High-permeability two-component polymer cement-based waterproof coating

A waterproof coating, two-component technology, applied in cement coatings, coatings, etc., can solve problems such as peeling, hardening and cracking of coatings, and achieve the effects of good tensile and compressive strength, strong toughness, and good waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of this permeable two-component polymer cement-based waterproof coating is realized according to the following steps:

[0032] 1. Preparation of liquid material component A material:

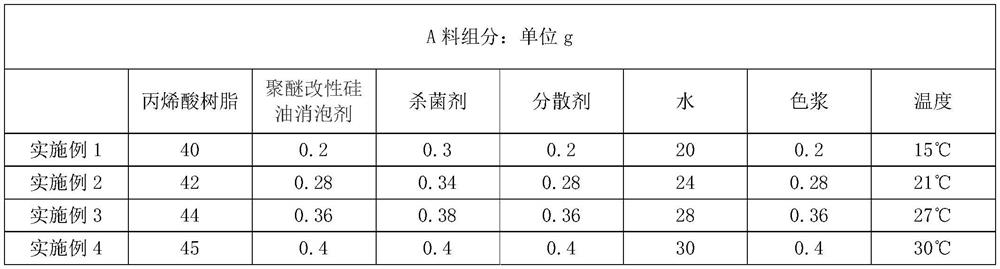

[0033] Step (1): Add 40g of acrylic resin with a solid content of 55% and 20g of water in the dispersing tank of the disperser, stir for 5 minutes at 15°C, the mixer speed is 900 rpm, and then add 0.2g of dispersant , and stir for 10 minutes.

[0034] Step (2): Adjust the speed of the disperser to 500 rpm, then add 0.3 g of fungicide and 0.2 g of color paste in sequence, without stopping the stirring during the addition, and stir for 10 minutes after adding.

[0035] Step (3): Adjust the rotational speed of the disperser to 300 rpm, add 0.2 g of silicone oil defoamer, do not stop stirring during the addition, and stir for 10 minutes after adding.

[0036] Material A is stored separately after production.

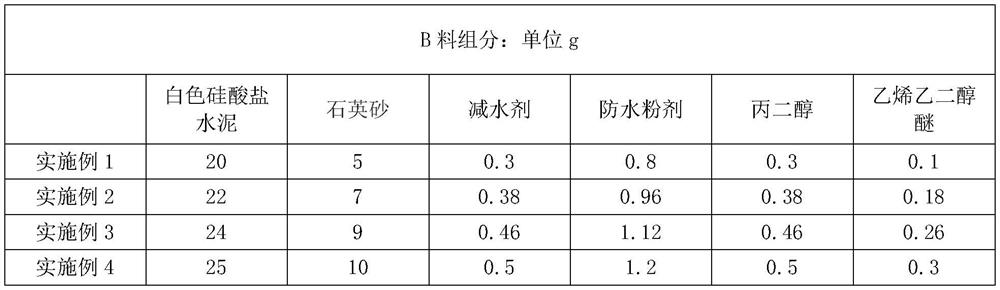

[0037] 2. Preparation of powder component B material

[0038] S...

Embodiment 2

[0045] Example 2: The differences between this example and Example 1 are shown in Table 1 and Table 2. The mixing device of component A and component B in Example 2 uses a powder-liquid stirring device, and the structure of the powder-liquid stirring device is as follows.

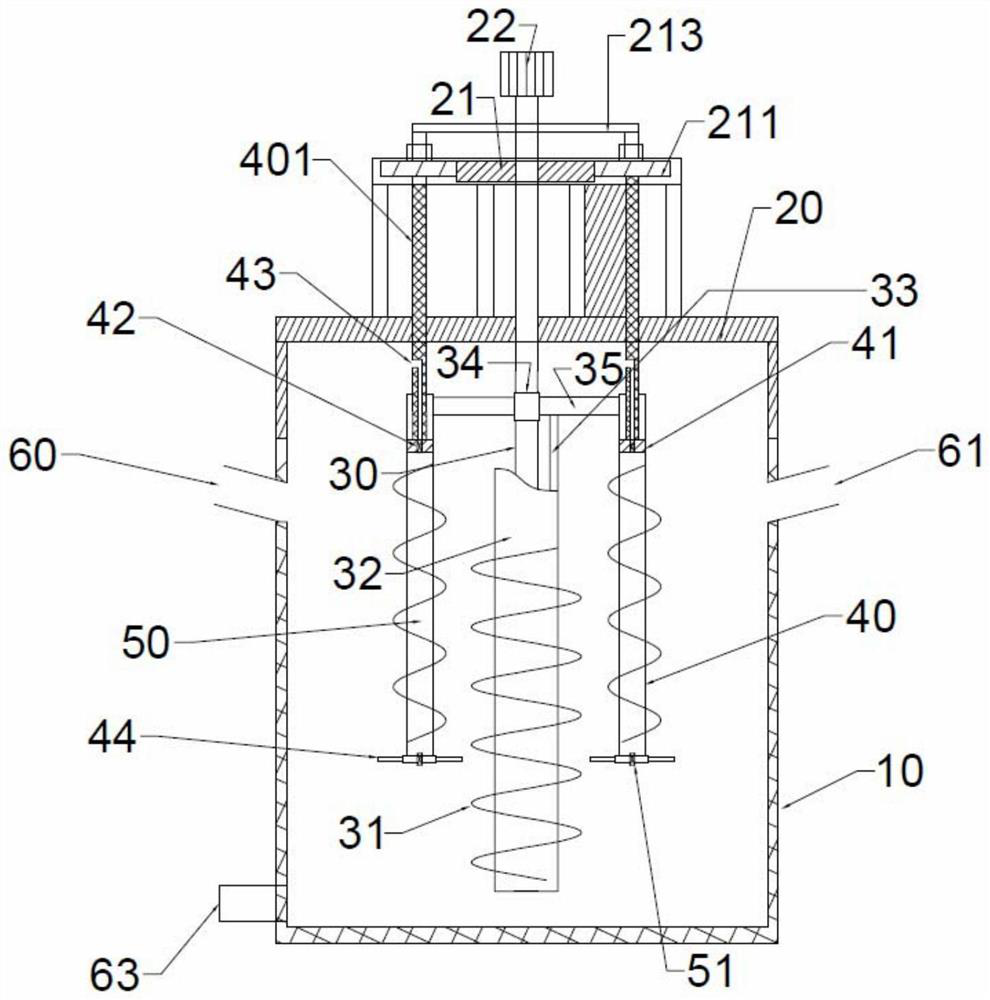

[0046] as attached figure 1 As shown, the powder-liquid stirring device includes a cover body 20 and a tank body 10; a central rotating shaft 30 driven by a gear and a stirring shaft 40 are installed on the cover body 20, and a powder material inlet 61 and a liquid material inlet 60 are arranged on the tank body 10; The body 20 and the tank body 10 are detachably connected by threads.

[0047] The cover body 20 is provided with a fixed ring gear 212 , and the center of the ring gear 212 is provided with a sun gear 21 . The outer periphery of the sun gear 21 meshes with a planetary gear 211 . The lower end of the central gear 21 is fixedly connected to the central shaft 30, and the upper end of the central ...

Embodiment 3

[0058] Embodiment 3: The differences between this embodiment and Embodiment 1 are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com