Machine tool body made from waste glass

A technology of waste glass and machine tools, which is applied in the field of machine tool beds, can solve the problems of affecting the machining performance of machine tools, being unable to degrade naturally, and poor vibration damping, so as to promote the sustainable development of resources, improve the performance of machine tools, and improve the anti-vibration performance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A machine bed made of waste glass, mainly made of the following raw materials in parts by weight: 75 parts of waste glass flakes and broken glass sand (including 45 parts of waste glass flakes and 30 parts of broken glass sand), 8 parts of waste glass powder 1 part, 7 parts of epoxy resin, 1.75 parts of curing agent, 1 part of carbon fiber, 1 part of basalt fiber, 1 part of bismuth, and 10 parts of silica powder.

[0027] The size of the waste glass pieces is 3-15mm, the size of the broken glass sand is 0.5-3mm, and the glass powder is 30-100 mesh. The alumina powder is 200-300 mesh powder. The silica powder is 500 powder. The carbon fiber and basalt fiber are short fibers with a length of 35-150 mm. The curing agent is a modified phenalkamine curing agent. The waste glass powder, silica powder and alumina powder are charged. The carbon fiber has an electric charge opposite in polarity to that of the discarded meal meal powder.

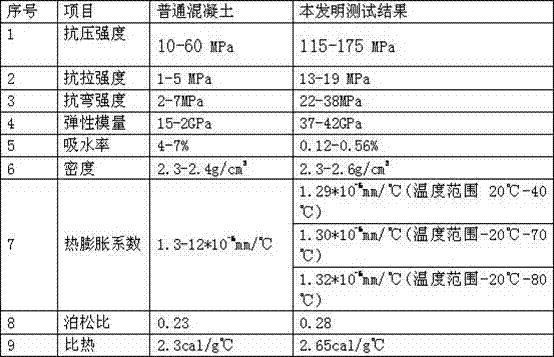

[0028] The performance of the machi...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, the difference is that:

[0041] A machine bed made of waste glass, mainly made of the following raw materials in parts by weight: 70 parts of waste glass flakes and broken glass sand (including 35 parts of waste glass flakes and 30 parts of broken glass sand), 10 parts of waste glass powder , 10 parts of epoxy resin, 2.5 parts of curing agent, 1 part of carbon fiber, 1 part of basalt fiber, 1 part of antimony, 8 parts of silica powder, and 10 parts of alumina powder.

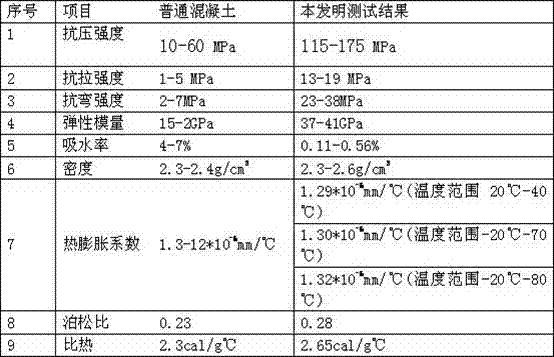

[0042] The performance of the machine tool bed cast according to the present embodiment is tested as follows:

[0043] Table four, embodiment two machine bed performance test parameters

[0044]

[0045] Table five, embodiment two anti-vibration analysis

[0046] Order

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com