Hollow glass bead/titanium dioxide membrane composite material and preparation method thereof

A technology of hollow glass microspheres and thin film composite materials, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of uneven coating, titanium dioxide coating Low coverage rate and other issues, to achieve the effect of high photocatalytic activity, stable reaction, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

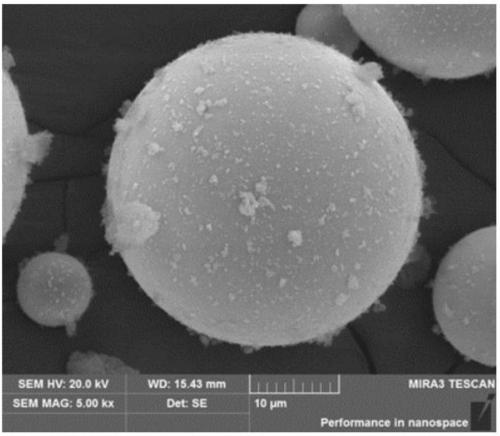

Embodiment 1

[0047] The volume ratio of tetrabutyl titanate, absolute ethanol, distilled water and glacial acetic acid is 1:2.5:0.2:0.15. Completely mix two parts of absolute ethanol with 2 / 3 of the total volume with tetrabutyl titanate and glacial acetic acid, and stir in a constant temperature water bath at 30°C at 300r / min for 40min to obtain a tetrabutyl titanate solution. The other 1 / 3 of absolute ethanol is fully mixed with water and a pH regulator to obtain a mixed aqueous solution, and the obtained mixed aqueous solution is evenly added dropwise to the tetrabutyl titanate solution at a speed of 1ml / min, and a uniform light yellow transparent sol is obtained after the drop is completed , control the pH value of the system at 3.5, continue to stir for 40 minutes, and then place it in the refrigerator for later use.

[0048] Take 3g of hollow glass microspheres, immerse in 100ml of organic solvent washing solution with a volume ratio of ethanol and distilled water of 10:1, ultrasonica...

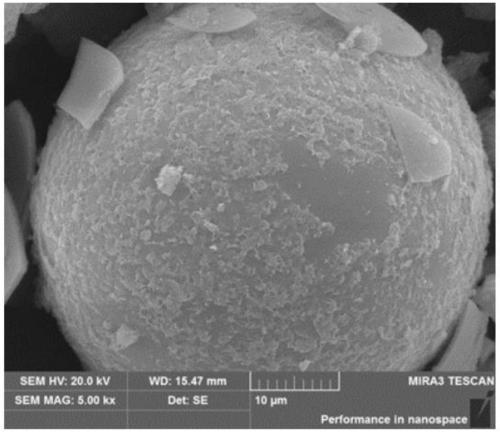

Embodiment 2

[0052] The volume ratio of tetrabutyl titanate, absolute ethanol, distilled water and glacial acetic acid is 1:3.0:0.18:0.25. Two parts of absolute ethanol were integrated according to the total volume, and 2 / 3 of the total volume was fully mixed with tetrabutyl titanate and glacial acetic acid, stirred at 300 r / min in a constant temperature water bath at 30°C for 30 minutes to obtain a tetrabutyl titanate solution. The other 1 / 3 of absolute ethanol was thoroughly mixed with water and a pH regulator to obtain a mixed aqueous solution, and the obtained mixed aqueous solution was evenly added dropwise to the tetrabutyl titanate solution at a speed of 2 ml / min. After dripping, a uniform light yellow transparent sol was obtained. The pH value of the system was controlled at 3, and the stirring was continued for 30 minutes, and then placed in the refrigerator for later use.

[0053] Take 3g of hollow glass microspheres, immerse in 100ml of organic solvent washing liquid with a volu...

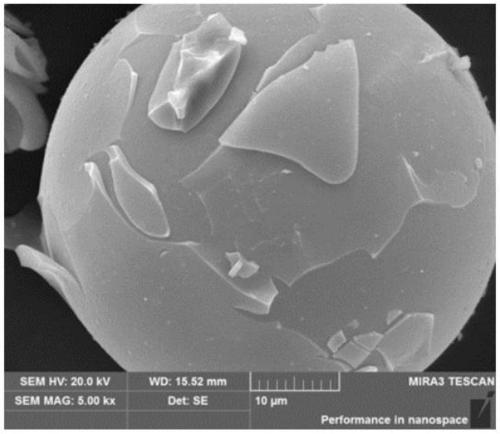

Embodiment 3

[0057] The volume ratio of tetrabutyl titanate, absolute ethanol, distilled water and glacial acetic acid is 1:3.5:0.15:0.35. Completely mix two parts of absolute ethanol with 2 / 3 of the total volume with tetrabutyl titanate and glacial acetic acid, stir in a constant temperature water bath at 25°C at 300r / min for 20min to obtain a tetrabutyl titanate solution. The other 1 / 3 of absolute ethanol was thoroughly mixed with water and a pH regulator to obtain a mixed aqueous solution, and the obtained mixed aqueous solution was evenly added dropwise to the tetrabutyl titanate solution at a speed of 3 ml / min. After dripping, a uniform light yellow transparent sol was obtained. The pH value of the system was controlled at 2, and the stirring was continued for 20 minutes, and then placed in the refrigerator for later use.

[0058] Take 3g of hollow glass microspheres, immerse in 100ml of organic solvent washing solution with a volume ratio of ethanol and distilled water of 8:1, ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com