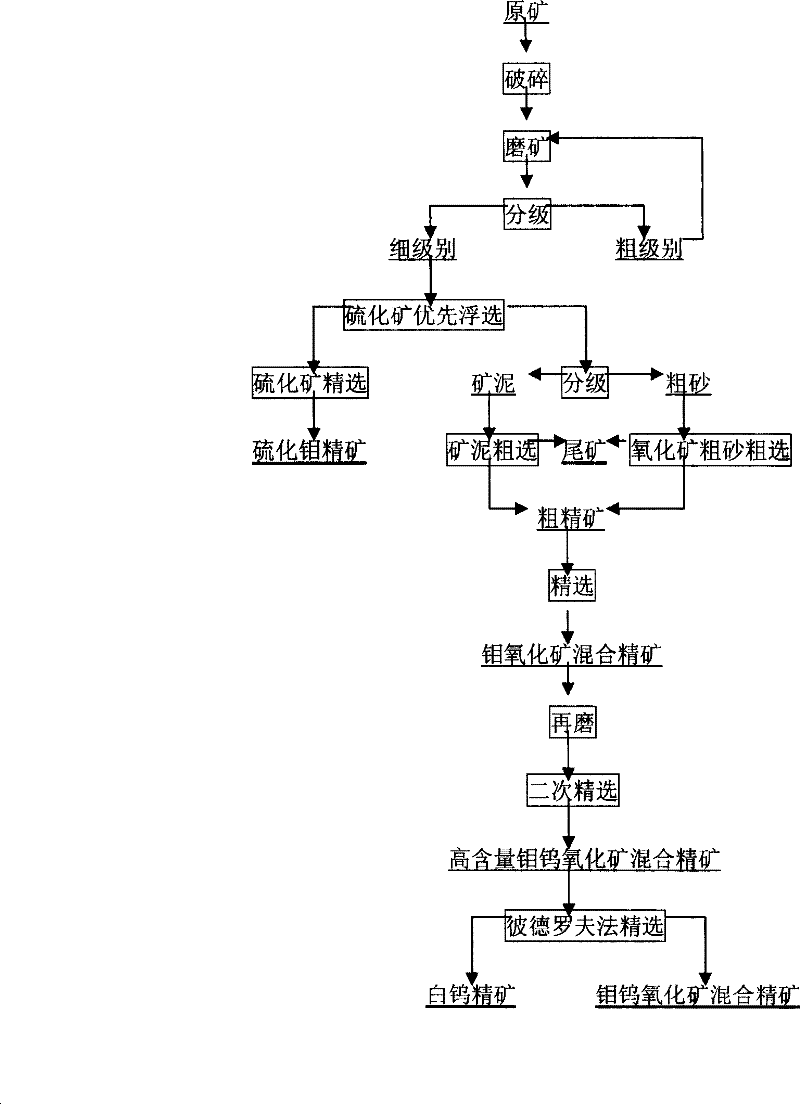

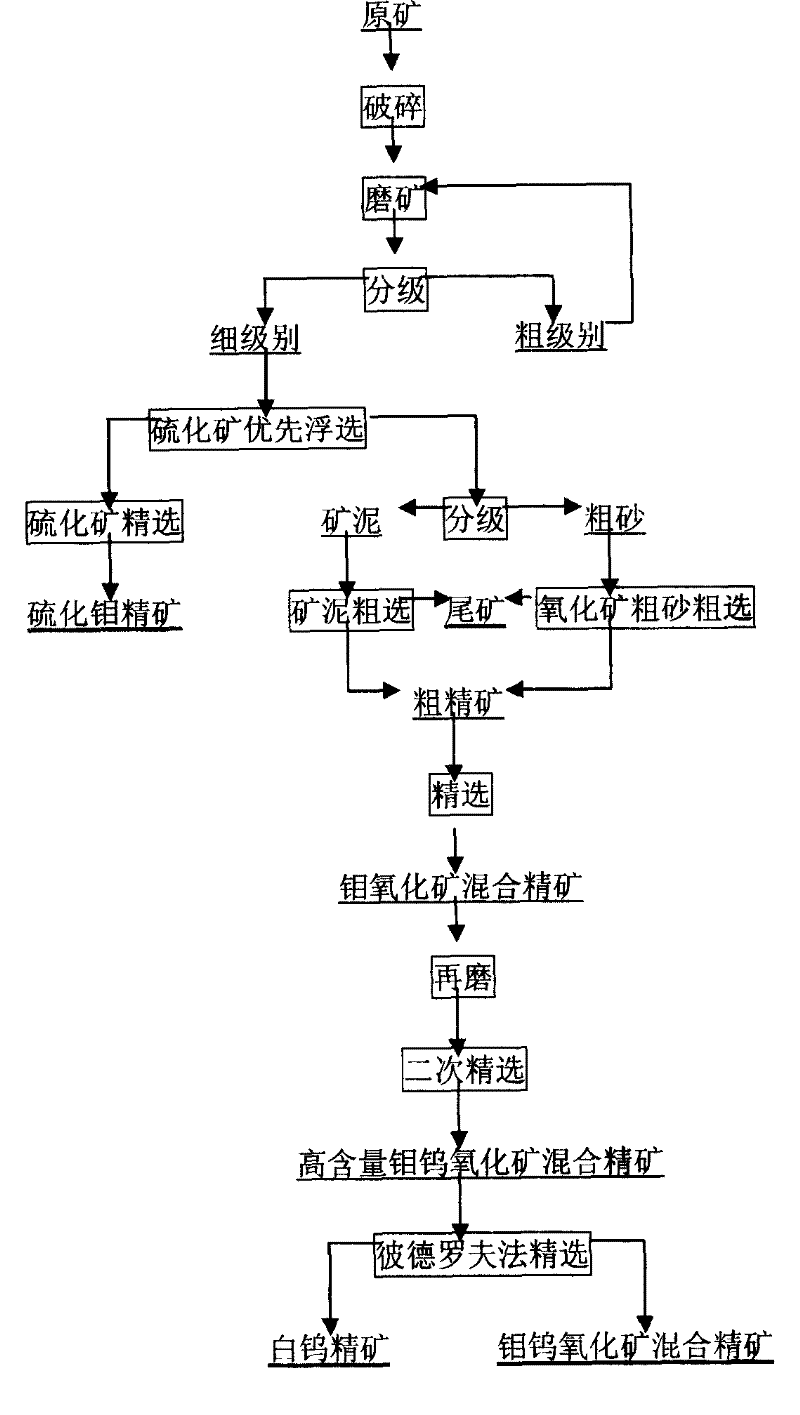

Processing technology for molybdenum and tungsten oxidized ore

A technology of tungsten oxide ore and oxide ore, which is applied in flotation, chemical instruments and methods, solid separation, etc., can solve the problems of low technical and economic indicators and high recovery cost of molybdenum-tungsten oxide ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The purpose of the present invention can be achieved by the following measures:

[0033] The process method of the present invention is as follows:

[0034] A. Molybdenum tungsten oxide ore is used as raw material, crushed to -200 mesh accounting for 43%, and the degree of dissociation of mineral monomer is ≥70%;

[0035] B. Use water glass, kerosene, 2 # Flotation of molybdenum sulfide in molybdenum tungsten oxide ore with oil or sodium hexametaphosphate, copper sulfate and butyl xanthate, and molybdenum sulfide concentrate is obtained after the coarse concentrate is selected;

[0036] C. The sulfide ore flotation tailings are classified, the classification particle size is 30μm, the coarse grain grade enters the coarse sand coarse separation process, and the fine grain grade enters the sludge coarse separation process;

[0037] D. The mud sand system uses sodium carbonate or sodium hydroxide or lime as the slurry regulator, and its dosage range is 300 g / ton ore; water glass is ...

Embodiment 2

[0042] The purpose of the present invention can be achieved by the following measures:

[0043] The process method of the present invention is as follows:

[0044] A. Molybdenum tungsten oxide ore is used as raw material, crushed to -200 mesh accounting for 49%, and the degree of dissociation of mineral monomer is ≥70%;

[0045] B. Use water glass, kerosene, 2 # Flotation of molybdenum sulfide in molybdenum tungsten oxide ore with oil or sodium hexametaphosphate, copper sulfate and butyl xanthate, and molybdenum sulfide concentrate is obtained after the coarse concentrate is selected;

[0046] C. Classify the sulfide ore flotation tailings, the classification particle size is 80μm, the coarse particles enter the coarse sand coarse separation process, and the fine particles enter the sludge coarse separation process;

[0047] D. The mud sand system uses sodium carbonate or sodium hydroxide or lime as the slurry regulator, and its dosage range is 400 g / ton of ore; water glass is gangue in...

Embodiment 3

[0052] The purpose of the present invention can be achieved by the following measures:

[0053] The process method of the present invention is as follows:

[0054] A. Molybdenum tungsten oxide ore is used as raw material, crushed to -200 mesh accounting for 53%, and the degree of dissociation of mineral monomer is ≥70%;

[0055] B. Use water glass, kerosene, 2 # Flotation of molybdenum sulfide in molybdenum tungsten oxide ore with oil or sodium hexametaphosphate, copper sulfate, butyl xanthate, and molybdenum sulfide concentrate after the coarse concentrate is selected;

[0056] C. The sulfide ore flotation tailings are classified, the classification particle size is 150μm, the coarse particle level enters the coarse sand roughing process, and the fine particle level enters the sludge roughing process;

[0057] D. The mud sand system uses sodium carbonate or sodium hydroxide or lime as the slurry regulator, and its dosage range is 1000 g / ton ore; water glass is gangue inhibitor, and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com