Latent active filler composition, solvent-free high-temperature-resistant permeation-resistant liquid polymer coating material, coating and preparation method thereof

A technology of active fillers and coating materials, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of inability to meet the application requirements of heavy corrosion coatings, and achieve the effect of high permeability resistance and high Tg value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

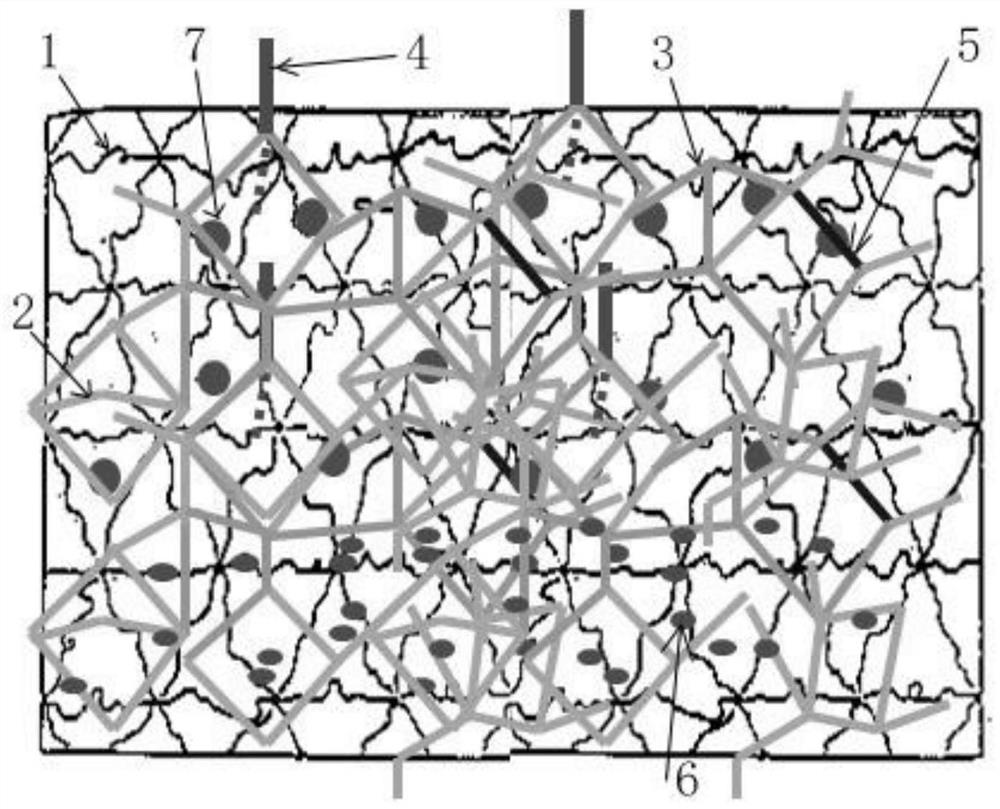

Image

Examples

Embodiment 1-3

[0179] A kind of latent active filler composition that the embodiment of the present invention 1-3 provides: with solid epoxy resin composition E G The main resin raw materials, by mass percentage, include the raw material components shown in Table 1.

[0180] The raw material composition (by mass percentage) of latent active filler composition in the embodiment 1-3 of table 1

[0181] composition Example 1 Example 2 Example 3 Solid Epoxy Composition E G

67% 63% 65% Modified phenolic curing agent Amanda 879X 12% 12% 11% 2-Methylimidazole Accelerator 0.30% 0.2% 0.3% Leveling agent (silicone acrylic) 1.10% 1.5% 1.2% Loose flow dispersant (fumed silica) 0.29% 0.39% 0.28% Degasser (benzoin) 0.50% 0.5% 0.5% Graphene 0.01% 0.01% 0.02% Silicon carbide 10% 12% 11% Mica powder 5% 6% 6% Porous powder quartz 3% 3% 3.5% Gold stone titanium dioxide 0.80% 1.4% 1.2%

[0182] Wherei...

Embodiment 4-6

[0193] A kind of solvent-free anti-high-temperature anti-penetration liquid polymer coating material provided by the present embodiment 4-6 is a composite coating material, including a primer coating material and a surface coating material; the primer coating material is composed of A D , B D Composition of three components, chopped fiber composition, surface coating material A M and B M Composed of two components. The composite coating material according to A D , B D , chopped fiber composition, A M and B M The five components are individually packaged. Wherein, embodiment 4 adopts the latent active filler composition prepared in embodiment 1, embodiment 5 adopts the latent active filler composition prepared in embodiment 2, embodiment 6 adopts the latent active filler composition prepared in embodiment 3, Add it to Base Coat Material A D and top coat material AM middle. Detailed A D , B D , chopped fiber composition, A M and B M See Table 3-7.

[0194] Table 3 ...

Embodiment 7-9

[0219] Present embodiment 7-9 prepares coating according to the prescription of the coating material in embodiment 4-6, concrete steps are as follows:

[0220] (1)A D Preparation of components:

[0221] (A) first liquid epoxy resin composition ED Y According to the ratio in Table 3, pre-mix in the reaction kettle at 120 degrees for 0.5-1h, discharge and cool to room temperature for use.

[0222] (B) According to the proportioning in Table 2, the liquid epoxy resin composition ED mixed in the above step (1) Y Add a platform type high and low speed disperser, and add to the resin composition ED under the stirring state at a low speed of 100-200r / min. Y Add active diluent, blend, then add latent active filler composition, flake filler, dispersant, defoamer to disperse for 1 hour; then add leveling agent, disperse at high speed of 700-900r / min for 0.5 hour to disperse evenly ; Then the horizontal sand mill grinds to a fineness of 40-60 μm, samples are detected every 10 minutes...

PUM

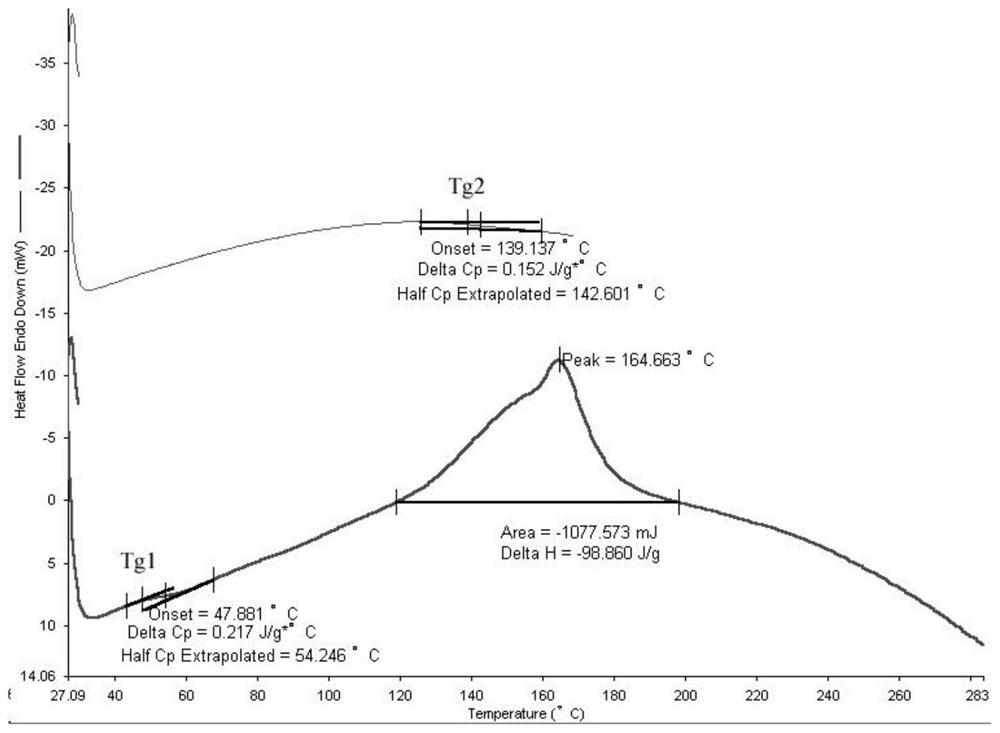

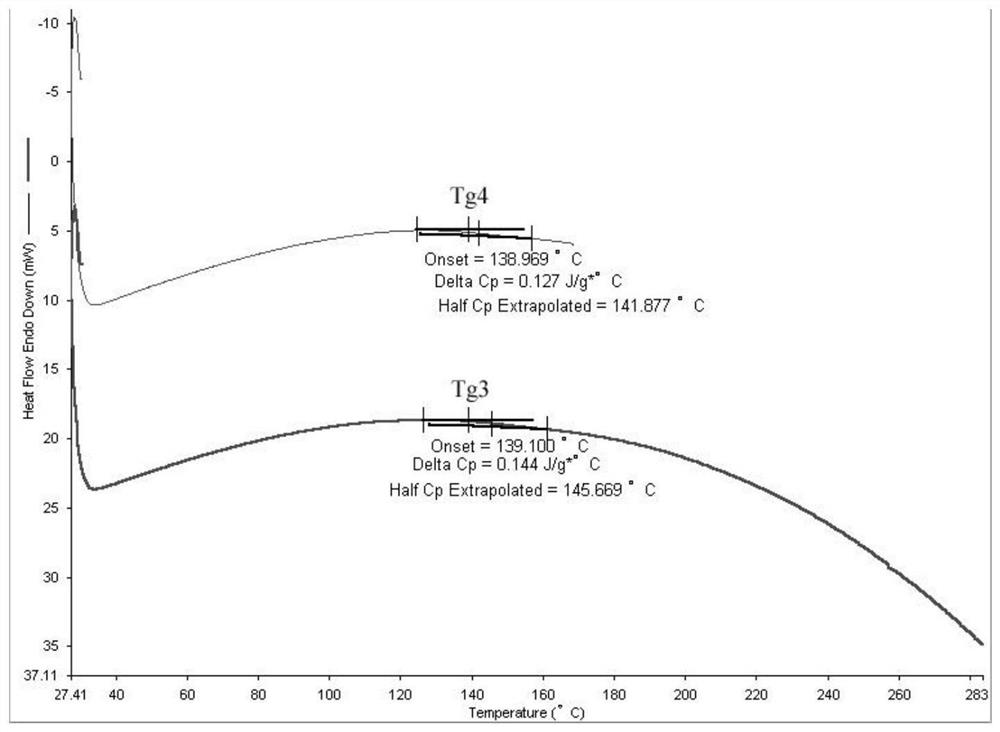

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com