Chocolate, and coated frozen beverage and preparation method thereof

A technology for frozen beverages and chocolate, which is applied to frozen desserts, food ingredients, cocoa, etc., can solve the problems of easy cracking, popping, and easy sedimentation of chocolate crispy skin, so as to enrich the taste and flavor, improve the adaptability, and be not easy to crack. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

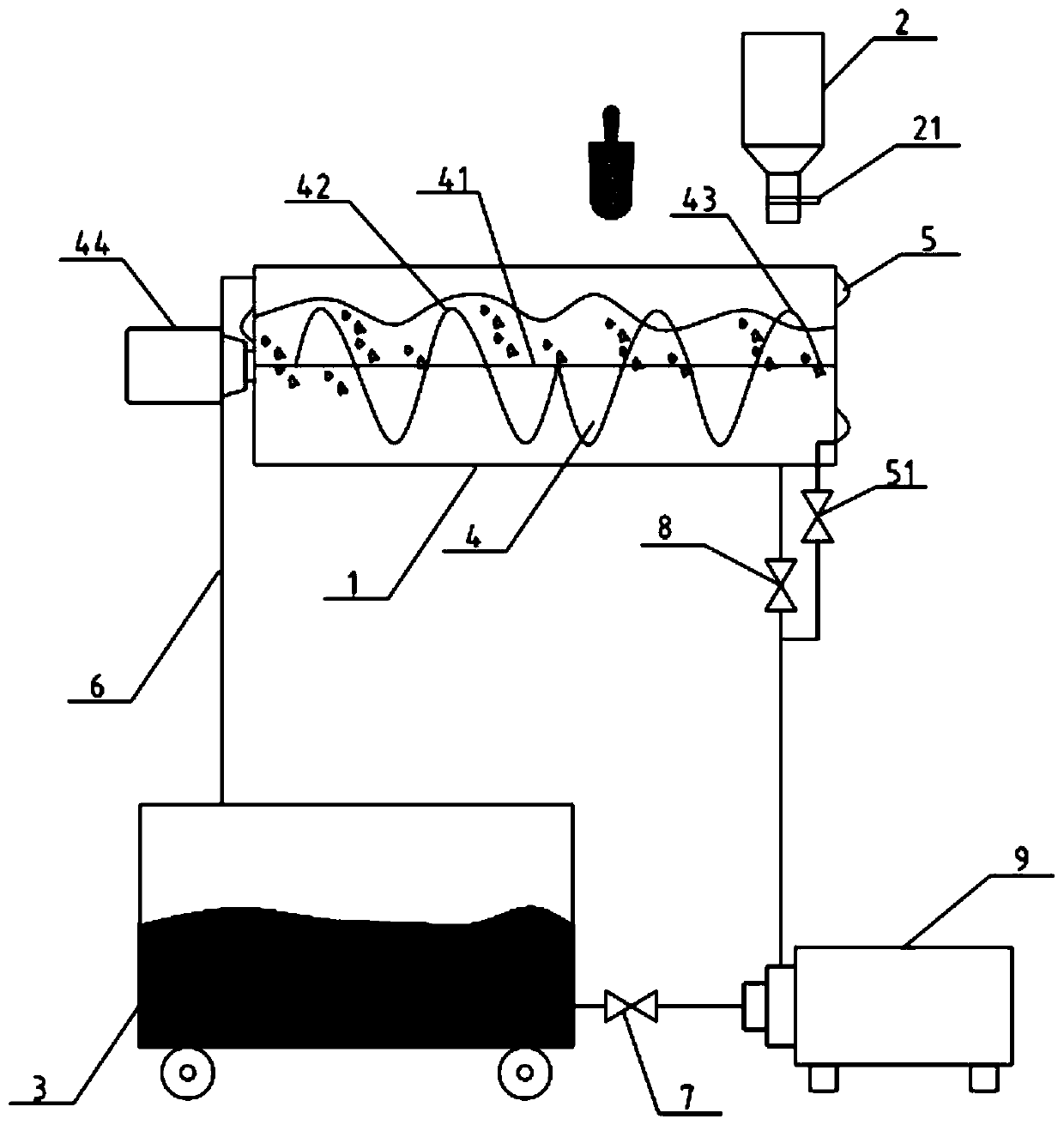

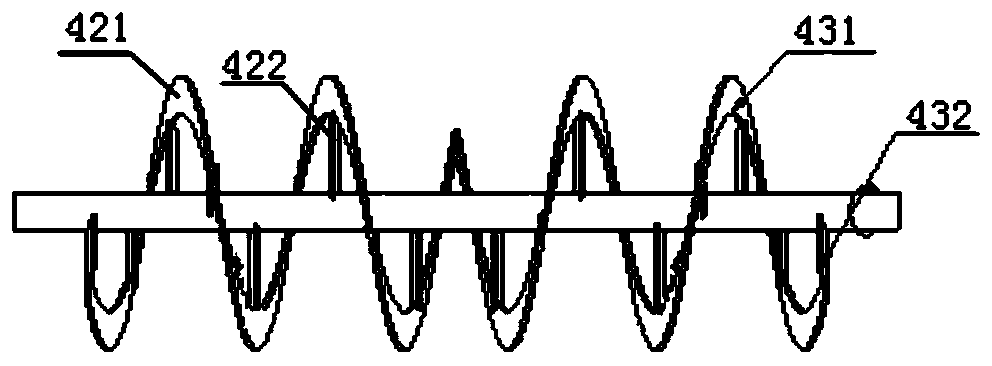

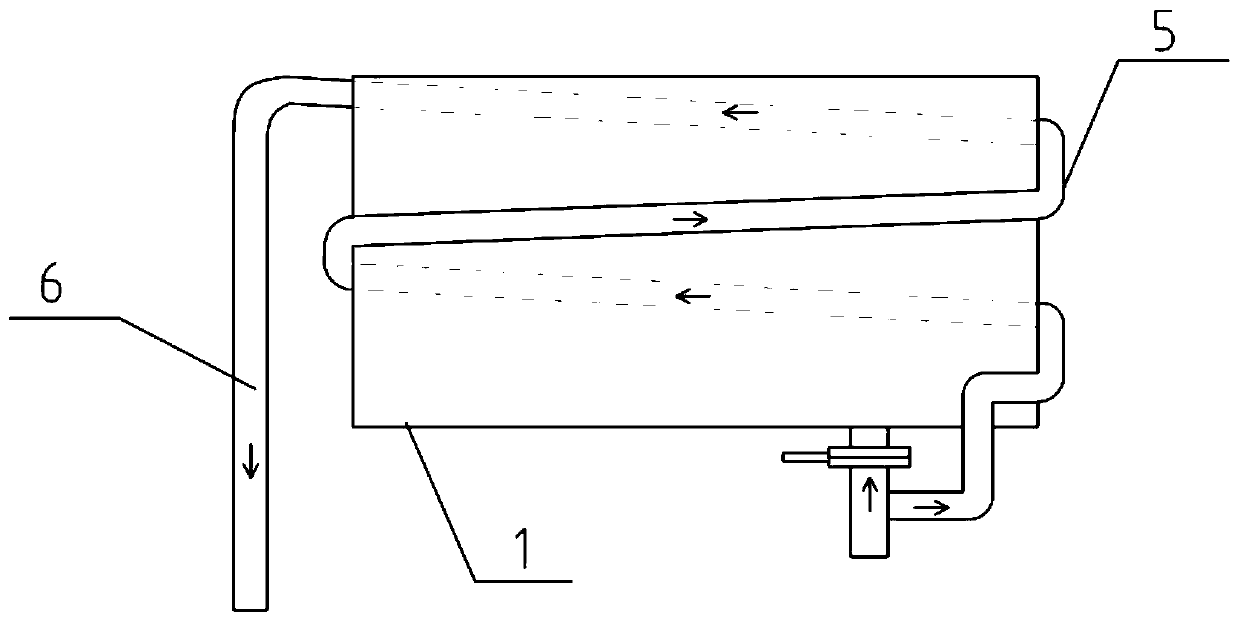

[0058] This embodiment provides a coated frozen drink and a preparation method. The coated frozen drink includes a frozen drink and a crispy chocolate layer arranged on its surface. The crispy chocolate layer is formed by chocolate coating, wherein the chocolate includes 32g of white sugar, 11g of whole milk powder, 27g of corn oil, artificial Butter 8g, natural low-fat cocoa powder 12g, black cocoa powder 1.0g, cocoa mass 5g, dextrin powder 4g, phospholipid 0.5g, polyglycerol ricinoleate 0.3g, lipase 0.25g; the frozen drink is ice cream, ice cream Including drinking water 58g, white sugar 12g, maltose 3g, skimmed milk powder 7g, vegetable oil 8g, dextrin powder 4g, locust bean gum 0.5g, sodium carboxymethylcellulose 1.1g, monoglyceride 2.2g, xanthan gum 0.5g , appropriate amount of flavor and pigment for food;

[0059] The preparation method of the above-mentioned coated frozen drink comprises the following steps:

[0060]

[0061] (1) Raw material receiving inspection: ...

Embodiment 2

[0085] This embodiment provides a coated frozen drink and a preparation method. The coated frozen drink includes a frozen drink and a crispy chocolate layer arranged on its surface. The crispy chocolate layer is formed by chocolate coating, wherein the chocolate includes 29g of white sugar, 12g of whole milk powder, 26g of corn oil, artificial Butter 9g, natural low-fat cocoa powder 10g, black cocoa powder 1.1g, cocoa mass 3g, dextrin powder 5g, phospholipid 0.4g, polyglycerol ricinoleate 0.5g, lipase 0.2g; frozen drinks are ice cream, ice cream Including drinking water 55g, white sugar 14g, maltose 2g, skimmed milk powder 9g, vegetable oil 6g, dextrin powder 5g, locust bean gum 0.3g, sodium carboxymethylcellulose 1.2g, monoglyceride 2.0g, xanthan gum 0.6g , appropriate amount of flavor and pigment for food;

[0086] The preparation method of the above-mentioned coated frozen drink comprises the following steps:

[0087]

[0088] (1) Raw material receiving inspection: the...

Embodiment 3

[0112] This embodiment provides a coated frozen drink and a preparation method. The coated frozen drink includes a frozen drink and a crispy chocolate layer arranged on its surface. The crispy chocolate layer is formed by chocolate coating, wherein the chocolate includes 34g of white sugar, 9g of whole milk powder, 29g of corn oil, artificial Butter 7g, natural low-fat cocoa powder 13g, black cocoa powder 0.8g, cocoa mass 6g, dextrin powder 3g, phospholipid 0.6g, polyglycerol castor ester 0.2g, lipase 0.3g; frozen drinks are ice cream, ice cream Including drinking water 60g, white sugar 11g, maltose 5g, skimmed milk powder 6g, vegetable oil 9g, dextrin powder 3g, locust bean gum 0.6g, sodium carboxymethyl cellulose 0.9g, monoglyceride 2.4g, xanthan gum 0.4g , appropriate amount of flavor and pigment for food;

[0113] The preparation method of the above-mentioned coated frozen drink comprises the following steps:

[0114]

[0115] (1) Raw material receiving inspection: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com