Electrical steel scrap recovery treatment method

A technology for recycling and processing electrical steel, applied in recycling technology, improving process efficiency, manufacturing converters, etc., can solve the problem of high cost, and achieve the effect of reducing smelting cost and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

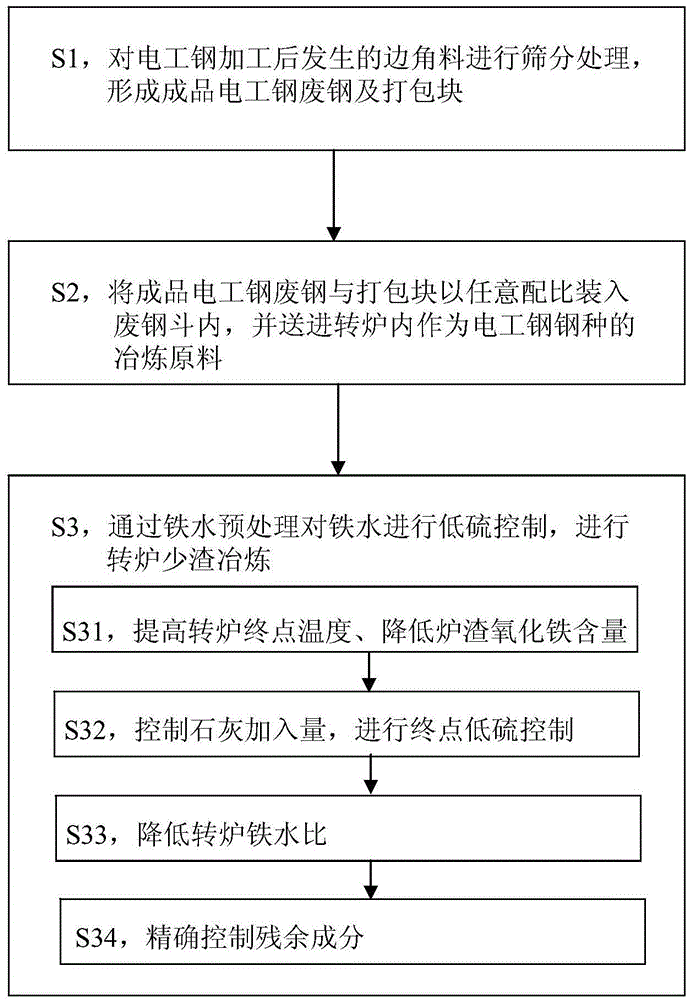

[0032] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

[0033] see figure 1 , the electrical steel scrap recovery processing method of the present invention comprises the following steps:

[0034] The method for recovering electrical steel scraps of the present invention specifically comprises the following steps:

[0035] S1, screen the leftovers generated after the electrical steel processing.

[0036] This refers to the following classification and treatment of electrical steel scraps of different specifications at the source of electrical steel production:

[0037] For blocky and flaky leftovers, they are directly classified as finished electrical steel scrap;

[0038] For strips and thin steel scraps, they are made into baled blocks. The method of making baled blocks: Before packing, the strips and light scraps are wrapped with a small inside and a large ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com