Transparent primer easy to apply and preparation method of transparent primer

A transparent primer and main paint technology, which is applied in primers, coatings, polyurea/polyurethane coatings, etc., can solve the problem of PU transparent primers with heavy solvent and thinner content, which cannot meet the requirements of high-end furniture coating and environmental protection If the performance does not meet the requirements and other problems, it can achieve the effect of dense surface and high flatness, excellent grinding performance, and anti-prickly heat in the grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An easy-to-paint transparent primer, including main paint, curing agent and thinner, the ratio of the three components is 1:0.3:0.7;

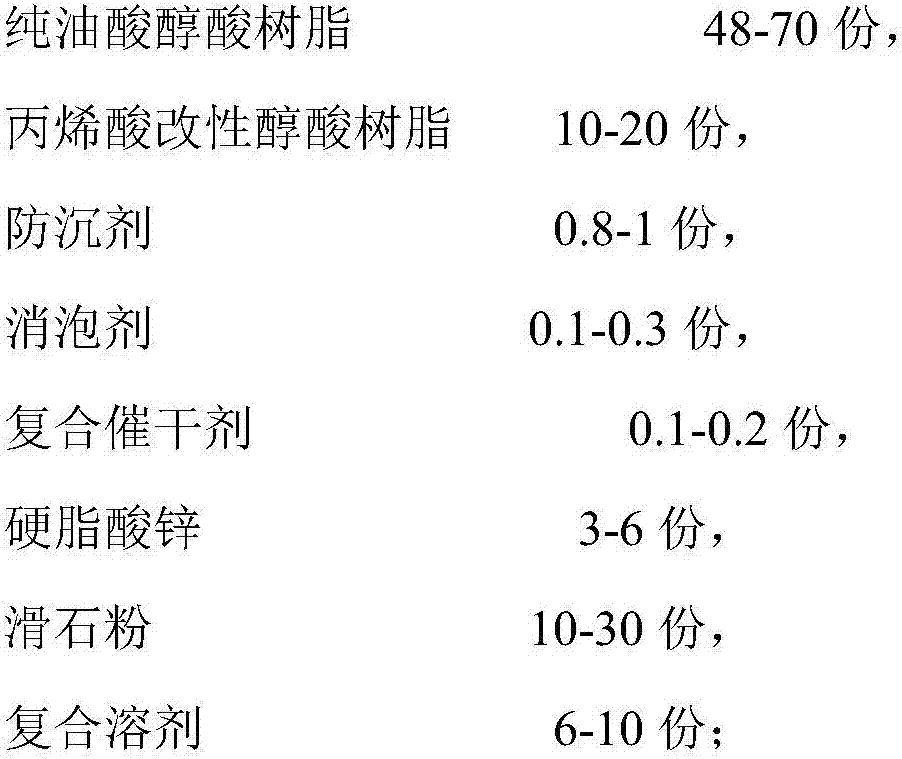

[0042] Wherein, by weight, the main paint includes the following raw materials:

[0043]

[0044] The composite drier is a mixture of T12 and ZH300 in a weight ratio of 1:1,

[0045] Described composite solvent is the mixture of butyl acetate and propylene glycol methyl ether acetate in mass ratio of 59:41;

[0046] In parts by weight, the curing agent includes the following raw materials:

[0047] 45 parts of TDI adduct curing agent,

[0048] 15 parts of TDI trimer,

[0049] 40 parts of butyl acetate,

[0050] In parts by weight, the diluent includes the following raw materials:

[0051] 20 parts of xylene,

[0052] 50 parts of butyl acetate,

[0053] 30 parts of propylene glycol methyl ether acetate.

[0054] The preparation method of above-mentioned easy-to-paint transparent primer comprises the following steps:

[0055] (...

Embodiment 2

[0060] An easy-to-paint transparent primer, including main paint, curing agent and thinner, the ratio of the three components is 1:0.3:0.7;

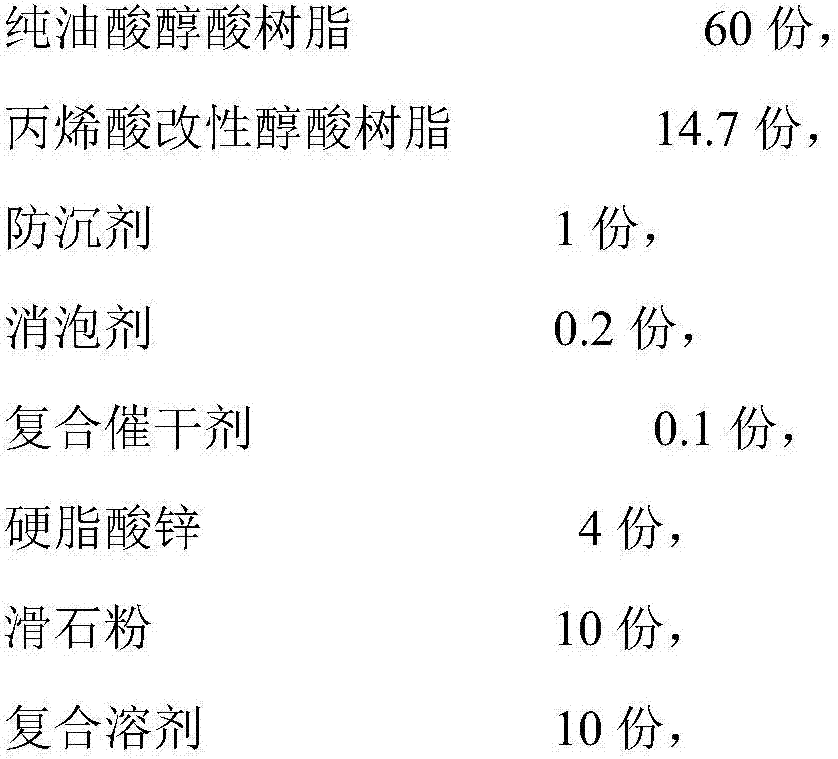

[0061] Wherein, by weight, the main paint includes the following raw materials:

[0062]

[0063] The composite drier is a mixture of T12 and ZH300 in a weight ratio of 1:1,

[0064] Described composite solvent is the mixture of butyl acetate and propylene glycol methyl ether acetate in mass ratio of 59:41;

[0065] In parts by weight, the curing agent includes the following raw materials:

[0066] 45 parts of TDI adduct curing agent,

[0067] 15 parts of TDI trimer,

[0068] 40 parts of butyl acetate,

[0069] In parts by weight, the diluent includes the following raw materials:

[0070] Xylene 20,

[0071] Butyl acetate 50,

[0072] Propylene glycol methyl ether acetate 30.

[0073] The preparation method of above-mentioned easy-to-paint transparent primer comprises the following steps:

[0074] (1) take each raw material b...

Embodiment 3

[0079] An easy-to-paint transparent primer, including main paint, curing agent and thinner, the ratio of the three components is 1:0.3:0.7;

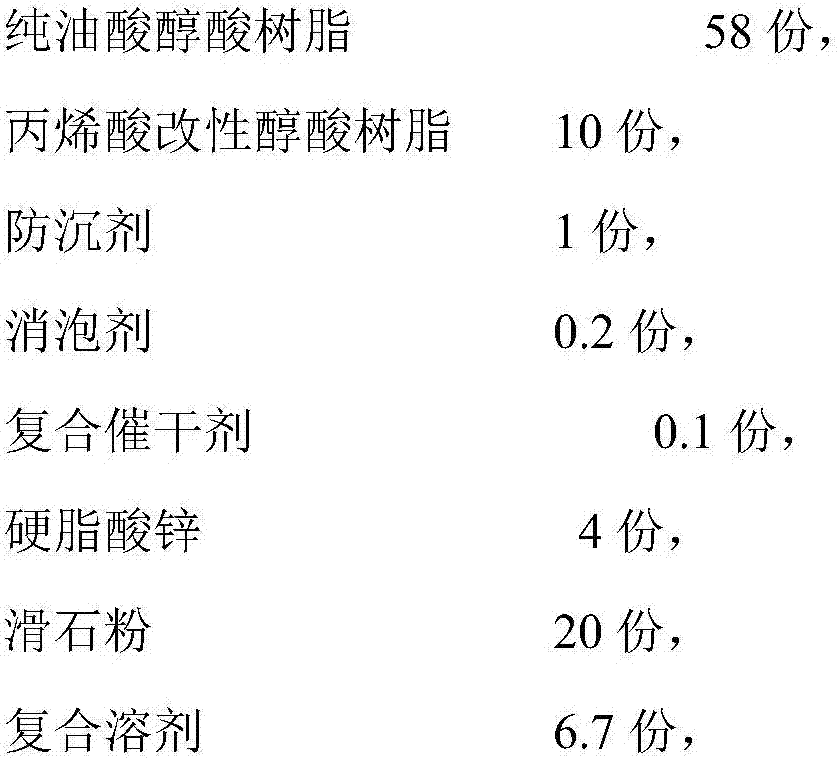

[0080] Wherein, by weight, the main paint includes the following raw materials:

[0081]

[0082] The composite drier is a mixture of T12 and ZH300 in a weight ratio of 1:1,

[0083] Described composite solvent is the mixture of butyl acetate and propylene glycol methyl ether acetate in mass ratio of 59:41;

[0084] In parts by weight, the curing agent includes the following raw materials:

[0085] 45 parts of TDI adduct curing agent,

[0086] 15 parts of TDI trimer,

[0087] 40 parts of butyl acetate,

[0088] In parts by weight, the diluent includes the following raw materials:

[0089] 20 parts of xylene,

[0090] 50 parts of butyl acetate,

[0091] 30 parts of propylene glycol methyl ether acetate.

[0092] The preparation method of above-mentioned easy-to-paint transparent primer comprises the following steps:

[0093] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com