Device and method for producing tobacco sheets

A technology of tobacco flakes and production methods, which is applied in the fields of tobacco, tobacco preparation, paper, etc., can solve problems such as increased viscosity and solid content, poor fluidity of coating liquid, and quality impact, so as to increase the degree of looseness and porosity, improve Coating amount, effect of avoiding porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

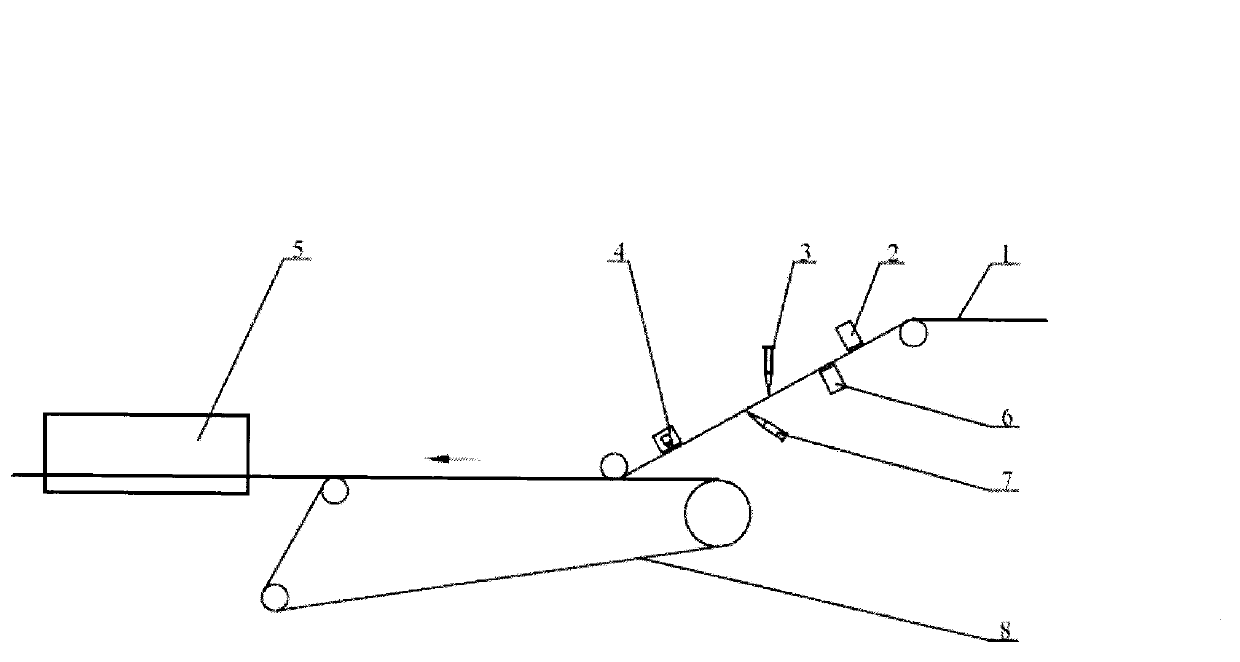

[0030] Such as figure 1 As shown, it is a structural schematic diagram of a production device for tobacco sheets, and the production device for tobacco sheets is composed of a foam spraying device, a mist spraying device, a sound wave or an ultrasonic generator 4, a nylon mesh belt 8 and a hot air drying box 5 arranged in sequence , the foam spraying device is made up of front foam spraying device 2 and rear foam spraying device 6, and front foam spraying device 2 is arranged opposite to rear foam spraying device 6, and mist spraying device is composed of front mist spraying device 3 and rear mist spraying device 7 Composition, the front mist spraying device 3 and the rear mist spraying device 7 are relatively arranged, and the nylon mesh belt 8 is arranged between the sound wave or the ultrasonic generator 4 and the hot air drying box 5, and is used to convert the tobacco sheet base 1 from the sound wave or the ultrasonic wave The generator 4 is transported to the hot air dry...

Embodiment 2

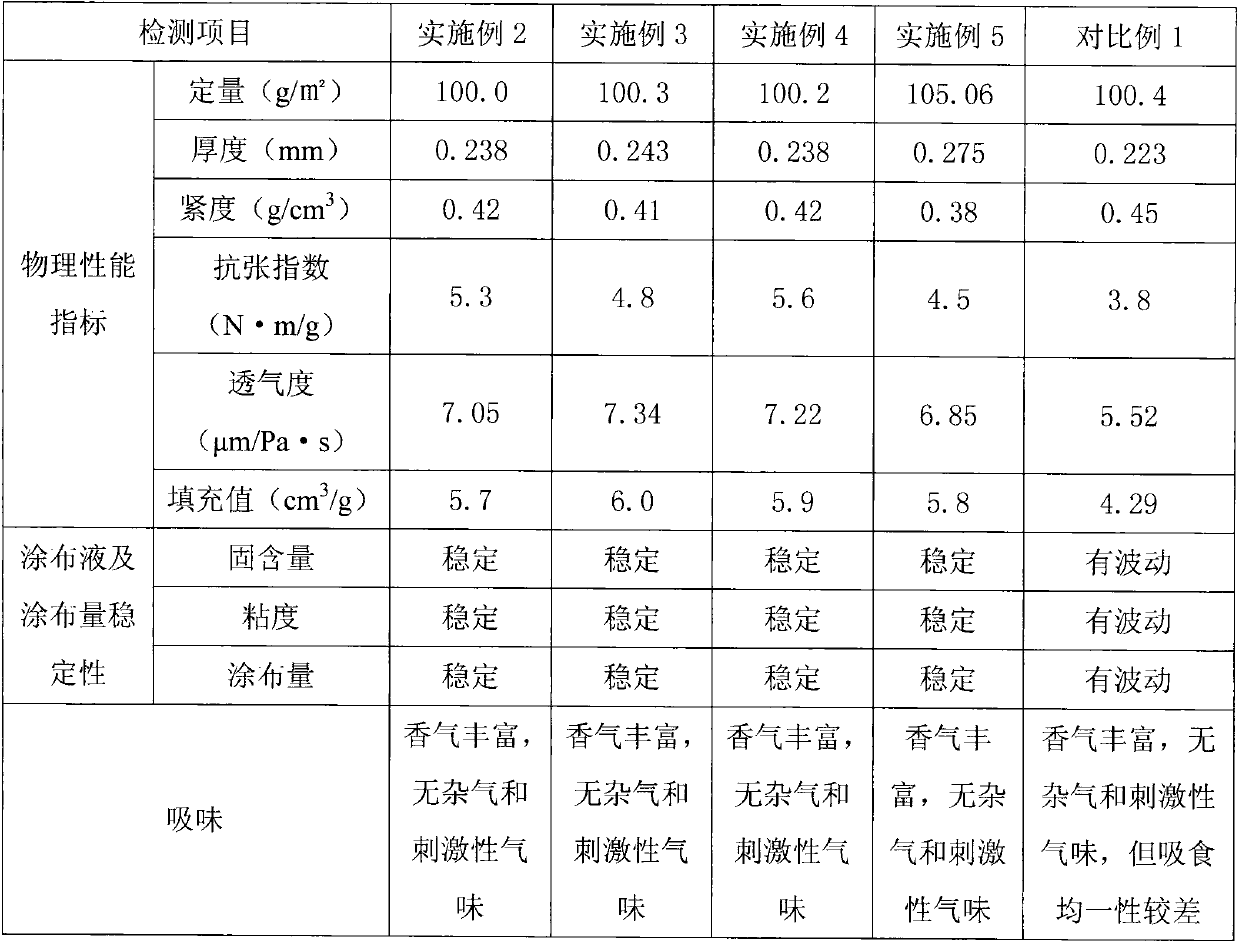

[0032] A tobacco sheet production method, using the tobacco sheet production device in Example 1, the specific steps are: extracting tobacco raw materials (tobacco stems, tobacco leaf fragments and tobacco powder) in an extraction tank with water at 40°C for 1.5h and then separating , the insoluble matter is pulped and copied online to form a tobacco sheet base 1, the extract containing soluble matter is filtered through a filter, concentrated and prepared to obtain a tobacco sheet coating liquid; the obtained concentrated coating liquid is divided into Two parts, a part of the coating solution is foamed with a foam generator to obtain a foam coating solution, and the foam coating solution is applied to the tobacco sheet base 1 through the front foam spraying device 2 and the rear foam spraying device 6 using a foam spraying process Above, where the foaming ratio is 1:3, the amount of coating liquid used for foam spraying accounts for 35% of the total coating liquid; then the r...

Embodiment 3

[0034] A tobacco sheet production method, using the tobacco sheet production device in Example 1, the specific steps are: extracting tobacco raw materials (tobacco stems, tobacco leaf fragments and tobacco powder) in an extraction tank with water at 40°C for 1.5h and then separating , the insoluble matter is pulped and copied online to form a tobacco sheet base 1, the extract containing soluble matter is filtered through a filter, concentrated and prepared to obtain a tobacco sheet coating liquid; the obtained concentrated coating liquid is divided into Two parts, a part of the coating solution is foamed with a foam generator to obtain a foam coating solution, and the foam coating solution is applied to the tobacco sheet base 1 through the front foam spraying device 2 and the rear foam spraying device 6 using a foam spraying process Above, where the foaming ratio is 1:5, the amount of coating liquid used for foam spraying accounts for 20% of the total coating liquid; The devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com