Coating method for water-based paint for engineering machines

A coating method and technology of water-based coatings, applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve problems such as difficulty in meeting the coating requirements of construction machinery, avoid the disadvantages of paint film, and achieve dimensional stability. Good performance and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

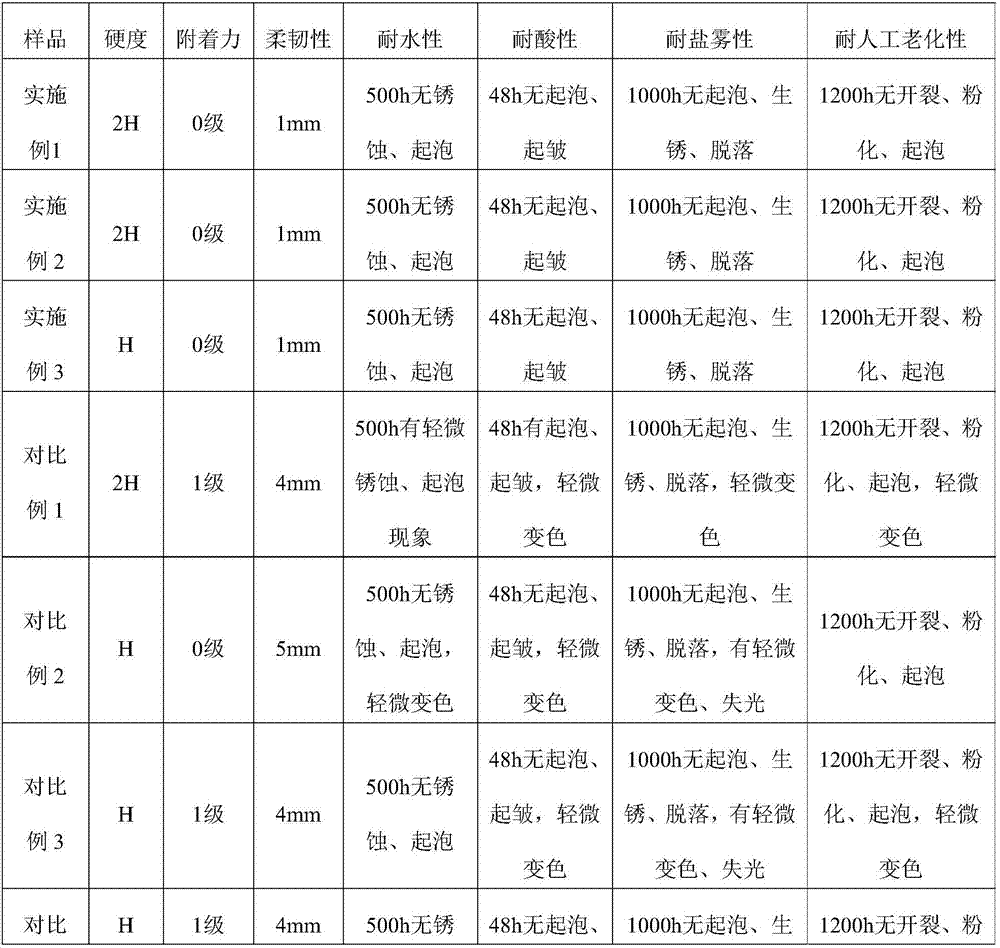

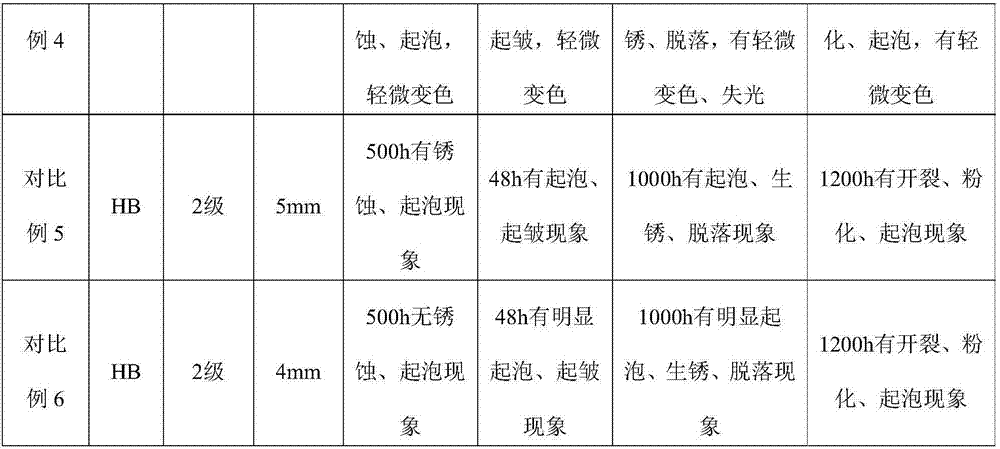

Examples

Embodiment 1

[0032] Substrate pretreatment: refers to the shot blasting treatment of the steel material construction machinery substrate, and then wiped with a solvent to remove rust, oil, dust, cutting fluid, anti-flying agent, flaw detection agent, etc. on the surface of the substrate to obtain pretreatment base material.

[0033] Baking after spraying the primer and leveling: keep the ambient temperature between 10-30°C and the ambient humidity ≤75%, and adjust the surface temperature of the substrate to be 5°C higher than the dew point temperature. The above-mentioned pretreated substrate is then subjected to a spray primer.

[0034]Wherein said primer is made up of A component and B component, and said A component is made up of waterborne epoxy resin, auxiliary agent (containing RAYBO60, U.S. Ruibao, 1% by weight), filler, pigment and water, so The B component is a water-based fatty amine curing agent. Mix 5 parts by mass of component A and 1 part by mass of component B, and use a p...

Embodiment 2

[0039] Substrate pretreatment: refers to the shot blasting treatment of the aluminum alloy engineering machinery substrate, and then wiped with a solvent to remove rust, oil, dust, cutting fluid, anti-flying agent, flaw detection agent, etc. on the surface of the substrate to obtain pretreatment base material.

[0040] Baking after spraying the primer and leveling: keep the ambient temperature between 10-30°C, the ambient humidity ≤75%, and adjust the surface temperature of the substrate to be 3°C higher than the dew point temperature. The above-mentioned pretreated substrate is then subjected to a spray primer.

[0041] Wherein said primer is made up of A component and B component, and said A component is made up of waterborne epoxy resin, auxiliary agent (containing RAYBO60, U.S. Ruibao, 1.5% by weight), filler, pigment and water, so The B component is a polyamide curing agent. Mix 4 parts by mass of component A and 1 part by mass of component B, and spray it with a pressu...

Embodiment 3

[0046] Substrate pretreatment: refers to the shot blasting treatment of the cast iron construction machinery substrate, and then wiped with a solvent to remove rust, oil, dust, cutting fluid, anti-flying agent, flaw detection agent, etc. on the surface of the substrate to obtain pretreated Substrate.

[0047] Baking after spraying primer and leveling: keep the ambient temperature between 10-30°C, ambient humidity ≤75%, and adjust the surface temperature of the substrate to be 4°C higher than the dew point temperature. The above-mentioned pretreated substrate is then subjected to a spray primer.

[0048] Wherein said primer is composed of A component and B component. The A component is composed of water-based epoxy resin, additives (including RAYBO60, American Ruibao, 0.8% by weight), filler, pigment and water, and the B component is a water-based fatty amine curing agent. Mix 6 parts by mass of component A and 1 part by mass of component B, and spray it with a pressure-feedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com