Fire resistive material for desulfurization spray gun and producing technique for the desulfurization spray gun

A technology of desulfurization spray gun and refractory materials, which is applied in the field of refractory materials, can solve the problems of poor stability and low service life, and achieve the effects of good thermal stability, small reburning shrinkage rate, and good high-temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

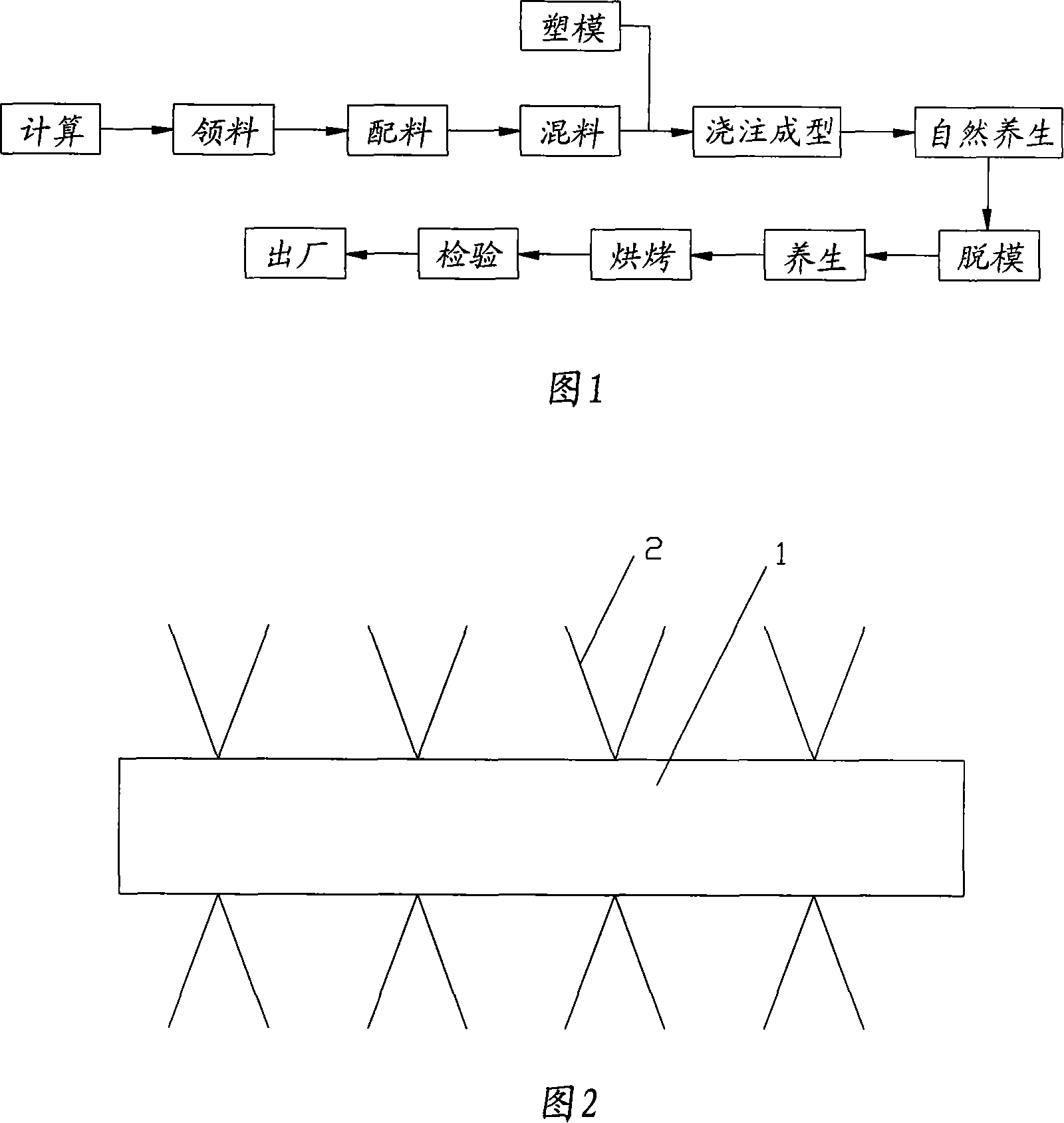

Method used

Image

Examples

Embodiment Construction

[0051] The present invention is described in detail below in conjunction with embodiment.

[0052] At present, the short service life and poor stability of desulfurization spray guns are the biggest disadvantages of this kind of products. The present invention effectively improves the service life of desulfurization spray guns through the improvement and innovation of material, pouring method, structure and baking. As for the material, the present invention starts with improving the quality of the raw material, improves the purity of the raw material, changes the microstructure of the raw material used, and adjusts the composition of the raw material, thereby prolonging the life of the product.

[0053] The main raw materials of refractory materials used in this desulfurization spray gun are: fused mullite, andalusite, plate-shaped corundum powder, α-Al 2 o 3 Micropowder, SiO 2 Micropowder, kyanite, steel fiber, 95 # Flake graphite, cement, spinel fine powder, and the refra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com