Recovery processing method of leftover materials of container plate

A technology for recycling and processing scraps, applied in the direction of manufacturing converters and improving process efficiency, which can solve problems such as unfavorable cost management, inability to use scrap steel, and carbon steel exceeding the standard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

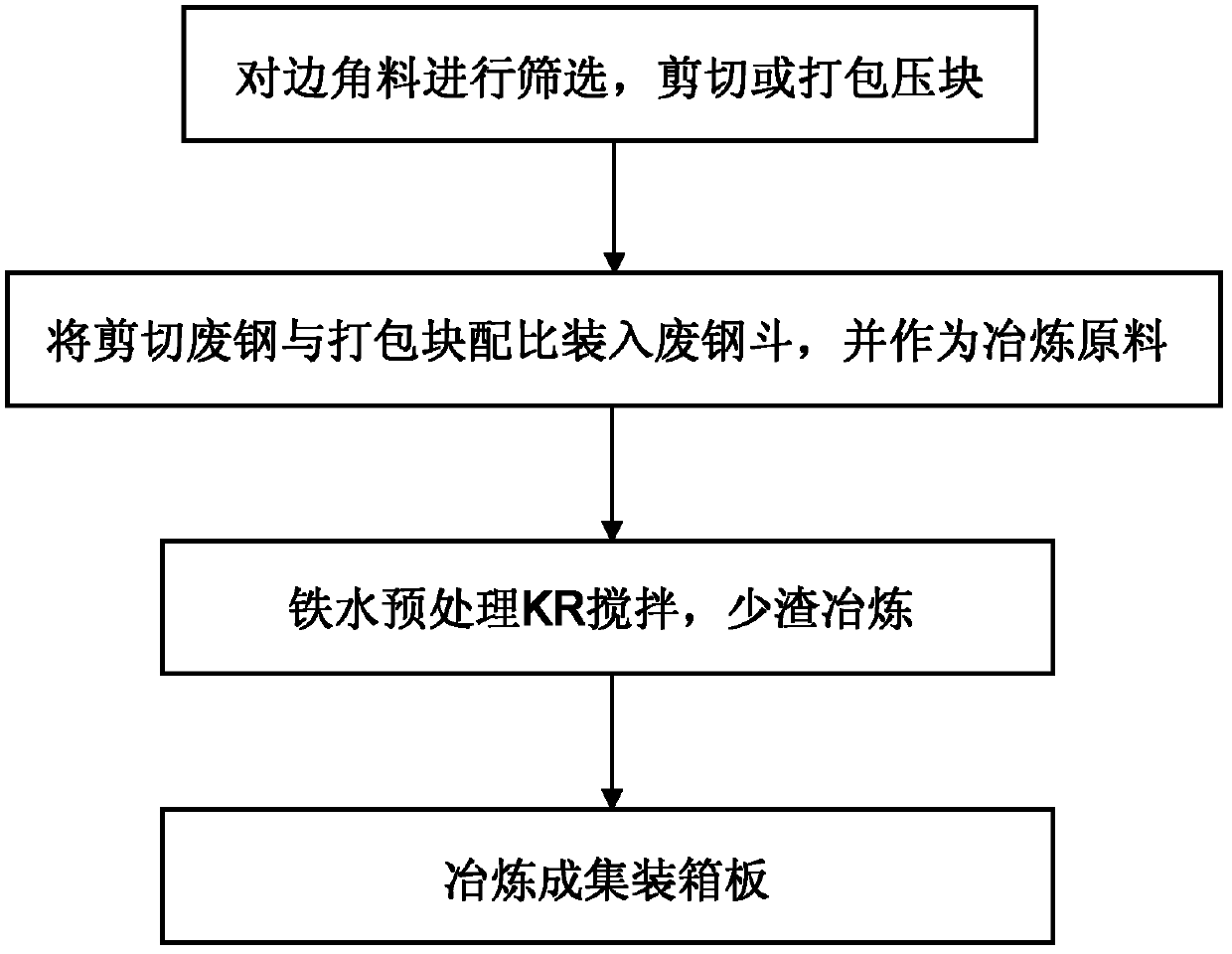

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] see figure 1 As shown, the method for recycling container board scraps of the present invention specifically includes the following steps:

[0028] Firstly, screen scraps of container boards of different specifications, namely:

[0029] Since the scraps with a thickness greater than 2mm or a width of more than 4mm have great toughness and are difficult to package and form, therefore, for scraps with a thickness greater than 2mm or a width greater than 4mm, they should be cut into sheared steel scrap within 20-60mm;

[0030] For scraps with a thickness of less than 2mm or a width of less than 4mm, before packaging, the scraps are tied into small bundles of 100-200mm with steel wire ropes, and packed by a baler with a pressure of 250-500 tons to make a package within 60mm×60mm. piece. After calculation, generally 60mm×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com