheet adhesives, etc., can solve the problems of anti-corrosion failure of heat-shrinkable tapes, inconvenient on-site operation, poor bonding of hot-melt adhesives, etc. problems, to achieve the effect of eliminating water intrusion and microbial corrosion, the technical level of construction personnel is small, and the treatment requirements are low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Accurately weigh the raw materials for preparing viscoelastic glue according to the following formula:

[0048] Butyl rubber (IIR268) 5kg, high molecular weight polyisobutylene (PIB B80) 8kg, medium molecular weight polyisobutylene (PIB B12) 30kg, low molecular weight polyisobutylene (PIB 2300) 15kg, activated calcium carbonate 40kg, antioxidant (1010) 0.5 kg, anti-aging agent (264) 0.5kg, colorant (phthalocyanine green) 1kg.

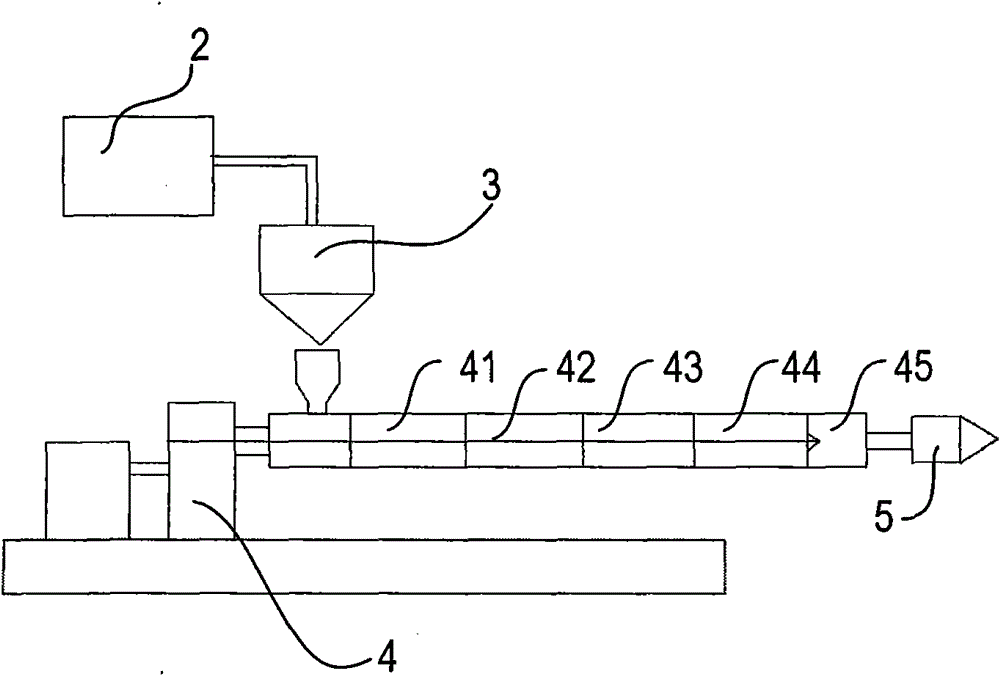

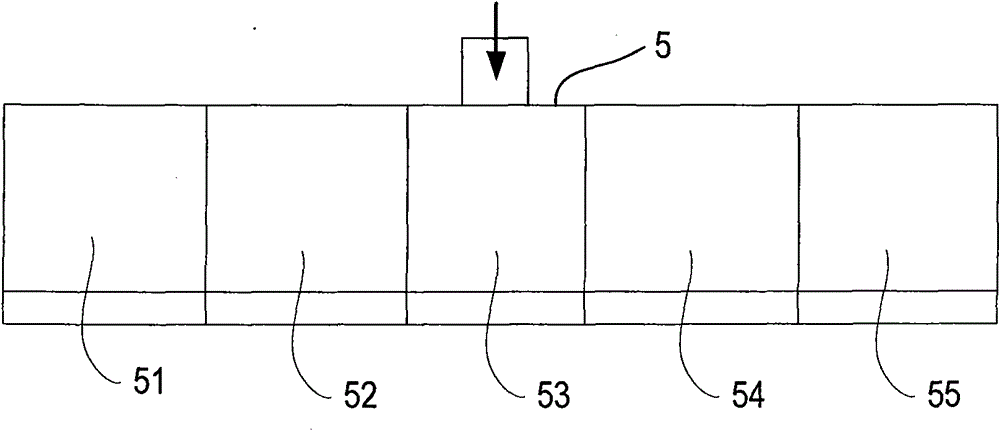

[0049] like figure 2 As shown, the above-mentioned weighed raw materials for preparing the viscoelastic glue are put into the kneader 2, and kneaded at 130±15° C. for 1 to 1.5 hours to make the glue. The cement is transported to the reactor 3 through a single-screw feeder for secondary mixing. The mixing temperature in the reactor is 110±10°C, and the mixing time is 0.5 to 1 hour. The cement mixed in the reaction kettle 3 is transported to the extruder 4 by a gear pump for mixing. The extruder 4 is equipped with a flat slit die forming die 5 ....

Embodiment 2

[0056] Adopt the method for embodiment 1, change the formula of elastic viscose glue as follows:

[0057] Butyl rubber (IIR268) 5kg, high molecular weight polyisobutylene (PIB B80) 5kg, medium molecular weight polyisobutylene (PIB B12) 35kg, low molecular weight polyisobutylene (PIB2300) 15kg, activated calcium carbonate 38kg, antioxidant (1010) 0.5kg , anti-aging agent (268) 0.5kg, colorant (phthalocyanine green) 1kg.

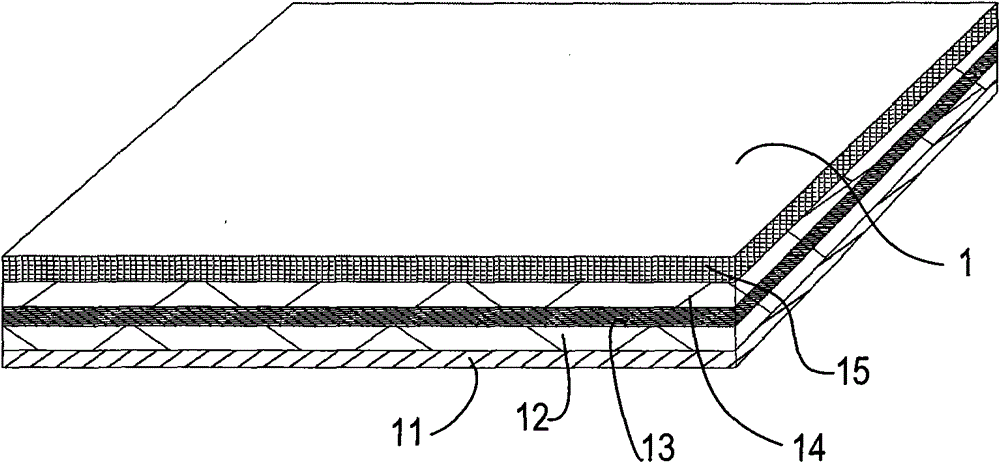

[0058] The reinforcement net 131 adopts a 0.1mm thick polyethylene net, the protective film 11 adopts a 0.05mm thick medium density polyethylene film, the release film 15 adopts a 0.075 thick PET release film, the first viscoelastic adhesive layer 12, the reinforcement net The total thickness of the layer 13 and the second viscoelastic adhesive layer 14 is 2.0-2.2mm.

[0059] The shear strength of the viscoelastic tape at 23±2°C is 0.035MPa, the shear strength at 50±2°C is 0.015MPa, and the peel strength at 23±2°C is 5N / cm. The peeling state is cohesive failu...

Embodiment 3

[0061] Adopt the method for embodiment 1, change the formula of elastic viscose glue as follows:

[0062] Butyl rubber (IIR268) 3kg, high molecular weight polyisobutylene (PIB B80) 10kg, medium molecular weight polyisobutylene (PIB B12) 30kg, low molecular weight polyisobutylene (PIB2300) 15kg, activated calcium carbonate 40kg, antioxidant (1010) 0.5kg , anti-aging agent (264) 0.5kg, colorant (phthalocyanine green) 1kg.

[0063] The reinforcement net 131 adopts a 0.1mm thick polyethylene net, the protective film 11 adopts a 0.05mm thick medium density polyethylene film, the release film 15 adopts a 0.075 thick PET release film, the first viscoelastic adhesive layer 12, the reinforcement net The total thickness of the layer 13 and the second viscoelastic adhesive layer 14 is 2.0-2.2mm.

[0064] The shear strength of the viscoelastic tape at 23±2°C was 0.040MPa, the shear strength at 50±2°C was 0.018MPa, the peel strength at 23±2°C was 5N / cm, and the peeling state was cohesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com