Polyurethane transparent top-coat for coating assembly line in three-dimensional effect and preparation method thereof

A technology of three-dimensional effect and transparent topcoat, applied in the field of coatings, can solve the problems of restricting nitrocellulose and failing to meet the requirements of three-dimensional effect coating on the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

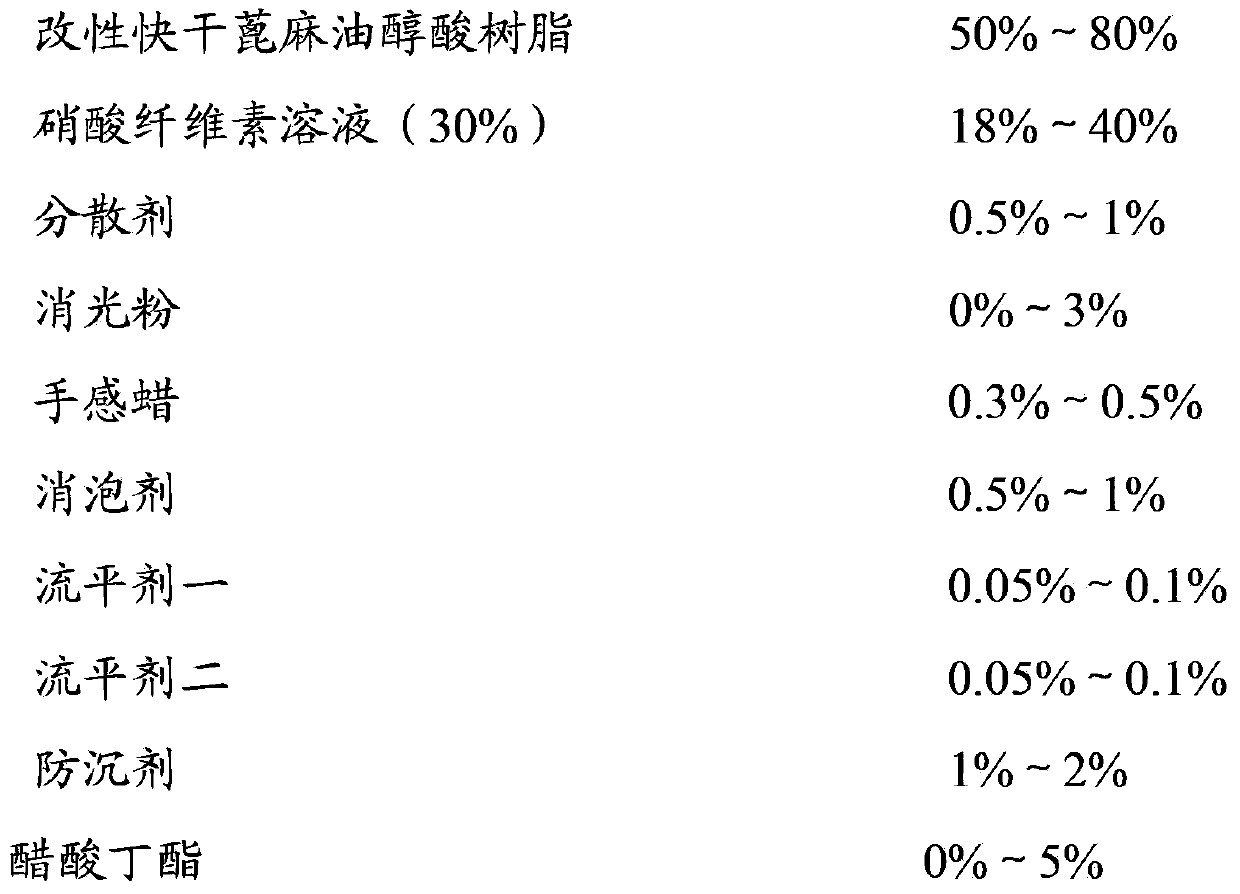

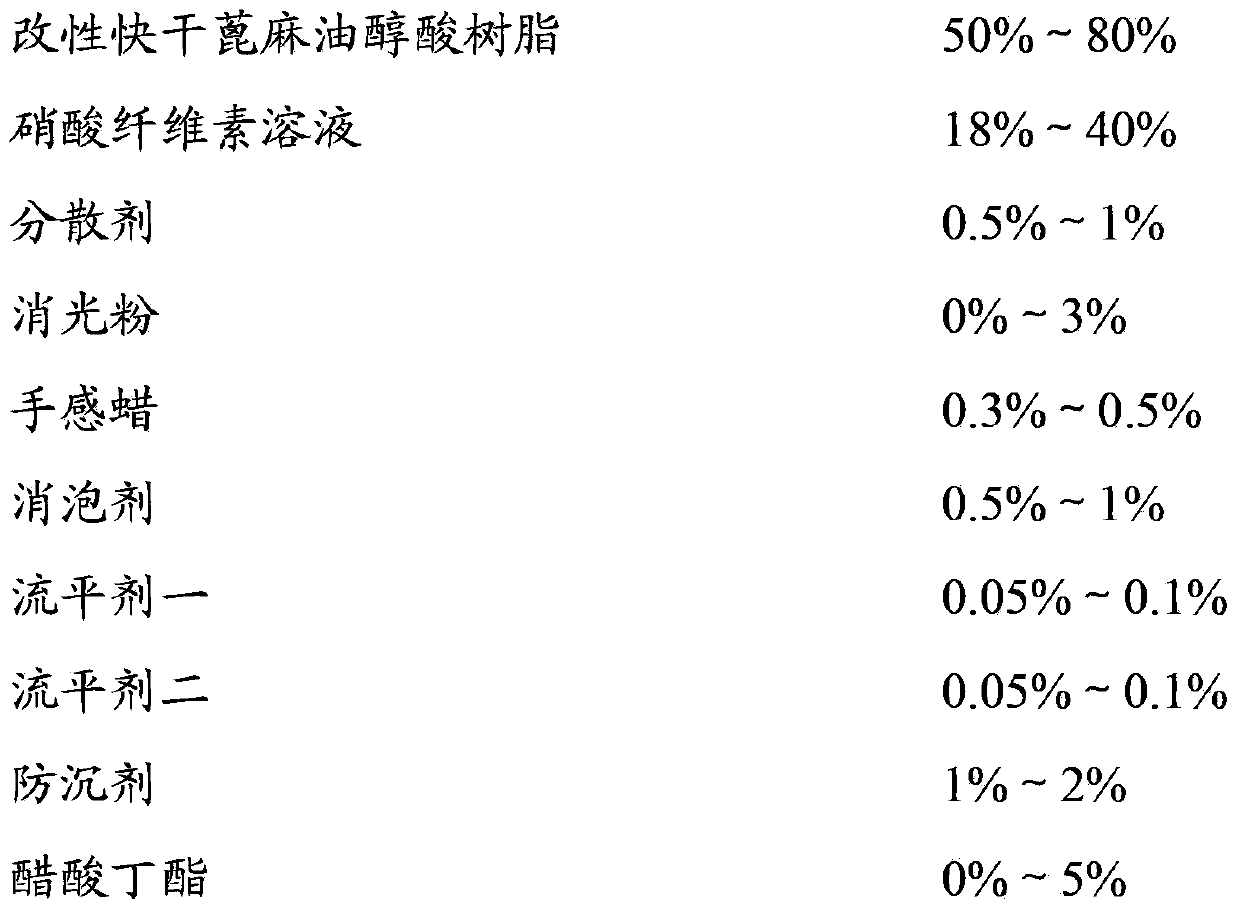

[0039] A polyurethane transparent topcoat for three-dimensional effect painting on an assembly line; comprising a component A, a component B and a thinner, and the weight ratio of the component A and the component B is 4:1,

[0040] Wherein, the solid content of the first component is 42%, and includes 50% of modified quick-drying castor oil alkyd resin, 40% of nitrocellulose solution (30%), 1% of dispersant, 3% of matting powder, hand feel Wax 0.5%, defoamer 1%, leveling agent 1 0.1%, leveling agent 2 0.1%, anti-settling agent 2%, butyl acetate 2.3%;

[0041] The solid content of the B component is 40%, and includes 20% of TDI trimer, 45% of TDI adduct, 15% of HDI trimer, and 20% of butyl acetate;

[0042] The diluent includes the following raw materials calculated by weight percentage:

[0043] Butyl acetate (BAC) 85%, propylene glycol methyl ether acetate 15%.

[0044] The preparation method of the described polyurethane transparent topcoat comprises the following prepara...

Embodiment 2

[0054] A polyurethane transparent topcoat for three-dimensional effect painting on an assembly line; comprising a component A, a component B and a thinner, and the weight ratio of the component A and the component B is 4:1,

[0055] Wherein, the solid content of the first component is 44%, and includes modified quick-drying castor oil alkyd resin 80%, nitrocellulose solution (30%) 18.6%, dispersant 0.5%, hand wax 0.3%, Foaming agent 0.5%, leveling agent 1 0.05%, leveling agent 2 0.05%, anti-settling agent 1%.

[0056] The solid content of the B component is 41%, and includes 30% of TDI trimer, 35% of TDI adduct, and 35% of butyl acetate;

[0057] The diluent includes the following raw materials calculated by weight percentage:

[0058] Butyl acetate (BAC) 95%, propylene glycol methyl ether acetate 5%.

[0059] The preparation method of the described polyurethane transparent topcoat comprises the following preparation steps:

[0060] (1) Preparation of component A:

[0061]...

Embodiment 3

[0069] A polyurethane transparent topcoat for three-dimensional effect painting on an assembly line; comprising a component A, a component B and a thinner, and the weight ratio of the component A and the component B is 4:1,

[0070] Wherein, the solid content of the first component is 46%, and includes 65% of modified quick-drying castor oil alkyd resin, 25% of nitrocellulose solution (30%), 0.9% of dispersant, 1% of matting powder, hand feel Wax 0.4%, defoamer 0.6%, leveling agent 1 0.05%, leveling agent 2 0.05%, anti-settling agent 2%, butyl acetate 5%.

[0071] The solid content of the B component is 43%, and includes 30% of TDI trimer, 45% of TDI adduct, 15% of HDI trimer, and 10% of butyl acetate;

[0072] The diluent includes the following raw materials calculated by weight percentage:

[0073] Butyl acetate (BAC) 90%, propylene glycol methyl ether acetate 10%.

[0074] The preparation method of the described polyurethane transparent topcoat comprises the following pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com