Waterproof and moisture-proof PVC container floor

A container and floor technology, which is applied in the direction of lamination device, lamination, coating, etc., can solve the problems of the impact on the health of personnel inside the container, the floor has no waterproof base layer, and the service life of the floor is short, so as to avoid moisture absorption and return halogen, improve Waterproof performance, good tensile and compressive strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

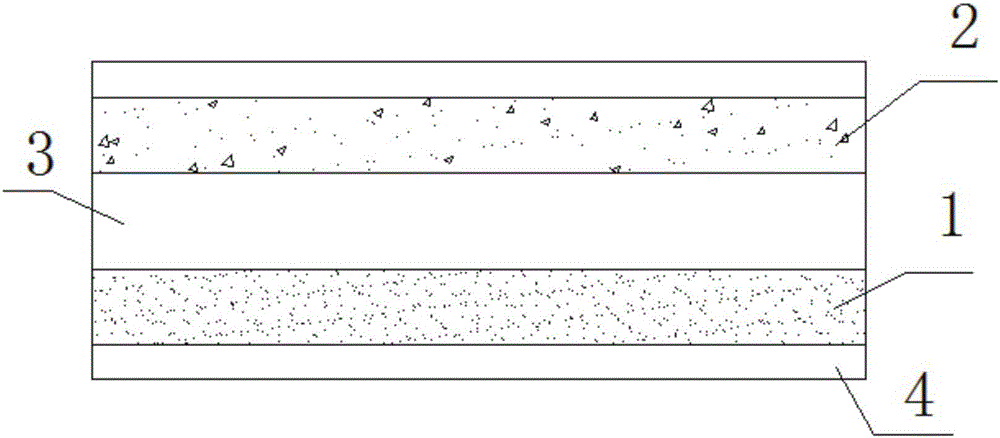

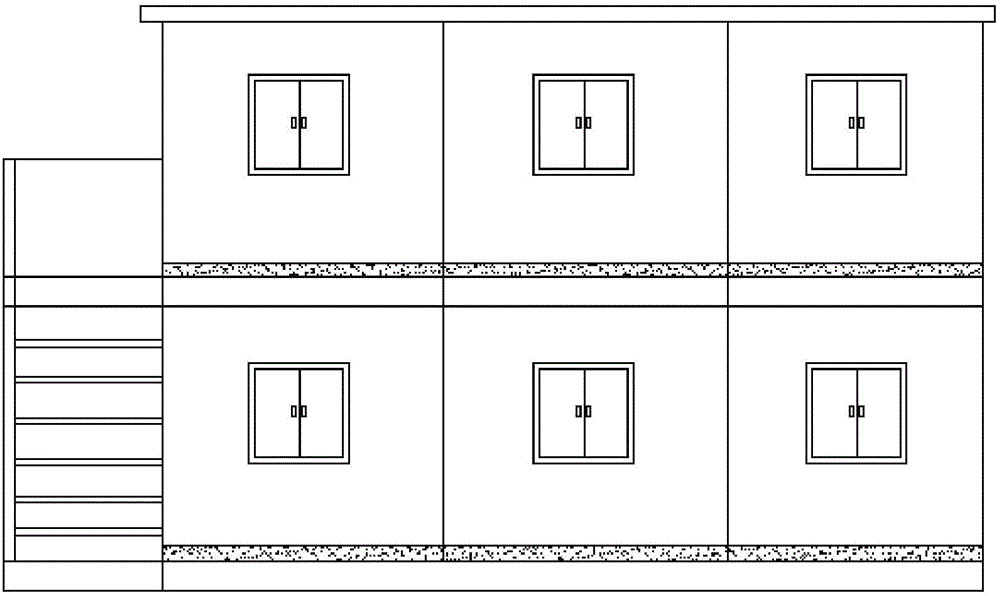

[0041] A kind of waterproof and moisture-proof PVC container floor of the present embodiment, as figure 1 and figure 2 As shown, including a plate body, a gelled layer 1 is provided in the plate, a PVC surface layer 2 is provided on the upper part of the gelled layer 1, and a mixing layer is provided between the PVC surface layer 2 and the gelled layer 1. In layer 3, reinforcement materials are provided in the board body, and a waterproof layer 4 is provided at the bottom of the gelled layer.

Embodiment 2

[0043] This embodiment is further defined on the basis of the above embodiments, and the material of the gelled layer 1 is magnesium oxychloride gelled material. The components of the cementitious layer 1 raw materials and the mass percentages of each component are: magnesium oxide: 31-35%, magnesium chloride: 28-37%, sawdust: 13-16%, leftover material: 14-17%, dyestuff : 0.3-1.8%. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0045] This embodiment is further defined on the basis of the above embodiments, the material of the PVC topping layer 2 is magnesium oxysulfate gelling material. The components of the batter raw materials and the mass percentages of each component are: magnesium oxide: 22-27%, magnesium sulfide: 55-71%, talcum powder: 8-11%, fly ash: 1.8-2.7%, quartz powder : 1.8-3.2%, dyes: 0.7-1.4%. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com