High-hardness acrylate-modified polysiloxane resin and coating employing high-hardness acrylate-modified polysiloxane resin as base material

A kind of polysiloxane resin, acrylate technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

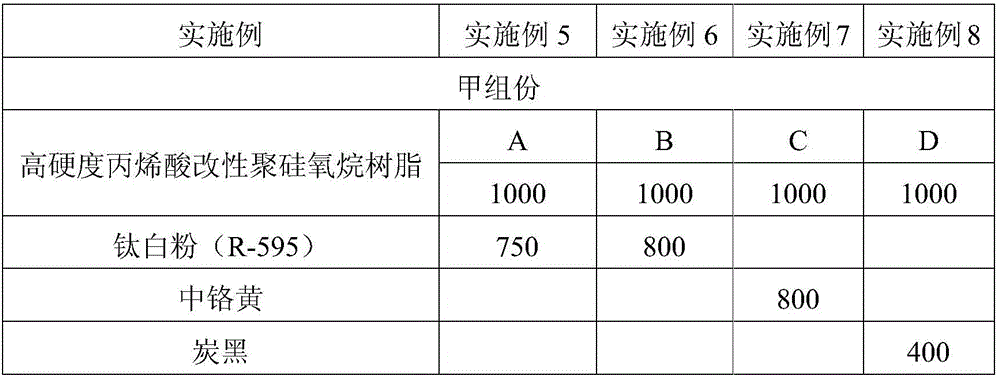

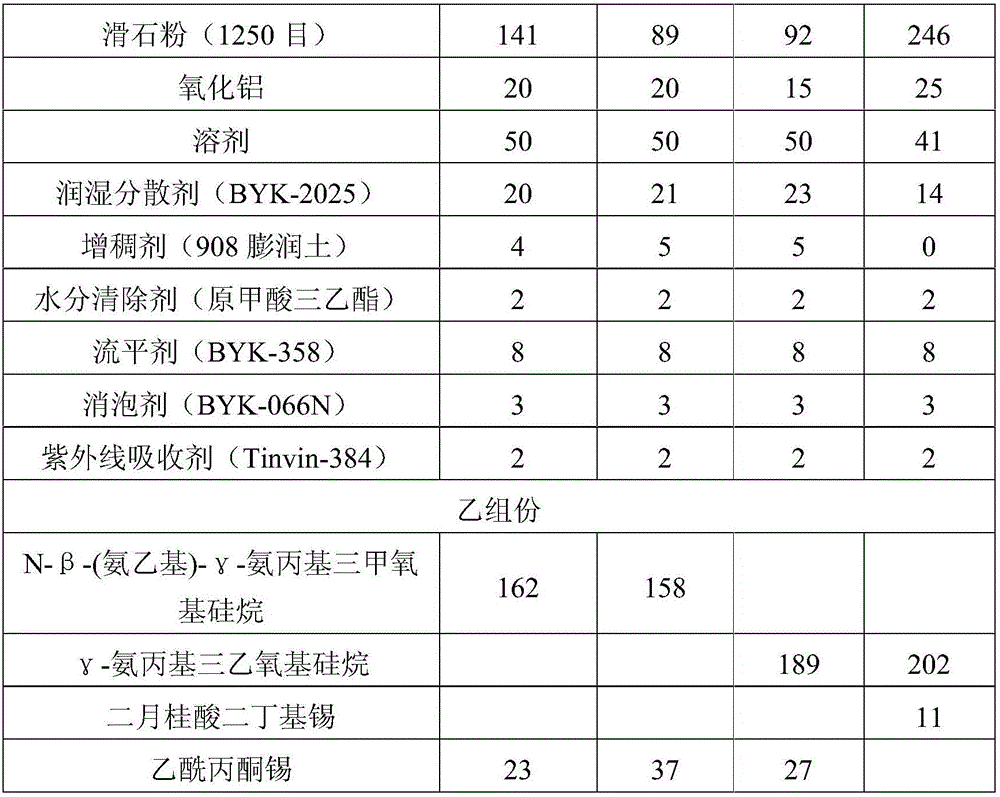

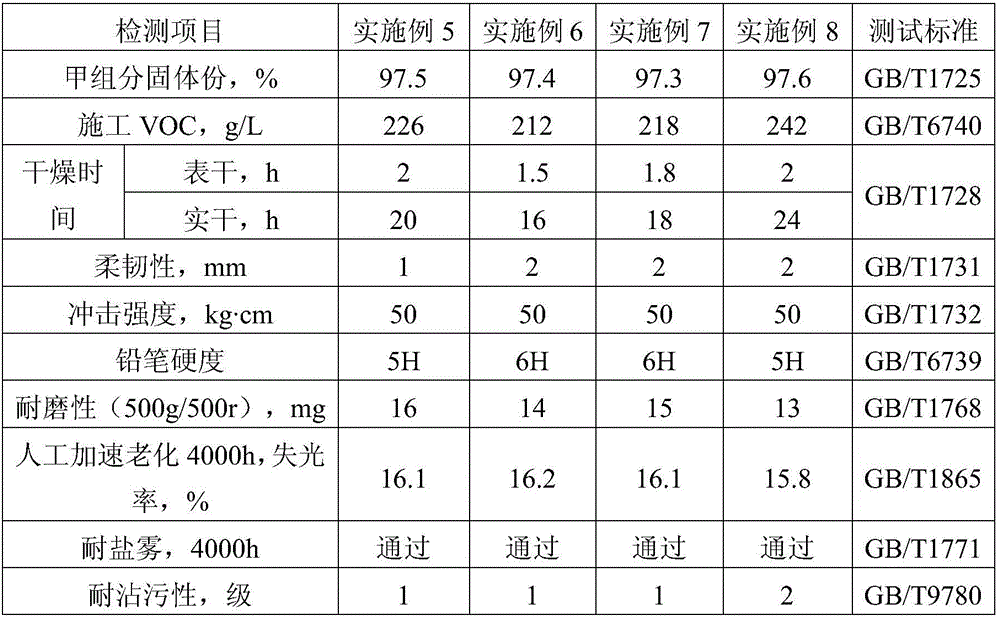

Examples

Embodiment 1

[0031] Embodiment 1 Preparation of High Hardness Acrylic Modified Polysiloxane Resin A

[0032] Put 208g of dicyclohexylmethane diisocyanate, 230g of hydroxypropyl methacrylate, and 0.3g of 2,6-di-tert-butylphenol into a reactor equipped with a stirrer, thermometer, reflux and dropping device, start stirring, and heat up to 80° C., keep warm for 4-5 hours, and measure the NCO% of the product by di-n-butylamine titration method. When NCO%≤0.3%, the cyclohexyl-containing acrylate (HBA-1) is obtained.

[0033] Add 123g of 1,6-hexanediol diacrylate and 510g of polysiloxane intermediate DC-3074 (Dow Corning) to the above-mentioned cyclohexyl-containing acrylate (HBA-1), and mix uniformly to obtain mixture A, which is packaged separately ,spare.

[0034] When in use, mix the above-mentioned mixture A with 152 g of curing agent N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane to obtain high-hardness acrylic modified polysiloxane resin A.

Embodiment 2

[0035] Example 2 Preparation of High Hardness Acrylic Modified Polysiloxane Resin B

[0036]Put 165g of dicyclohexylmethane diisocyanate, 165g of hydroxyethyl methacrylate, and 0.3g of p-hydroxyanisole into a reactor equipped with a stirrer, a thermometer, reflux and dropping devices, start stirring, and heat up to 80°C. After incubation and reaction for 4-5 hours, the NCO% of the product was measured by di-n-butylamine titration method. When NCO%≤0.3%, cyclohexyl-containing acrylate (HBA-2) was obtained.

[0037] Add 70 g of neopentyl glycol diacrylate and 575 g of polysiloxane intermediate DC-3037 (Dow Corning) to the above-mentioned cyclohexyl-containing acrylate (HBA-2), and mix uniformly to obtain Mixture A, which is packaged separately and set aside.

[0038] When in use, mix the above-mentioned mixture A with 164 g of curing agent N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane to obtain high-hardness acrylic modified polysiloxane resin B.

Embodiment 3

[0039] Example 3 Preparation of High Hardness Acrylic Modified Polysiloxane Resin C

[0040] Put 180g of dicyclohexylmethane diisocyanate, 122g of hydroxyethyl methacrylate, 61g of hydroxypropyl acrylate, 0.3g of 2,6-di-tert-butylphenol into the reactor equipped with stirrer, thermometer, reflux and dropping device. g, start stirring, heat up to 80°C, and after 4-5 hours of insulation reaction, use the di-n-butylamine titration method to measure the NCO% of the product. When NCO%≤0.3%, the cyclohexyl-containing acrylate (HBA-3 ).

[0041] Add neopentyl glycol diacrylate 36g, 1,6-hexanediol diacrylate 36g, polysiloxane intermediate SY231 (Wack) 835g to the above-mentioned cyclohexyl-containing acrylate (HBA-3), mix Mixture A is obtained after homogenization, which is packaged separately and set aside.

[0042] When in use, mix the above-mentioned mixture A with 145 g of the curing agent γ-aminopropyltriethoxysilane to obtain the high-hardness acrylic modified polysiloxane res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com