Method for removing silicon in molten iron

A molten iron and removal technology, which is applied in the field of pre-desilication of molten iron using KR method, can solve the problems of unfavorable metal material yield, large amount of desilication agent added, and increased amount of desilication slag, etc. The effect of avoiding slag foaming and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

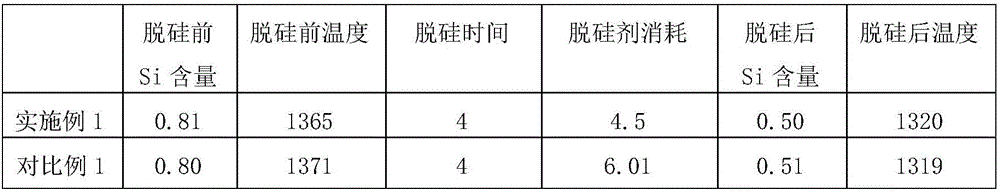

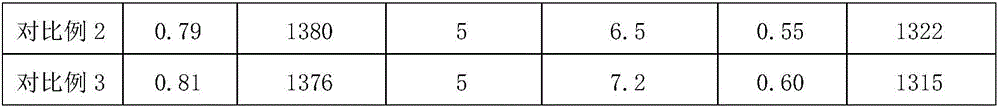

Embodiment 1

[0036] 1) 3-22990 heats of molten iron entered the station, sampling and testing the composition of the molten iron, the analysis result was Si: 0.81%, the measured temperature of the molten iron was 1365°C, and the weight of the molten iron was 130t.

[0037] 2) Transport the molten iron tank to the desulfurization position to start the desiliconization operation: run at a paddle speed of 80 rpm for 1 minute, 110 rpm for 2-8 minutes, and 70 rpm for the 9th minute; the depth of the stirring head is 1700mm; The feed rate was 195kg / min in the first 8 minutes, no feed was added in the 9th minute, and the desiliconization agent was a composite desiliconization agent.

[0038] The desiliconization agent is prepared according to the aforementioned ratio. Specifically, the mixture: iron oxide scale = 1:5 ~ 1:4 can be used as the desiliconization agent, wherein CaO: CaF in the mixture 2 =9:1, see the table below for the composition of iron oxide scale.

[0039] Rolled Steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com