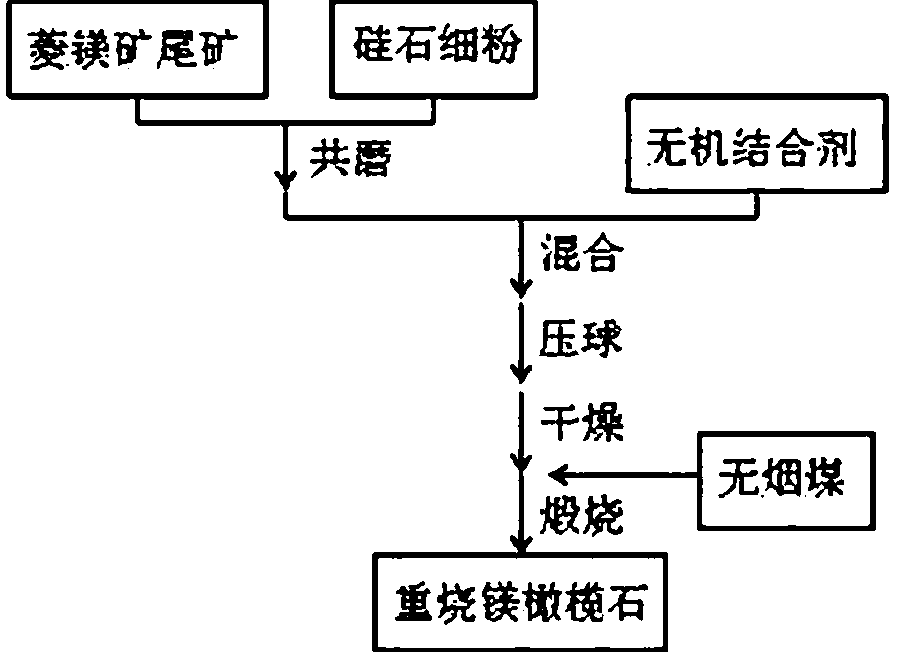

Method for preparing sintered forsterite by re-firing magnesite tailings

A technology for sintering forsterite and magnesite, which is applied in the direction of magnesium silicate and silicate, can solve the problems of waste of resources, pollution of the environment by magnesite tailings, etc., and achieve better fire resistance, improved refractoriness, The effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 75kg of magnesite tailings magnesite tailings and 15kg of silica fine powder silica fine powder were placed in a tube mill for co-grinding for 20 minutes to obtain a co-grinding material; the co-grinding material was mixed with 2kg of Mg(OH) 2 Put them together in a mixer, mix at 300r / min for 12 minutes to obtain a mixture; use a ball press to press the mixture into balls with a diameter of 10mm at 5Mpa; place the balls at 110°C and dry for 3 hours to obtain Dry pellets: Alternately mix dry pellets with 10kg of anthracite (thickness of dry pellets 120mm, thickness of anthracite 75mm), distribute and calcinate in a shaft kiln at 1450°C for 5.5 hours, and leave the kiln after the kiln naturally cools down to obtain heavy Burnt forsterite.

[0026] Test the bulk density and porosity of the sample according to GB / T2997~2000; test the iron oxide content of the sample according to GB / T 21114~2017; test the refractoriness of the sample according to GB / T 7322~2007. The dead bu...

Embodiment 2

[0028] 75kg of magnesite tailings magnesite tailings and 15kg of silica fine powder silica fine powder were placed in a tube mill for co-grinding for 25 minutes to obtain a co-grinding material; the co-grinding material was mixed with 2kg of MgSO 4 Put them together in a mixer, mix at 300r / min for 15 minutes to obtain a mixture; use a ball press to press the mixture into balls with a diameter of 10mm at 5Mpa; place the balls at 110°C and dry for 3 hours to obtain Dried pellets: alternately dry pellets and 10kg of anthracite (the thickness of pellets after drying is 120mm, and the thickness of anthracite is 75mm), distribute and calcinate in a vertical kiln at 1600°C for 8 hours, and leave the kiln after the kiln naturally cools down to obtain Burnt forsterite.

[0029] Test the bulk density and porosity of the sample according to GB / T 2997~2000; test the iron oxide content of the sample according to GB / T 21114~2017; test the refractoriness of the sample according to GB / T 7322~...

Embodiment 3

[0031] 75kg of magnesite tailings magnesite tailings and 15kg of silica fine powder silica fine powder were placed in a tube mill for co-grinding for 25 minutes to obtain a co-grinding material; the co-grinding material was mixed with 2kg of MgCl 2 Put them together in a mixer, mix at 300r / min for 15 minutes to obtain a mixture; use a ball press to press the mixture into balls with a diameter of 10mm at 5Mpa; place the balls at 110°C and dry for 3 hours to obtain Dried pellets: alternately dry pellets and 10kg of anthracite (the thickness of pellets after drying is 120mm, and the thickness of anthracite is 75mm), distribute and calcinate in a vertical kiln at 1650°C for 10 hours, and leave the kiln after the kiln naturally cools down to obtain Burnt forsterite.

[0032] Test the bulk density and porosity of the sample according to GB / T 2997~2000; test the iron oxide content of the sample according to GB / T 21114~2017; test the refractoriness of the sample according to GB / T 7322...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com